Double-layer punching machine for photovoltaic aluminum alloy frame

A technology of aluminum alloy and frame, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effects of improving production efficiency, facilitating mold loading and unloading, and uniform impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

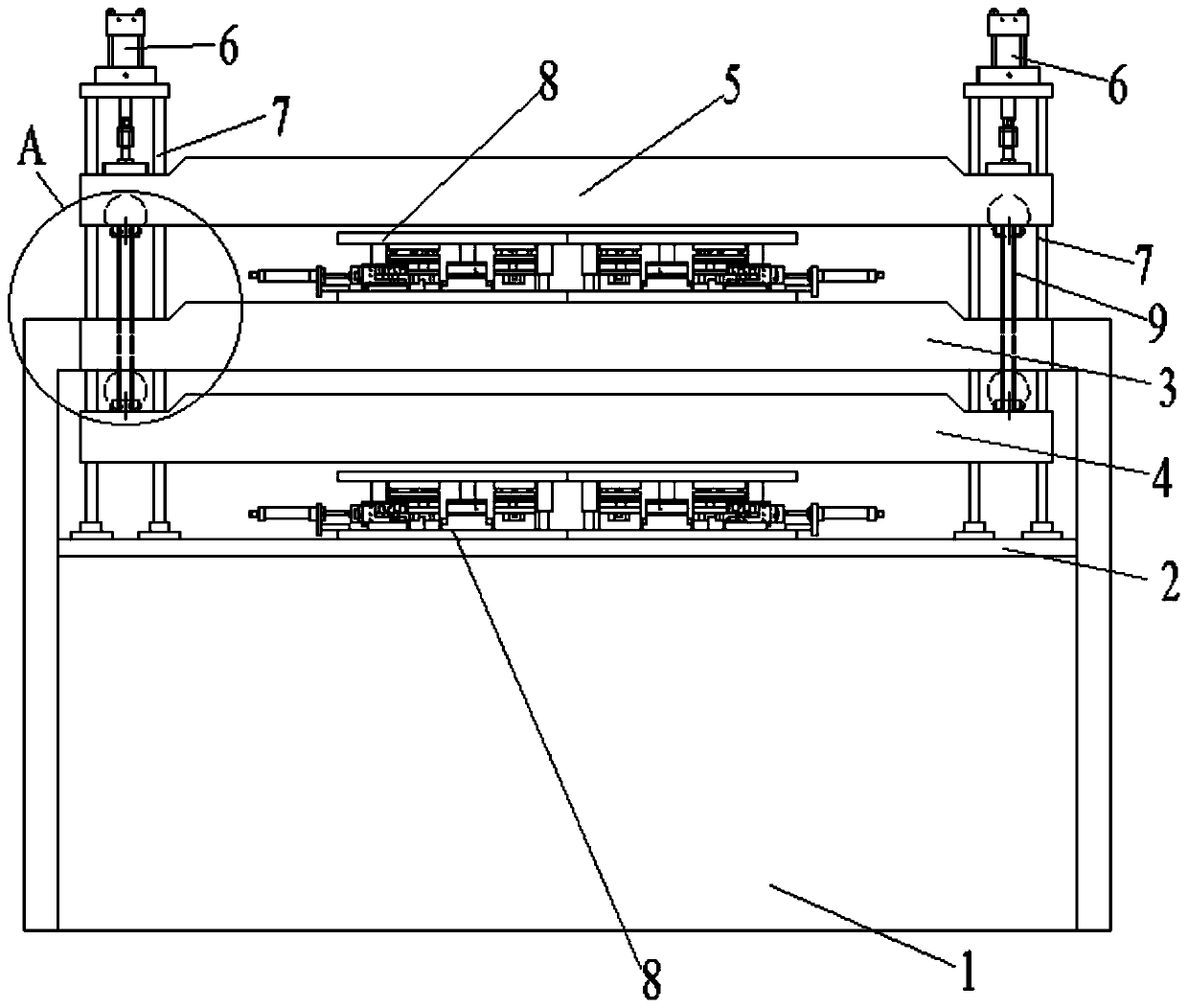

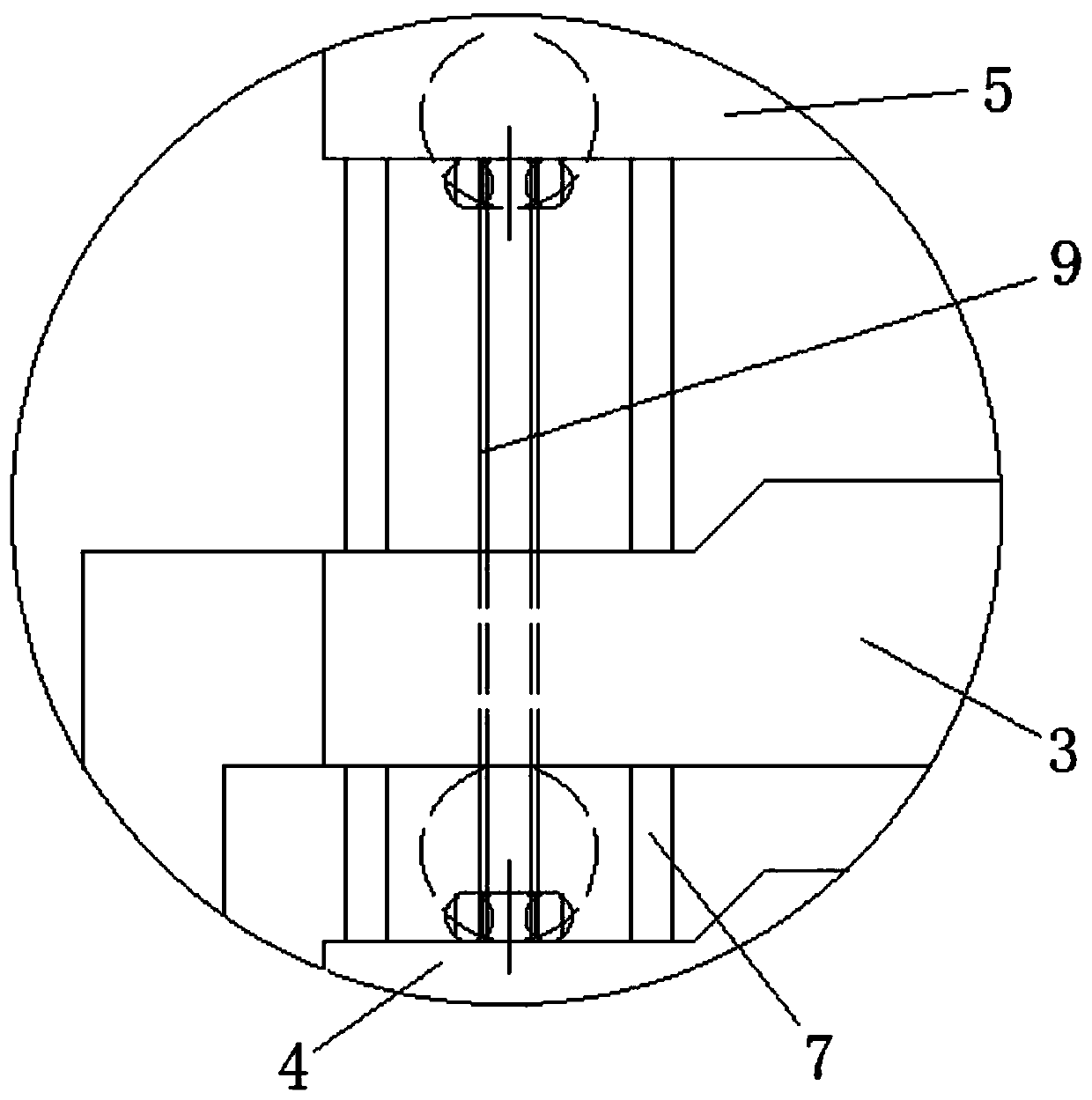

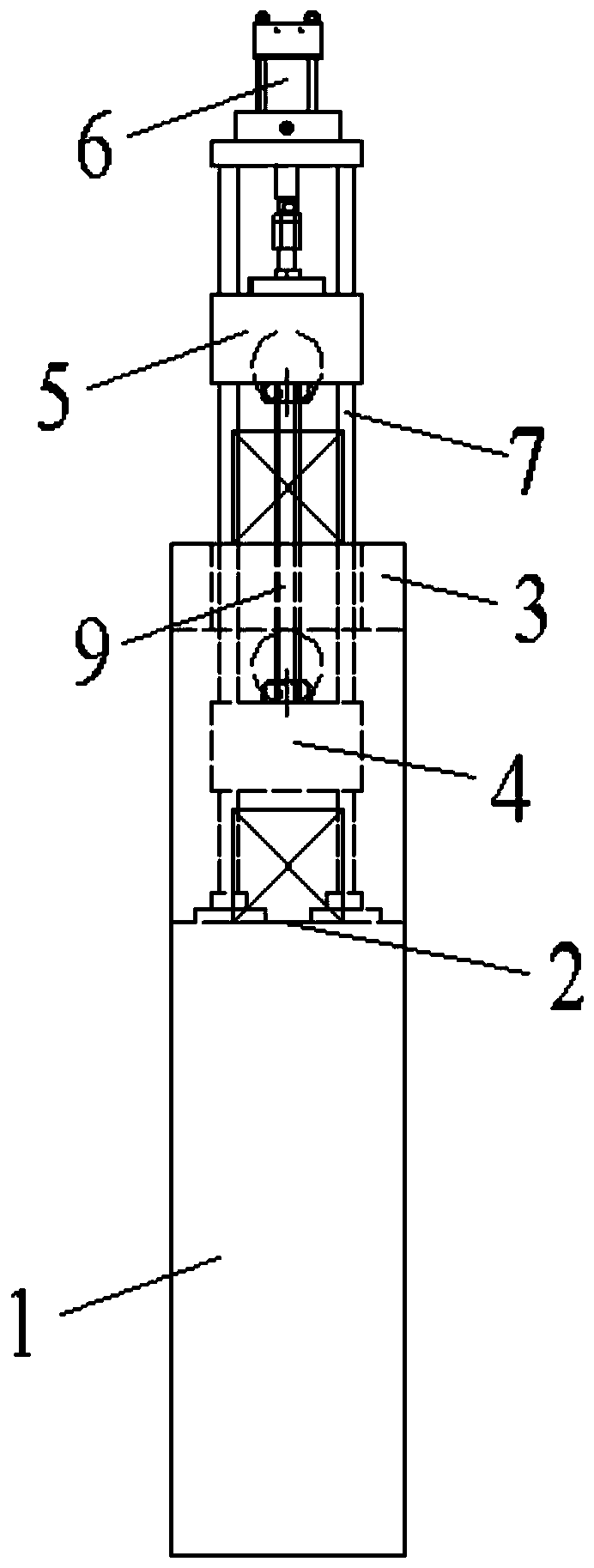

[0023] as attached Figure 1-3 As shown, a double-layer punch press with a photovoltaic aluminum alloy frame includes a vertical punch frame 1, a first-layer work surface 2, a second-layer work surface 3, a first-layer punching beam 4, a second-layer punching beam 5 and a driving device 6. The vertical punch frame 1 adopts a gantry structure; the vertical punch frame 1 is provided with a first layer of worktable 2 for placing a mold 8; above the first layer of worktable 2 is provided with a mold 8 The second layer of the work table 3; the two sides of the vertical punch frame 1 are vertically arranged guide column 7; the guide column 7 runs through the second layer of work table 3, fixed on the first layer of work table 2 ; Between the first layer of worktable 2 and the second layer of worktable 1, the first layer of stamping beam 4 is arranged on the guide column 7; a straight line is arranged between the guide column 7 and the first layer of stamping beam 4 Bearing; above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com