Camera module assembly carrier tool

A technology for camera modules and components, applied in the field of vehicles, can solve the problems of damaged camera modules, weak adhesion of metal reinforcing plates, unstable impedance of electrical connections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

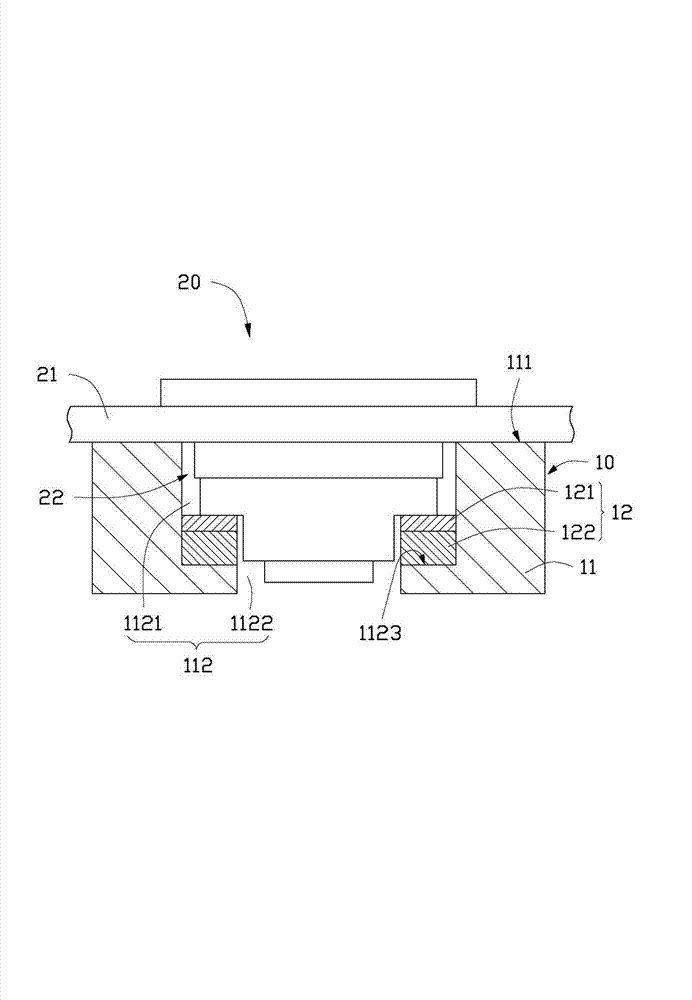

[0013] see figure 1 , the camera module assembly carrier 10 of the preferred embodiment of the present invention is used to carry a camera module assembly 20 .

