Patents

Literature

76 results about "Myofibril" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A myofibril (also known as a muscle fibril) is a basic rod-like unit of a muscle cell. Muscles are composed of tubular cells called myocytes, known as muscle fibers in striated muscle, and these cells in turn contain many chains of myofibrils. They are created during embryonic development in a process known as myogenesis.

Method for processing flavourings instant sea cucumber

The invention discloses a processing method of seasoned instant sea cucumber, comprising the steps of the decontamination of raw sea cucumber, pressure boiling, low temperature fermentation, cutting, seasoning, vacuum packing, super high pressure sterilization, etc. The myofibril of the sea cucumber tissue becomes thinner after the process of fermented preparation, the inter-place between the fiber is large, organization structure is even, the volume of the sea cucumber is large, tenderness is improved and water capacity is enhanced, being conducive to the absorption of nutritional components; the sea cucumber tastes good after being seasoned by two liquid condiment; the super high pressure sterilization comparatively maintains the original favor, shape and nutrition of the instant sea cucumber product and the shelf life is greatly prolonged. The instant sea cucumber processed and produced by the method has no ocean fishy smell, delicious with good taste, proper hardness and softness, easy to carry and instant, basically maintaining the original nutritional components of the sea cucumber. The product can be preserved for a long time with freshness, nutrition, convenience and safety and overcomes the shortages of the coarse texture and the poor taste of the sea cucumber processed by the current technology.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Food product and process for reducing oil and fat content in cooked food

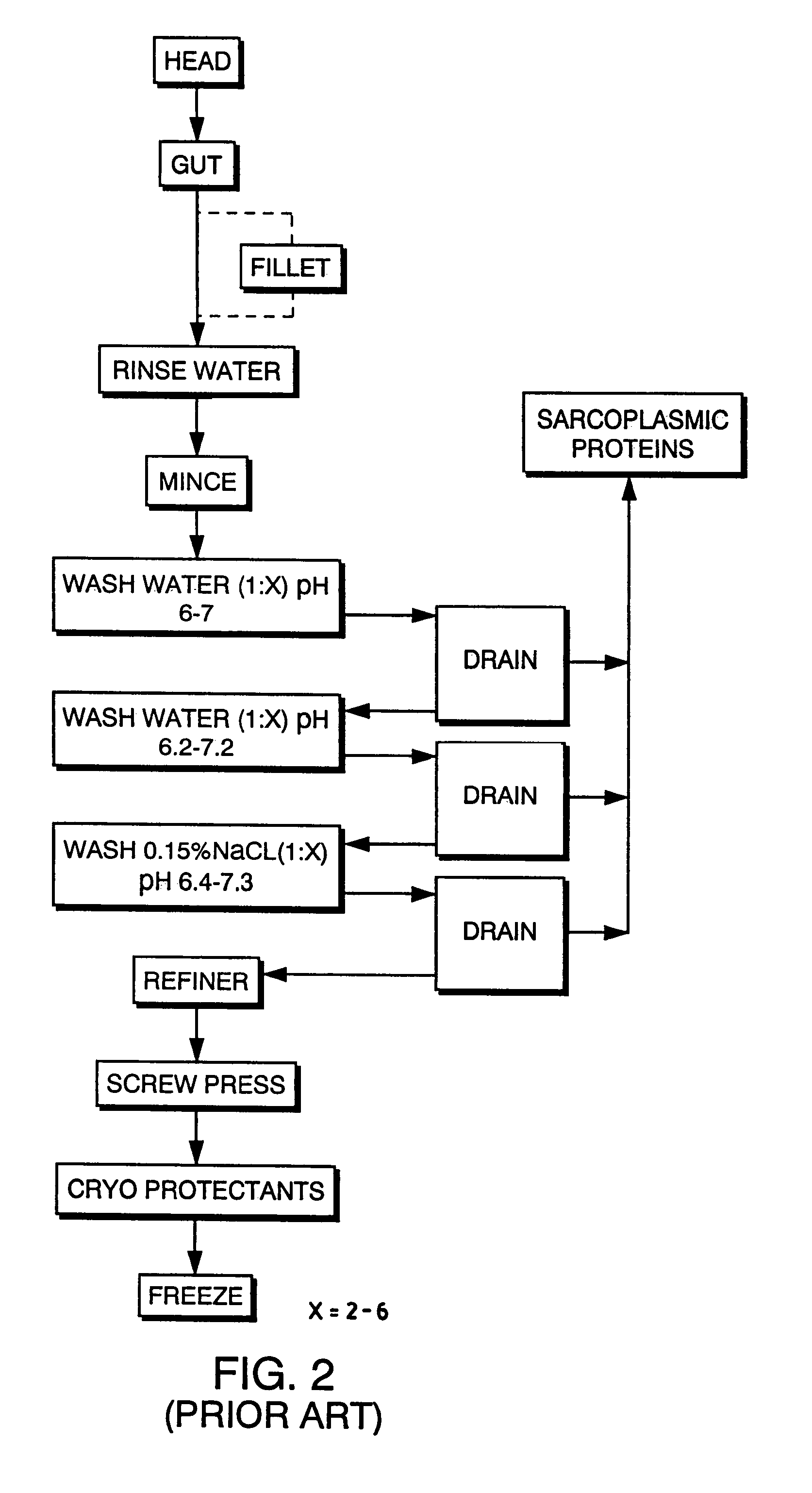

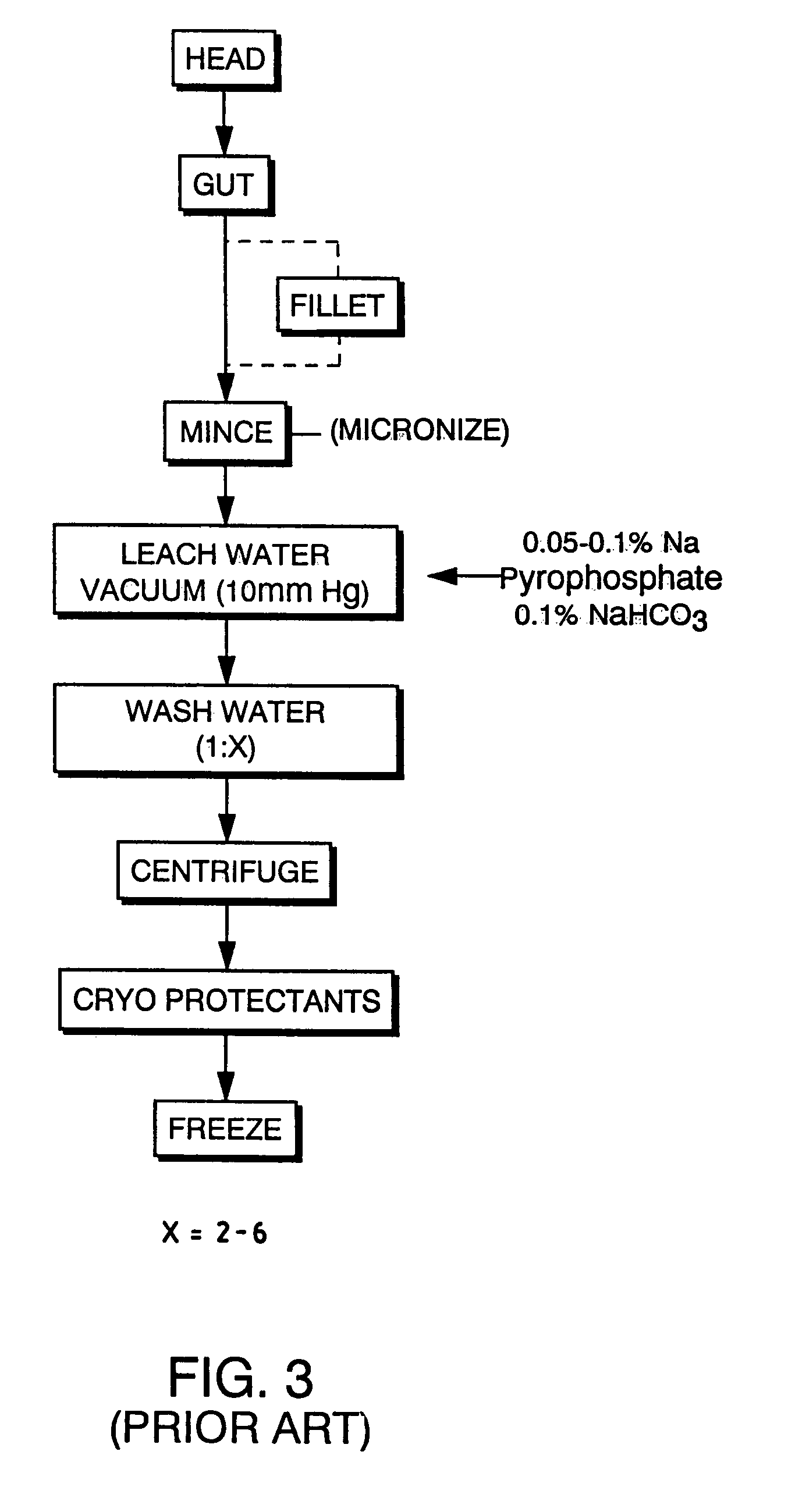

InactiveUS7163707B2Minimize absorptionLess fatProtein composition from fishMeat/fish preservationProtein solutionMyofibril

A process for cooking a food in oil and / or fat is provided. A dry protein mixture, a dry alkaline protein mixture, an aqueous alkaline protein mixture or an aqueous acidic protein is added to a food prior to cooking. The dry protein mixture, dry alkaline protein mixture, aqueous alkaline protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres. The amount of oil and / or fat absorbed by the food during cooking is substantially reduced.

Owner:PROTEUS INDUSTRIES INC

Functional animal muscle protein concentrate composition and process

InactiveUS20050233060A1Reduce degradationStay hydratedProtein composition from fishPeptide/protein ingredientsProtein solutionMuscle tissue

A meat or fish composition which retains moisture during cooking is provided. A concentrated aqueous acidic protein solution derived from animal muscle tissue is added to the meat or fish prior to cooking. The concentrated aqueous acidic protein solution comprises myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres.

Owner:KEMIN PROTEINS LLC

Process for retaining moisture in cooked animal muscle

InactiveUS6855364B2Vast majorityProtein composition from fishMeat/fish preservationMyofibrilProtein solution

A meat or fish composition which retains moisture during cooking is provided. A dry protein mixture or an aqueous acidic protein solution derived from animal muscle tissue is added to the meat or fish prior to cooking. The dry protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres.

Owner:PROTEUS INDUSTRIES INC

Process for retaining moisture in cooked food with peptide

InactiveUS20050064085A1Protein composition from fishMeat/fish preservation using chemicalsMyofibrilMuscle tissue

A peptide composition derived from a protein composition when added to uncooked food effects moisture retention during cooking of the food. The peptide composition is derived from a dry protein mixture or an aqueous acidic protein solution which, in turn, is derived from animal muscle tissue. The peptide composition is added to uncooked poultry, meat or fish prior to cooking. The dry protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres.

