Patents

Literature

99results about How to "Retain natural flavor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of pure camellia oil

ActiveCN101824361AKeep active ingredientsRetain natural flavorFatty-oils/fats refiningFatty-oils/fats productionOil and greaseFlavor

The invention relates to a preparation method of pure camellia oil. Impurities are removed by filtration in a pure physical cold pressing way to obtain the pure camellia oil and the active components of the camellia oil are effectively reserved by a pure physical method without using any chemical agents during oil refining. The invention has light oil color, can obtain the camellia oil fit to a national GB1 1765-2003 pressed tea-seed oil standard without processing processes, i.e. deacidification, decoloration, deodorization, and the like, during the oil refining, reservess the natural flavor and aroma of the camellia oil, and has simple process, low cost and high oil yield.

Owner:广东新大地生物科技股份有限公司

Low sugar honey pomelo fruit paste and preparation method thereof

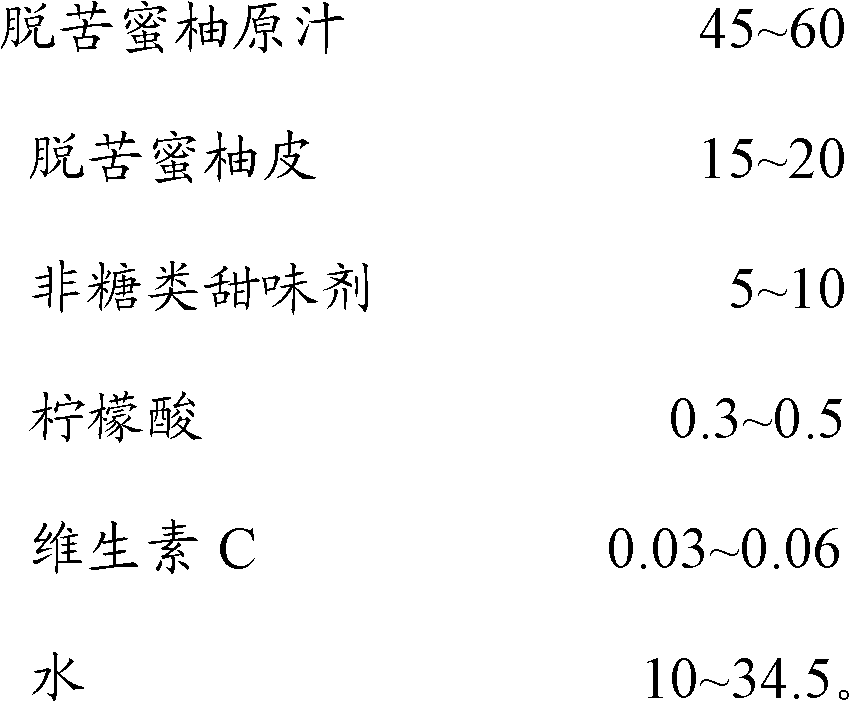

The present invention discloses a low sugar honey pomelo fruit paste and a preparation method thereof. The honey pomelo fruit paste of the present invention comprises the following components, by weight, 45-60 parts of a debittering honey pomelo natural juice, 15-20 parts of debittering honey pomelo pericarp, 5-10 parts of a non-sugar sweeting agent, 0.3-0.5 part of lemon acid, 0.03-0.06 part of vitamin C, and 10-34.5 parts of water, wherein the honey pomelo fruit paste of the present invention has low sugar content and low calory, does not easily cause fattening, and is suitable for taking by diabetes patients. According to the preparation method of the present invention, an ion exchange resin is adopted to carry out debittering on the honey pomelo natural juice, such that a debittering time is short, debittering efficiency is high, a production time on pulp destruction is reduced, production efficiency is improved, production cost is reduced, and the produced product maintains color, natural flavor and nutrients of fresh honey pomelo, and has good taste.

Owner:FUJIAN NANHAI FOOD

Method for processing blackberry fruit pulp with low sugar

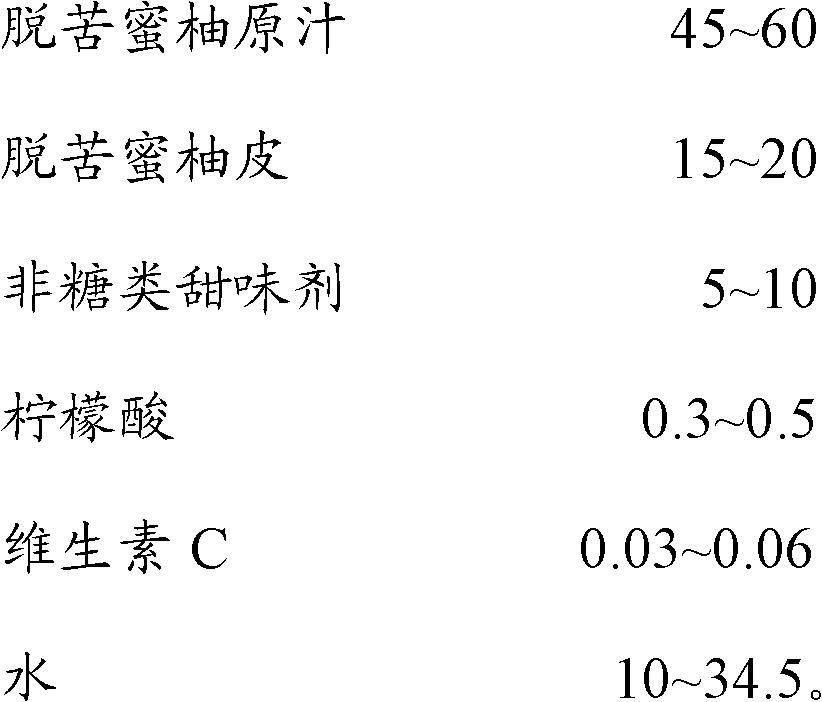

The invention relates to a making method of low-sugar blackberry jam in the jam process technological field, which is characterized by the following: choosing flash-freezing or fresh blackberry with good color and flavor and high sugar acidity as raw material; choosing natural food additives; using modern process technique and unique dispense prescriptions; making the blackberry jam with low sugar content, beautiful in color and sour-sweet taste; having more dense scent of raspberry with stable quality. The invention has the merits of (1) the dispense prescriptions is formed through researching over many years and fits the needs of food with low sugar and high pulp content and mellowing taste for modern people, and (2) the invention utilizes the methods of vacuum concentration, homogeneity and degassing to reserve nutrient in high limit and retains the natural flavor of the blackberry and stability of the product.

Owner:INST OF BOTANY JIANGSU PROVINCE & CHINESE ACADEMY OF SCI

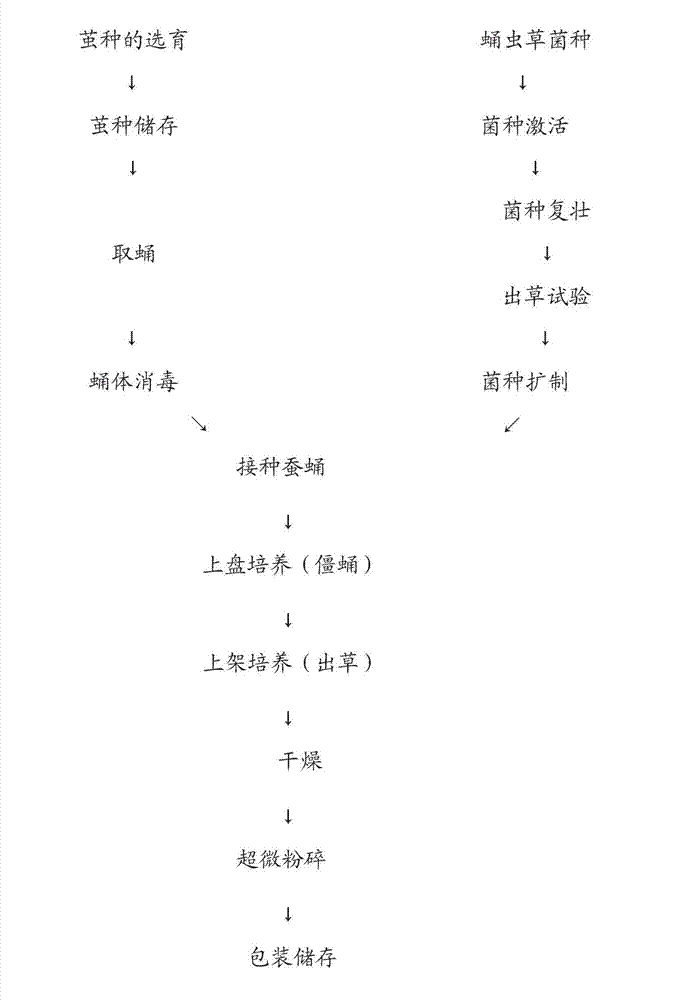

Cordyceps militaris (L) link as well as preparation method and application thereof

The invention provides a cordyceps militaris (L) link as well as a preparation method and an application thereof. The preparation method comprises the following steps of: (1) injecting fugal liquid of cordyceps militaris (L) link into silkworm chrysalis of biological cocoons of tussah, and cultivating the fugal liquid for 7-10 days at a temperature of 16-18 DEG C to obtain stiff cocoons; (2) carrying out no-illumination cultivation on the stiff cocoons for 7-10 days to form fruit body primordium on the surface of cocoon bodies; and (3) carrying out illumination cultivation on the stiff cocoons for 10-15 days with illumination intensity of 800-1000 lux, and then carrying out natural light illumination cultivation on the stiff cocoons at daytime and illumination cultivation on the stiff cocoons at night with illumination intensity of 800-1000 lux until fruit bodies grow out ascocarps. According to the invention, the biological cocoons of tussah and strains of the rejuvenated cordyceps (L) link are selected for cultivating the cordyceps militaris (L) link with high yield and high quality, a superfine grinding technology is adopted to fundamentally improve the dispersibility, dissolubility and absorptivity of the cordyceps militaris (L) link, the original biological activity and nutritional ingredients of the cordyceps militaris (L) link are maintained, and the utilization rate of raw materials is greatly improved.

