Ice cream and preparation method thereof

A technology of ice cream and weight ratio, applied in frozen desserts, food science, applications, etc., can solve the problems that ordinary ice cream cannot meet, and achieve good stability and anti-thawing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

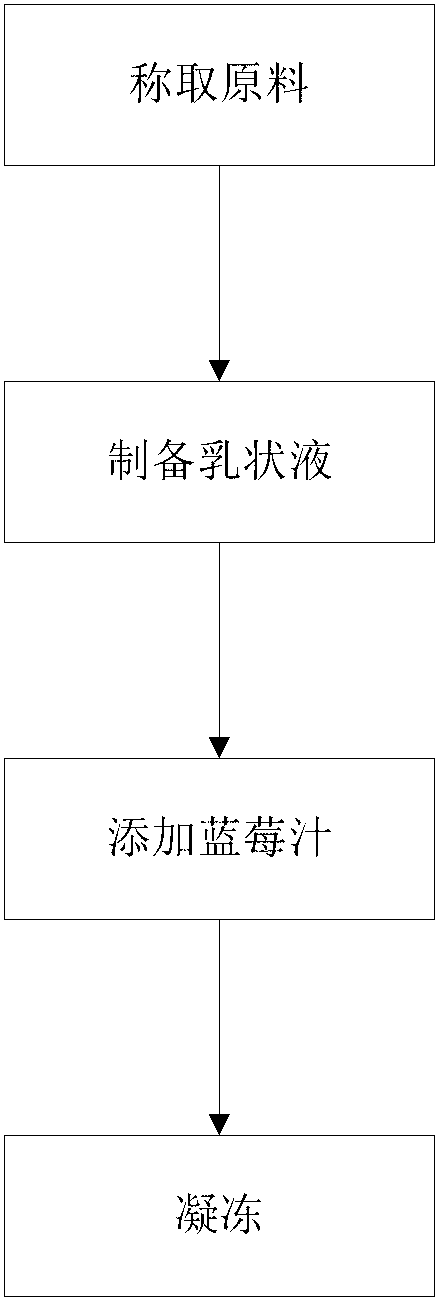

[0023] figure 1 A schematic flow chart showing the preparation method of the ice cream of the present invention. Such as figure 1 As shown, in order to prepare ice cream, first weigh the raw materials in the following weight ratio: milk powder 6-15%, butter 4-8%, sugar 12-18%, maltodextrin 1-5%, nano-microcrystalline cellulose 0.2- 0.5%, blueberry juice 2-10%, food additive 0.21-0.7%, and the balance is drinking water. Preferably, the weight ratio of the nanocrystalline cellulose is 0.35%, and the weight ratio of the blueberry juice is 5%.

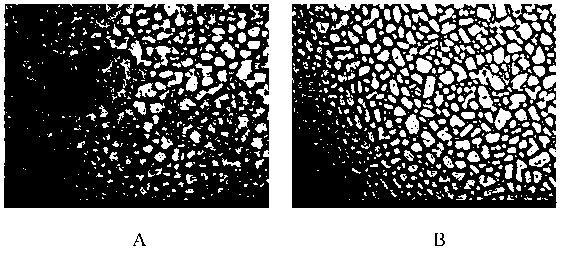

[0024] In the above raw materials, the nano-microcrystalline cellulose is a kind of microcrystalline cellulose with a particle size range of 50-1000nm, which belongs to non-nutritive substances, is not digested and absorbed by the human body, and does not provide energy for the human body. It has the health care function of improving intestinal microecological balance and preventing diseases such as hypertension and hyperlipidemia. Due...

Embodiment 1

[0035] In order to prepare the ice cream of the present invention, first weigh the following raw materials: 300 grams of whole milk powder, 200 grams of butter, 600 grams of sucrose, 50 grams of maltodextrin, 10 grams of nanocrystalline cellulose, 5 grams of molecularly distilled monoglycerides Ester, 3 grams of stabilizer, 2.5 grams of sodium citrate, wherein the stabilizer is composed of 2.5 grams of sodium alginate and 0.5 gram of carrageenan; the above-mentioned raw materials are mixed uniformly, and drinking water is added to the total weight of the raw material mixture It is 4000 grams, stirring continuously in the process of adding water to form a uniform emulsion; sterilizing the emulsion at 83°C for 10 minutes; 15MPa, homogenization under the condition of the secondary homogenization pressure of 3MPa; when the homogenized emulsion is cooled to 2°C, it is aged for 3 hours; after aging, 100g of blueberry concentrated juice is diluted to 1000g was added to the above-ment...

Embodiment 2

[0037] In order to prepare the ice cream of the present invention, first weigh the following raw materials: 750 grams of whole milk powder, 400 grams of butter, 900 grams of sucrose, 250 grams of maltodextrin, 25 grams of nanocrystalline cellulose, 15 grams of molecularly distilled monoglycerides ester, 10 grams of stabilizer, 10 grams of potassium citrate, wherein the stabilizer is made up of 8.75 grams of tamarind gum and 1.25 grams of carrageenan; the above-mentioned raw materials are mixed uniformly, and drinking water is added to the total weight in the raw material mixture It is 4000 grams, stirring continuously in the process of adding water to form a uniform emulsion; sterilizing the emulsion at 85°C for 15 minutes; 18MPa, homogenization under the condition of secondary homogenization pressure of 5MPa; when the homogenized emulsion is cooled to 5°C, it is aged for 3 hours; after aging, 500g of blueberry concentrated juice is diluted to 1000g was added to the above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com