Preparation method for dried reverse osmosis composite membrane

A reverse osmosis composite membrane, dry technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of dry reverse osmosis composite membrane separation performance attenuation and other problems, and achieve the effect of solving separation performance attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

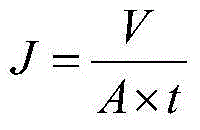

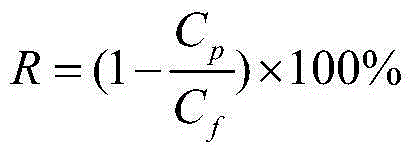

Method used

Image

Examples

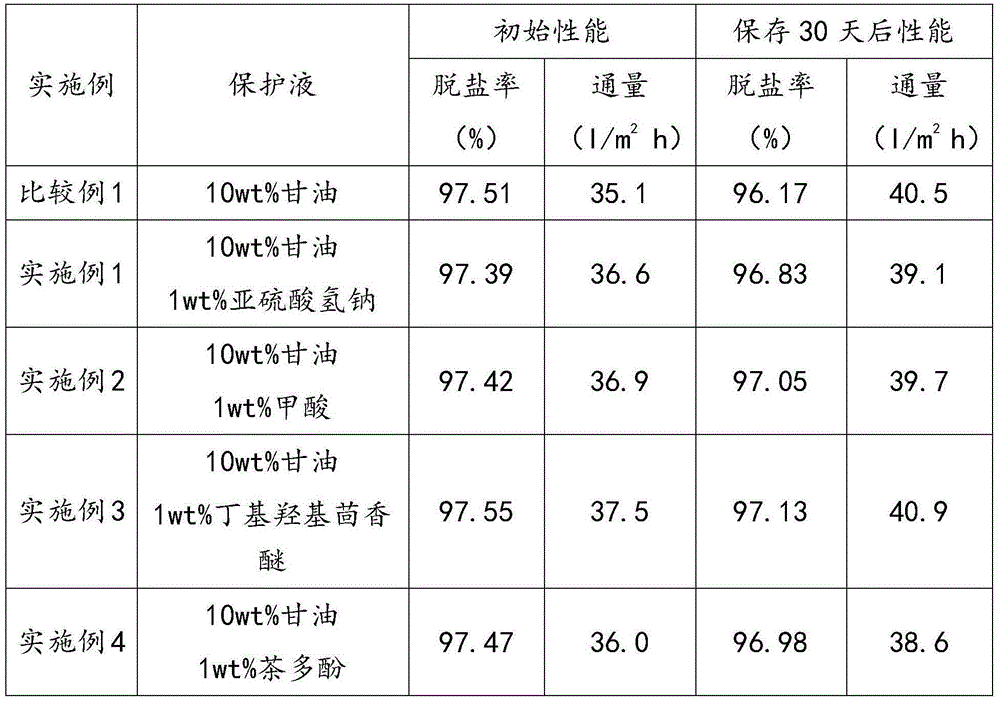

Embodiment 1

[0019] First, scrape-coat the N,N-dimethylacetamide solution containing 16.0wt% polysulfone on the surface of the non-woven fabric, and immerse it in water to remove the solvent to obtain the polysulfone support layer; then immerse the polysulfone support layer into the m-phenylenediamine solution (containing 0.1wt% sodium dodecylsulfonate surfactant), remove excess solution on the surface with a rubber roller; then the polysulfone support layer is contacted with an organic solution of trimesoyl chloride for 50 seconds, and at 80 Heat treatment in an oven at ℃~100℃ for 10 minutes; finally, soak the nascent reverse osmosis composite membrane in an aqueous solution containing 10wt% glycerin and 1wt% sodium bisulfite at a temperature of 40℃ for 2 minutes, and heat it in an oven at 80℃~100℃ heat treatment in an oven for 10 minutes to obtain a dry fully aromatic polyamide composite reverse osmosis membrane.

Embodiment 2

[0021] First, scrape-coat the N,N-dimethylacetamide solution containing 16.0wt% polysulfone on the surface of the non-woven fabric, and immerse it in water to remove the solvent to obtain the polysulfone support layer; then immerse the polysulfone support layer into the m-phenylenediamine solution (containing 0.1wt% sodium dodecylsulfonate surfactant), remove excess solution on the surface with a rubber roller; then the polysulfone support layer is contacted with an organic solution of trimesoyl chloride for 50 seconds, and at 80 Heat treatment in an oven at ℃~100℃ for 10 minutes; finally soak the nascent reverse osmosis composite membrane in an aqueous solution containing 10wt% glycerin and 1wt% formic acid at a temperature of 40℃ for 2 minutes, and heat treat in an oven at 80℃~100℃ In 10 minutes, a dry fully aromatic polyamide composite reverse osmosis membrane was obtained.

Embodiment 3

[0023] First, scrape-coat the N,N-dimethylacetamide solution containing 16.0wt% polysulfone on the surface of the non-woven fabric, and immerse it in water to remove the solvent to obtain the polysulfone support layer; then immerse the polysulfone support layer into the m-phenylenediamine solution (containing 0.1wt% sodium dodecylsulfonate surfactant), remove excess solution on the surface with a rubber roller; then the polysulfone support layer is contacted with an organic solution of trimesoyl chloride for 50 seconds, and at 80 Heat treatment in an oven at ℃~100℃ for 10 minutes; finally soak the nascent reverse osmosis composite membrane in an aqueous solution containing 10wt% glycerin and 1wt% butyl hydroxyanisole at a temperature of 40℃ for 2 minutes, and heat it at 80℃~100℃ Heat treatment in an oven for 10 minutes to obtain a dry fully aromatic polyamide composite reverse osmosis membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com