Owner:吉林省中晟制药有限公司 +1

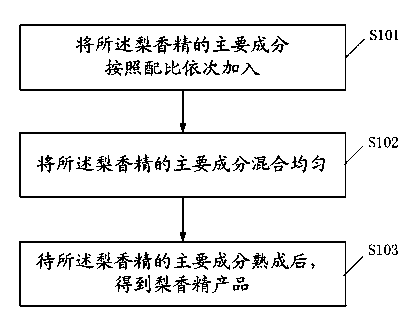

Pear essence and preparation method thereof

ActiveCN103564405APlenty of natural flavorRetain natural flavorFood ingredient as taste affecting agentFood ingredient as flavour affecting agentAcetic acidFruit juice

The invention discloses pear essence. The pear essence mainly comprises the following components: 95-97.5% of ethyl alcohol, 0.5-1% of ethyl butyrate, 0.2-0.7% of ethyl acetate, 0.2-0.7% of ethyl propionate, 0.1-0.5% of ethyl-2-methyl butyrate, 0.1-0.5% of butyl acetate, 0.1-0.6% of isoamyl acetate, 0.1-0.5% of ethyl hexanoate, 0.1-0.5% of hexenyl acetate and 0.1-0.7% of methyl 3-methylthiopropionate. Accordingly, the invention also discloses a preparation method of the pear essence. The preparation method of the pear essence comprises the steps of sequentially adding main ingredients of the pear essence in proportion, uniformly mixing and ripening, thus the pear essence product is obtained. By adopting the preparation method of the pear essence, the pear essence has strong fruit juice taste and sufficient characteristic fragrance and can reserve natural flavour of natural pear juice; the pear essence belongs to a beverage product, and reality, smoothness and fragrance of beverage taste can be obviously enhanced.

Owner:广东顺大食品调料有限公司 +1

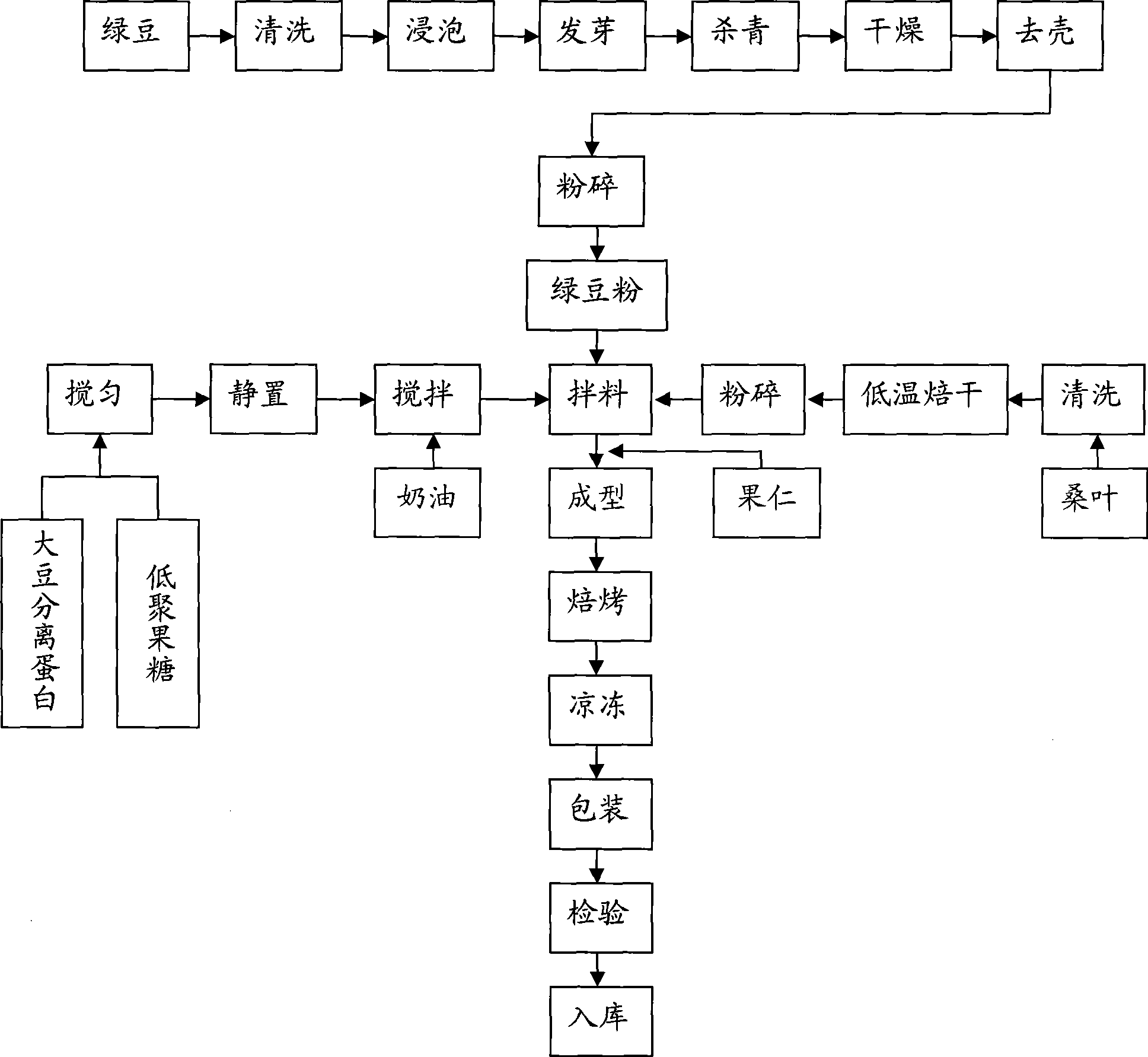

Chinese almond cake and production method thereof

The invention relates to an almond cake and a production method. The almond cake takes mung bean powder, soy protein isolate, fructo-oligosaccharides and mulberry leaf powder as raw material, can also use the nuts with a certain flavor and taste as the supporting material; and the improved almond cake raw material formula is more scientific, while the nutrition is more balanced. To produce the almond cake, firstly, first-grade mung beans are selected, soaked, germinated, blanched, dried, peeled and finely ground into mung bean powders; fresh mulberry leaves are picked, washed, dried at low temperature and crushed to get mulberry leaf dry powders which are then reserved; then the soy protein isolate and the fructo-oligosaccharides are added into a mixing barrel, stirred into uniform emulsion and kept static for 45 to 60 minutes; after butter is added into the uniform emulsion and stirred evenly, the green bean powders and the mulberry leaf powders are added into the mixture to generate the powder material; finally, the prepared powder material is placed in a cake mold, molded into a cake, put into an oven with the temperature less than 100 DEG C, baked for 35-60 minutes, cooled, sorted and packed.

Owner:JUXIANGYUAN HEALTH FOOD ZHONGSHAN

Durian juice drink containing mangosteen pulp

The invention discloses a durian juice drink containing mangosteen pulp, characterized in that various raw materials of the durian juice drink are proportioned by weight percent: 20-40% of durian pulp, 1-7% of mangosteen pulp, 0.55% of stabilizer, 0.10% of citric acid, 0.1% of sodium citrate, 0.5% of honey, 0.5% of vitamin C, 0.005% of solid natural perfume and the balance of purified water. The drink is capable of maintaining the natural flavor and nutritional ingredients of durian, convenient for people to eat trustingly and capable of overcoming body dryness and heat caused by the hot-natured durian.

