Fruit adsorption device for fruit harvesting robot

A technology of adsorption device and robot, applied in the direction of picking machine, harvester, application, etc., can solve the problems of low picking efficiency and low automation degree of the picker, and achieve the effect of improving picking efficiency and protecting from harm.

Active Publication Date: 2018-03-09

ZHEJIANG OCEAN UNIV

View PDF7 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the picker has a low degree of automation and low picking efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0022] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

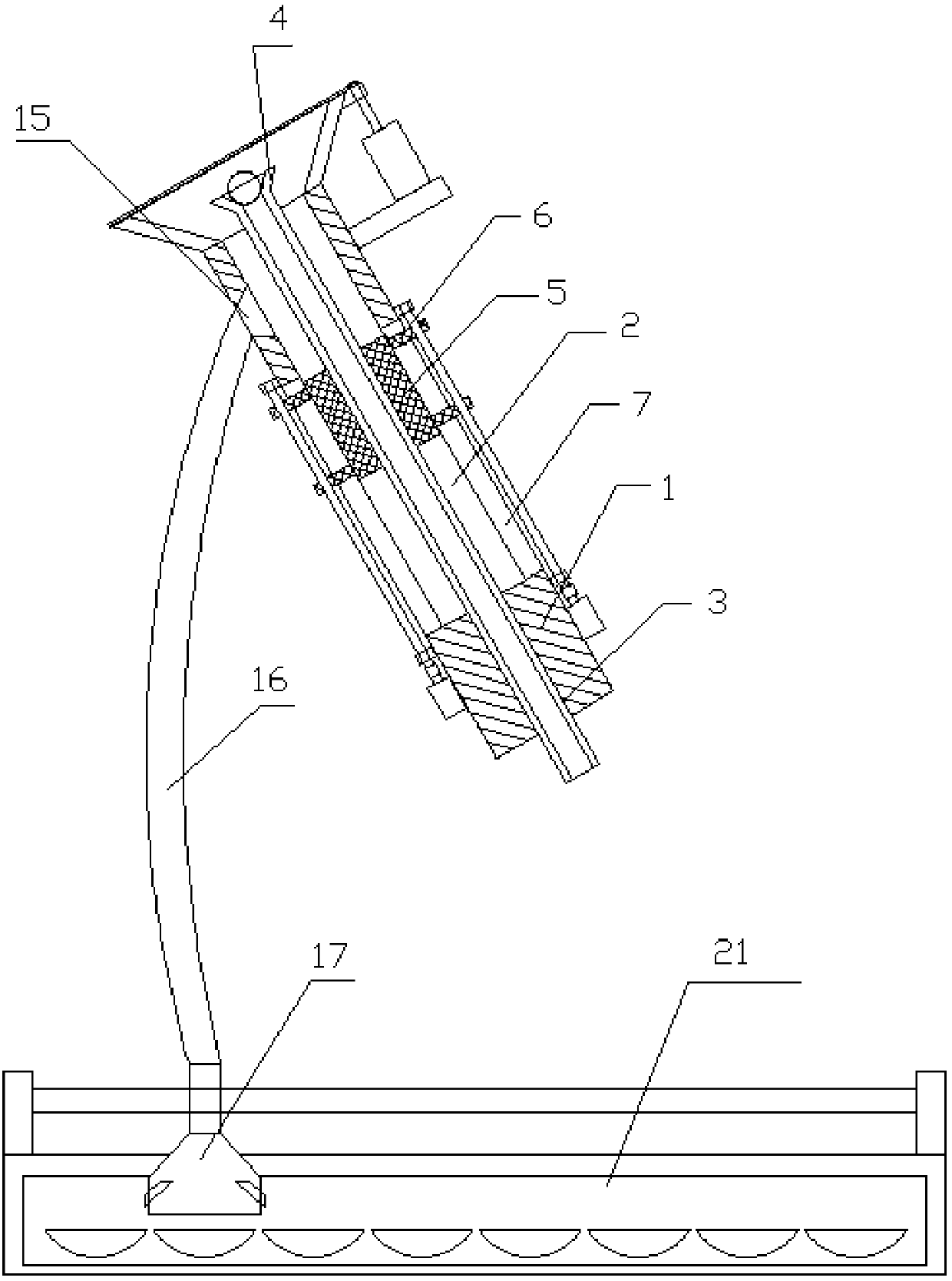

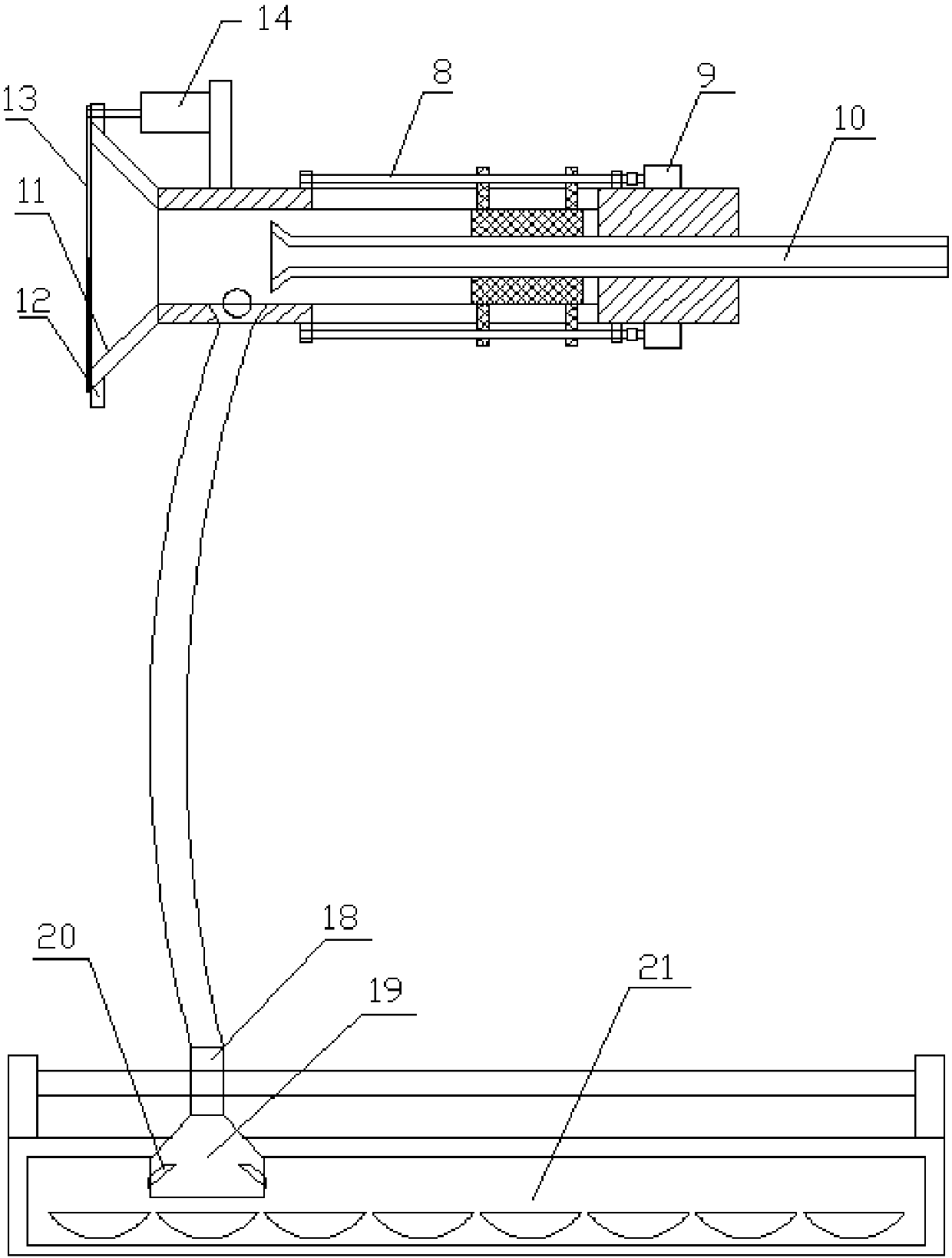

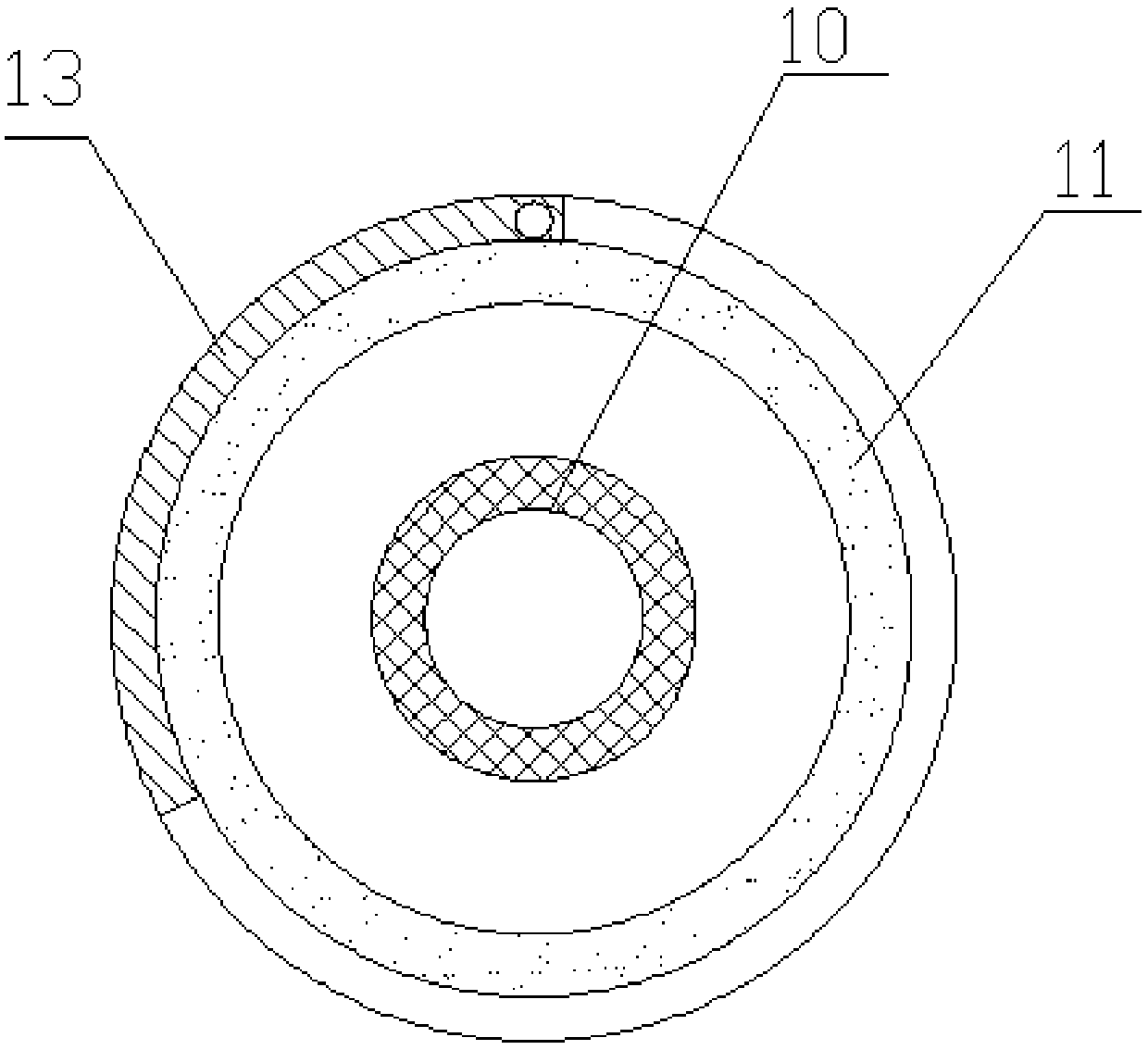

The invention provides a fruit adsorption device for a fruit harvesting robot. The device comprises a picking arm, wherein a first channel is arranged at the front end of the picking arm, a second channel is arranged at the rear end of the picking arm, the inner diameter of the first channel is larger than that of