Flexible stab-proof fabric and production method thereof

A flexible waterproof and fabric technology, applied in the field of fabrics, can solve the problems of human discomfort, low safety, heavy weight, etc., and achieve the effects of comfortable and convenient wearing, strong wearing comfort and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

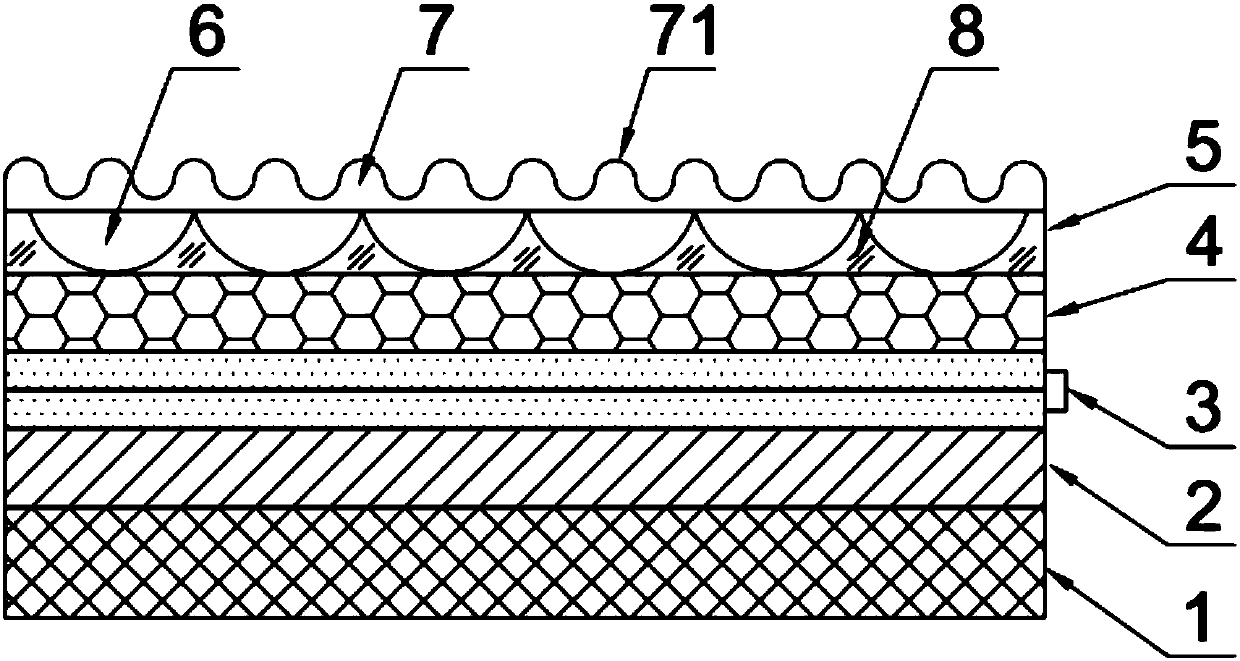

[0028] like figure 1 As shown, a schematic structural diagram of a flexible stab-resistant fabric provided in this embodiment includes an inner layer 1, a first protective layer 2, a first connection layer 3, a second protective layer 4 and The stab-proof layer 5, the stab-proof layer 5 includes a stab-proof block 7 and a buffer protrusion 6, the stab-proof block 7 is exposed to the outside, the buffer protrusion 6 is located in the interior of the stab-proof layer 5, and a buffer solution 8 is filled between the buffer protrusions 6 .

[0029] The stab-proof block 7 is formed by repeatedly connecting the bumps 71 and the grooves to form a wave shape, and the material is a carbon fiber reinforced composite material; the buffer protrusion 6 is formed by connecting several hemispheres, and the material is a highly elastic rubber material; the upper and lower parts of the buffer protrusion 6 Flexible waterproof fabric on both sides. The connection point of the buffer protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com