Pavement structure of cement concrete bridge deck

A cement concrete and concrete layer technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems that affect the service life of bridge decks and threaten the safety of high-speed traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

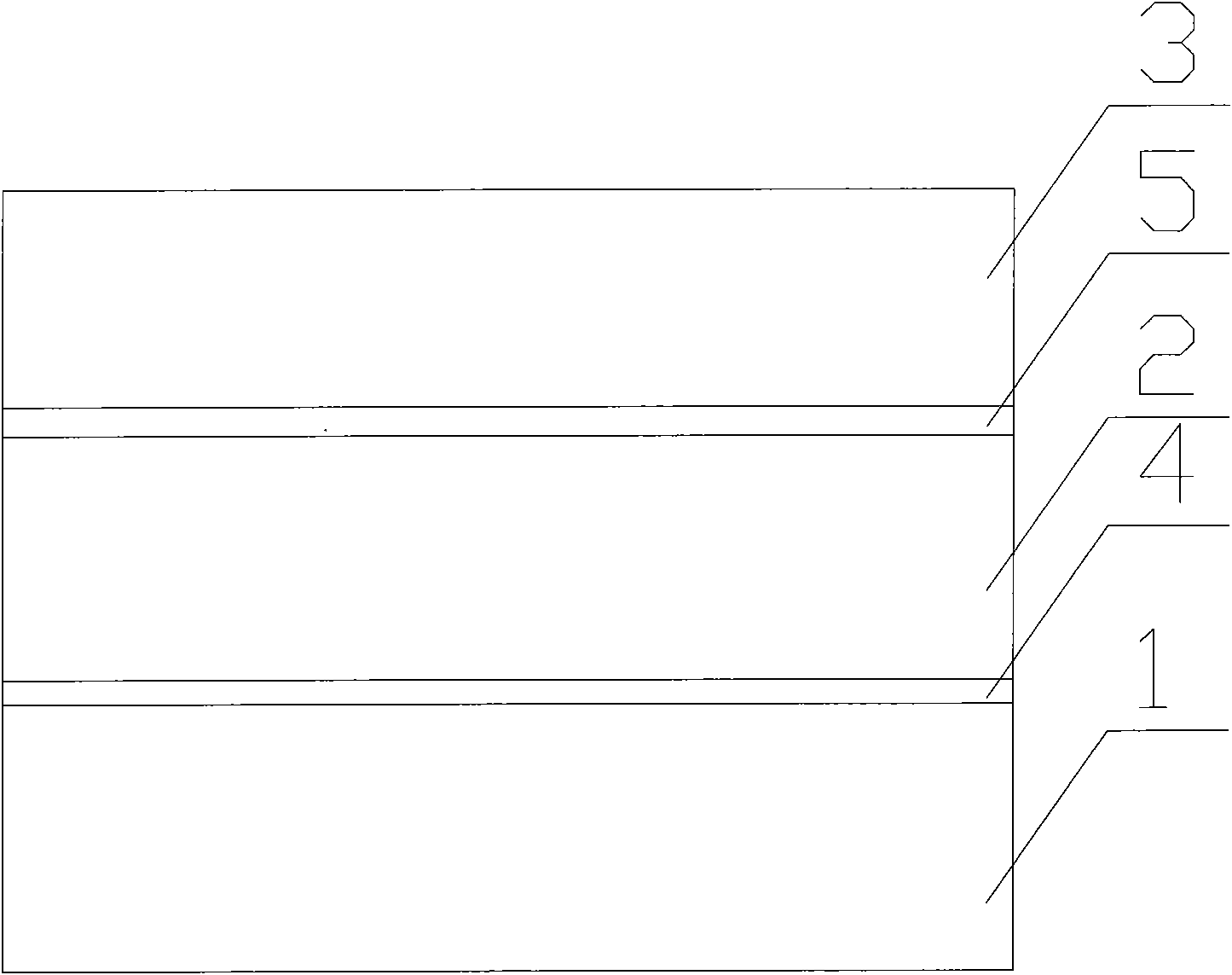

[0051] Such as figure 1 Shown, a pavement structure of cement concrete bridge deck, the top of cement concrete bridge deck 1 is successively provided with epoxy asphalt concrete layer 2 and SMA13 asphalt concrete layer 3; Described cement concrete bridge deck 1 and epoxy asphalt concrete layer 2 are bonded by a waterproof bonding layer 4, and the epoxy asphalt concrete layer 2 and the SMA13 asphalt concrete layer 3 are bonded by a bonding layer 5;

[0052] The thickness of the epoxy asphalt concrete layer 2 is 35mm; the thickness of the SMA13 asphalt concrete layer 3 is 38mm; the thickness of the waterproof adhesive layer 4 is 0.6mm; the thickness of the adhesive layer 5 is 1.5mm.

[0053] Epoxy asphalt concrete in the epoxy asphalt concrete layer 2 is formed by mixing epoxy asphalt binder and asphalt mixture, and the mixing ratio is 6: 100, in parts by weight; the epoxy asphalt binder is made of epoxy The resin is heated to 83°C and mixed with epoxy asphalt binder heated to ...

Embodiment 2~4

[0074] Such as figure 1 Shown, a pavement structure of cement concrete bridge deck, the top of cement concrete bridge deck 1 is successively provided with epoxy asphalt concrete layer 2 and SMA13 asphalt concrete layer 3; Described cement concrete bridge deck 1 and epoxy asphalt concrete layer 2 are bonded by a waterproof bonding layer 4, and the epoxy asphalt concrete layer 2 and the SMA13 asphalt concrete layer 3 are bonded by a bonding layer 5;

[0075] The thickness and material parameters of each layer are shown in Table 18, and the others are the same as in Example 1.

[0076] The thickness and material parameter of each layer in table 18 embodiment 2~4

[0077]

[0078] Explanation: In the table, A represents epoxy asphalt binder, B represents asphalt mixture, and A:B represents the ratio of the two;

[0079] C represents epoxy resin, D represents base asphalt with curing agent for epoxy asphalt binder, C:D represents the ratio of epoxy resin and base asphalt with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com