Preparation method of strong gelatin fibrillin

The technology of myofibrillar protein and strong gel is applied in the field of preparation of strong gel myofibrillar protein, which can solve the problems of decreased water holding capacity, poor gelation ability of fish meat protein, and reduction of the number of sulfhydryl groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

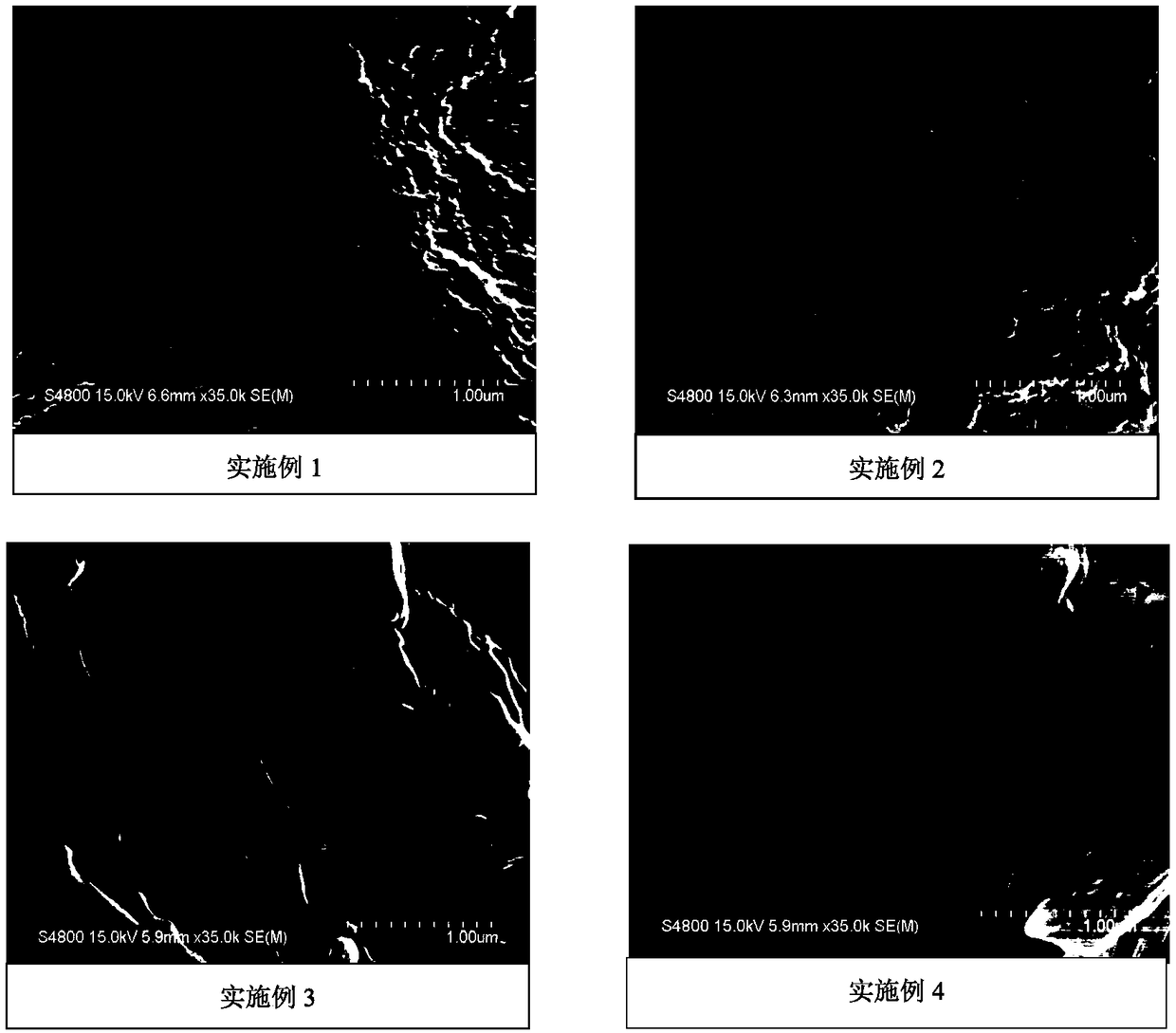

Embodiment 1

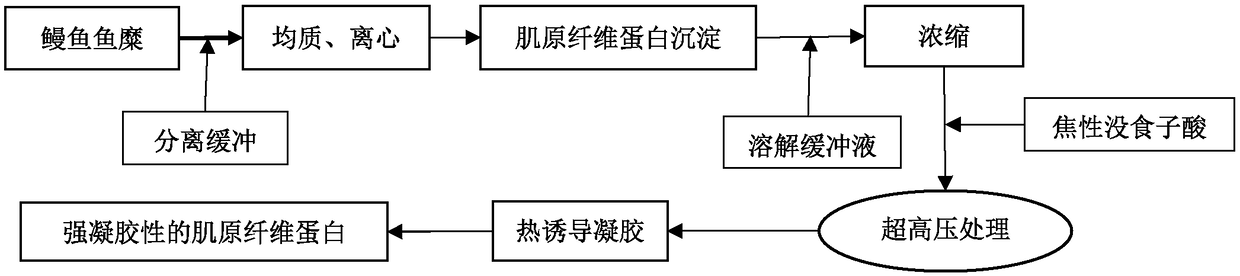

[0024] Such as figure 1 Shown, a kind of preparation method of strongly gelatinous myofibrillar protein comprises the steps:

[0025] (1) Add the first separation buffer to the minced surimi, and then homogenize and centrifuge to remove the soluble protein to obtain the first precipitate, then add the second separation buffer to the first precipitate, and then Homogenize, filter the liquid with three layers of gauze and centrifuge to get the second precipitate; the pH of the above first separation buffer is 7.0, including 0.1M KCl, 2mM MgCl 2 , 1mM EGTA, 0.5mM DTT and 10mM K 2 HPO 4 ; The pH of the above second buffer is 6.0, including 0.1M NaCl and 1mM NaN 3 ; In this step, the homogenization condition is 8000rpm, 5min, and the centrifugation condition is 8000rpm, 15min, 4°C;

[0026] (2) Add cold dissolving buffer solution to the above-mentioned second precipitation, place it at 0°C for 30 minutes after homogenization, then centrifuge to take the supernatant, and then co...

Embodiment 2

[0031] (1) Add the first separation buffer to the minced surimi, and then homogenize and centrifuge successively to remove the soluble protein to obtain the first precipitate, then add the second separation buffer to the first precipitate, and then Homogenize, filter the liquid with