the second channel, and the first channel and the second channel are communicated with each other; the adsorption end of a vacuum adsorption pipe passes through the second channel and is located in the first channel, the second channel is in clearance fit with the vacuum adsorption pipe, and an adsorption head is arranged at the adsorption end of the vacuum adsorption pipe; a fixed clamping seat is in clearance fit in the first channel and fastened on the outer wall of the vacuumadsorption pipe; a first screw is rotationally fixed above each guide channel through a bearing seat, guide blocks are arranged on the first screws, the first screws are connected with first servo motors, the first servo motors control the first screws to rotate so as to drive the vacuum adsorption pipe to move, and the vacuum adsorption pipe is connected with a vacuum negative pressure device. Picking efficiency is improved, and fruits and fruit trees can be effectively protected from damage.

Description

technical field [0001] The invention relates to a fruit adsorption device, in particular to a fruit adsorption device for a fruit harvesting robot. Background technique [0002] Fruit is the third largest planted crop after grain and vegetables in my country, and has become a pillar industry for rural economic development in many areas. my country's current fruit planting area is 8.4 million hectares, accounting for about 21% of the world's total fruit tree area; the total annual fruit output is more than 59 million tons, accounting for 13.4% of the world's total fruit output, and these two indicators have already ranked first in the world . As an important link in the whole process of orchard production, fruit harvesting has strong seasonality and labor-intensive characteristics, and the labor force used accounts for 35% to 45% of the labor force used in the entire production process. The quality of harvesting operations is directly related to the storage, processing and s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): A01D46/24A01D46/22

CPCA01D46/005A01D46/22

Inventor 朱从容

Owner ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com