Owner:PROTEUS INDUSTRIES INC

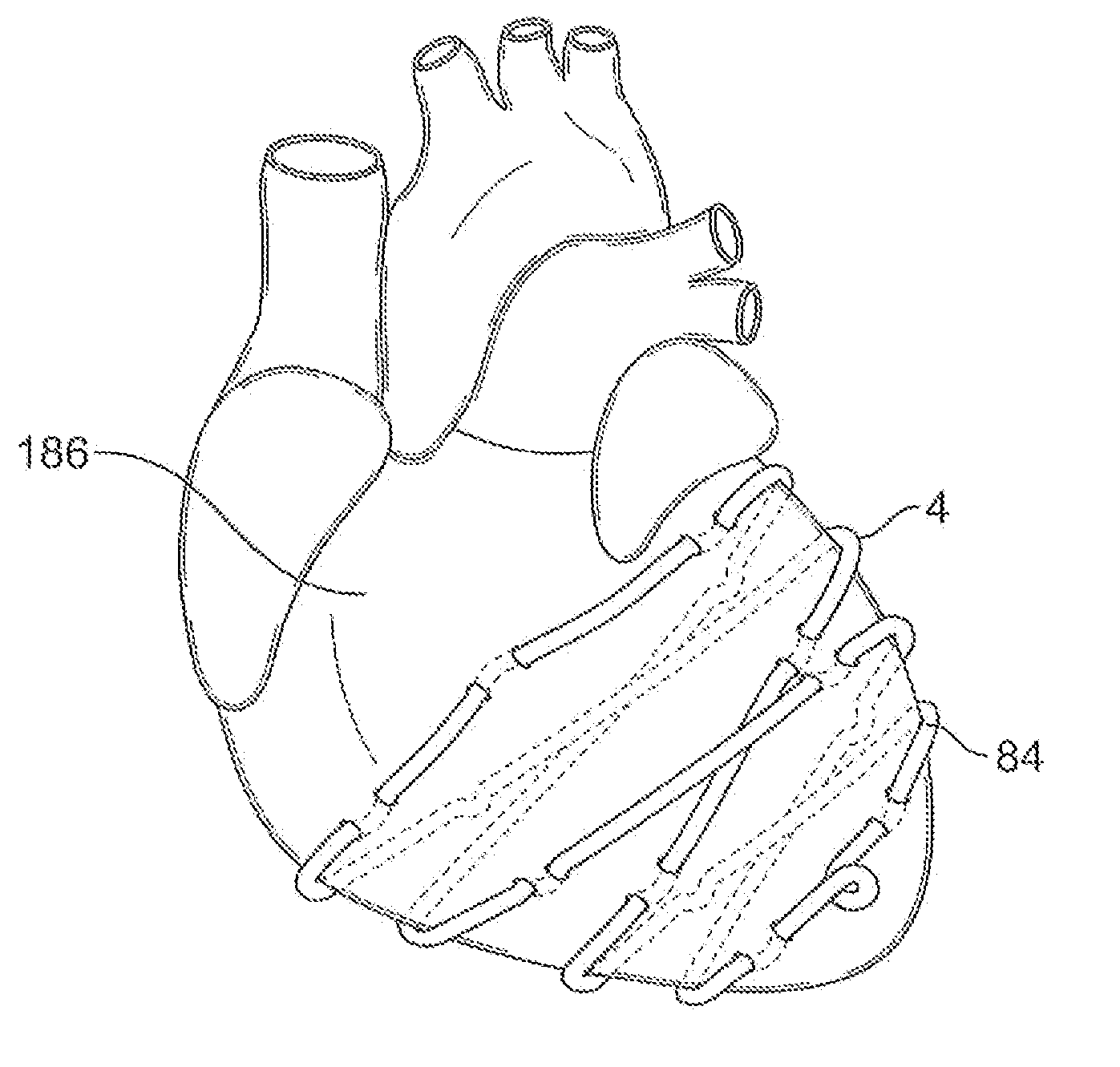

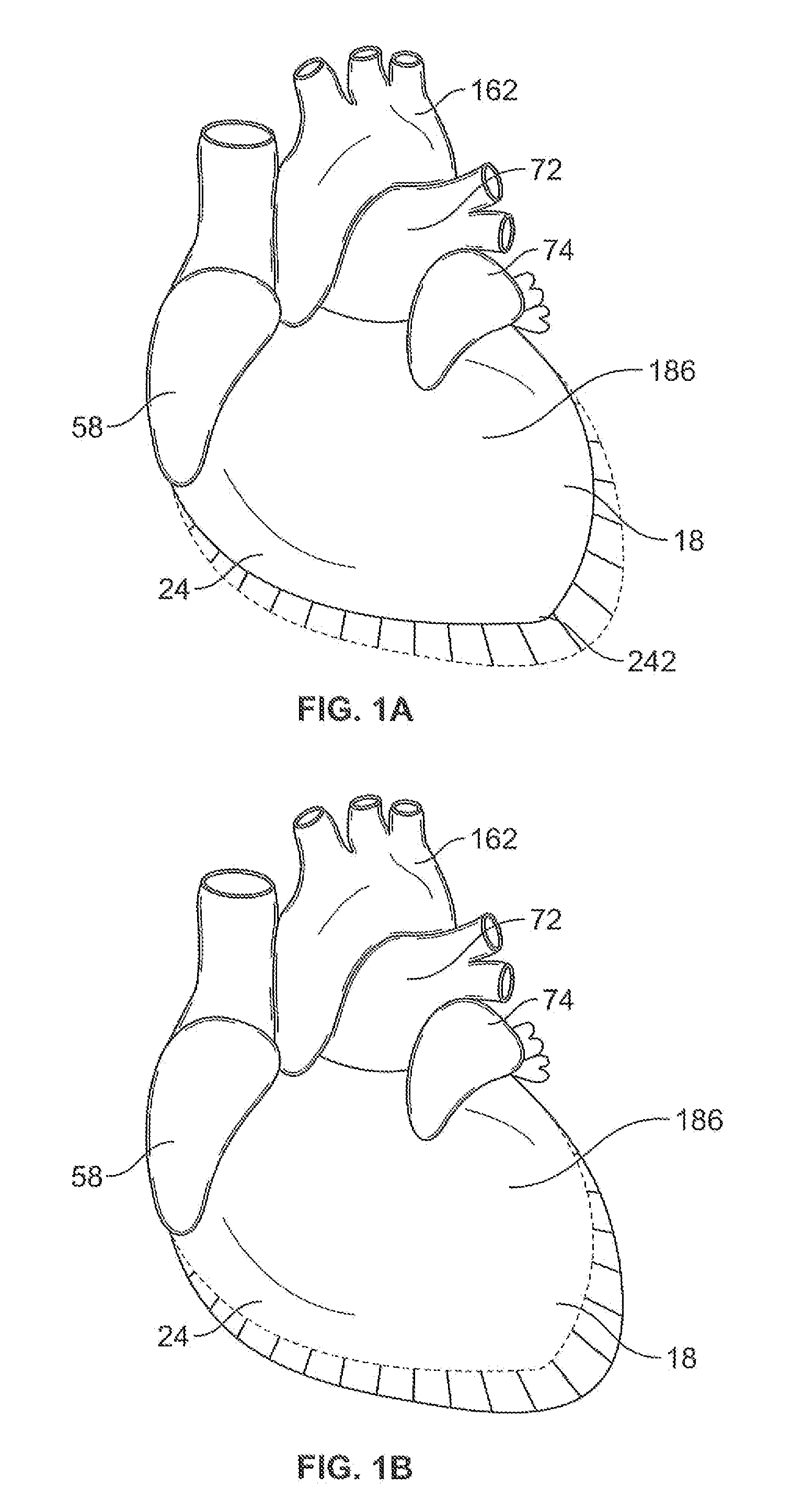

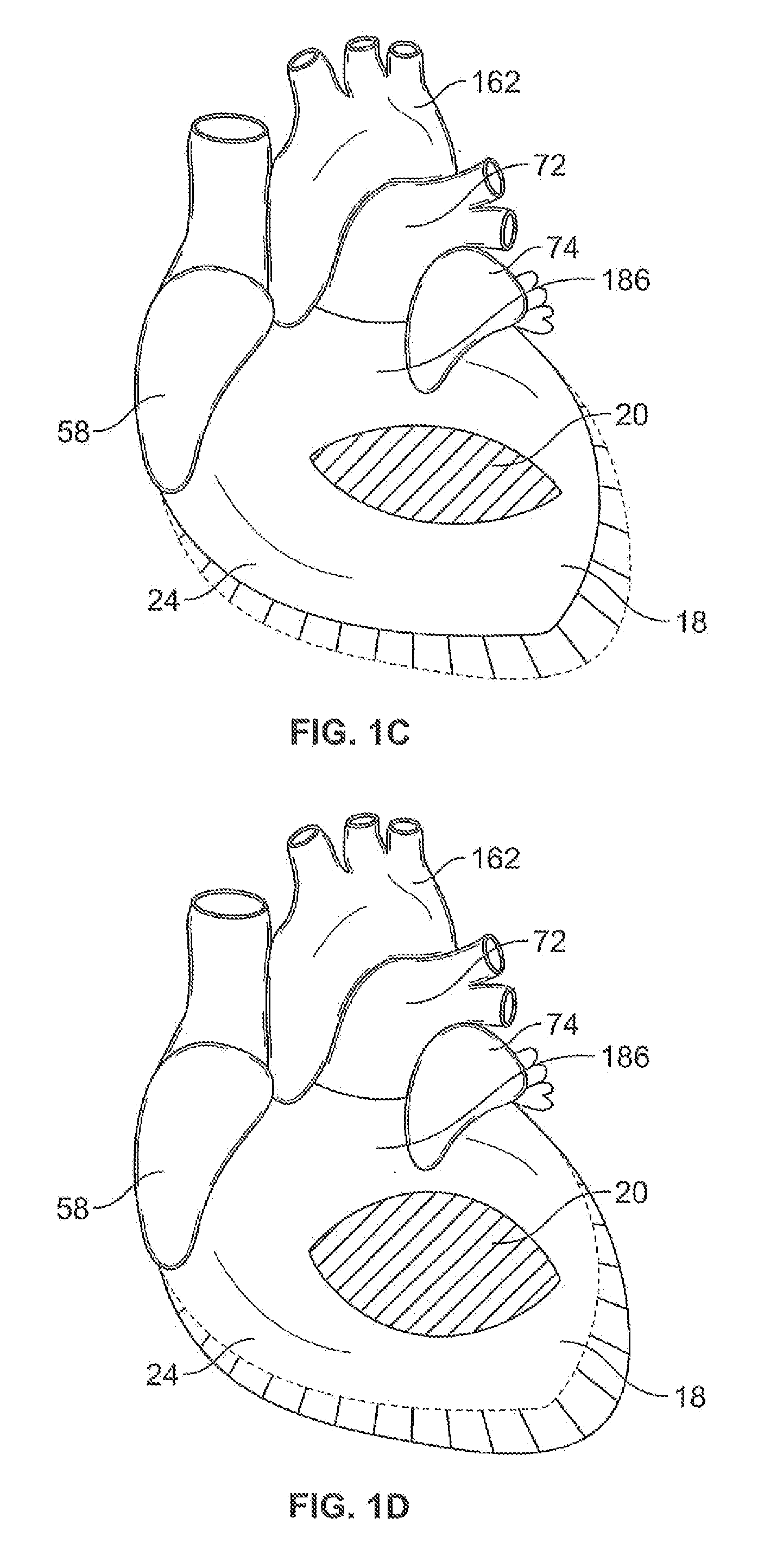

Systems for heart treatment

InactiveUS20080081942A1Facilitate positive or reverse remodelingImprove efficiencyHeart valvesInternal electrodesMyofibrilFunctional disturbance

Owner:BAY INNOVATION GROUP

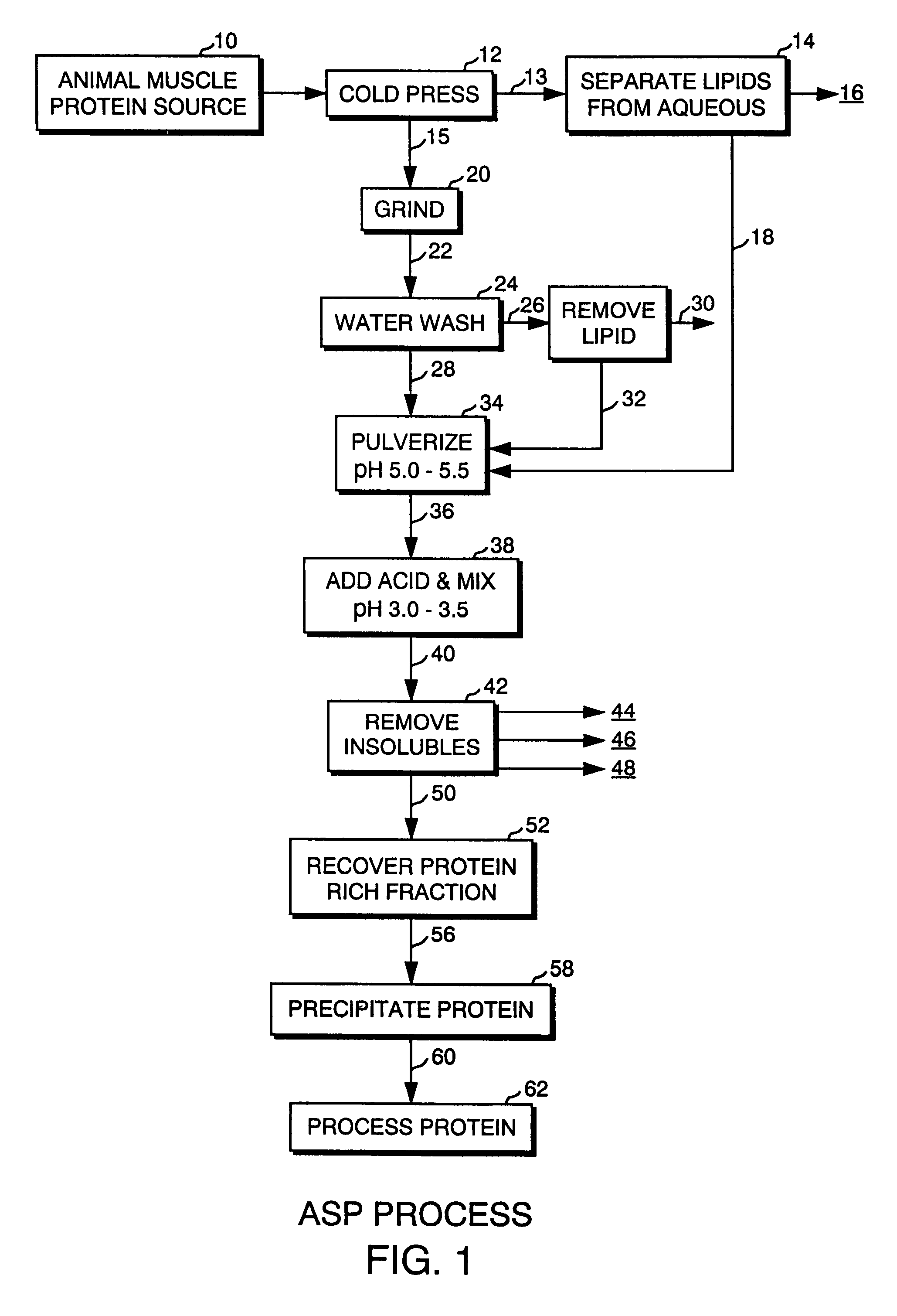

Protein composition obtained from a muscle source

InactiveUS7473764B2Simple treatmentSufficient low viscosityProtein composition from fishDepsipeptidesSAA proteinMuscle tissue

A process is provided for isolating a protein component of animal muscle tissue by mixing a particulate form of the tissue with an acidic aqueous liquid having a pH below about 3.5 to produce a protein rich solution substantially free of myofibrils and sarcomere tissue structure. The protein rich aqueous solution can be treated to effect protein precipitation, followed by protein recovery.

Owner:ADVANCED PROTEIN TECH INC

Quality modifier for pre-treatment of aquatic product before drying and its prepn and application

InactiveCN101066066APrevent oxidationProblems preventing muscle fiber contractionMeat/fish preservation using chemicalsMyofibrilAdditive ingredient

The present invention provides one kind of quality modifier for dried aquatic product and its composition and usage. The quality modifier consists of white spirit, antioxidant, phosphate, gluconic acid-delta-lactone, ascorbic acid and mycose, and may also have enzyme, such as glucose oxidase, added to further raise antioxidant effect. The quality modifier may be used to prevent oxidation, myofibril contraction and microbe propagation during drying aquatic product, eliminate fish smell and raise rehydration property. When the quality modifier is used, aquatic product and the quality modifier in the weight ratio of 2-15 to 1 are set in a basin, and the aquatic product is soaked for 30-60 min before being dried at 50 deg.c to obtain dried aquatic product.

