Turbomachine fan rotor

A fan rotor, turbine technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve unsatisfactory, wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

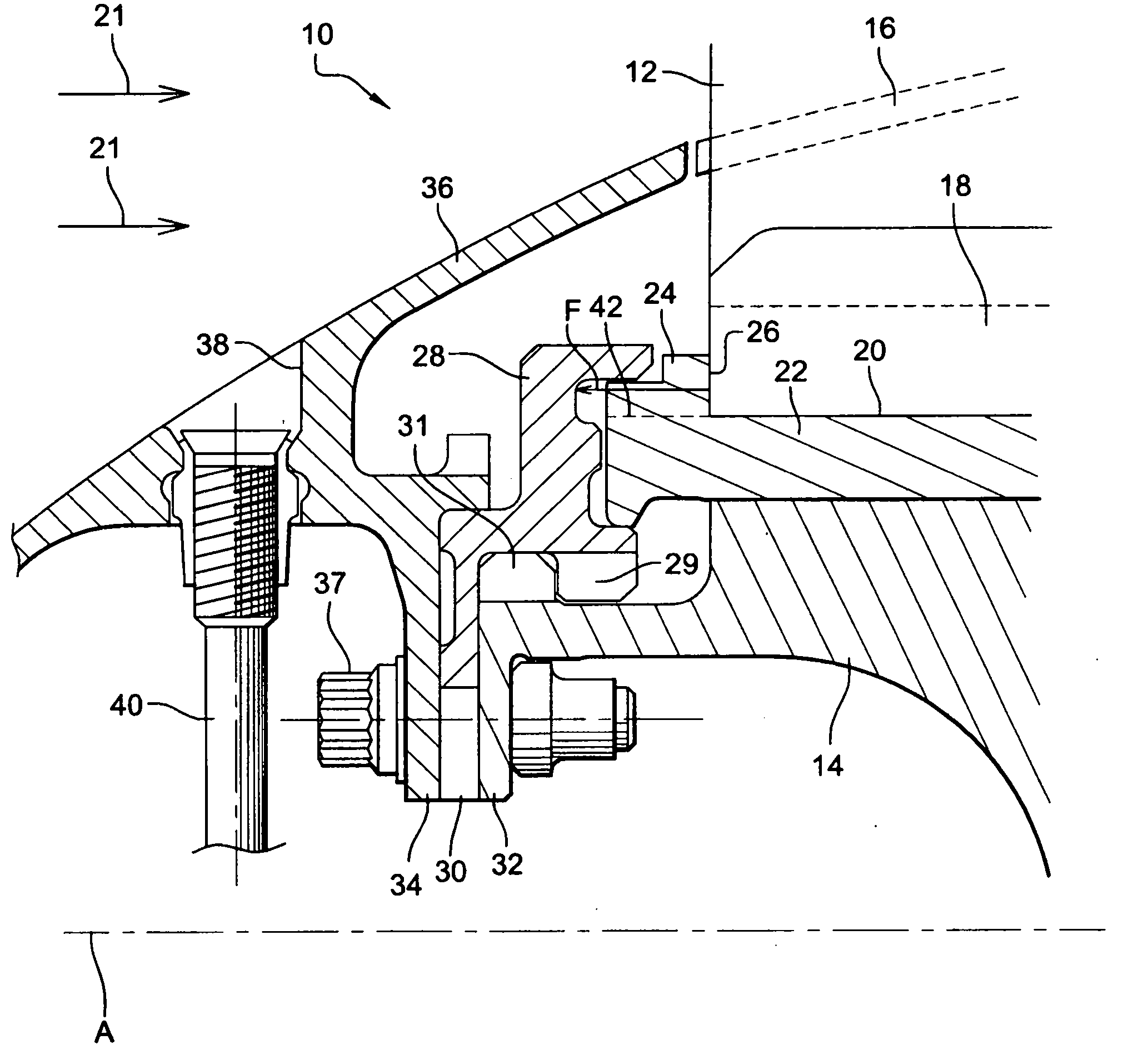

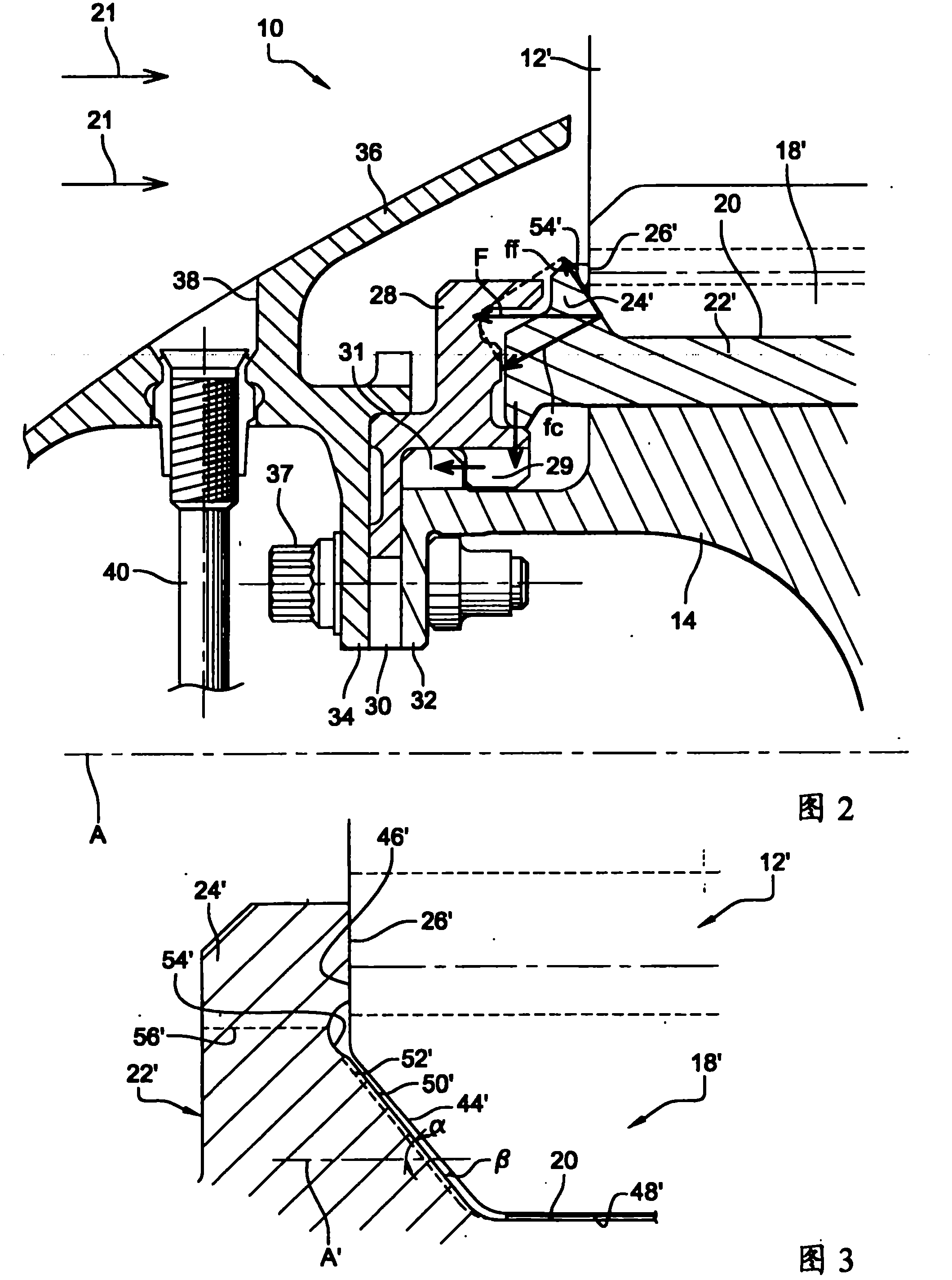

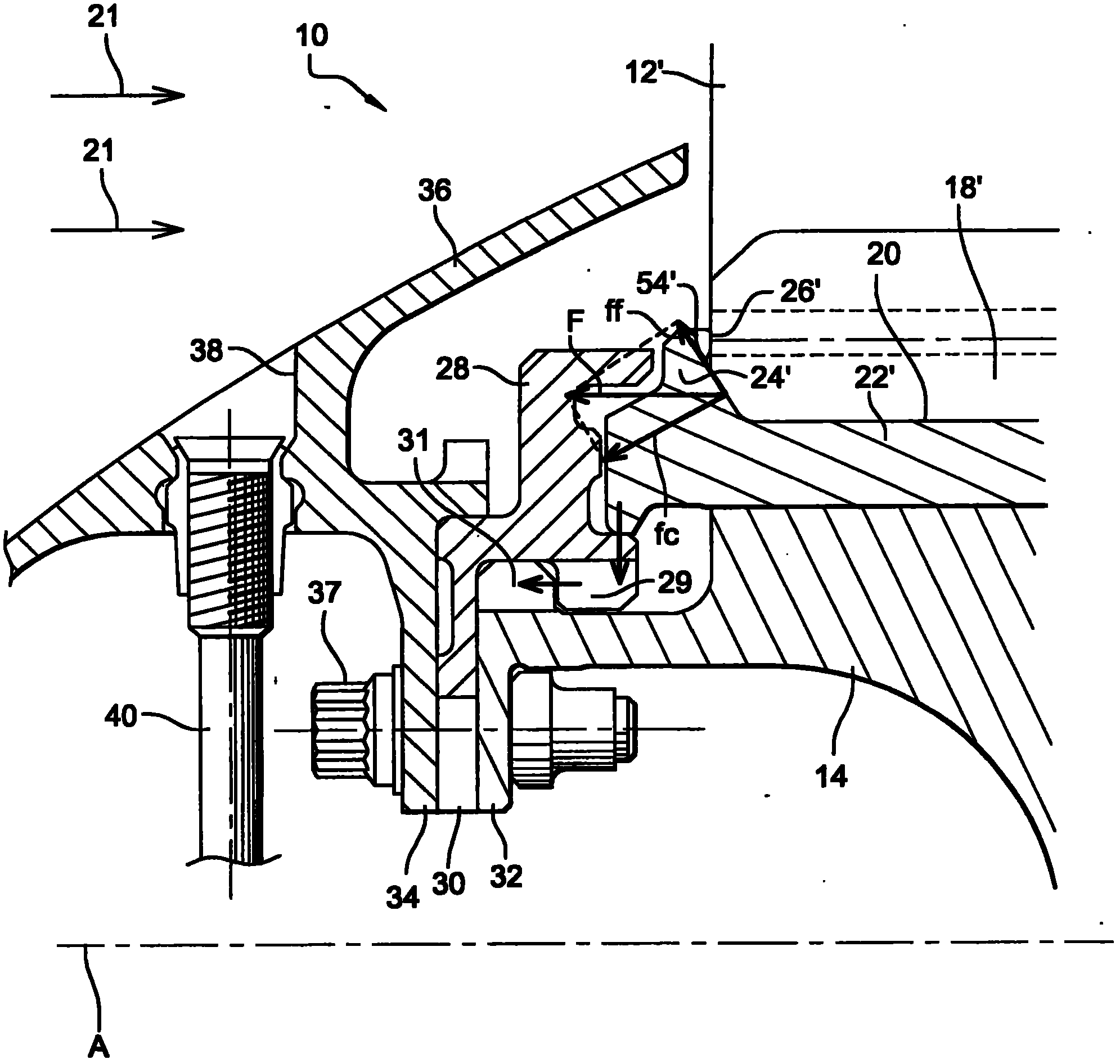

[0024] see first figure 1 , which shows a prior art turbomachine fan rotor 10 prior to the present invention.

[0025] The fan rotor 10 comprises blades 12 carried by a disc 14 secured to the upstream end of a shaft (not shown) of the turbine, with an interblade platform 16 interposed between the blades.

[0026] Each fan blade 12 comprises an airfoil connected at its radially inner end to a root 18 which engages in a complementary shaped generally axial slot 20 in the disk 14 for retaining the blade radially on the disk. superior.

[0027] The inter-blade platforms 16 form walls defining the inside of the air flow 21 entering the turbine, and they include means between the slots 20 cooperating with corresponding means provided on the disc 14 for fastening the platforms to the disc.

[0028] A spacer 22 is interposed between the root 18 of each blade and the bottom of a corresponding slot 20 in the disk to prevent radial movement of the blade in the slot. Each spacer 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com