Quartz stone panel molding press

A technology for quartz stone plates and presses, which is applied to forming indenters, ceramic forming machines, and auxiliary forming equipment. Vacuuming time, achieving tightness, reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

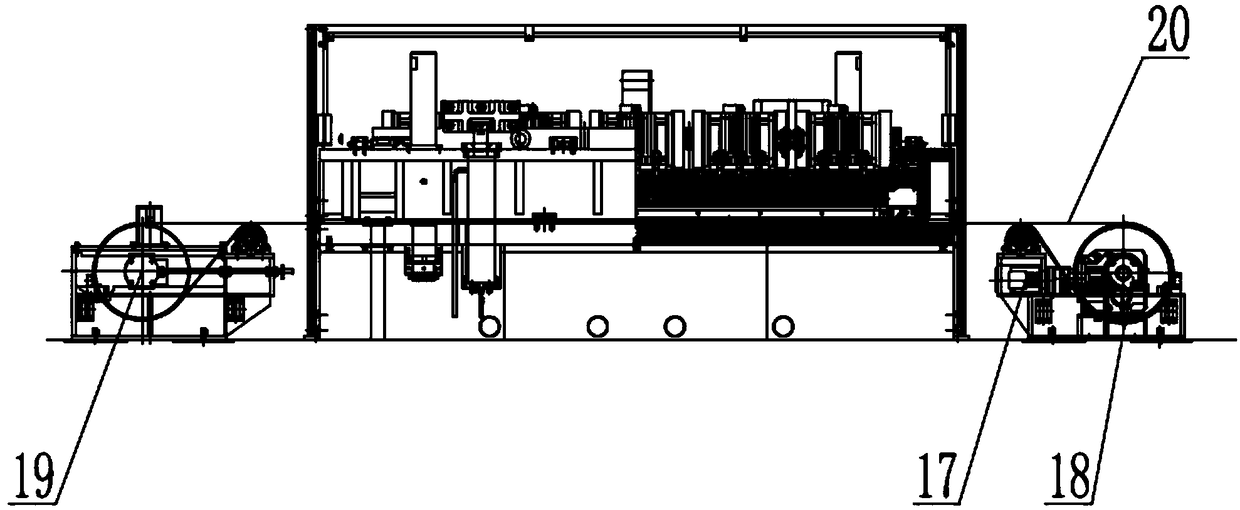

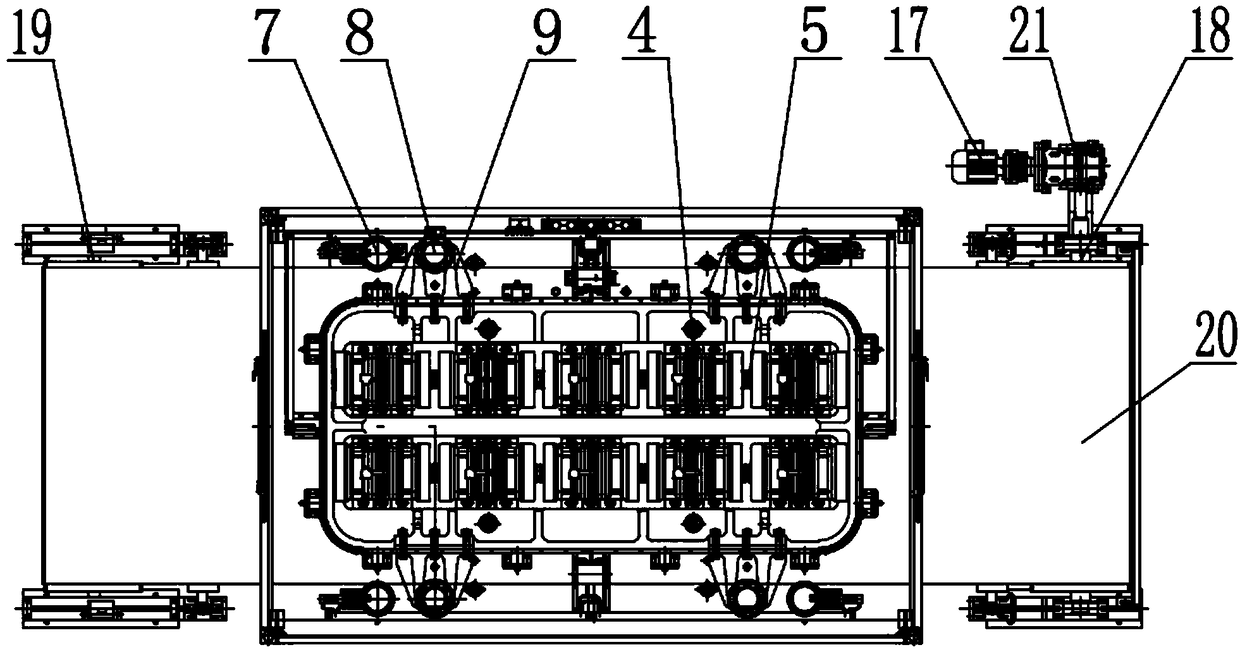

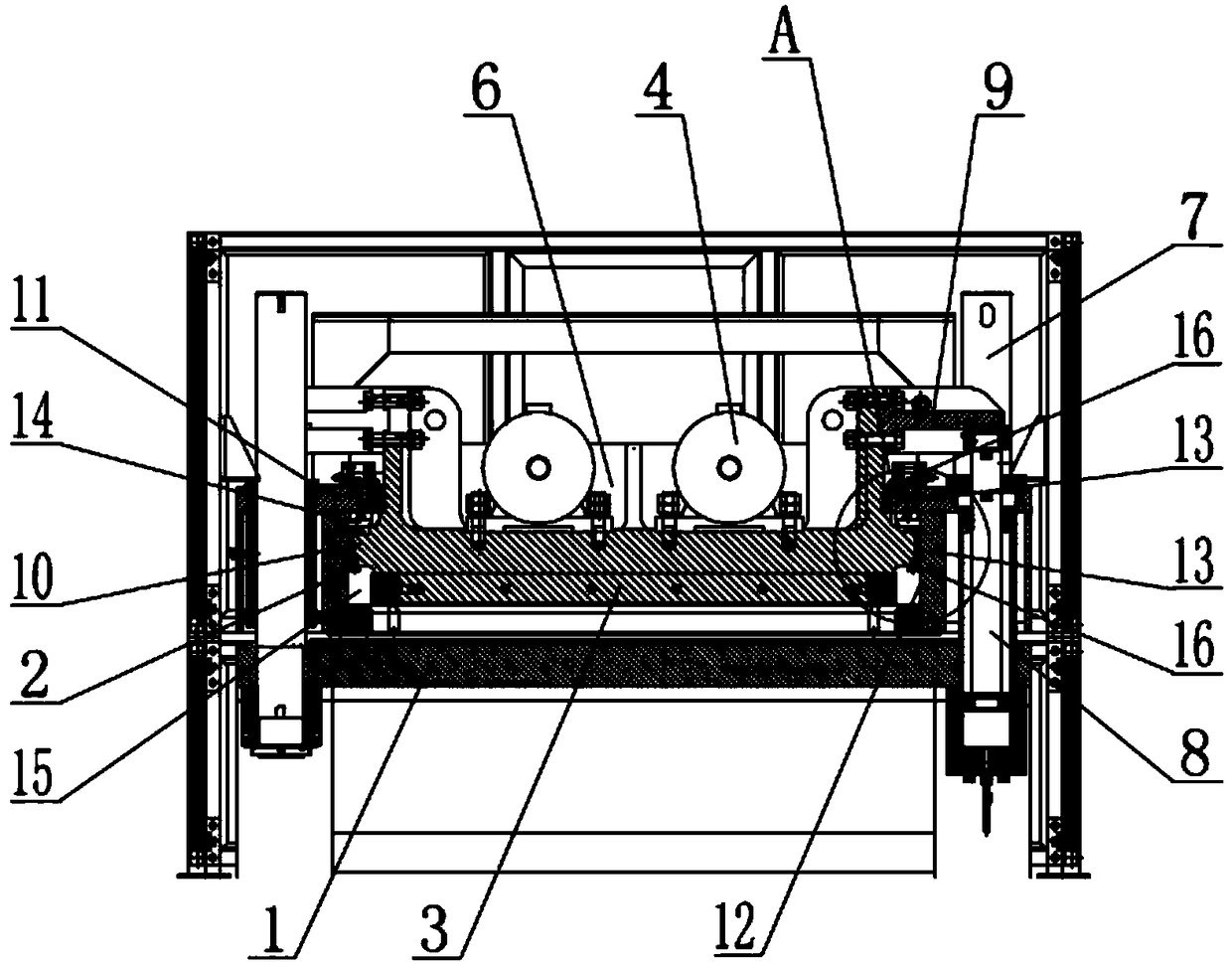

[0024] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0025] Such as Figure 1-4 As shown, a quartz stone slab forming press of the present invention includes a machine base 1, an outer cover 2, a punch 3 and a vibrating mechanism. Head 3 suffered interface fracture during strenuous exercise. The vibrating mechanism is two sets of vibrating units with opposite directions, and each vibrating unit includes a plurality of vibrating motors 4 connected in series by couplings 5, and the exciting force can reach 120KN. The punch 3 is provided with a concave cavity 6, and the vibration mechanism is located in the concave cavity 6. There are 4 sets of guide columns 7 and hydraulic cylinders 8 on the base 1, and the punch 3 moves upward along the guide columns 7 under the action of the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com