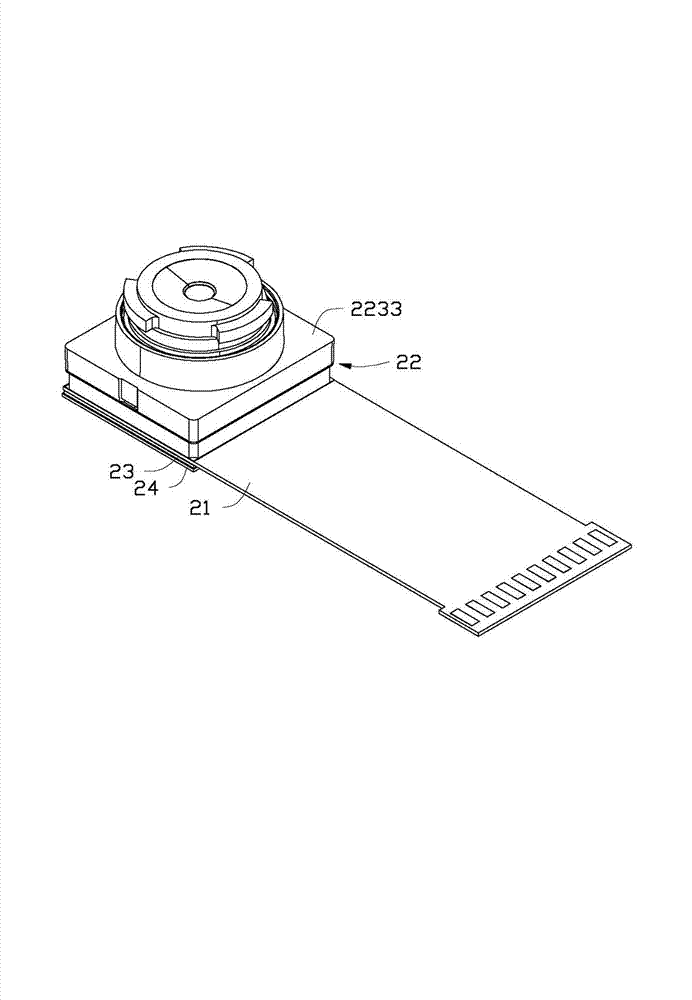

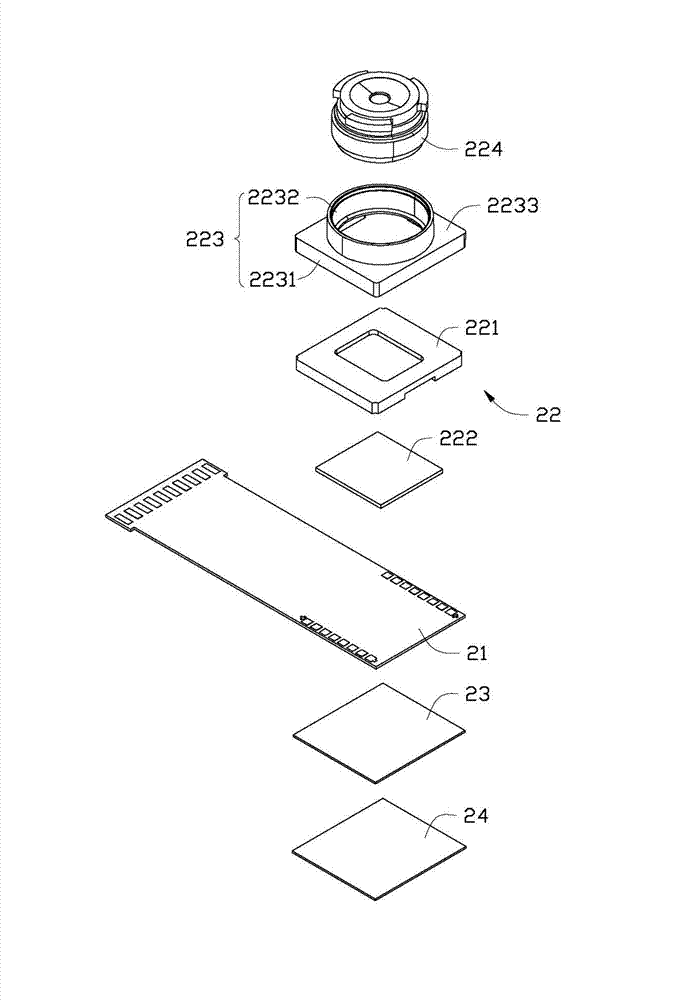

[0014] Please also refer to Figure 2-4 , the camera module assembly 20 includes a flexible circuit board 21, a camera module 22 arranged on the flexible circuit board 21, a conductive adhesive layer 23 and a flexible circuit board 21 and a The metal reinforcing plate 24 on the opposite side of the camera module 22 . The camera module 22 includes a first step 2233 opposite to the flexible circuit board 21 .

[0015] Specifically, the camera module assembly carrier 10 is used for carrying the camera module assembly 20 when stamping the metal reinforcement plate 24 to fix the metal reinforcement plate 24 to the flexible circuit board 21 .

[0016] The camera module assembly carrier 10 includes a base 11, the base 11 includes a supporting surface 111 for supporting the flexible circuit board 21, and the supporting sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com