Owner:陈立晓

Durian and mangosteen blended fruit juice beverage

The invention belongs to a durian deep process technology and particularly relates to a durian and mangosteen blended fruit juice beverage. The durian and mangosteen blended fruit juice beverage is characterized by comprising, by weight, 30-40% of durian pulp, 8% of mangosteen pulp, 0.55% of stabilizer (SB-4E), 0.15% of citric acid, 0.08% of sodium citrate, 0.5% of honey, 0.05% of sodium chloride, 0.005% of solid natural perfume, and the balance purified water. The durian and mangosteen blended fruit juice beverage can retain natural flavor and nutritional ingredients of the durian and can be eaten conveniently and safely, the mangosteen which is extremely cold is utilized to restrain hot internal heat of the durian, and the beverage is nourished and not dry, is mild in property, has various dietary therapy effects, is suitable for drinking by people of different physiques and is eaten in autumn and winter most suitably.

Owner:陈立晓

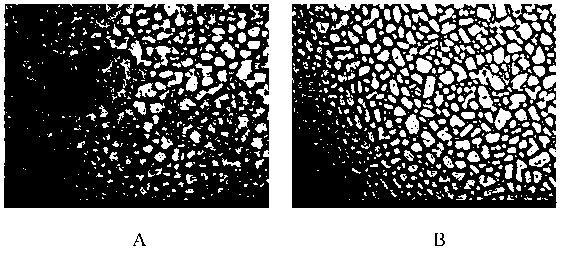

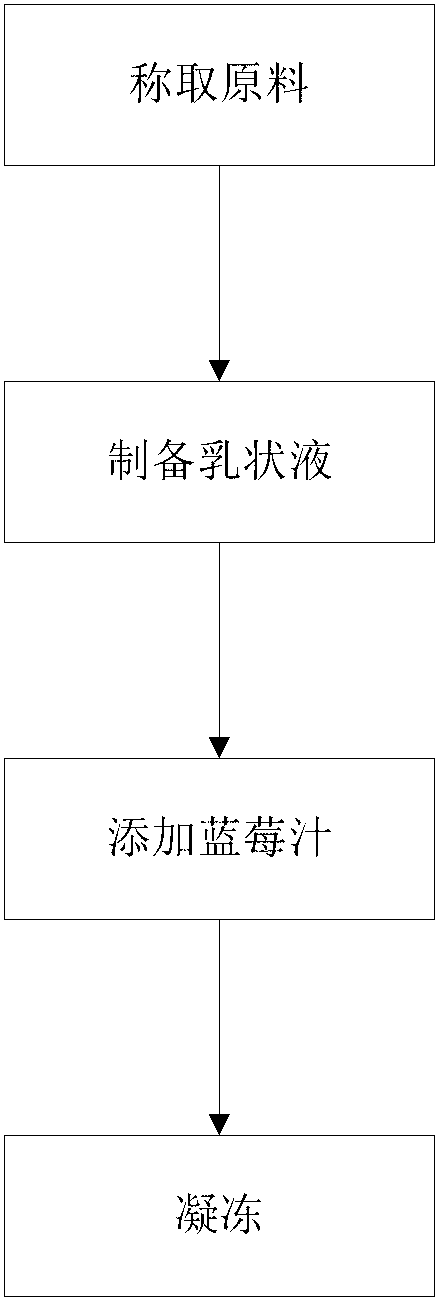

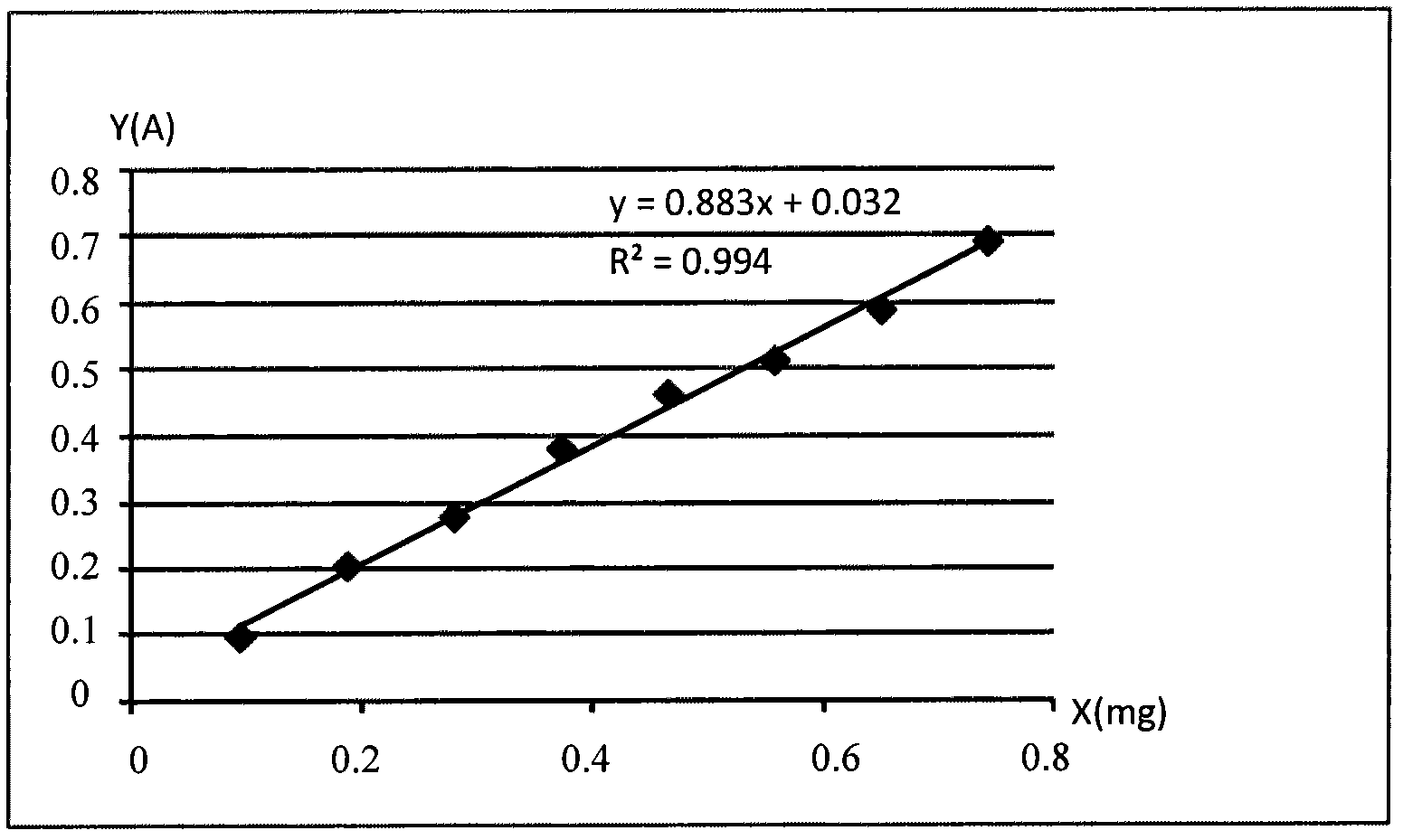

Ice cream and preparation method thereof

The invention discloses a preparation method of ice cream. The method comprises the following steps of: (1) weighing the following raw materials by weight percentage: 6%-15% of milk powder, 4%-8% of butter, 12%-18% of sugar, 1%-5% of maltodextrin, 0.2%-0.5% of nanometer microcrystalline cellulose, 2%-10% of blueberry juice, 0.21%-0.7% of a food additive, and the balance of drinking water; (2) uniformly mixing the milk powder, butter, sugar, maltodextrin, nanometer microcrystalline cellulose, food additive and water according to the weight percentage so as to form an emulsion; and (3) adding the blueberry juice into the emulsion according to the weight percentage and then cooling and freezing the emulsion into semisolid. The invention further discloses ice cream prepared by the preparation method, and the ice cream retains the unique natural flavor and taste of blueberry, has good stability and melting resistance, has a health care effect, and satisfies the pursue of people on natural nutritive health care ice cream.

Owner:珠海市红旌发展有限公司 +1

Papaya wine having health-care function on damp-heat physique and preparation method thereof

ActiveCN102021104ASave raw materialsThe composition is simpleAlcoholic beverage preparationVitamin CToxic material

The invention relates to papaya wine having a health-care function on damp-heat physique and a preparation method thereof. The papaya wine is formed by brewing medicine food homologous Chaenomeles lagenaria as main raw material with raw coix seed with the functions of strengthening the spleen and eliminating dampness and clearing away heat and toxic materials and mung beans with the function of clearing away heat and toxic materials. The invention is characterized in that a food therapy for preserving health and conditioning crowds with the damp-heat physique can be provided by a health-care wine manner. The papaya wine not only retains natural flavor of papaya fruit wine, but also contains total flavone, oleanolic acid, vitamin C, superoxide dismutase (SOD) and other abundant functional nutrient components, has very high nutrient values and health-care values and has definite pertinence at the health preservation and health care of the crowds with the damp-heat physique.

