Cold aerosol fire extinguishing device

A cold aerosol and fire extinguishing device technology, applied in the field of fire extinguishing, can solve the problems of immovable fire extinguishing system, difficulty in extinguishing small fires, high reaction temperature, etc., and achieve the effects of wide range of fire extinguishing types, strong penetration and good fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

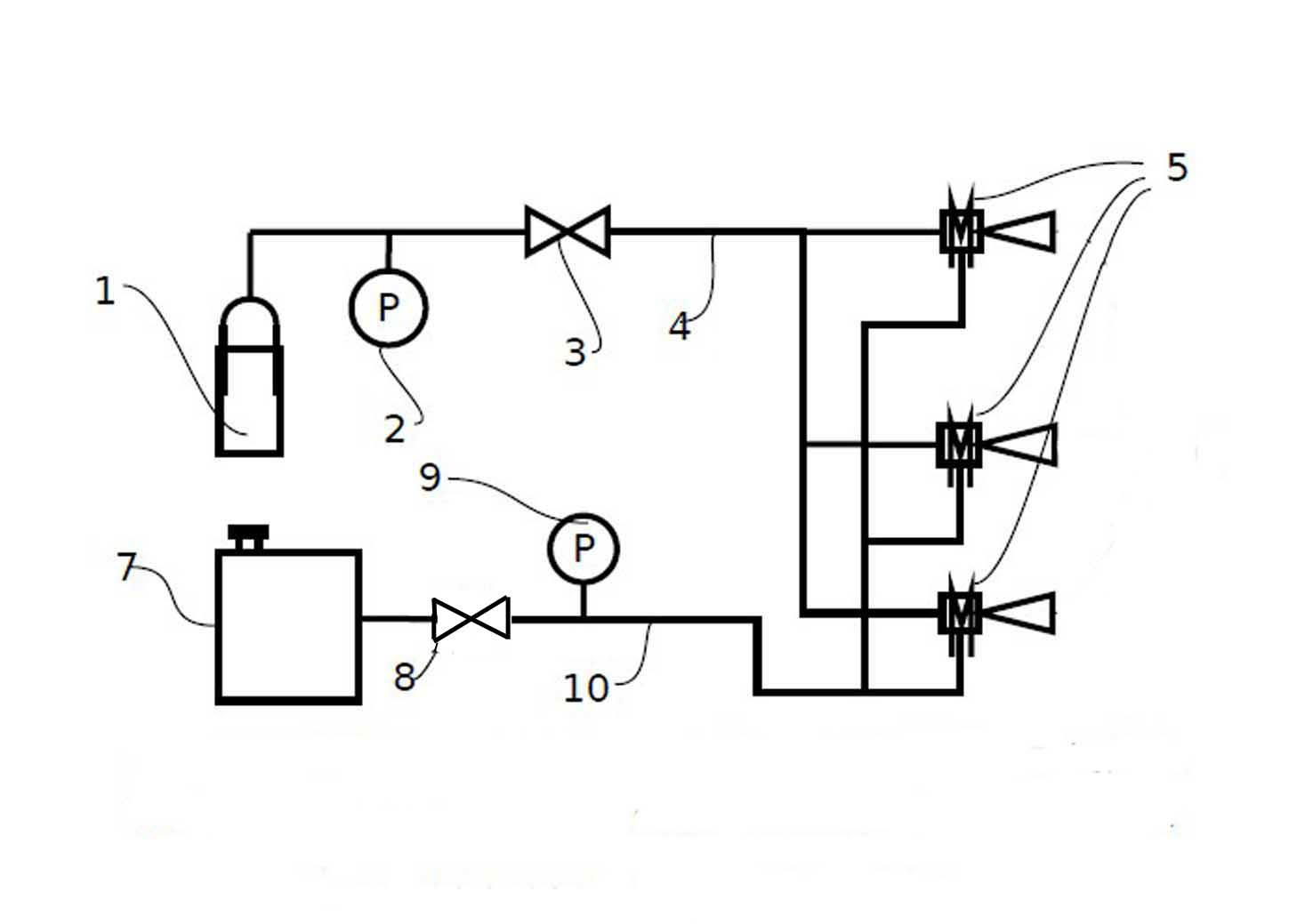

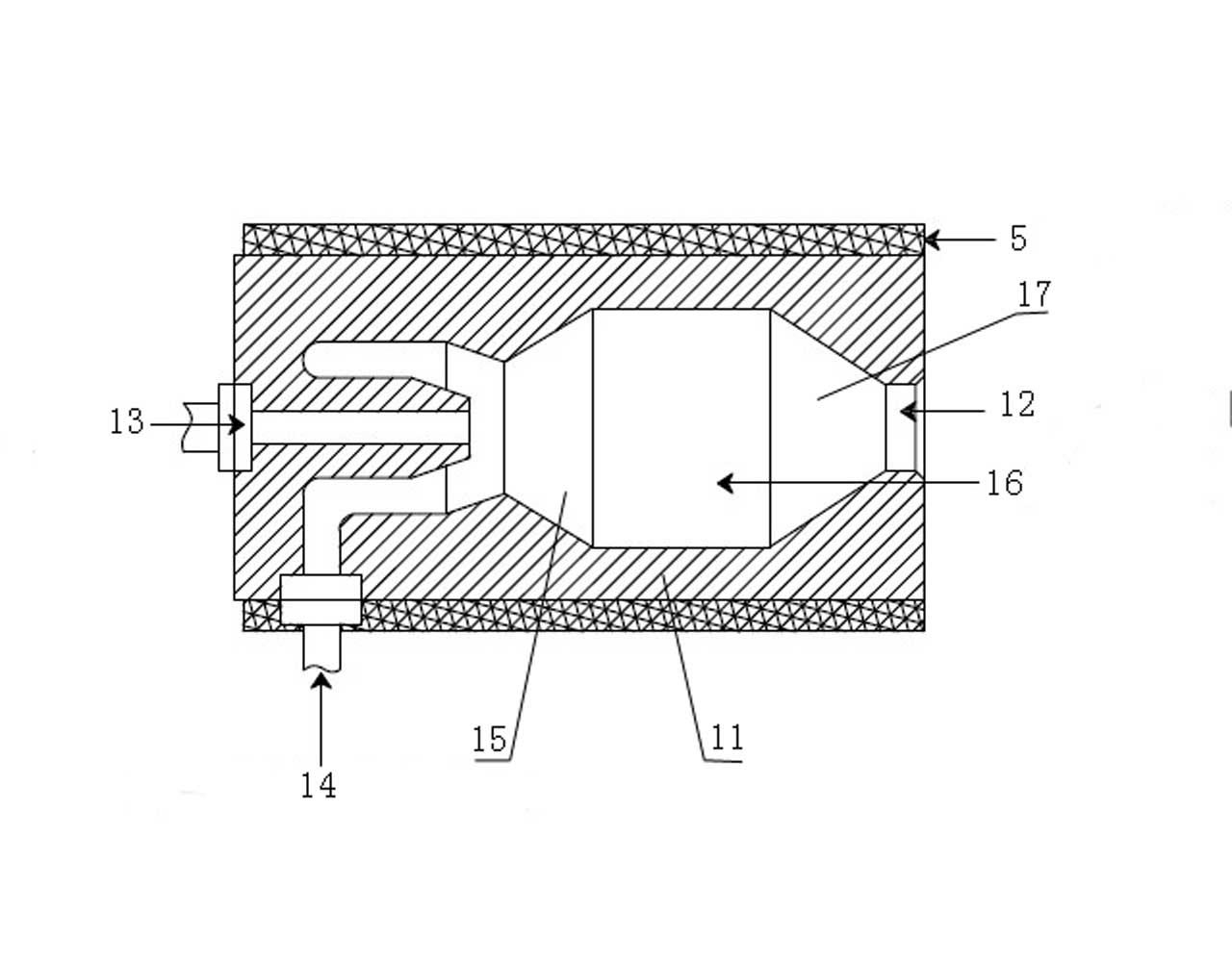

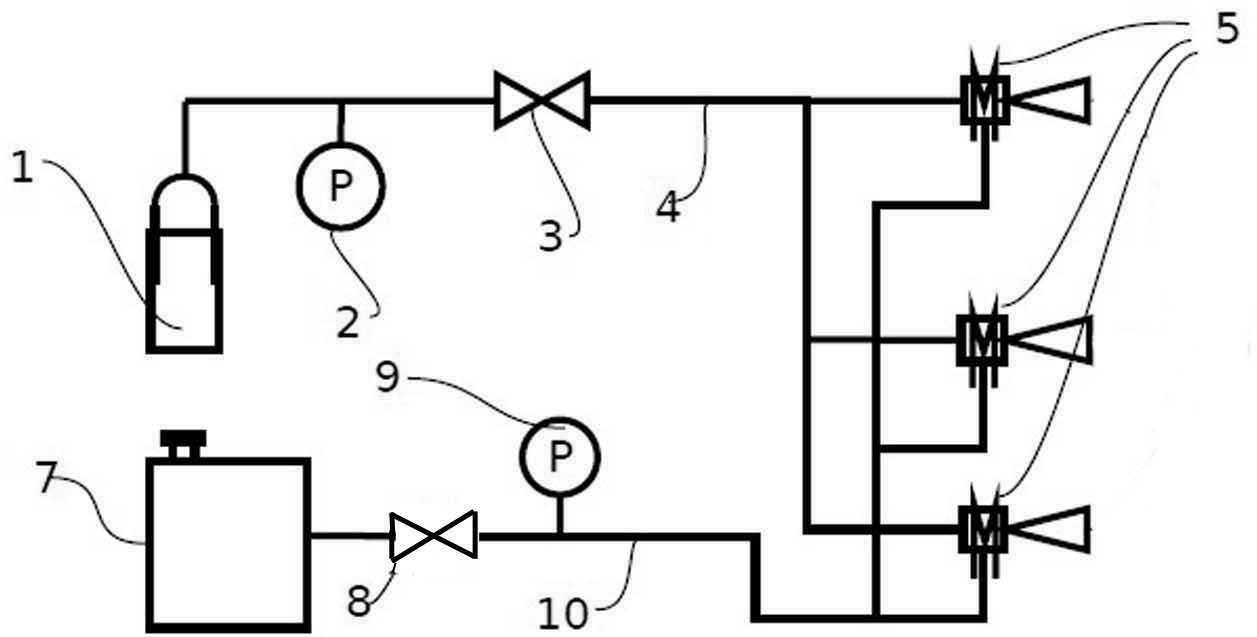

[0030] A cold aerosol fire extinguishing device, comprising a dry powder aqueous solution tank 7 storing a dry powder aqueous solution, a carbon dioxide storage tank 1 storing carbon dioxide and a nozzle coated with a heating jacket 5 on the outside, the dry powder aqueous solution is an aqueous solution of a sodium carbonate compound, and the The dry powder aqueous solution is saturated at -5°C; the nozzle includes a housing 11, the right end of the housing 11 is provided with a spout 12, the left end is provided with a carbon dioxide feed port 13, and the left end is radially provided with a dry powder Aqueous solution feed port 