Acid-soluble pressure-bearing plugging agent for drilling fluid and preparation method

An acid-soluble, drilling fluid technology, applied in the field of plugging agents, can solve problems such as cumbersome operation methods, flexion and extension of motor shafts or shafts, and damage to plugging structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

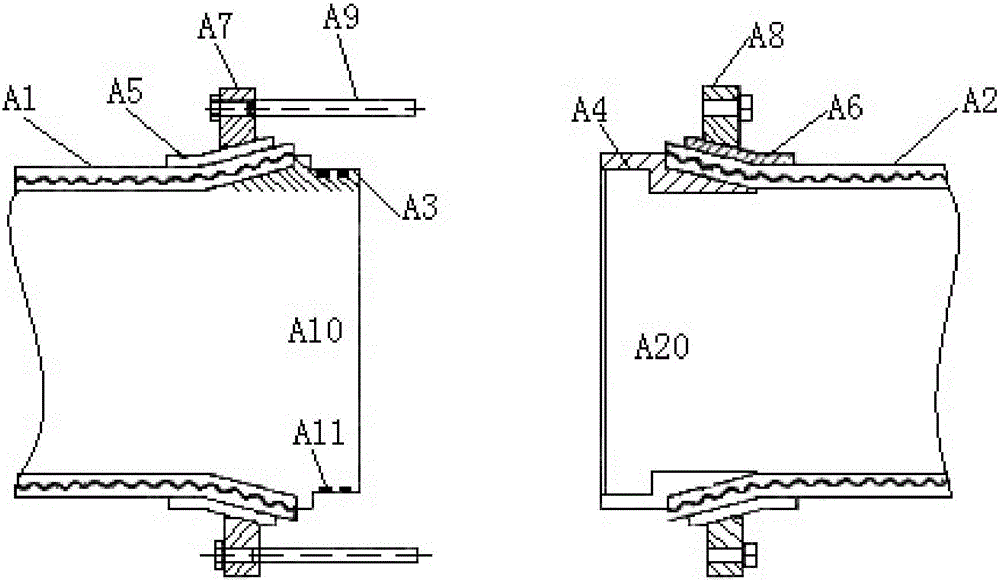

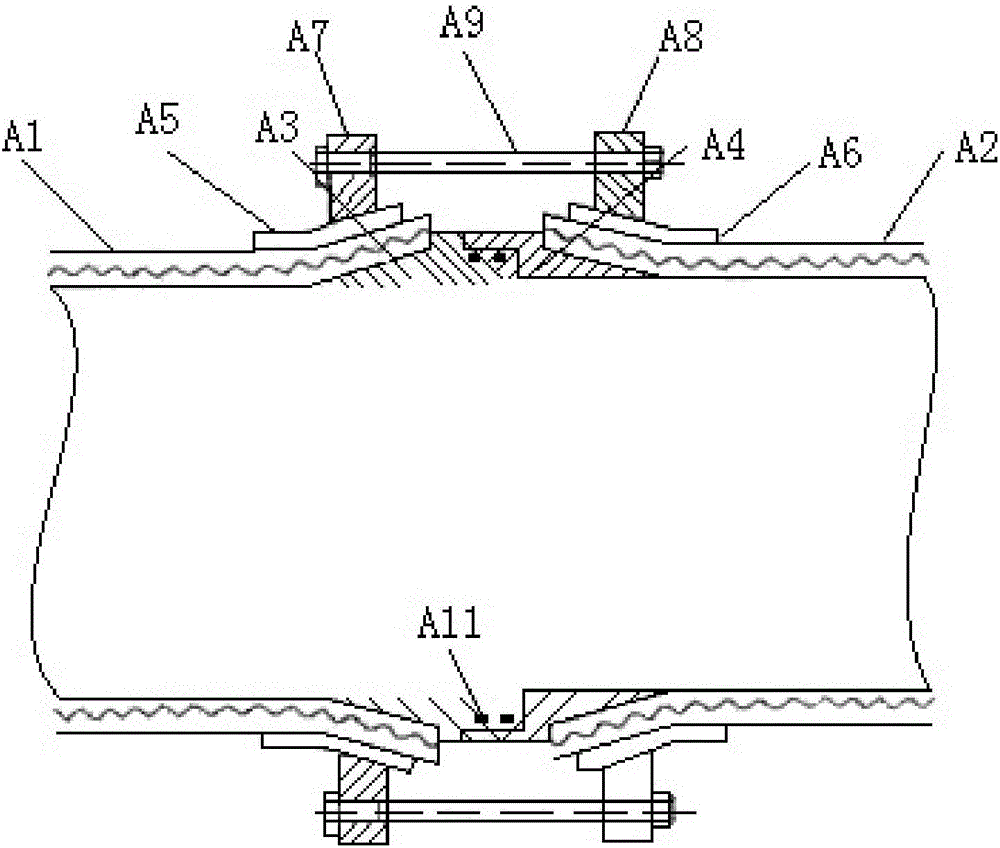

[0028] refer to Figure 1-Figure 2 As shown, the acid-soluble pressure-bearing plugging agent for drilling fluid is prepared from the following raw materials in parts by weight: 10 parts by weight of friction material, 45 parts by weight of bridging material, and 45 parts by weight of bridging material. 35 parts of filler material, parts by weight of 50 parts of iron tailings, parts by weight of volcanic ash powder of 16 parts, woody activated carbon powder of 15 parts by weight, and nano zinc calcium phosphate of 6 parts by weight , parts by weight are 8 parts of paraffin wax, parts by weight are 8 parts of polyol fatty acid esters, parts by weight are 80 parts of titanium dioxide, parts by weight are 40 parts of red clay, parts by weight are 2 parts of Alginic acid, parts by weight are 1 part of dimethyl diallyl ammonium chloride, parts by weight are polyvinyl acetate, parts by weight are 1 part of glyceryl monostearate, parts by weight Be 60 parts of gelatinous cementitiou...

Embodiment 2

[0056] refer to Figure 1-Figure 2 As shown, the acid-soluble pressure-bearing plugging agent for drilling fluid is prepared from the following raw materials in parts by weight: 15 parts by weight of friction material, 48 parts by weight of bridging material, and 48 parts by weight of bridging