Owner:NEW ERA HEALTH IND GRP

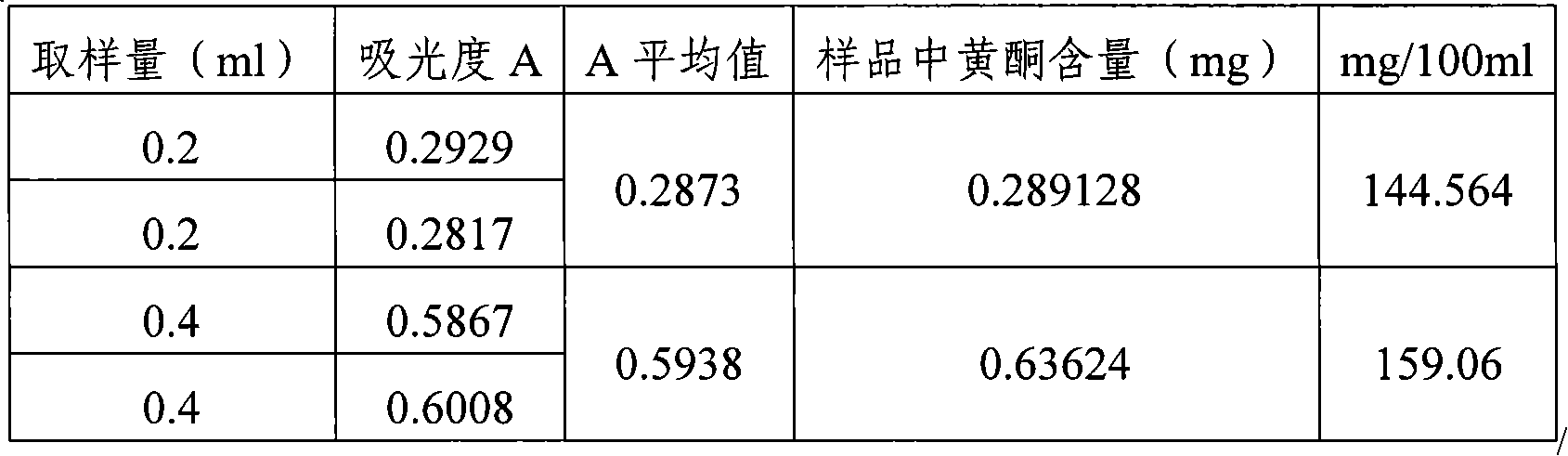

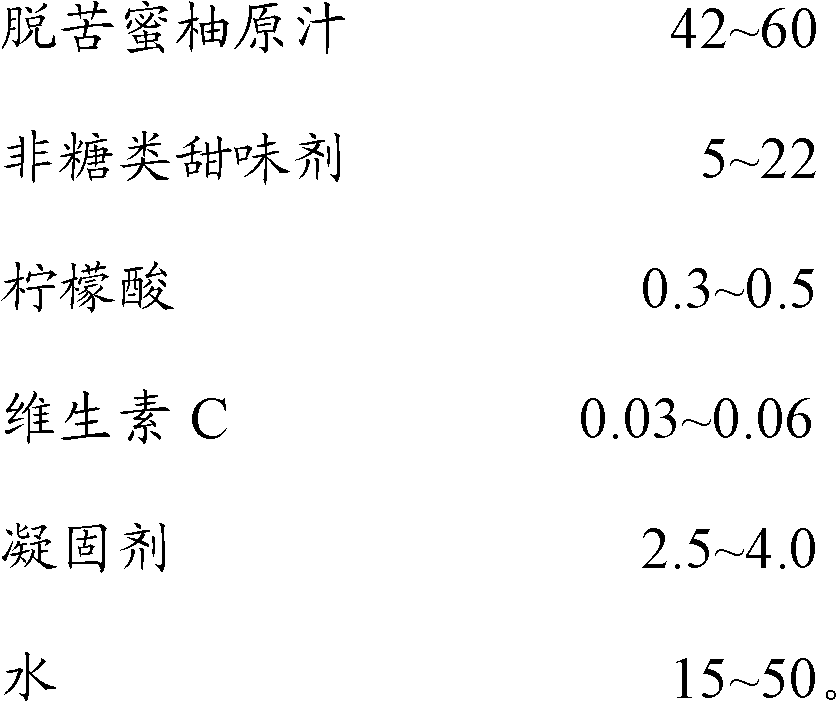

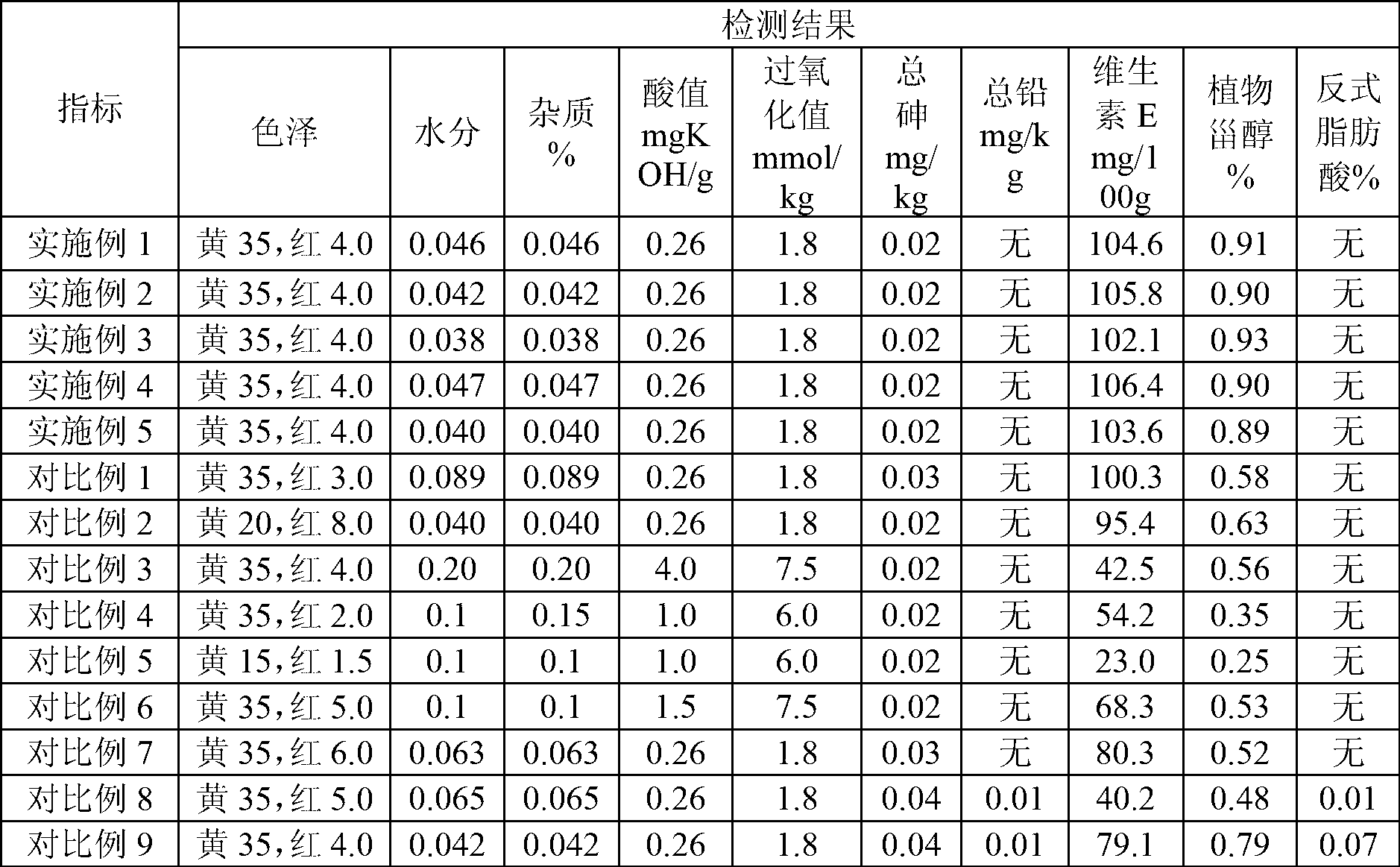

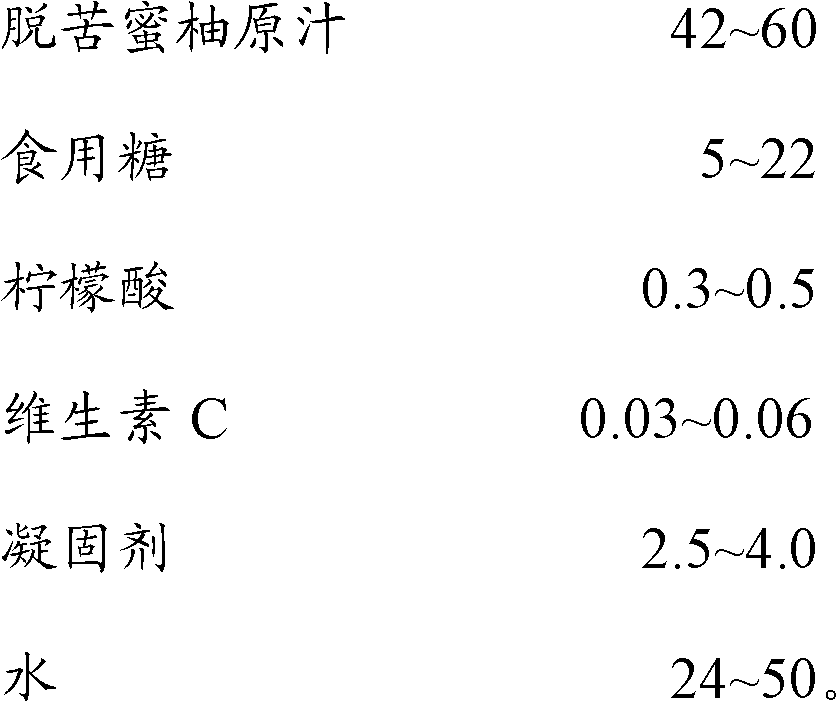

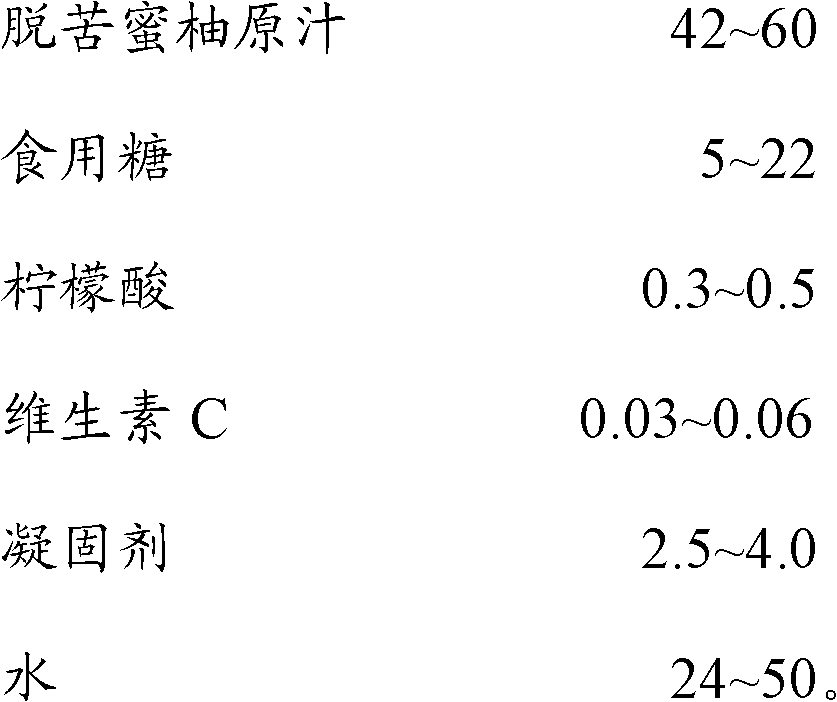

Low-sugar honey pomelo soft sweets and preparation method thereof

The invention discloses low-sugar honey pomelo soft sweets and a preparation method thereof. The low-sugar honey pomelo soft sweets comprise the following components in parts by weight: 42-60 parts of debitterized honey pomelo juice, 5-22 parts of non-sugar sweetener, 0.3-0.5 part of citric acid, 0.03-0.06 part of vitamin C, 2.5-4.0 parts of coagulant and 15-50 parts of water. The low-sugar honey pomelo soft sweets and the preparation method have the following beneficial effects: the low-sugar honey pomelo soft sweets have low sugar content and heat, are not easy to fatten people and are suitable for patients with diabetes; in the preparation method, ion exchange resins are adopted to debitterize the honey pomelo juice, the debitterizing time is short and the debitterizing efficiency is high, thus reducing the pulp damage production time, improving the production efficiency and lowering the production cost; and the produced products maintain the colors, natural flavors and nutritional ingredients of fresh honey pomelos and have good taste.

Owner:FUJIAN NANHAI FOOD

Edible blending oil and preparation method thereof

The invention provides edible blending oil. The edible blending oil consists of 300 to 500 weight parts of camellia oleosa seed oil, 250 to 450 weight parts of rapeseed oil, 100 to 150 weight parts of peanut oil and 100 to 200 weight parts of pine seed oil. The edible blending oil solves the technical problems that the edible oil in the prior art has single nutritional ingredient, non-pure flavor and low nutritional value.

Owner:HUNAN JINDIAN GREASE

Preparation method of powdery sheet-type honey

InactiveCN107890059AEasy to joinEasy to transportFood thermal treatmentFood preservationFiltrationTwo step

The invention belongs to the technical field of honey processing and provides a preparation method of powdery sheet-type honey. The method mainly comprises preparing a honey dilution liquid, storing the honey dilution liquid at a low temperature, removing impurities by two-step filtration, carrying out sterilization and homogenization, carrying out three-effect concentration and carrying out spraydrying. The honey dry powder sheets in a solid form are prepared from the liquid honey so that the original nutrients and pure taste and aroma of honey are kept, are easy to transport, store and carry and have a long shelf life.

