Gas mixed pressurization free-return bending water-saving toilet

A water-reverse trap and air-mixing technology, applied in the field of sanitary ware, can solve the problems of inconvenient installation and maintenance, difficult disassembly, etc., and achieve the effects of reducing sewage resistance, smooth mutual circulation of water, and large opening range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific technical solutions of the present invention will be further described below in conjunction with the embodiments.

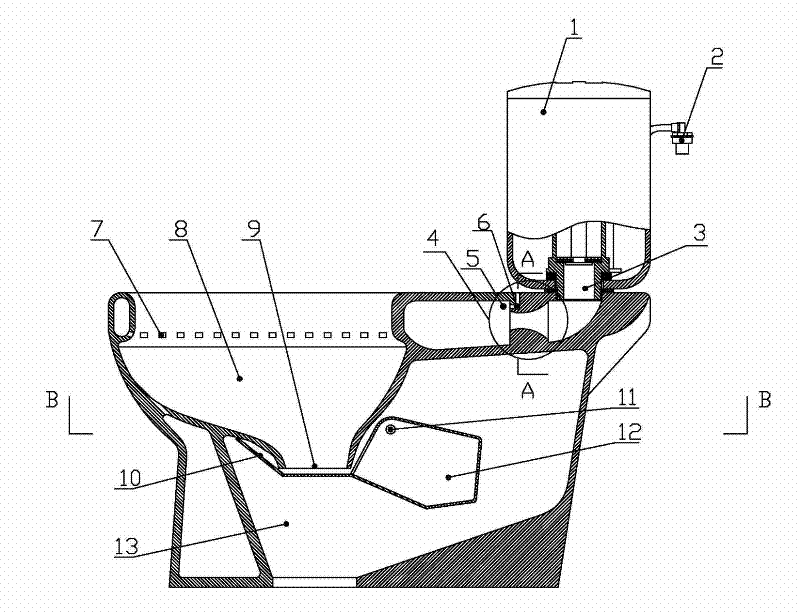

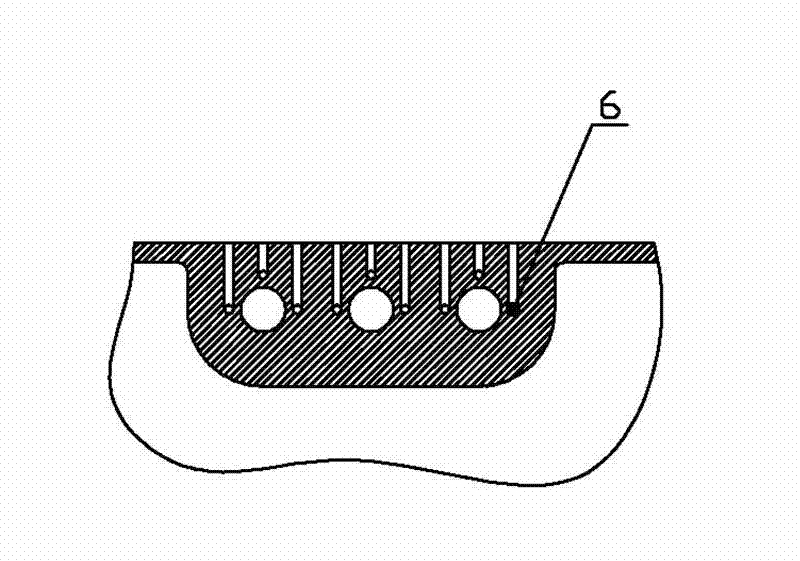

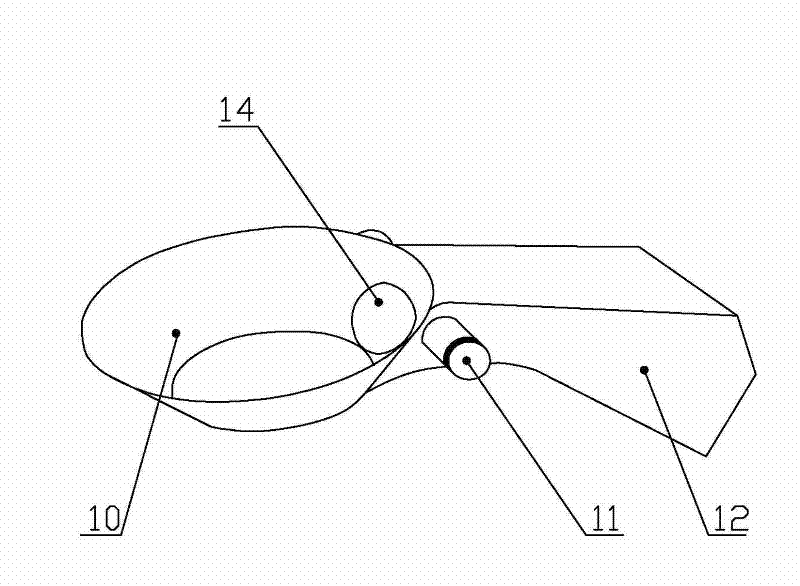

[0036] like Figure 1 ~ Figure 4 As shown, this air-mixed pressurized water-saving toilet without reverse water bend includes a pressurized water tank 1, a urinal 8, a water sealing box 10, a counterweight box 12, and a compartment 13, wherein the urinal 8 and the compartment 13 As an integral structure, the urinal 8 can be for sitting or squatting; the pressurized water tank 1 is arranged on the upper end of the urinal 8; the water inlet of the pressurized water tank 1 is provided with a water inlet check valve 2, and the water outlet 3 of the water tank is connected An air mixing device 4 is arranged between the pool flushing ports 7; the water sealing box 10 is arranged at the outer end of the sewage outlet 9 at the lower end of the urinal 8, and a rotating shaft 11 is also provided between the water sealing box 10 and the counterweight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com