Owner:ZHEJIANG UNIV OF TECH

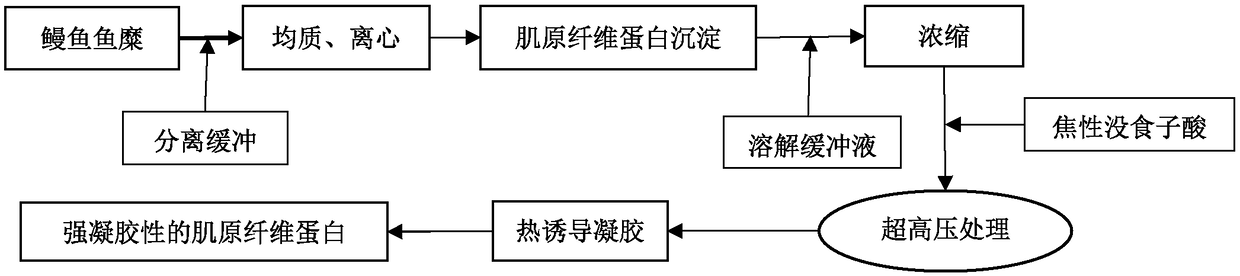

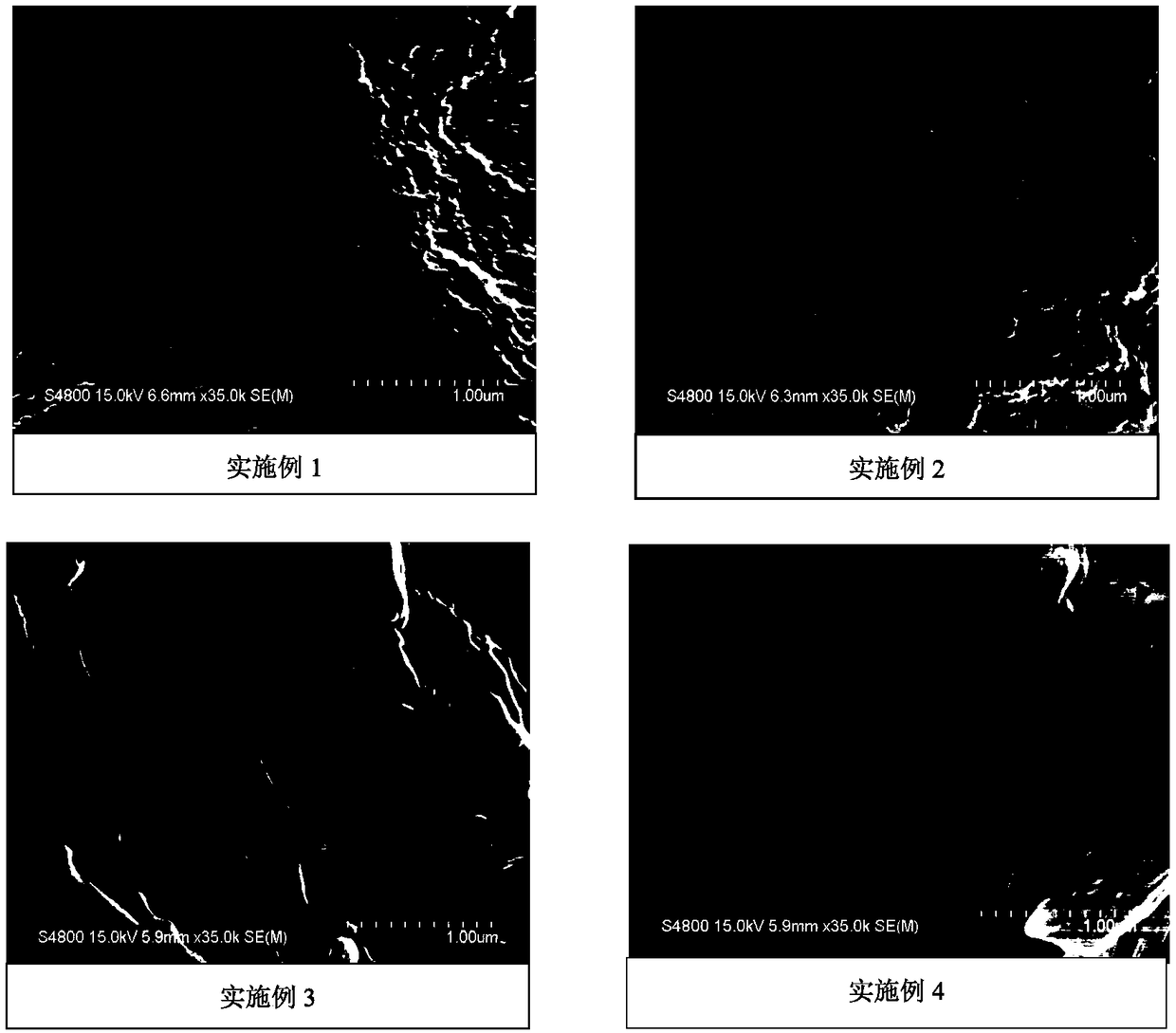

Preparation method of strong gelatin fibrillin

InactiveCN108617848AChange internal structureAdjust qualityProtein composition from fishProteins working-up by texturisingProtein solutionMyofibril

The invention discloses a preparation method of strong gelatin fibrillin. The method comprises the following steps of (1) preparing fibrillin; (2) dissolving the fibrillin; performing concentration toobtain concentration liquid; (3) adding the concentration liquid into pyrogallic acid; performing uniform mixing; thus obtaining a mixed protein solution after the placement at the normal temperature; (4) performing vacuum packaging on the mixed protein solution; performing treatment at ultrahigh pressure; (5) performing program temperature rise on materials obtained in the step (4); performing sharp cooling to obtain the strong gelatin fibrillin. The system oxidization degree of the fibrillin is weakened by using the oxidization resistance of pyrogallic acid; ultrahigh pressure treatment iscombined, so that the inside structure of the fibrillin is changed; the uniform three-dimensional network gel structure is formed. The method is applicable to the field of food processing auxiliary materials; the quality of fish meat products is regulated.

Owner:XIAMEN UNIV

Method for extracting fibrillin from chicken

InactiveCN101161671AHigh purityHigh yieldPeptide preparation methodsAnimals/human peptidesMyofibrilForeign protein

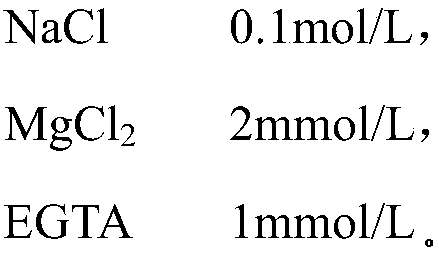

The present invention discloses a method to extract myofibril protein from chicken, aiming to provide a method to extract myofibril protein with high purity, simplicity and low cost. The procedures are as follows: chicken under room temperature is cut into pieces, added with a low-ionic-strength extract with the pH of 6.0-7.0 to dissolve the dissolvable under the condition of low ionic acid strength, the solution undergoes even centrifuge to obtain a deposit containing myofibril protein, which is added with a high-ionic-strength extract with the pH of 6.0-7.0, the solution undergoes even centrifuge, and the separated myofibril protein deposit undergoes cycles of extraction with the high-ionic-strength extract, each of which is followed by centrifuges to eliminate the foreign proteins and the other impurities from the chicken, the deposit obtained from centrifuged suspension is the myofibril protein, which is added with the high-ionic-strength extract to prepare a solution, which is dialyzed under room temperature, frozen and dried to obtain the intended product of myofibril protein.

Owner:TIANJIN UNIV OF COMMERCE

Process for retaining moisture in cooked food with a peptide

InactiveUS7160567B2Protein composition from fishMeat/fish preservation using chemicalsMuscle tissueProtein solution

A peptide composition derived from a protein composition when added to uncooked food effects moisture retention during cooking of the food. The peptide composition is derived from a dry protein mixture or an aqueous acidic protein solution which, in turn, is derived from animal muscle tissue. The peptide composition is added to uncooked poultry, meat or fish prior to cooking. The dry protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres.

Owner:PROTEUS INDUSTRIES INC

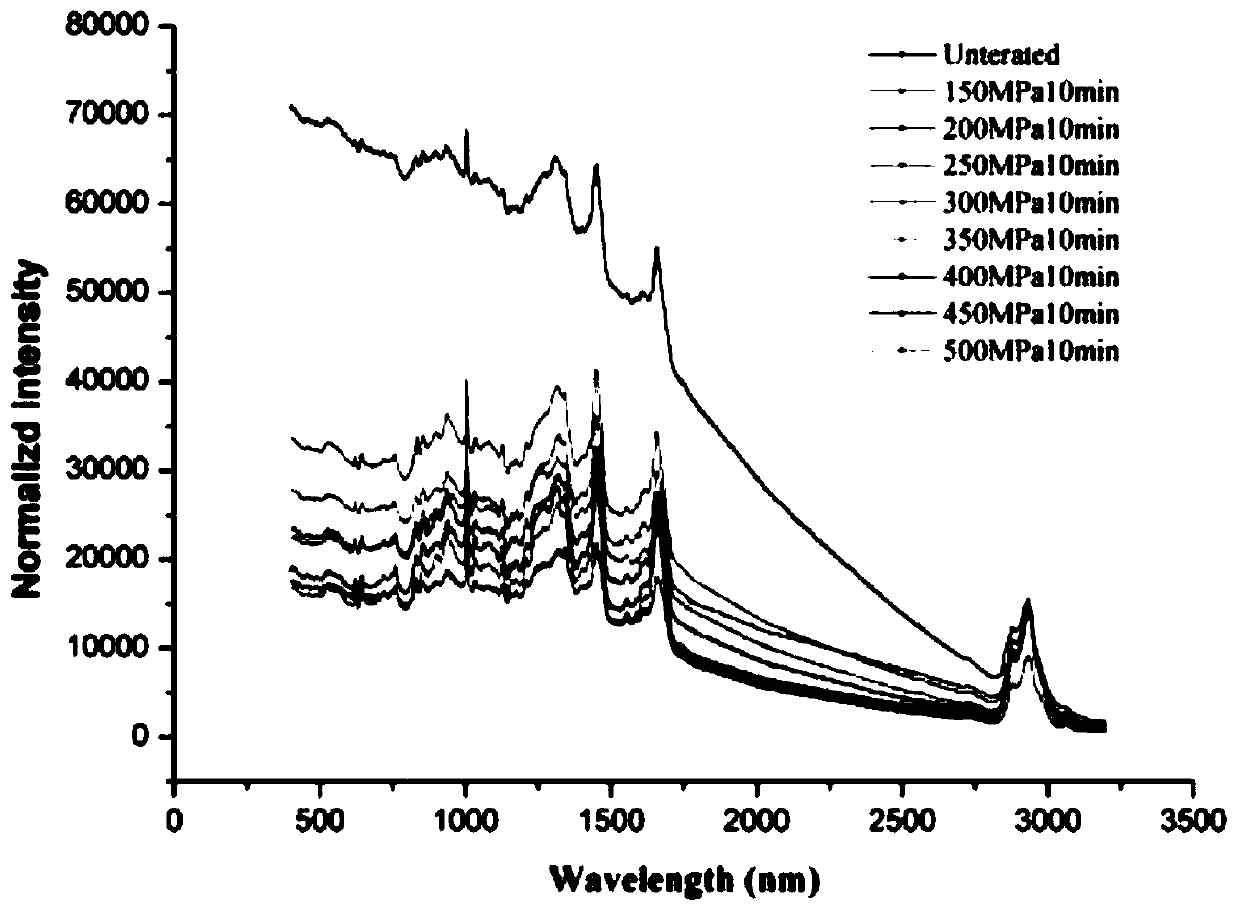

Fast discrimination method for iced fish and unfrozen fish

The present invention discloses fast identifying method of freshly frozen fish and defrozen fish in food identifying range. Based on the principle that the freezing of fish will cause the concentration change of intracellular fluid and extracellular fluid of muscle fibril, the transfer of intracellular and extracellular water, the change in cell shape and change in conducting characteristic of muscle medium, the conducting characteristic of fish is detected with an impedance measuring instrument at the conditions of 1000-16000 Hz frequency and voltage 3-9 V, the defrozen fish has Q value lower than 10 % and the freshly frozen fish has Q value higher than 20 %. The present invention makes it possible to detect freshly frozen fish and defrozen fish within 2 min without damage to fish, and the present invention has identification accuracy over 95 % and low cost.

Owner:CHINA AGRI UNIV

Method for regulating adsorption capacity of sea-fish myofibrillar protein to flavor compound

ActiveCN110100942AGood physical propertiesImprove adhesionProtein composition from fishAnimal proteins working-upWater bathsMyofibril

The invention relates to a method for regulating the adsorption capacity of sea-fish myofibrillar protein to a flavor compound. The method mainly comprises the steps that the myofibrillar protein anda Tris-HCl buffer solution react under magnetic stirring to obtain a myofibrillar protein solution, sodium chloride and transglutaminase are added into the protein solution and fully stirred to be uniform, after a reaction is carried out for 1.5 hours at the temperature of 40 DEG C, cooking is conducted for 30 minutes in a water bath at the temperature of 75 DEG C, cooling and standing are conducted for 24 hours at the temperature of 4 DEG C, and then myofibrillar protein gel is obtained; through the cooperation of ultrahigh pressure treatment, the structure of the myofibrillar protein is further improved, and the adsorbing effect of the myofibrillar protein on the flavor compound is changed. By using the method, the adsorption capacity of the myofibrillar protein to the flavor compound can be effectively improved, the method plays an important role in improving the flavor of a surimi product, and the method is high in commercial value.