Owner:MINGGUANG HAOHAO BEES

Preparation method and application of hemp essential oil containing hemp bisphenol

InactiveCN110343571APromote absorptionHigh medicinal valueCosmetic preparationsOrganic chemistrySilica columnCannabidiol

The invention discloses a preparation method and application of hemp essential oil containing hemp bisphenol and belongs to the technical field of processing of industrial hemp. The preparation methodcomprises the following steps: 1, preparation of hemp bisphenol: drying, smashing and drying fresh industrial hemp flowers and leaves, carrying out CO2 supercritical extraction to obtain a crude extract, and carrying out silica column chromatography separation and purification, concentration, crystallization and drying to obtain 99% or above of hemp bisphenol (CBD); 2, preparation of hemp oil: drying, smashing and drying fresh hempseeds, and carrying out CO2 supercritical extraction to obtain hemp oil; and 3, preparation of the hemp essential oil containing hemp bisphenol: mixing the hemp bisphenol with the hemp oil according to a certain proportion, and carrying out stirring to sufficiently dissolve a solid so as to obtain the hemp essential oil containing hemp bisphenol. The hemp essential oil obtained by using the preparation method can be applied to the addition of daily chemical products, drugs, health products, food and beverages.

Owner:YUNNAN LVXIN BIOLOGICAL PHARMA CO LTD

Laver paste and preparation method thereof

The present invention discloses a laver paste and a preparation method thereof, wherein the laver paste includes a mixing powder composed of a laver powder of 10%-35% by weight, a puffed rice meal of 50%-80%, a parched rice meal of 10%-35% and a right amount of common salt, then a seed fat of 3%-6% of the mixing powder weight is sprayed to the mixing powder, then the laver paste will be obtained. The laver paste of the invention is not only reserved with the natural local flavor and the color and lustre of the laver, also an edible method is simple namely it is edible as long as opening the bag; it is capable of being used as a novel paste foods and conforms to the life habit of the modern.