three layers of gauze and centrifuge to get the second precipitate; the pH of the above first separation buffer is 7.0, including 0.1M KCl, 2mM MgCl 2 , 1mM EGTA, 0.5mM DTT and 10mM K 2 HPO 4 ; The pH of the above second buffer is 6.0, including 0.1M NaCl and 1mM NaN 3 ; In this step, the homogenization condition is 8000rpm, 5min, and the centrifugation condition is 8000rpm, 15min, 4°C;

[0032] (2) Add cold dissolving buffer solution to the above-mentioned second precipitation, place it at 0°C for 30 minutes after homogenization, then centrifuge to take the supernatant, and then concentrate it with an ultrafiltration tube to obtain a concentrated solution with a concentration of 20mg / mL; the abo...

Embodiment 3

[0036] (1) Add the first separation buffer to the minced surimi, and then homogenize and centrifuge successively to remove the soluble protein to obtain the first precipitate, then add the second separation buffer to the first precipitate, and then Homogenize, filter the liquid with three layers of gauze and centrifuge to get the second precipitate; the pH of the above first separation buffer is 7.0, including 0.1M KCl, 2mM MgCl 2 , 1mM EGTA, 0.5mM DTT and 10mM K 2 HPO 4 ; The pH of the above second buffer is 6.0, including 0.1M NaCl and 1mM NaN 3 ; In this step, the homogenization condition is 8000rpm, 5min, and the centrifugation condition is 8000rpm, 15min, 4°C;

[0037] (2) Add cold dissolving buffer solution to the above-mentioned second precipitation, place it at 0°C for 30 minutes after homogenization, then centrifuge to take the supernatant, and then concentrate it with an ultrafiltration tube to obtain a concentrated solution with a concentration of 20mg / mL; the above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com