material. It is 38 parts of filling materials, the parts by weight are 53 parts of iron tailings, the parts by weight are volcanic ash powder of 19 parts, the woody activated carbon powder of 17 parts by weight, and the nano zinc calcium phosphate of 9 parts by weight , parts by weight are 10 parts of paraffin wax, parts by weight are 11 parts of polyol fatty acid esters, parts by weight are 90 parts of titanium dioxide, parts by weight are 45 parts of red clay, parts by weight are 3 parts of Alginic acid, 2 parts by weight of dimethyl diallyl ammonium chloride, 2 parts by weight of polyvinyl acetate, 2 parts by weight of glyceryl monostearate, parts by weight 65 parts of gelatinous cem...

Embodiment 3

[0085] refer to Figure 1-Figure 2 As shown, the acid-soluble pressure-bearing plugging agent for drilling fluid is prepared from the following raw materials in parts by weight: 20 parts by weight of friction material, 50 parts by weight of bridging material, and 50 parts by weight of bridging material. 40 parts of filler material, parts by weight of 55 parts of iron tailings, parts by weight of volcanic ash powder of 21 parts, woody activated carbon powder of 18 parts by weight, and nano zinc calcium phosphate of 12 parts by weight , parts by weight are 12 parts of paraffin wax, parts by weight are 13 parts of polyol fatty acid esters, parts by weight are 100 parts of titanium dioxide, parts by weight are 50 parts of red clay, parts by weight are 4 parts of Alginic acid, 2 parts by weight of dimethyl diallyl ammonium chloride, 2 parts by weight of polyvinyl acetate, 2 parts by weight of glyceryl monostearate, parts by weight It is 70 parts of gelatinous cementitious material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com