Glycosylation method for improving PSE chicken breast myofibrillar protein gel quality

A technology for myofibrillar protein and chicken breast meat, which is applied in climate change adaptation, food science and other directions, can solve problems such as poor performance of gel products, improve water retention and gel hardness, improve gel quality and economic benefits, The effect of mild treatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

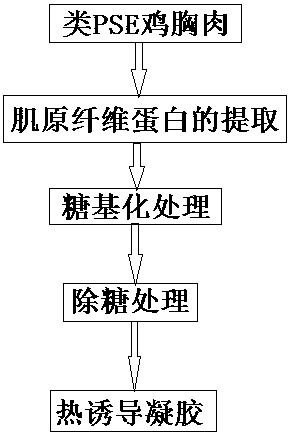

Method used

Image

Examples

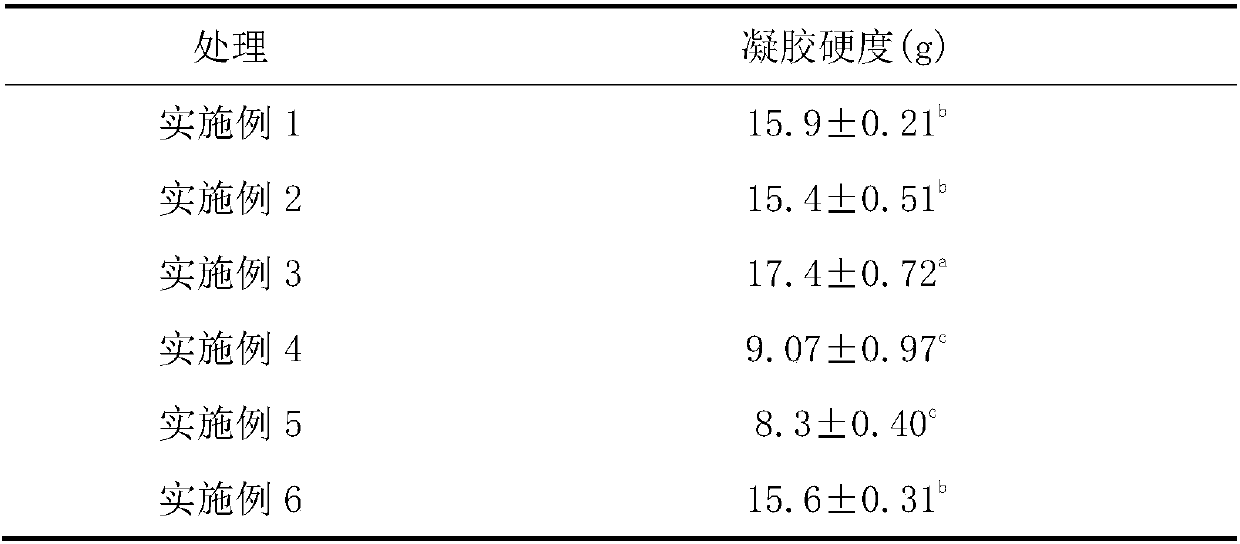

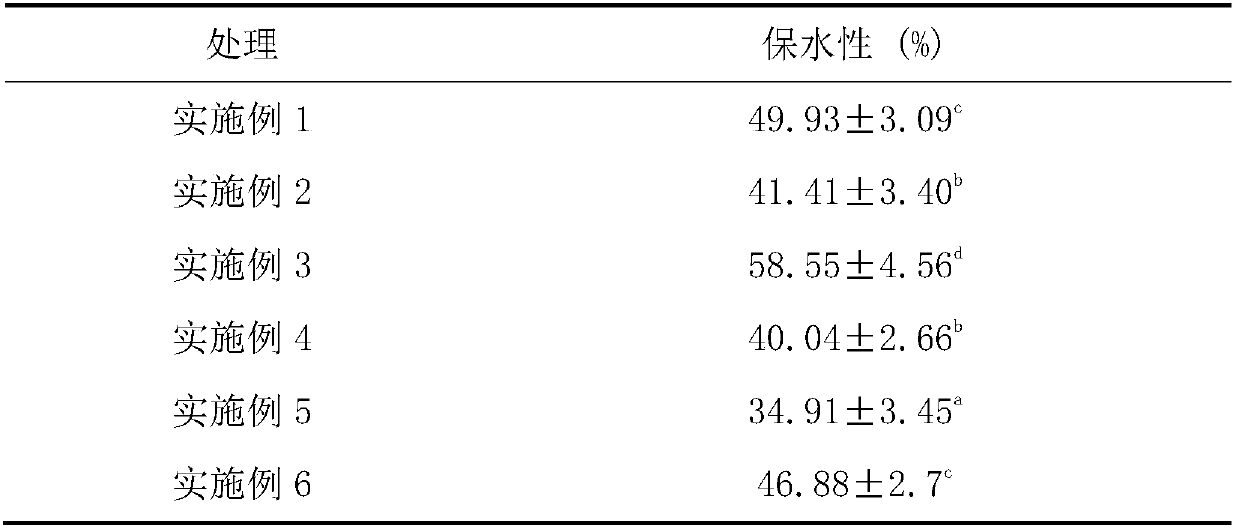

Embodiment 1

[0028] Remove connective tissue and fat from 100g normal chicken breast, cut into small pieces and mince, add four times standard salt solution (0.1mol / L KCl, 20mmol / L KCl, 20mmol / L K 2 HPO 4 / KH 2 PO 4 , 2mmol / L of MgCl 2 , 1mmol / L EGTA in a salt solution with a pH value of 7.0), homogenate, filter with double-layer gauze, and then elute with 2000×g, 10min centrifugation conditions; Add four times the standard salt solution, homogenize and then elute with 2000×g, 10min centrifugation; then add four times the standard salt solution to the precipitate obtained after the second elution according to the mass volume ratio, and homogenize Use 2000×g, 10min centrifugation conditions for elution; repeat the elution three times; add four times the 0.1mol / L KCl solution to the precipitate obtained after elution with standard salt solution according to the mass volume ratio, and use 2000× g, 10min centrifugal conditions for elution, add the precipitate obtained after elution again i...

Embodiment 2

