Kiwi fruit distilled liquor and production technology thereof

A production process and kiwifruit technology, applied in the field of kiwifruit distilled liquor and its production process, can solve the problems of uncoordinated aroma, insufficiently clear color and limited dissolution of nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of production technology of kiwi fruit distilled liquor, comprises the following steps:

[0035] (1) Juice preparation: screen fresh and ripe kiwifruit, squeeze the juice, add 100-120mg / L of sulfur dioxide, 70-80mg / L of pectinase, leave it for 12-15 hours and centrifuge out the juice;

[0036] (2) Activation of fermentation bacteria: boil distilled water and cool to 30-37°C, mix 1g of fermentation bacteria spore powder with 10-20mL of distilled water to obtain fermentation bacteria spore suspension, put the fermentation bacteria spore suspension into soaked cooked rice , cultivated for 30-40 hours to obtain activated fermented bacteria; wherein the fermented bacteria spore powder is Aspergillus oryzae spore powder and ester-producing yeast spore powder;

[0037] (3) Fruit juice fermentation: After adjusting the fruit juice obtained in step (1) with sugar and acid, add it to a fermenter, inoculate the fermented bacteria activated in step (2), and carry out pre-fer...

Embodiment 2

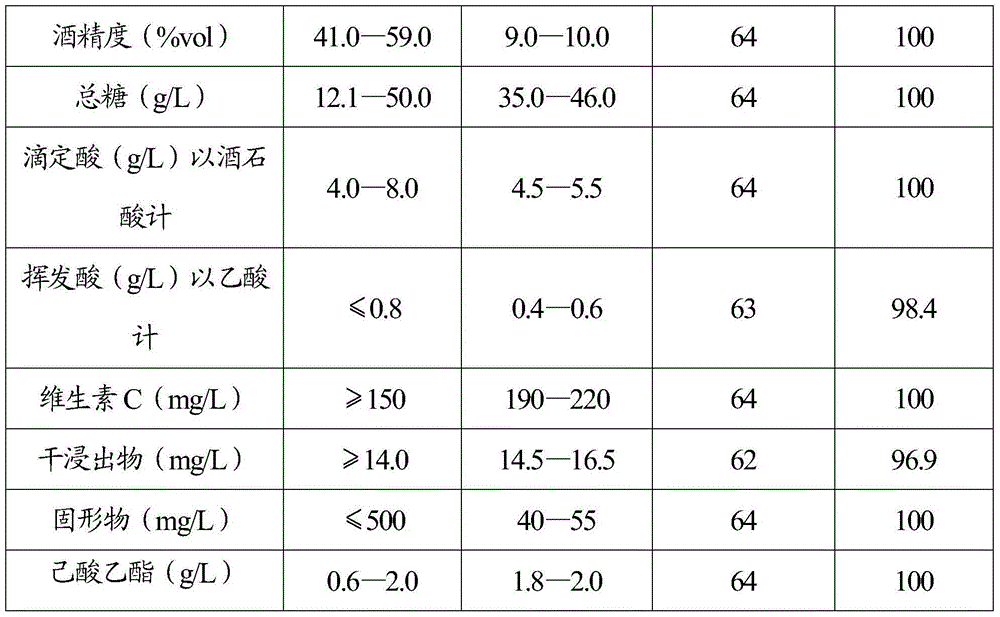

[0048] Adopt the production process of kiwifruit distilled liquor described in Example 1 to produce several batches of kiwifruit distilled liquor, randomly select 8 boxes of different batches of bottled kiwifruit distilled liquor, and randomly select 8 bottles of distilled liquor from each case, a total of 64 bottles, using The quality is tested by the experimental method in GB / T15038 and GB2757-1981, and the average quality index of 30 days, 60 days, 90 days, 180 days, 360 days and 720 days after opening the bottle is counted. The experimental data are shown in Table 2.

[0049] Table 2 Example 2 Kiwi Fruit Distilled Liquor Sampling Experimental Results

[0050]

[0051] Titration acid (g / L) is calculated as tartaric acid

[0052] As can be seen from the above data, the quality of the distilled kiwi fruit distilled liquor made by the application process is stable. After opening the bottle for 720 days, most of its indicators do not have large-scale change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com