Owner:ZHEJIANG WANLI UNIV

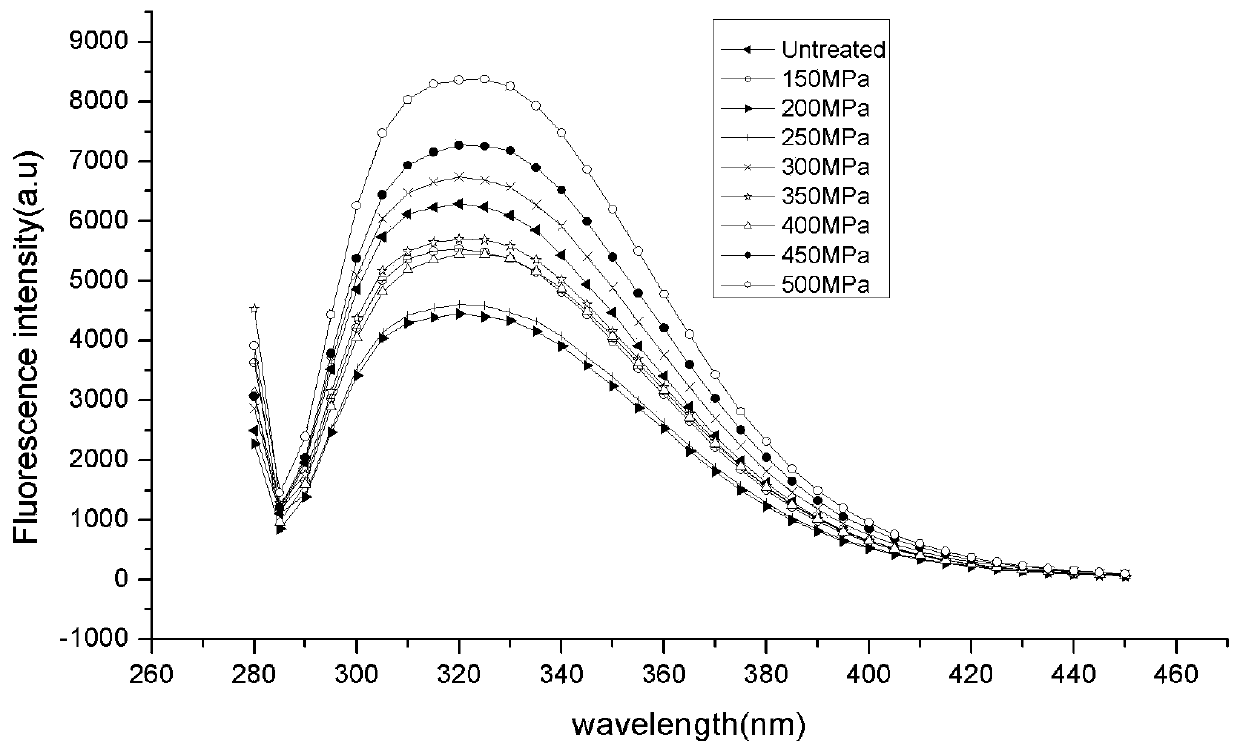

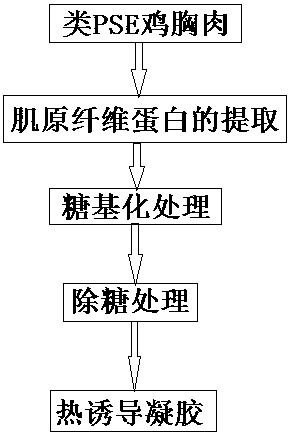

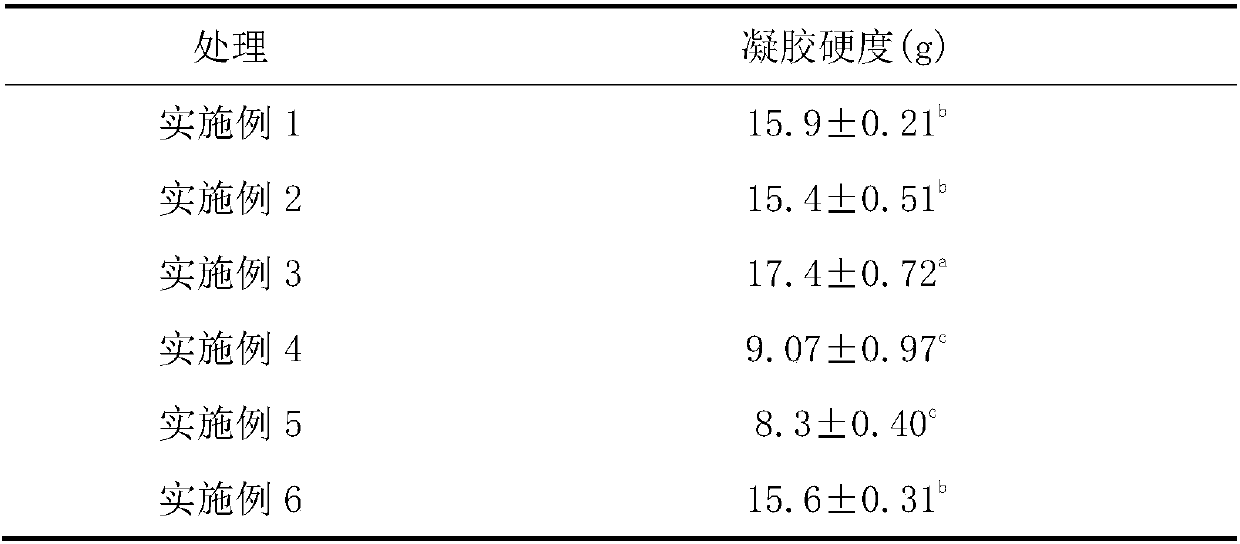

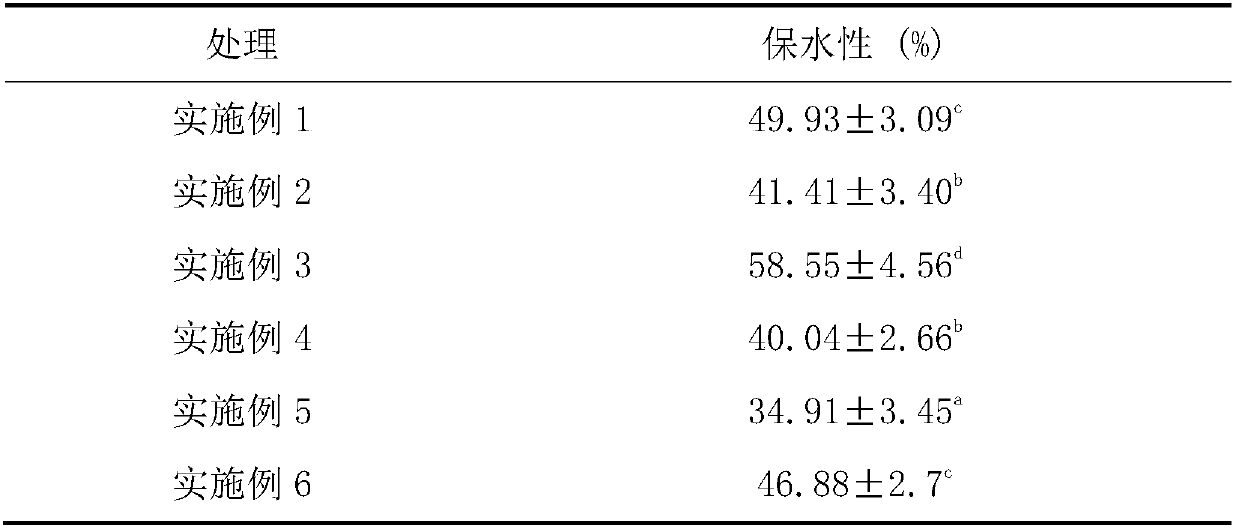

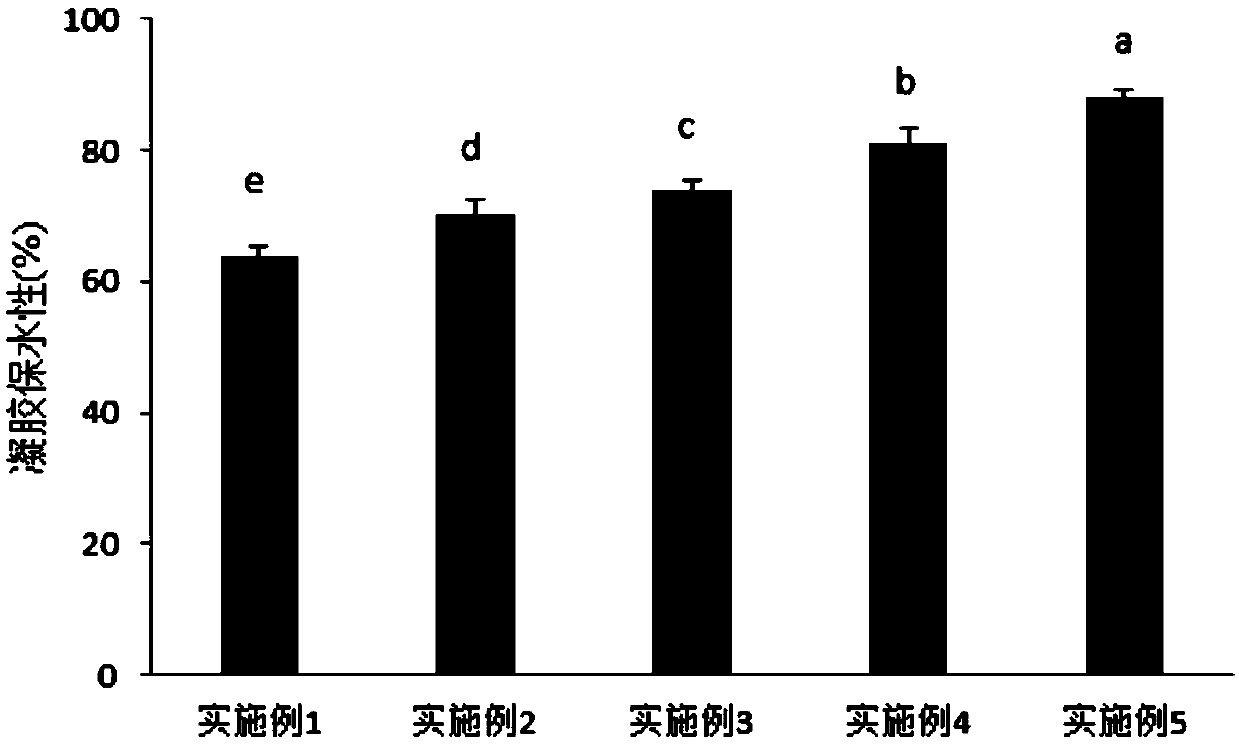

Glycosylation method for improving PSE chicken breast myofibrillar protein gel quality

ActiveCN107821989AChange structural propertiesImprove water retentionClimate change adaptationFood scienceMyofibrilEconomic benefits

The invention discloses a glycosylation method for improving PSE chicken breast myofibrillar protein gel quality. The method includes the steps: (1) raw material treatment; (2) myofibrillar protein extraction; (3) glycosylation treatment; (4) sugar removing treatment; (5) gel preparation to obtain protein gel. PSE chicken breast is treated by the non-enzymatic wet glycosylation method, treatment conditions are mild, uniform and harmless, PSE chicken breast myofibrillar proteins can be modified in a covalent binding mode according to a glycosylation technology, the structures and processing characteristics of the proteins are changed, and the gel quality and economic benefits are improved by improving the water-retaining property and the gel hardness of the chicken breast myofibrillar protein gel.

Owner:NANJING AGRICULTURAL UNIVERSITY

Method for producing artificial crab meat with improved boiling property

InactiveCN101473974AGood cooking resistanceExpand the scope of consumptionFood preparationFiberSocial benefits

The invention relates to a production method improving the boiling fastness of artificial crab meat. Frozen minced fillet is used as a main raw material, and auxiliary materials such as edible salt and the like are added. In the method, the nature of salt soluble protein-myofibrillar protein in fish muscle is adjusted, so that under the action of the edible salt, thick filaments and thin filaments of myofibril of the salt soluble protein are dissolved properly; myoglobulin and actin absorb proper water and are combined to form colloidal sol of actomyosin; the colloidal sol loses the plasticity by the change of the temperature to form gel with elasticity and tenacity; and the gel becomes a heat-resistant and stable gel system and meets the requirement of improving the boiling fastness. Compared with the boiling fastness of the artificial crab meat produced by the traditional method, the boiling fastness of the artificial crab meat of the invention increases more than 110 percent through the improvements of the prescription and the technology. The artificial crab meat is an instant foodstuff which has the fresh taste of crab meat, red crab surface, white meat, good elasticity, abundant nutrition and diversified edible methods. The artificial crab meat of the invention is more popular in market with better economic and social benefits.

Owner:GUANGDONG OCEAN UNIVERSITY

Feed for improving mutton quality and application thereof

InactiveCN102934748APromote rapid growthImprove folding strengthFood processingAnimal feeding stuffBiotechnologyMyofibril

The invention discloses a feed for improving mutton quality and an application thereof, relates to a feed for improving mutton quality and belongs to the technical field of livestock feeds. The feed is characterized by comprising, by weight, 60% to 80% of broad bean or broad bean halves, 2% to 6% of caragana microphylla, 6% to 13% of cottonseed meal, 6% to 12% of rapeseed meal, 0.5% to 2% of maize straw, 2.0% to 3.0% of soya-bean oil, 1.5% to 2.0% of monocalcium phosphate, 0.15% to 0.25% of choline chloride and 1% to 2% of preliminary powders. The feed has the advantages that the growth of sheep can be accelerated, the growth speed is increased, the feed coefficient during breeding of sheep can be remarkably decreased, the production cost is lowered, the feed is suitable for industrialized production, the muscle moisture content can be decreased, the muscle water loss rate can be remarkably lowered, the muscle myofibril folding-resistant force and muscle fiber diameter are improved, the contents of amino acid, aspartic acid, glutamic acid and glycine which have delicate flavor in the muscle can be remarkably increased, and the meat is fresh and delicious.

