Preparation method of fish oil

A fish oil and rough extraction technology, which is applied in the fields of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc. It can solve the problems of low extraction rate, production stagnation, and reduction of fish catch, so as to improve the extraction volume and purity , prevent the production of odorous substances, and improve the extraction rate of fish oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

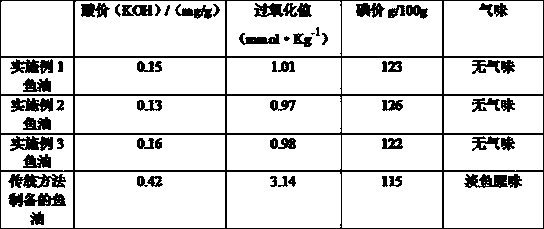

Examples

Embodiment 1

[0021] A kind of preparation method of fish oil, concrete steps are as follows:

[0022] 1) Raw material processing: take the discarded internal organs of the fish for processing, wash them twice, mince them, add 0.6 times the water of the minced products to obtain a homogenate, ultrasonic treatment, 380w ultrasonic treatment at 42°C for 12s, let stand for 35s, and 54°C Under 150w ultrasonic treatment for 22s, repeat the above operation 3 times;

[0023] 2) Crude extraction of fish oil: Mix the homogenate to a pH value of 8.7, stir and heat to 85°C, keep for 40 minutes, add salt with a mass of 5% of the homogenate, stir and homogenize for 15 minutes, filter with double-layer gauze or nylon cloth, press the filter residue, and combine Filtrate and squeeze liquid to get crude fish oil;

[0024] 3) Fish oil essence extraction: Take the crude fish oil, add 0.035% tert-butyl hydroquinone and 0.0026% glucosamine sulfate by weight of the crude fish oil, heat in a water bath to 74°C,...

Embodiment 2

[0027] A kind of preparation method of fish oil, concrete preferred steps are as follows:

[0028] 1) Raw material processing: take the discarded internal organs of the fish for processing, wash them twice, mince, add 1 times the amount of water to obtain a homogenate, ultrasonic treatment, 500w ultrasonic treatment at 43°C for 12s, let stand for 38s, and 55°C Under 200w ultrasonic treatment for 24s, repeat the above operation 2 times;

[0029] 2) Crude extraction of fish oil: Mix the homogenate to a pH value of 9.0, stir and heat to 85°C, keep for 42 minutes, add salt with a mass of 5% of the homogenate, stir and homogenize for 15 minutes, filter with double-layer gauze or nylon cloth, press the filter residue, and combine Filtrate and squeeze liquid to get crude fish oil;

[0030]3) Fish oil essence extraction: take the crude fish oil, add 0.03% tert-butyl hydroquinone and 0.002% glucosamine sulfate by weight of the crude fish oil, heat in a water bath to 75°C, stir and add...

Embodiment 3

[0033] A kind of preparation method of fish oil, concrete steps are as follows:

[0034] 1) Raw material processing: take the discarded internal organs of the fish for processing, wash them three times, mince them, add 0.7 times the water of the minced products to obtain a homogenate, ultrasonic treatment, 400w ultrasonic treatment at 44°C for 15s, let stand for 40s, and 53°C Under 200w ultrasonic treatment for 25s, repeat the above operation 3 times;

[0035] 2) Crude extraction of fish oil: Mix the homogenate to a pH value of 8.8, stir and heat to 86°C, keep for 40 minutes, add 5% salt of the homogenate, stir and homogenate for 15 minutes, filter with double-layer gauze or nylon cloth, press the filter residue, and combine Filtrate and squeeze liquid to get crude fish oil;

[0036] 3) Fish oil essence extraction: Take the crude fish oil, add 0.035% tert-butyl hydroquinone and 0.003% glucosamine sulfate by weight of the crude fish oil, heat in a water bath to 75°C, stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com