14, described spout 12 communicates with carbon dioxide feed port 13 and dry powder aqueous solution feed port 14 through cavity; The cylindrical hole 16 corresponding to the shape hole 15 is connected, and the right tapered hole 17 with a large left and a small right is connected with the cylindrical hole 16; The feed port 13 is connected, and the p...

Embodiment 2

[0032] A cold aerosol fire extinguishing device, comprising a dry powder aqueous solution tank 7 storing a dry powder aqueous solution, a carbon dioxide storage tank 1 storing carbon dioxide and a nozzle coated with a heating jacket 5 on the outside, the dry powder aqueous solution being sodium carbonate, potassium chloride or The aqueous solution of the compound mixed at a ratio of 1:3, the dry powder aqueous solution is saturated at -5°C; the carbon dioxide storage tank 1 is connected to the nozzle through a high-pressure pipeline 4 with a valve 3, and the inlet of the nozzle is The pressure of the carbon dioxide is 7.5MPa; the dry powder aqueous solution tank 7 is connected with the nozzle by the low-pressure pipeline 10 provided with the water pump 8, and the pressure of the dry powder aqueous solution at the nozzle inlet is 0.4MPa; the dry powder at the nozzle inlet is The mass flow ratio of water and carbon dioxide in the aqueous solution is 1:2.6.

Embodiment 3

[0034] A cold aerosol fire extinguishing device, comprising a dry powder aqueous solution tank 7 storing a dry powder aqueous solution, a carbon dioxide storage tank 1 storing carbon dioxide and a nozzle covered with a heating jacket 5 on the outside, the dry powder aqueous solution being sodium bicarbonate, dihydrogen phosphate Potassium and sodium chloride are mixed in a ratio of 1:1.5:2 to an aqueous solution of a compound, and the dry powder aqueous solution is saturated at -5°C; the carbon dioxide storage tank 1 passes through a high-pressure pipeline 4 with a valve Connected with the nozzle, the pressure of the carbon dioxide at the nozzle inlet is 8.0MPa; the dry powder aqueous solution tank 7 is connected with the nozzle by a low-pressure pipeline 10 provided with a water pump 8, and the pressure of the dry powder aqueous solution at the nozzle inlet is 0.45MPa; The mass flow ratio of water and carbon dioxide in the dry powder aqueous solution at the inlet of the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com