Owner:SOUTH CHINA AGRI UNIV

Chinese rice wine low-ethanol beverage and preparation method thereof

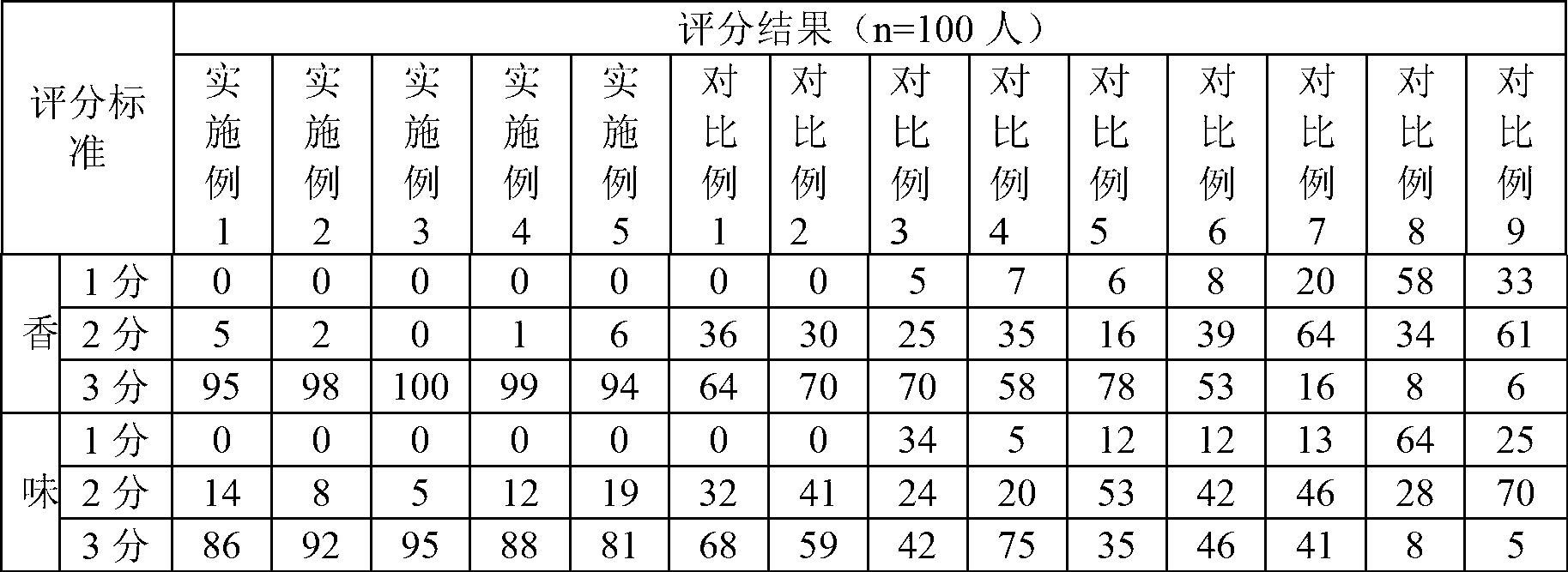

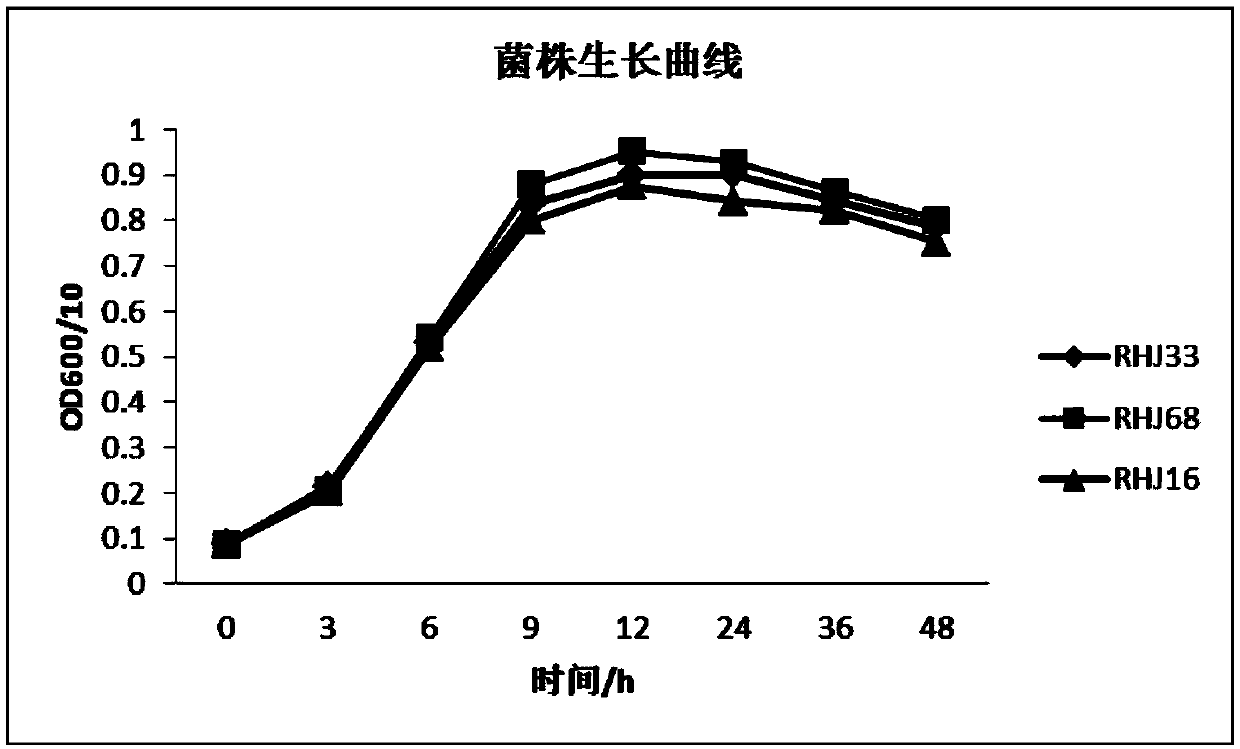

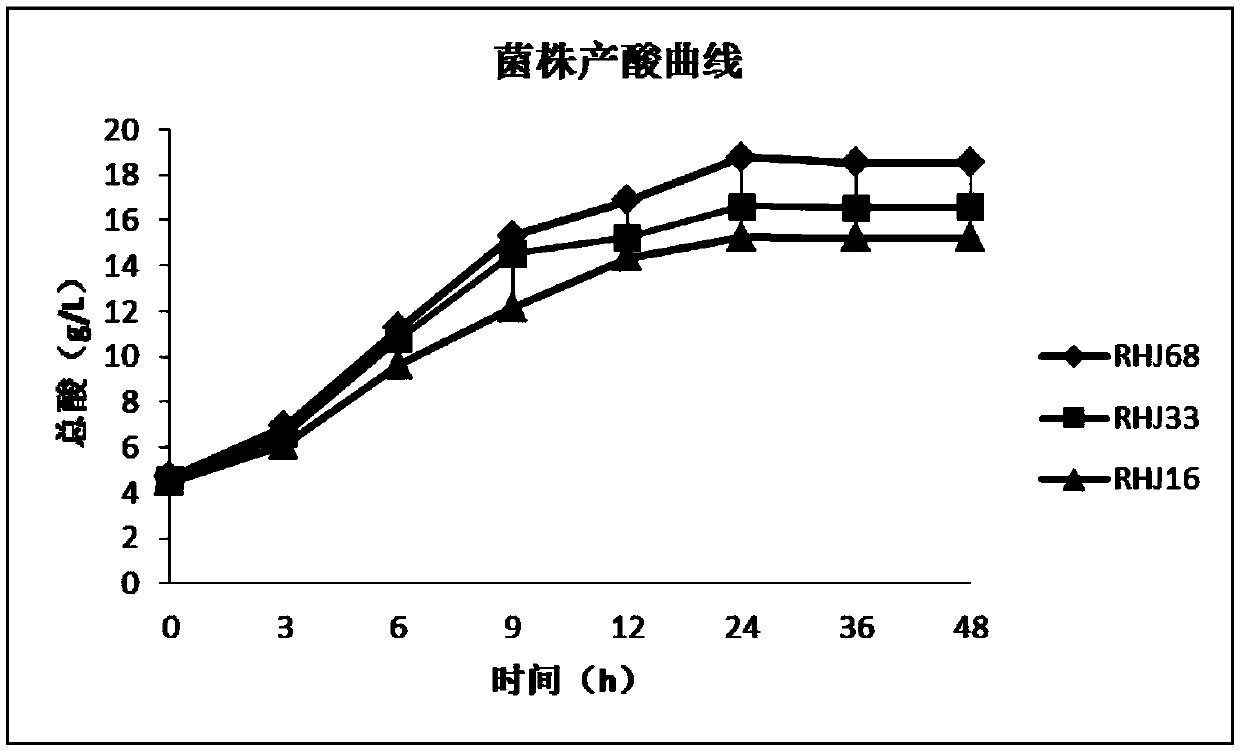

ActiveCN109554265ASolve the problem of susceptibility to miscellaneous bacteriaImprove efficiencyAlcoholic beverage preparationMicroorganism based processesFood additiveFiltration

The invention discloses a Chinese rice wine low-ethanol beverage and a preparation method thereof. The method comprises the following steps of (1) preparing cooked polished glutinous rice; (2) addingamylases and glucoamylase to steamed cooked rice, performing enzymolysis treatment, then performing bottling, performing sterilization, performing cooling, performing inoculation with lactic acid bacteria of pediococcus pentosaceus RHJ68 and the like, and performing fermentation to obtain lactic acid bacteria fermentation liquid; (3) adding purified water, sweet distiller's yeast and the lactic acid bacteria fermentation liquid to the cooled cooked polished glutinous rice, and performing fermentation so as to obtain sweet wine mash; (4) performing cooling treatment on the sweet wine mash for 1-5 days, and performing filtration so as to obtain Chinese rice wine; and (5) adjusting the sugar degree and the acidity of the Chinese rice wine, performing filling, and performing sterilization so as to obtain the Chinese rice wine low-ethanol beverage. According to the Chinese rice wine low-ethanol beverage and the preparation method thereof disclosed by the invention, rice saccharification liquid is used as a natural culture medium for enlarged culture of lactic acid bacteria, the lactic acid bacteria are supplemented to the sweet distiller's yeast, and artificially-controlled reinforced fermentation is performed, so that the acidity of the wine mash at the fermentation initial stage can be quickly increased, the effect of restraining infectious microbes can be achieved, and favorablefermentation flavor and taste can be given to the Chinese rice wine; and the product namely the Chinese rice wine low-ethanol beverage is free from food additives, and is a low-ethanol beverage havingcleaning label and being suitable for old people and young people.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