[0030] Remove connective tissue and fat from 100g normal chicken breast, cut into small pieces and mince, add four times standard salt solution (0.1mol / L KCl, 20mmol / L KCl, 20mmol / L K 2 HPO 4 / KH 2 PO 4 , 2mmol / L of MgCl 2 , 1mmol / L EGTA in a salt solution with a pH value of 7.0), homogenate, filter with double-layer gauze, and then elute with 2000×g, 10min centrifugation conditions; Add four times the standard salt solution, homogenize and then elute with 2000×g, 10min centrifugation; then add four times the standard salt solution to the precipitate obtained after the second elution according to the mass volume ratio, and homogenize Use 2000×g, 10min centrifugation conditions for elution; repeat the elution three times; add four times the 0.1mol / L KCl solution to the precipitate obtained after elution with standard salt solution according to the mass volume ratio, and use 2000× g, 10min centrifugal conditions for elution, add the precipitate obtained after elution again i...

Embodiment 3

[0032] Remove connective tissue and fat from 100g normal chicken breast, cut into small pieces and mince, add four times standard salt solution (0.1mol / L KCl, 20mmol / L KCl, 20mmol / L K 2 HPO 4 / KH 2 PO 4 , 2mmol / L of MgCl 2 , 1mmol / L EGTA in a salt solution with a pH value of 7.0), homogenate, filter with double-layer gauze, and then elute with 2000×g, 10min centrifugation conditions; Add four times the standard salt solution, homogenize and then elute with 2000×g, 10min centrifugation; then add four times the standard salt solution to the precipitate obtained after the second elution according to the mass volume ratio, and homogenize Use 2000×g, 10min centrifugation conditions for elution; repeat the elution three times; add four times the 0.1mol / L KCl solution to the precipitate obtained after elution with standard salt solution according to the mass volume ratio, and use 2000× g, 10min centrifugal conditions for elution, add the precipitate obtained after elution again i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com