Owner:胡春艳

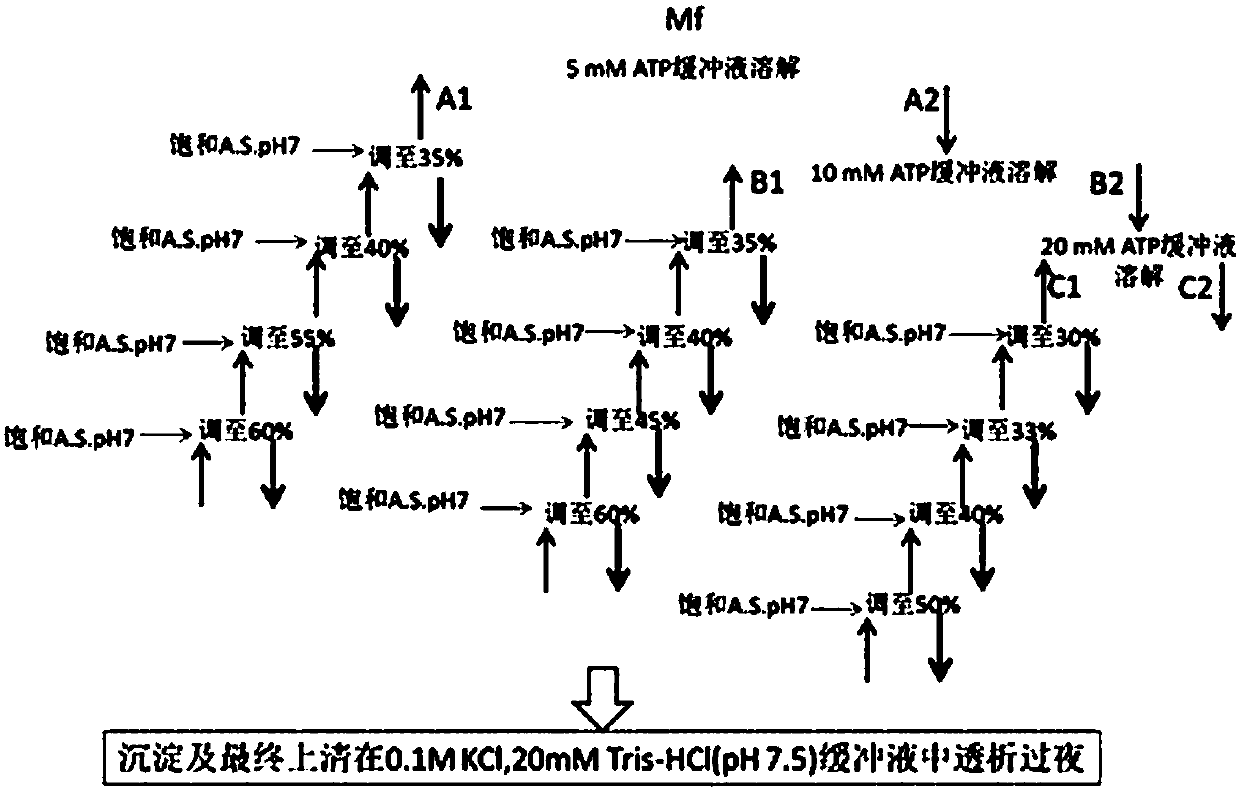

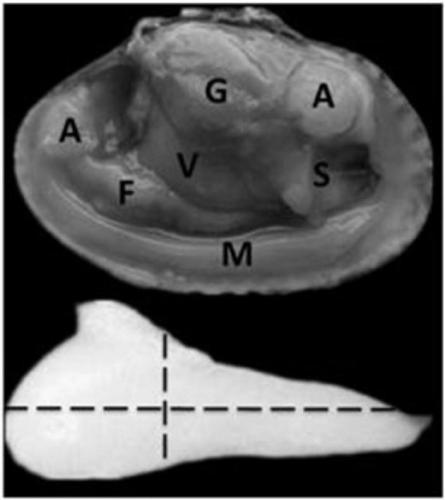

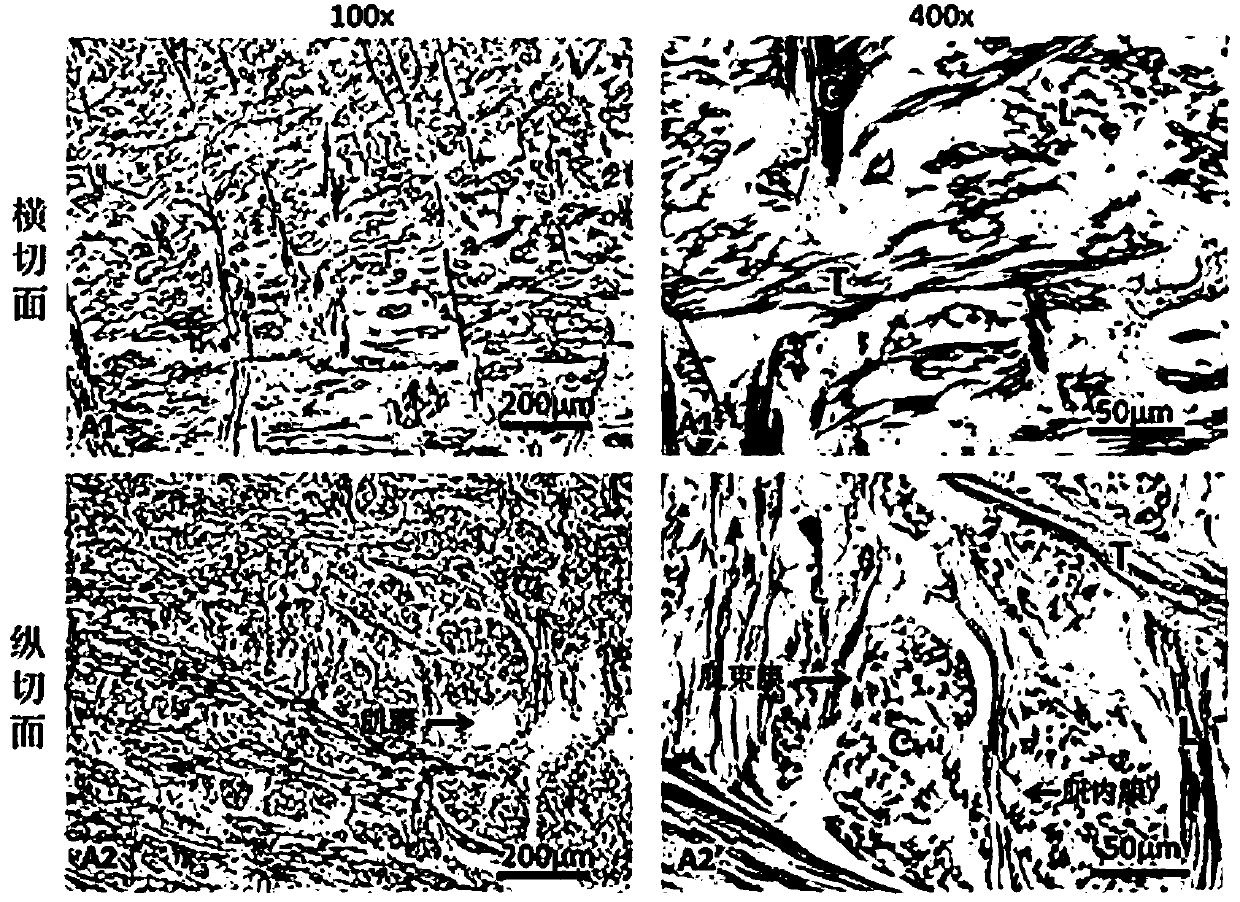

Muscle protein purifying method

InactiveCN109942692ALow denaturationEfficient purificationPeptide preparation methodsAnimals/human peptidesSmooth muscleMyofibril

A muscle protein purifying method adjusts the concentrations of KCl, ATP and ammonium sulfate (A.S.) through the influences of different solution mediums on separation and purification and analyzes the dissociation and precipitation law of all fibrillin components and determines the separation and purification conditions of actin, myoballs and paramyosin with the ATPase activity as the protein denaturation indicating parameter. The method has the advantages that compared with a traditional protein purifying method, the novel method is low in purified protein denaturation degree and simple in purifying process, the actin, myoballs and paramyosin in smooth muscles of aquatic invertebrates are efficiently obtained through purification, and the purifying cost is saved to the maximum extent.

Owner:SHANGHAI OCEAN UNIV

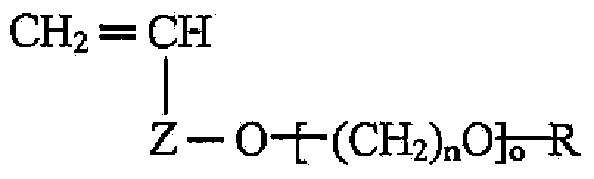

Myofibrillar protein/xanthan gum composite emulsion rich in functional factors

InactiveCN108634172AImprove stabilityUniform particle size distributionFood shapingMyofibrilEmulsion

The invention belongs to the technical field of food processing, and particularly relates to a myofibrillar protein / xanthan gum composite emulsion rich in functional factors and a preparation method of the myofibrillar protein / xanthan gum composite emulsion. The preparation method comprises the following steps: separately dissolving myofibrillar protein and xanthan gum in deionized water, performing stirring for 1-2 h, and regulating the pH of the solution to 3-7 so as to obtain a protein stock solution and a xanthan gum stock solution separately; mixing the protein stock solution with the xanthan gum stock solution in proportion, and performing stirring for 2-4 h so as to obtain a mixed solution; and dissolving liposoluble functional factors in fat, adding the fat in which the functionalfactors dissolve to the myofibrillar protein / xanthan gum mixed solution, performing stirring for 1-2 h, performing shearing and homogenizing for 2 min, and then performing high-pressure homogenizing so as to obtain the myofibrillar protein / xanthan gum composite emulsion rich in functional factors. The obtained myofibrillar protein / xanthan gum composite emulsion is good in stability and uniform insize distribution. As one ingredient, the myofibrillar protein / xanthan gum composite emulsion is applied to trade of functional foods and health-care products.

Owner:FUJIAN AGRI & FORESTRY UNIV

Process for reducing oil and fat content in cooked potato

InactiveUS20060210680A1Minimize absorptionLess oilFood ingredient functionsFood preparationProtein solutionMyofibril

A process for cooking a food in oil and / or fat is provided. An acidic dry protein mixture, an alkaline dry protein mixture, an aqueous alkaline protein mixture or an aqueous acidic protein is added to a food prior to cooking. The food containing the protein is cooked in a fat and / or oil. Accumulated fat and / or oil on the surfaces of the cooked food then is removed. The acidic dry protein mixture, alkaline dry protein mixture, aqueous alkaline protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres. The amount of oil and / or fat absorbed by the food during cooking is substantially reduced.

Owner:PROTEUS INDUSTRIES INC

Fish quality maintaining and conditioning processing method

InactiveCN109567067AHigh surface glossGood muscle textureFood freezingFood mechanical treatmentMyofibrilFlavor

The invention discloses a fish quality maintaining and conditioning processing method. The fish quality maintaining and conditioning processing method comprises the steps of live fish pretreatment, fish body pretreatment, pulse-type breathing tumbling and coating film-fixing of the surface of fish, fish packaging, and freezing and refrigeration, wherein pretreatment comprises color development ofmyohemoglobin and stress contraction of myofibrils. According to the fish quality maintaining and conditioning processing method, the color and luster of the fish and the toughness of the myofibrils can be improved well, and the way is paid for a subsequent technology; and in pulse-type breathing tumbling and coating film-fixing of the surface of the fish, vacuum tumbling, a carrageenan and potassium chloride gelation reaction and a trehalose and polyphosphate anti-protein freezing denaturation treatment technology are adopted for pickling. Through the two steps, the purposes of improving theflavor and prolonging the shelf period by freezing the fish can be achieved, and the demands of consumers are more met; and the fish quality maintaining and conditioning processing method is easy tooperate, the fish product quality is high, and the edible flavor is excellent.