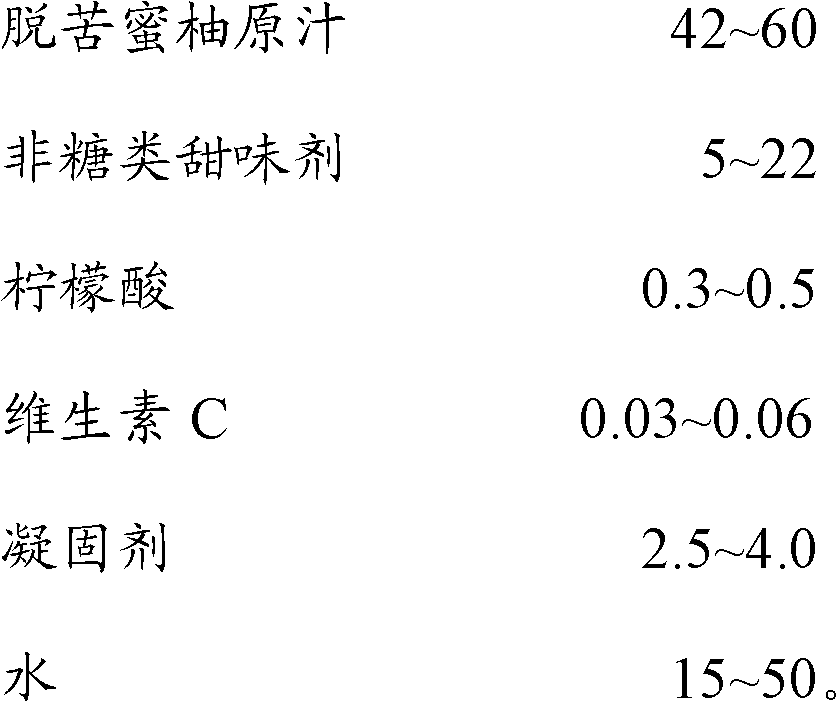

Honey pomelo soft sweets and preparation method thereof

ActiveCN102907547AEasy to store for a long timeIncrease added valueConfectionerySweetmeatsIon exchangeFlavor

The invention discloses honey pomelo soft sweets and a preparation method thereof. The honey pomelo soft sweets comprise the following components in parts by weight: 42-60 parts of debitterized honey pomelo juice, 5-22 parts of edible sugar, 0.3-0.5 part of citric acid, 0.03-0.06 part of vitamin C, 2.5-4.0 parts of coagulant and 24-50 parts of water. The honey pomelo soft sweets and the preparation method have the following beneficial effects: the honey pomelo soft sweets are easy to store for a long time and have high added value; in the preparation method, ion exchange resins are adopted to debitterize the honey pomelo juice, the debitterizing time is short and the debitterizing efficiency is high, thus reducing the pulp damage production time, improving the production efficiency and lowering the production cost; and the produced products maintain the colors, natural flavors and nutritional ingredients of fresh honey pomelos and have good taste.

Owner:FUJIAN NANHAI FOOD

Preparation method for cannabis oil

InactiveCN105316103AKeep active ingredientsIncrease added valueFatty-oils/fats refiningFatty-oils/fats productionCannabisFlavor

The invention discloses a preparation method for cannabis oil and belongs to the technical field of plant oil processing. According to the method, the pure cannabis oil is obtained after impurities are filtered out in a purely-physical cold pressing mode. No chemical reagent is added during oil and fat refining, effective active ingredients of the cannabis oil are effectively reserved through a relative low-temperature purely-physical method, and the added value is increased. No deacidification or decoloration or deodorization or else is conducted during oil and fat refining, the cannabis oil meeting the national GB11765-2003 pressed tea seed oil standard can be obtained, and the natural flavor of the cannabis oil is reserved. The process is simple, production efficiency is high, the period is short, the color of the oil is light, the oil yield and purity are high, production cost is low, and application and popularization are easy.

Owner:南宁市桂福园农业有限公司

Processing method of high-quality camellia oil

InactiveCN106318602AIncrease acidityQuality assuranceFatty-oils/fats refiningFatty-oils/fats productionComponents of crude oilFood processing

The invention discloses a processing method of high-quality camellia oil, and belongs to the technical field of food processing. The processing method of high-quality camellia oil comprises the following steps of pretreatment of camellia seed, primary squeezing, repeated squeezing, refining and filtering, and obtaining tea oil. The camellia oil prepared through the invention is pure and thick in fragrance, cool in taste; color, smell and taste are just right; besides, the original active nutrient components of the camellia oil is well reserved.

Owner:贵州石阡佛顶山野生油茶油业有限公司

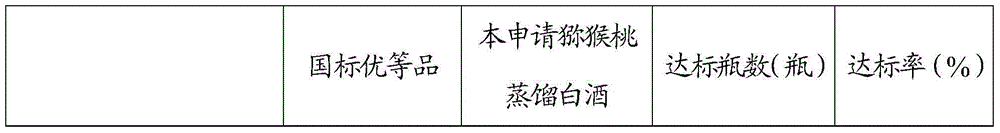

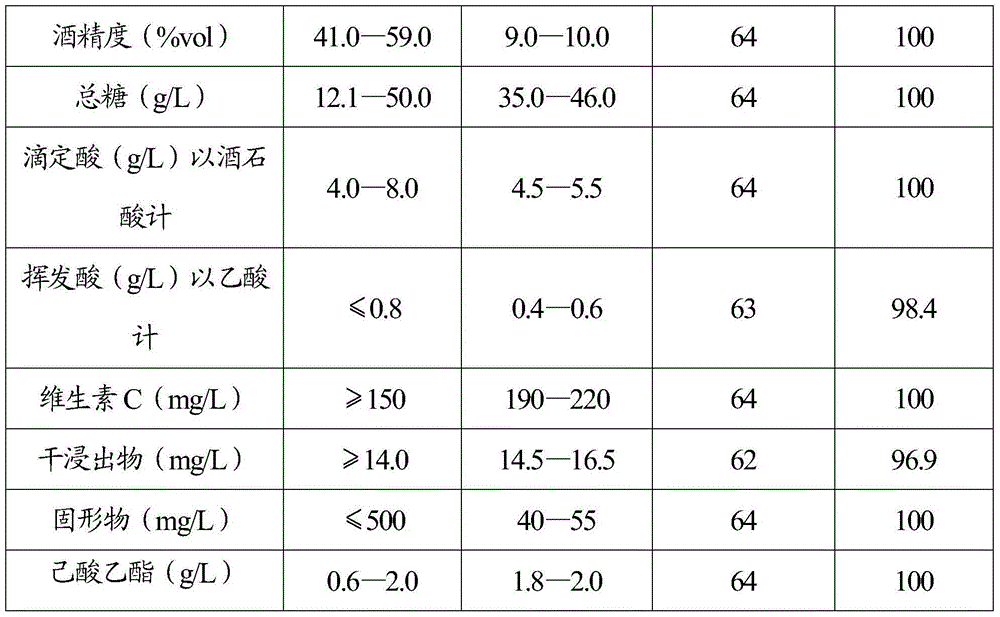

Kiwi fruit distilled liquor and production technology thereof

InactiveCN104479976ARetain natural flavorKeep the aromaAlcoholic beverage preparationPectinaseFruit juice

The invention discloses kiwi fruit distilled liquor and a production technology thereof. The production technology comprises the technological steps of fruit juice preparation, zymocyte activation, fruit juice fermentation, clarification, filtration, distillation and ageing, to be specific, the ripe kiwi fruit is juiced; sulfur dioxide and pectinase are added to the fruit juice; meanwhile, the zymocyte is screened and activated, a two-stage fermentation process is utilized and the fermentation technological parameters are improved, so that the fermentation effect is more thorough; the two-time distillation treatment is adopted to gradually improve the alcoholic strength of the distilled liquor; impurities are removed from the distilled liquor; aroma substances are extracted, so that the aroma of the distilled liquor is purer. Therefore, the aroma and the flavor of the kiwi fruit can be retained while the taste of the distilled liquor is improved; the distilled liquor is transparent and clear; proved by experiments, even in the case of long-term storage or poor storage conditions, the distilled liquor can be still kept stable in quality and deposit-free.

Owner:SICHUAN NONGXINGYUAN AGRI DEV

Production method of squeezed camellia oil

InactiveCN109135908AGreat tasteRetain natural flavorFatty-oils/fats refiningFatty-oils/fats productionFlavorActivated carbon

The invention relates to a production method of squeezed camellia oil. The method comprises the steps of 1), camellia fruit processing; 2), camellia seed processing; 3), camellia seed kernel processing; 4), squeezing for the first time; 5), squeezing for the second time; 6), refining. According to the method, the camellia fruit and the camellia seeds are piled and stored to make oil yield higher and oil quality better. The camellia seed kernels are frozen and pulverized before ultrasonic processing is conducted to change the internal physical structures of the seed kernels, the oil yield can be improved, and the taste of camellia oil is improved. The oil yield is maximized through squeezing for multiple times to prevent waste. Purification is finally conducted by adopting activated carbon,deodorizing processing is not needed, and natural flavors of the camellia oil is retained. According to the method, artificial intervening is started to improve the oil yield at the camellia fruit stage, an alternate cold and hot squeezing or extracting manner is adopted, no chemical additive is used, a pure physical method is adopted to efficiently retain the active ingredients of the camellia oil, the camellia oil is conformed to squeezed camellia seed oil standards of China, the natural flavors and fruit fragrance of the camellia oil are retained, the technique is simple, the cost is low,oil extraction is thorough, and the oil yield is high.