Owner:ZHEJIANG UNIV OF TECH

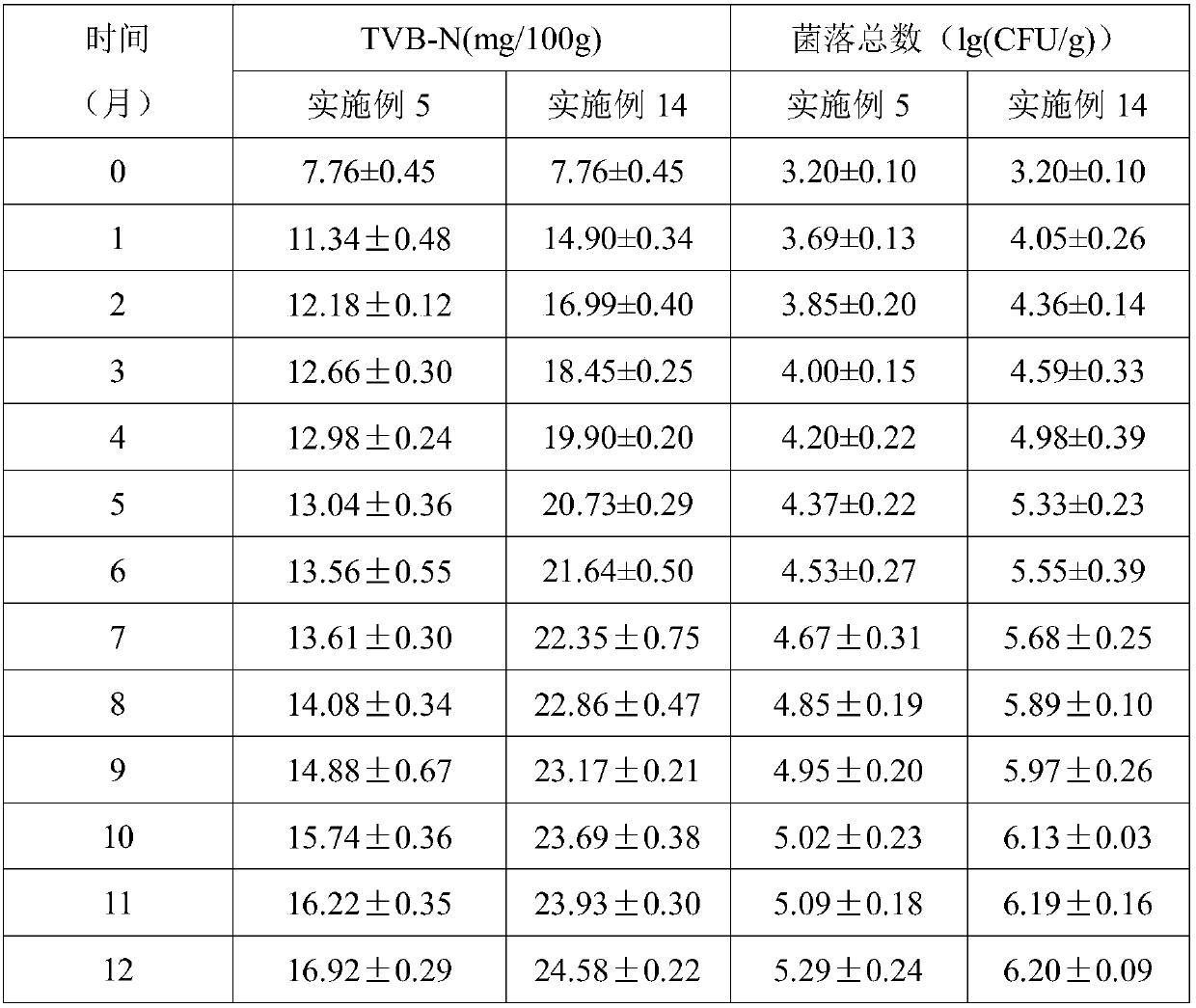

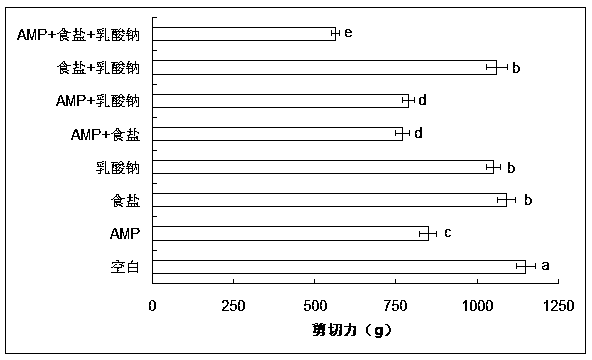

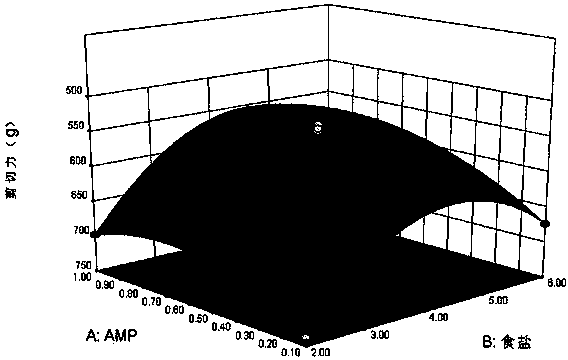

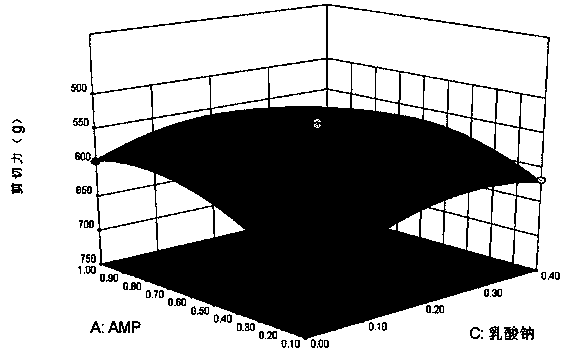

Meat tenderizing method for improving pyrolysis of myofibril

ActiveCN104286912AImprove qualityImprove freshnessFood ingredient functionsFood preparationNutritive valuesSodium lactate

The invention discloses a meat tenderizing method for improving the pyrolysis of myofibril and belongs to the field of food processing technologies. The meat tenderizing method is characterized in that fresh or unfrozen raw meat is cleaned and put into clear water with the mass of 0.8-1.2 times that of the raw meat, and a meat tenderized agent with the mass 4-8% of that of the raw meat is added, stirred uniformly, soaked and drained off to obtain tenderizing raw meat; adenine nucleotide, salt and sodium lactate constitute the meat tenderized agent. According to the invention, the salt and sodium lactate are used for restraining adenine nucleotide deaminizing enzyme; compared with the conventional salt pickling method, more than 40% of a shearing force can be lowered, the cooking loss is reduced, the color and luster are improved, the freshness and nutritive value of meat can be improved, and the quality of the meat can be improved, so that the meat tenderizing method has a wide application prospect in the meat processing field.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Regenerated cellulose-myofibrillar protein gel and preparation method thereof

ActiveCN109673810AImprove qualityImprove water retentionAnimal proteins working-upProtein composition from meatMyofibrilWater baths

The invention discloses regenerated cellulose-myofibrillar protein gel. The regenerated cellulose-myofibrillar protein gel is prepared by the following method: removing ham butt connective tissues andfat, cutting into small blocks and mincing; mixing minced ham butt and a standard salt solution; after homogenizing, centrifuging; repeating homogenization and centrifuging operation; mixing sedimentobtained by centrifuging and a 0.1 mol / L NaCl solution; after homogenizing, centrifuging to obtain myofibrillar protein; preparing the myofibrillar protein into a myofibrillar protein dissolving solution through a phosphate buffered solution; adding regenerated cellulose and uniformly mixing; homogenizing under an ice bath condition to obtain a uniformly-mixed sample; heating in a water bath at 75 to 80 DEG C to prepare the regenerated cellulose-myofibrillar protein gel. According to the regenerated cellulose-myofibrillar protein gel, the quality of myofibrillar protein gel of pork is improved by applying the regenerated cellulose, and the water-retaining property and the texture property of the protein gel of the pork are effectively improved; the regenerated cellulose-myofibrillar protein gel also has abundant protein and cellulose and the nutrients of the myofibrillar protein gel are enriched.

Owner:NANJING AGRICULTURAL UNIVERSITY

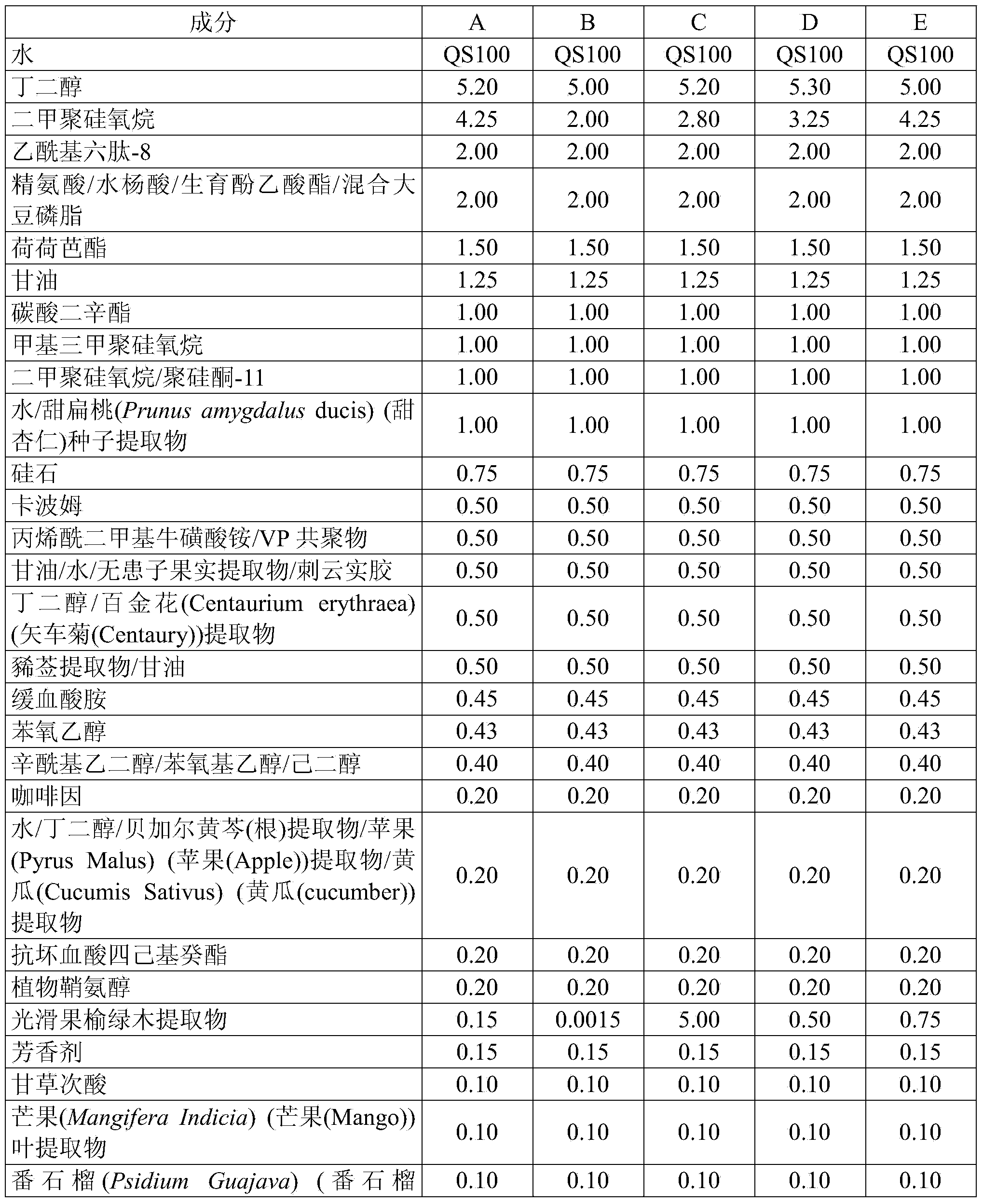

Use of anogeissus extract for fibrillin production in skin

Use of at least one extract from the Anogeissus genus for treating human skin by producing fibrillin and thereby increasing skin elasticity.

Owner:ELC MANAGEMENT LLC

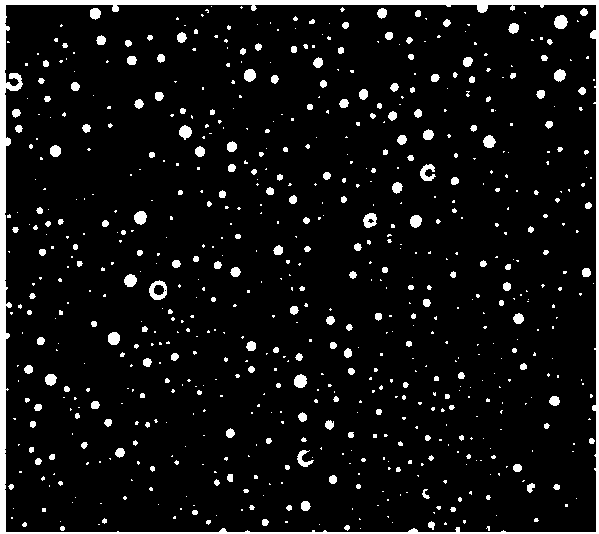

Method for determining myofibrillar fragmentation index (MFI) by microscopy

InactiveCN102841221AEliminate the measurement stepReduce accidental errorScanning probe microscopyFiberMyofibril

The invention discloses a method for determining a myofibrillar fragmentation index (MFI) by microscopy. A meat sample without visual fat or connective tissue is put into a homogenizer, a separating medium with the temperature of 2 DEG C is added into the homogenizer for homogenating at a high speed and a low temperature, then supernatant liquor is slowly poured out, precipitate is retained, and the separating medium with the temperature of 2 DEG C is added into the precipitate again in the precipitation process to make a suspension with a stirring rod; and the steps are repeated for the prepared suspension, the supernatant liquor is poured out, the precipitate is still retained, the separating medium with the temperature of 2 DEG C is added into the precipitate and is mixed with the precipitate uniformly on a turbine mixer, the connective tissue is filtered out with a screen of 200 meshes, the separating medium with the temperature of 2 DEG C is added again to help myofibril to pass through sieve holes, the volume of the suspension is adjusted to be 10mL, the myofibril and the suspension are uniformly blended, 1 muL of myofibril suspension is sucked and dropped on a mica plate, and is naturally withered, an atomic power microscopic examination is directly carried out, and myofibrillar fragments are counted. The influence of the size of the myofibrillar fragment on a light absorption value in an absorption photometry of the existing method is avoided, and accidental errors are reduced.

Owner:西安中基药用植物工程有限公司

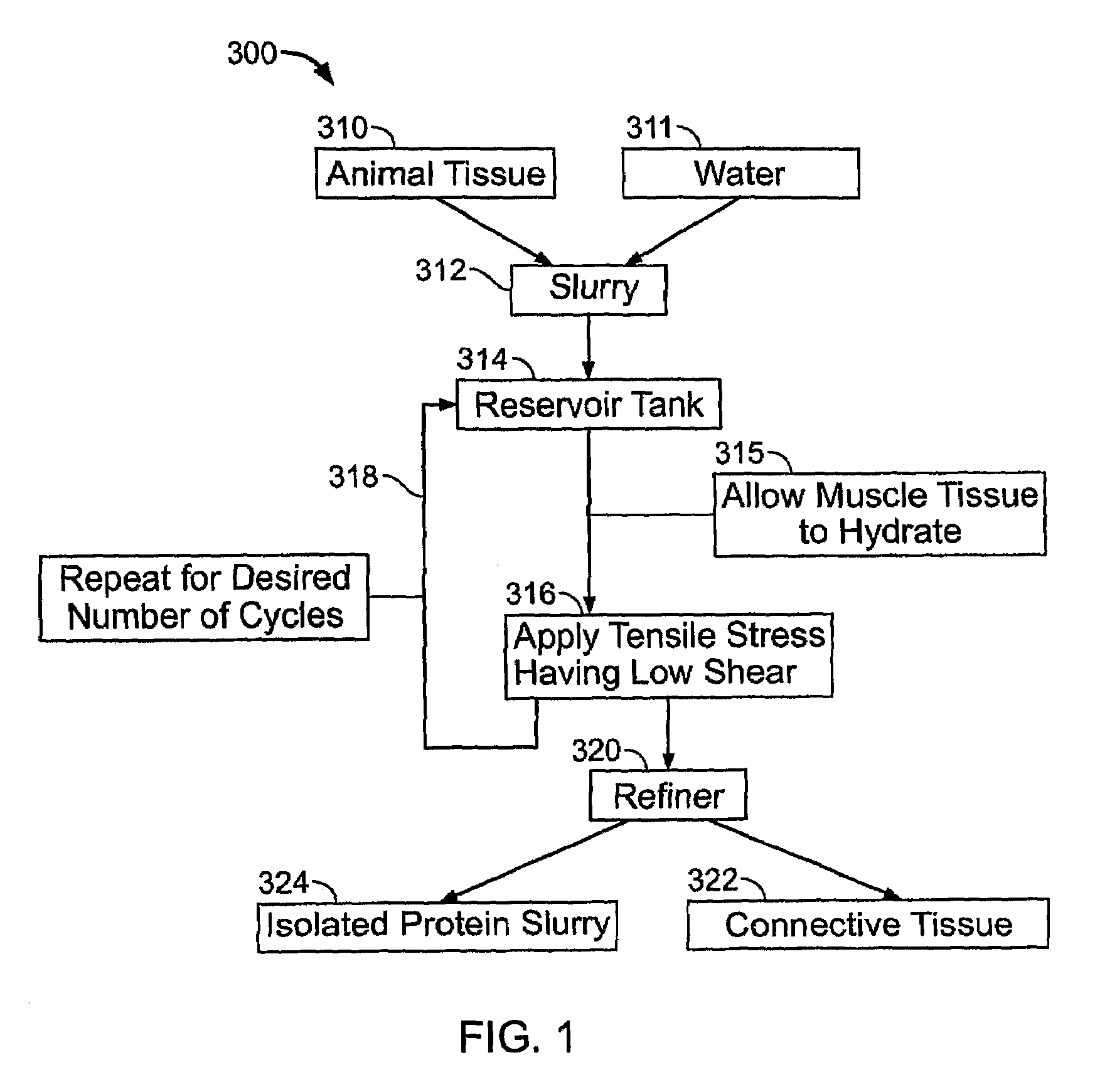

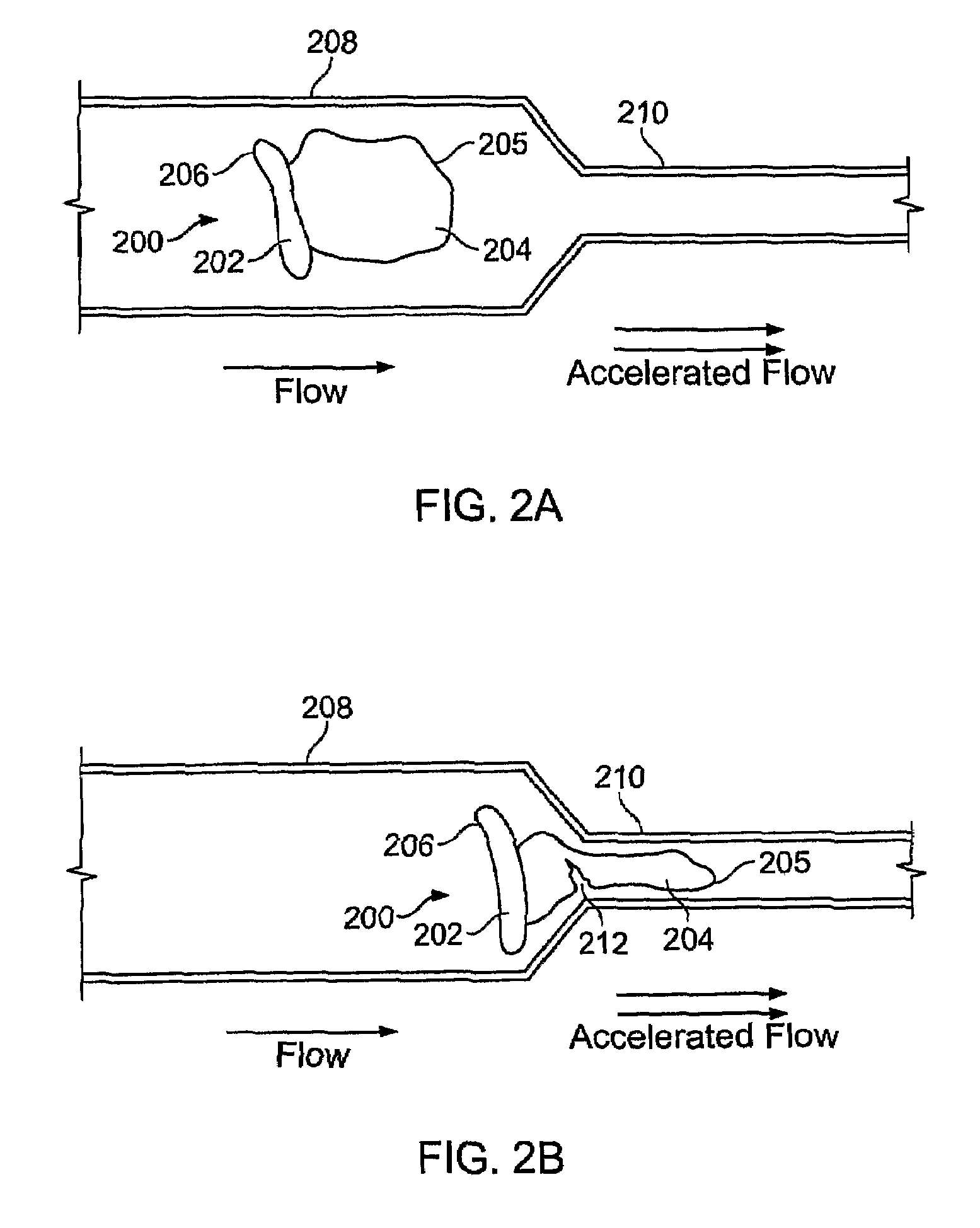

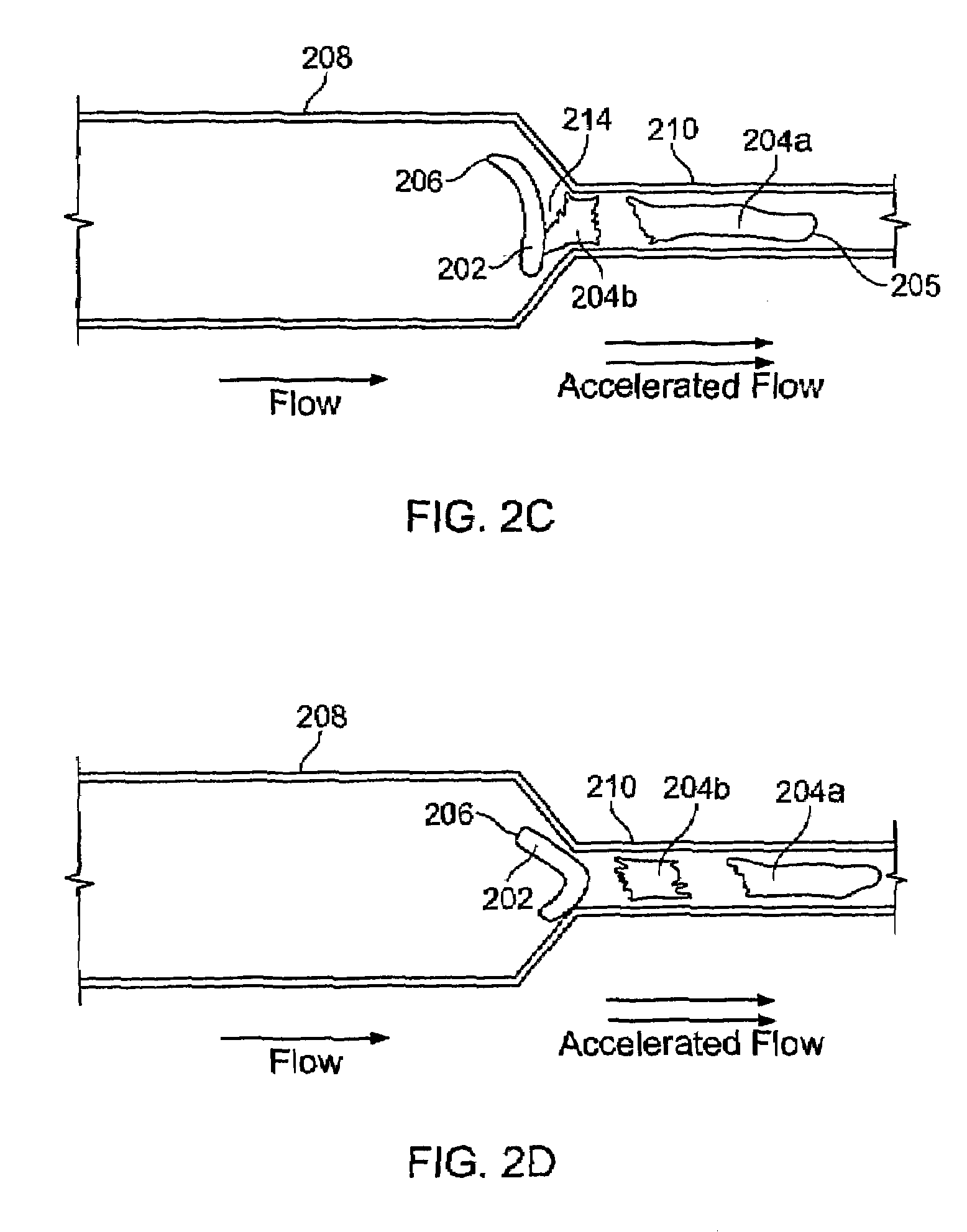

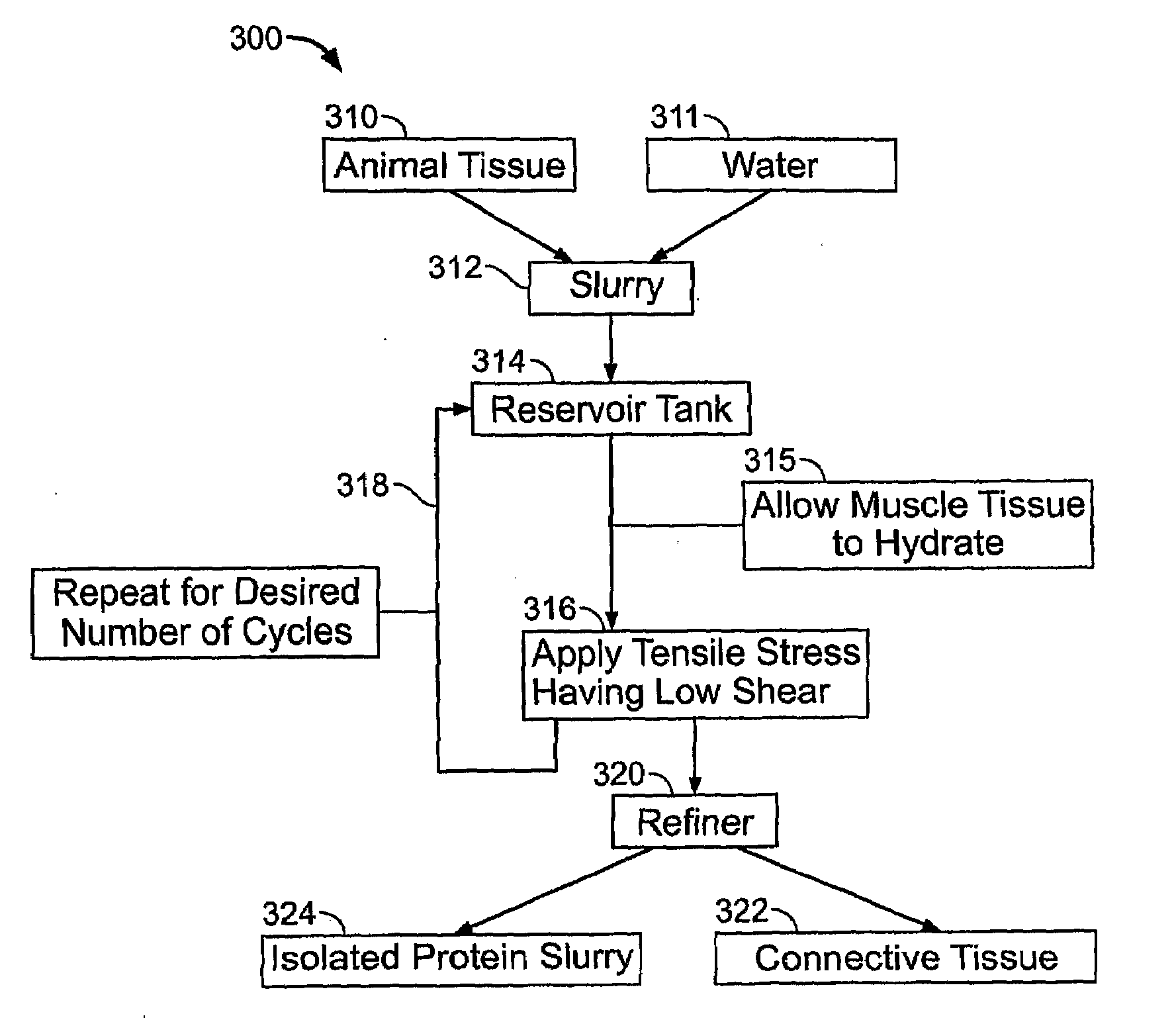

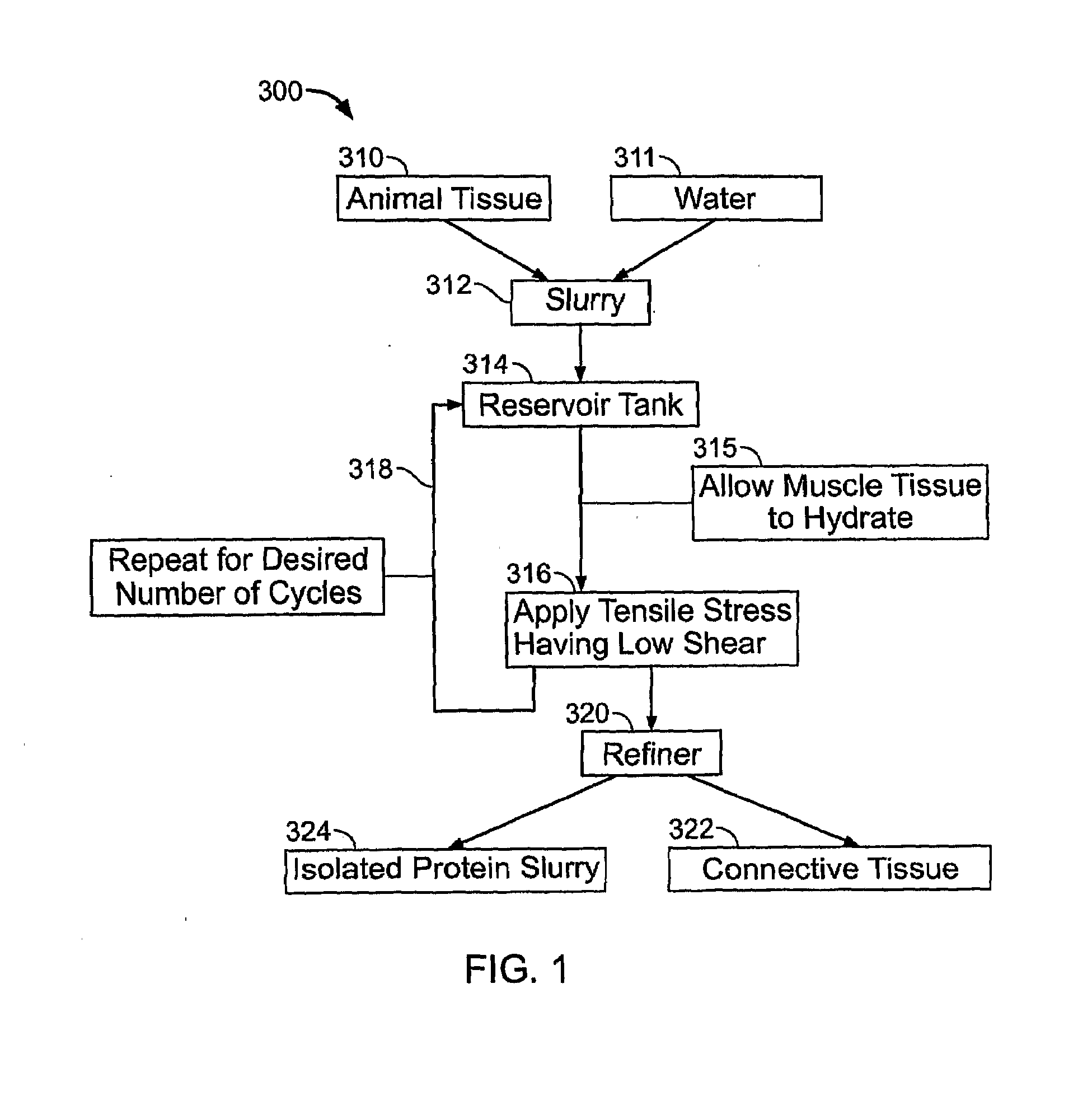

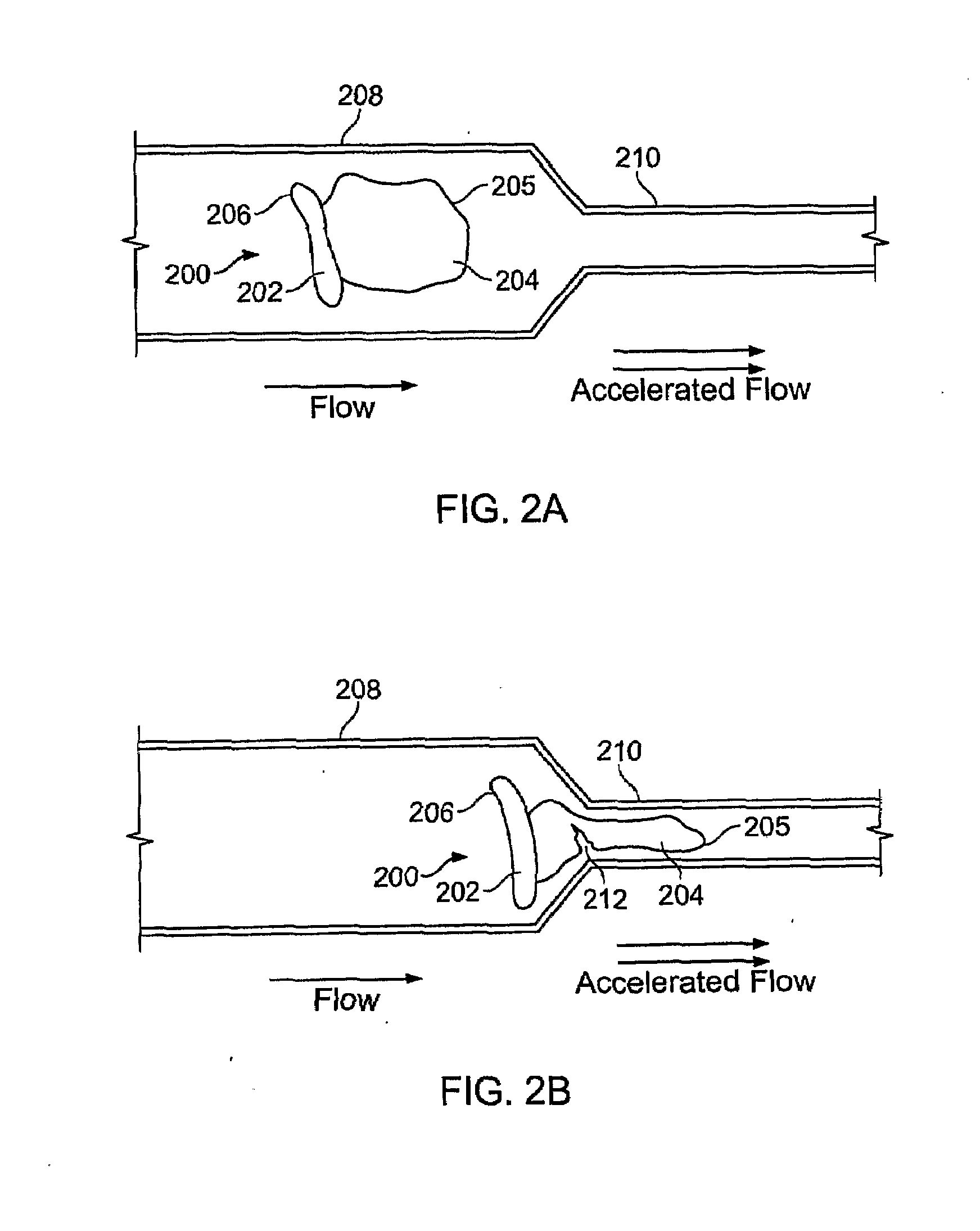

Systems and methods for separating proteins from connective tissue

InactiveUS8021709B2Avoid tearingEasy to separateImmunoglobulinsLiquid solutions solvent extractionMuscle tissueMyofibril

Methods and systems for separating muscle tissue from connective tissue are provided, in which animal tissue containing both muscle tissue and connective tissue is subjected to stress, and muscle proteins are separated from the connective tissue. Slurries of separated myofibrillar protein are also provided.

Owner:M P F

Systems and Methods For Separating Proteins From Connective Tissue

ActiveUS20080214792A1High protein yieldUndesirable low levelImmunoglobulinsLiquid solutions solvent extractionMyofibrilMuscle tissue

Methods and systems for separating muscle tissue from connective tissue are provided, in which animal tissue containing both muscle tissue and connective tissue is subjected to stress, and muscle proteins are separated from the connective tissue. Slurries of separated myofibrillar protein are also provided.

Owner:M P F

Quality modifier for pre-treatment of aquatic product before drying and its preparation and application

InactiveCN101066066BPrevent oxidationGood rehydrationMeat/fish preservation using chemicalsMyofibrilAquatic product

Owner:ZHEJIANG UNIV OF TECH

Method for preparing modified protein from freshwater minced fillet rinsing water and application of modified protein

InactiveCN109247424AReduce wasteIncrease forceProtein composition from fishFood ingredient as gelling agentMyofibrilIce water

The invention discloses a method for preparing modified protein from freshwater minced fillet rinsing water, the method comprises the following steps: 1) preparing the freshwater minced fillet rinsingwater, to be more specific, mixing freshwater fish meat with 4 DEG C ice water, homogenizing at a high speed for 60-90 seconds, and filtering to obtain the freshwater minced fillet rinsing water, wherein the mass ratio of the freshwater fish meat to the ice water is 1: (2-6); and 2) modifying, to be more specific, carrying out vacuum concentration on the freshwater minced fillet rinsing water at35-55 DEG C under-0.1MPa to a volume of 1 / 2-1 / 5 of the original volume so as to obtain a concentrated solution, and carrying out vacuum freeze-drying on the concentrated solution into powder to obtainthe modified protein. The invention also discloses application of the modified protein in improving the characteristics of myofibrillar protein gel of freshwater minced fillet. According to the method disclosed by the invention, the waste of protein resources is effectively reduced; the modified protein powder is added into the myofibrillar protein of the freshwater minced fillet, the acting force among protein molecules is increased, and the gel strength is improved.