Owner:涟源市紫龙腾农业科技有限公司

Camellia nitidissima sugar lowering low-fat nutritious biscuit

InactiveCN104957221AGuaranteed tasteGuaranteed efficacyBakery productsCooking & bakingAdditive ingredient

The present invention discloses a camellia nitidissima sugar lowering low-fat nutritious biscuit which belongs to the health-care food industry. The biscuit consists of the following raw materials in percentage by weight: camellia nitidissima 15-20%, pea flour 15-20%, sweet potato flour 12- 18%, corn flour 10-15%, red bean powder 5-10%, egg white 8-15%, corn germ oil 5-10%, oligomeric maltose 5-10%, baking powder 1-2%, baking soda 1-2%, edible salt 0.05-0.15%, citric acid 0.01-0.1%, and the balance water. The biscuit is prepared from the above materials according to the ratio, and specifically is prepared by extracting raw liquid, screening and selecting flour, stirring and mixing into a dough, rolling and shaping, baking, screening, and finally packaging. The camellia nitidissima sugar lowering low-fat nutritious biscuit is finely prepared by scientifically matching various types of coarse cereals and added raw materials with high nutritional value, maximumly maintains the essence ingredients and natural flavor of the coarse cereals, does not add any flavoring agent, maintains the natural grain flavor, has characteristics of excellent mouthfeel and rich nutrition, and is suitable for people who avoid sugar.

Owner:李霞

Preparation method of citrus reticulata powder

InactiveCN106722452ARetain colorRetain natural flavorFruit and vegetables preservationSolubilityNutritive values

The invention relates to a preparation method of citrus reticulata powder, belonging to the food processing field. The preparation method of the citrus reticulata powder comprises the following steps: raw material preparation, pulping, enzymolysis, high temperature sterilization, homogenization, spray drying and the like. By virtue of the preparation method, the utilization rate of citrus reticulata reaches 100%, and nutritional components and pharmaceutical components such peels, kernels and pulp of the citrus reticulata are greatly kept; and the prepared citrus reticulata powder has extremely high nutritive values and pharmaceutical values, can be taken as a health food and an additive for food ingredients, is good in solubility and has an attractive color.

Owner:钟山县洲星食品有限公司

Production method for squeezing tea oil

InactiveCN109825360AImprove oil yieldGood oil qualityFatty-oils/fats refiningFatty-oils/fats productionFlavorChemistry

The invention discloses a processing method for squeezing tea oil. The method comprises the steps of collecting tea-oil tree seeds, performing drying, separating cores and shells, breaking, steaming materials and squeezing materials. Artificial intervention is started from the oil tea fruit stage, cold and hot alternate squeezing is adopted, no any chemical auxiliary is adopted, the pure physicalmethod is adopted, tea oil active ingredients are effectively reserved, the national squeezing tea seed oil standard is met, the natural flavor and fruit fragrance of camellia oil are reserved, the technology is simple and low in cost, oil extraction is sufficient, and the oil extraction rate is high.

Owner:郭世希

Banana fruit taste potato chips and making method thereof

The invention discloses banana fruit taste potato chips. The banana fruit taste potato chips are prepared from, by weight, 50-70 parts of potatoes, 5-15 parts of banana jam, 40-60 parts of egg white and 3-10 parts of water, wherein the banana jam is prepared from, by weight, 90-95 parts of bananas, 1-3 parts of brown sugar, 1-3 parts of honey, 0.3-1 part of salt, 6-12 parts of sunflower seed oil, 0.02-0.08 part of citric acid and 0.1-0.8 part of ground peppers, and the sunflower seed oil is cold pressed oil. The invention further provides a making method of the banana fruit taste potato chips. The making method includes the making process of raw material selecting, potato cooking, banana jam decocting, fed material stirring and compressing, discharged material slicing, baking and cooling and packaging.

Owner:NINGBO CITY YINZHOU FENGMING IND PROD DESIGN

Sauced goose processing method

InactiveCN106418246AResidue reductionImprove fatFood ingredient functionsProtein food ingredientsFood materialCooking process

The invention discloses a sauced goose processing method. According to the present invention, amaranthus tricolor l powder and coriandrum sativum l powder are used to replace chemical nitrite and are added into an injection as a sousing agent, such that the fishy odor can be removed and the seasoning can be achieved while the nutrition is diversified and the benefits are provided for body health; the artificially synthesized coloring agent is not added, and the tonifying food materials such as ginseng stems and leaves, milkvetch root, codonopsis pilosula and the like are added during the cooking process, such that the nourishing health edible value of the sauced goose is comprehensively improved; the modern production process and the traditional process are combined, the processing process is optimized, and the homogeneous step is set; the residual sodium nitrite content in the prepared finished product sauced goose is less than or equal to 10 mg / kg and is lower than the national standard; and the produced sauced goose has characteristics of stable color, mellow taste, diversified nutrition, moderate salty, uniform color, fragrance and taste in the internal and on the surface, production efficiency and processing health ensuring, and original taste and flavor retaining, and is the healthy food.

Owner:JIANGSU EFFORT TECH & DEV

Sugaring method of flavored preserved apples

InactiveCN110915972ARetain natural flavorImprove permeabilityYeast food ingredientsConfectioneryBiotechnologyFlavor

The invention belongs to the technical field of food and beverage processing, particularly relates to a sugaring method of flavored preserved apples, and mainly relates to preparation of a sugaring solution and vacuum gradient sugar permeation dehydration. According to the preparation method of the preserved apples provided by the invention, the natural flavor of apples is reserved, meanwhile, thefermentation characteristic flavor is increased, the problems of single taste, poor color and luster and the like of traditional preserved apples are solved, the nutritional and health-care values ofpreserved apple products are improved, and the method has good industrial application values.

Owner:SHANDONG FEILONG FOOD

Ultramicro fern powder and production technology thereof

InactiveCN101133812AWide range of usesRetain natural flavorCosmetic preparationsToilet preparationsNatural resourceFiber

The present invention relates to an ultramicro pteridium aquilinum root powder and its production process. Said production process includes the following steps: (a), digging for root of wild pteridium aquilinum, cleaning, drying and pulverizing to 50-80 meshes; and (b), further treating said pulverized pteridium aquilinum root powder by using ultramicropulverizing machine to obtain ultramicro pteridium aquilinum root powder with 300-12000 meshes. Said invention can be extensively-used in raw material production of various foods and cosmetics.

Owner:徐大军

Preparation method of freeze-dried chokeberry powder

A preparation method of freeze-dried chokeberry powder comprises the following steps: cleaning chokeberries, performing low-temperature cold squeezing on the cleaned chokeberries at 5 to 10 DEG C, performing concentration and pasteurization to obtain cloudy chokeberry juice, filtering the prepared cloudy chokeberry juice and freezing, and performing vacuum freeze drying to obtain the freeze-dried chokeberry powder. According to a common squeezing method, processing is conducted at 25 to 50 DEG C, and nutritional components, particularly thermosensitive substances are damaged easily, so that the nutritional substances are lost. Low-temperature cold squeezing is conducted at 5 to 10 DEG C, so that the cloudy chokeberry juice maintains the natural flavor and color of the raw materials, the nutritional components, anthocyanin and physiological active substances (vitamin E has an anti-ageing function, and sterol has skin-care effect and a function of enhancing human body metabolism), and the cold-pressing fruit juice has original fruit and original flavor and is good for health. The chokeberries are prepared into freeze-dried powder by a vacuum freeze-drying process.

Owner:大连海升果业有限责任公司 +1

Litchi-flavor functional beverage capable of improving sleep quality of spacemen and preparation method of litchi-flavor functional beverage

InactiveCN104544405ATaste meetsHigh nutritional valueFood ingredient functionsFood preparationBiotechnologyFruit juice

The invention discloses a litchi-flavor functional beverage capable of improving the sleep quality of spacemen and a preparation method of the litchi-flavor functional beverage. The litchi-flavor functional beverage is prepared from the following raw materials in percentage by weight: 1%-60% of litchi whole fruit juice, 1%-5% of a ganoderma extracting solution, 1%-5% of a radix polygalae extracting solution, 1%-5% of a fructus schisandrae chinensis extracting solution, 1%-5% of a lotus seed extracting solution, 1%-5% of a wolfberry extracting solution, 1%-5% of semen ziziphi spinosae, 1%-5% of a lily extracting solution and 5%-65% of honey. Compared with products in the prior art, the litchi-flavor functional beverage has the advantages that the special natural flavor and nutritional ingredients of litchi whole fruits are preserved, the beverage is capable of improving the conjugation energy of sleeping, the practical value of the fruit beverage is obviously increased, and the litchi-flavor functional beverage conforms to the uptake trend that the nutrition and health of foods and beverages are considered at home and abroad.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com