Owner:TIANJIN AGRICULTURE COLLEGE

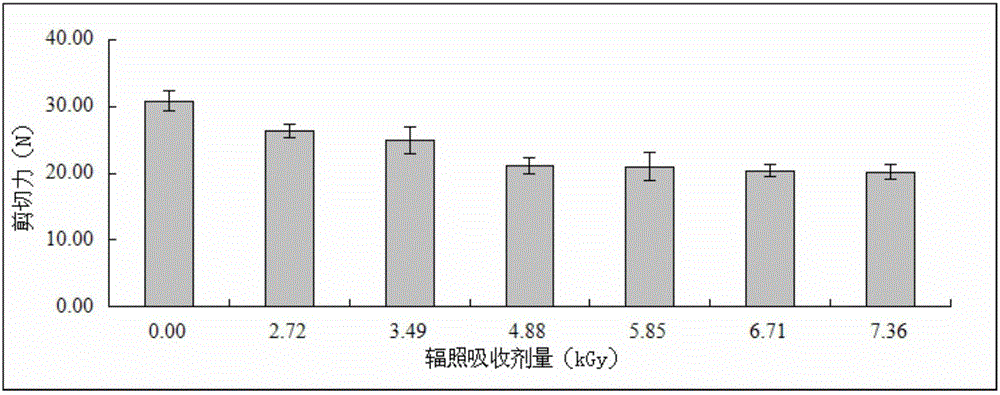

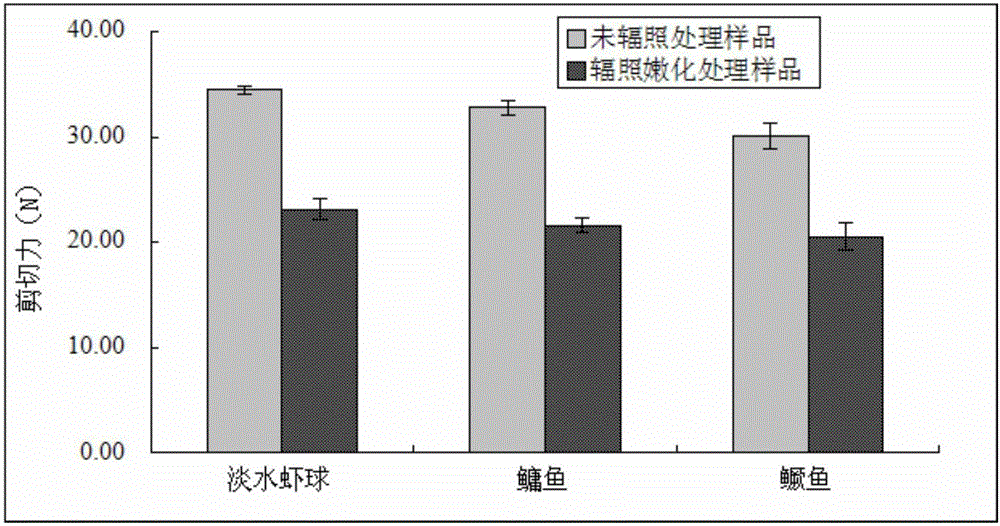

Method for tenderizing aquatic products through <60>Co-gamma irradiation

The invention relates to a method for tenderizing an aquatic product through <60>Co-gamma irradiation. The method comprises the following steps: cleaning up the aquatic product, removing non-edible parts of the aquatic product, and slicing the other part of the aquatic product; adding 0.1-2% of salt and 0.5% gourmet powder for pickling; adding Vc and Ve antioxidants for dipping at the end of the pickling process; cleaning up, draining off, and steam-cooking to enable the processed edible parts to be well done; vacuumizing and packing; performing <60>Co-gamma irradiation with the absorbed dose of 2.72-7.36 kGy. As <60>Co-gamma high-energy rays acts on macromolecules, a degradation reaction is generated, the Ca<2+> concentration in myoplasm is increased, calpain can promote the increase of a myofibril fragmentation index, the meat shearing force is reduced, and the meat tenderness is improved; along with the increase of irradiation absorbed dose, the aquatic product shearing force is reduced, and the tenderness is improved. The method is performed at the condition of 0-10 DEG C, operation can be carried out on the packed product, and tender and sterilization are conducted simultaneously, so that not only is eating quality improved, but also the sterilization effect is realized.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Process for reducing oil and fat content in cooked potato

A process for cooking a potato in oil and / or fat is provided. An acidic dry protein mixture, an alkaline dry protein mixture, an aqueous alkaline protein mixture or an aqueous acidic protein or peptide derived therefrom is added to a food prior to cooking. The acidic dry protein mixture, alkaline dry protein mixture, aqueous alkaline protein mixture and aqueous acidic protein solution comprise myofibrillar proteins and sarcoplasmic proteins substantially free of myofibrils and sarcomeres. The uncooked potato and protein and / or peptide is frozen and then cooked in a fat or oil. The amount of oil and / or fat absorbed by the food during cooking is substantially reduced.

Owner:PROTEUS INDUSTRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com