Method for tenderizing aquatic products through <60>Co-gamma irradiation

A technology of aquatic products and gamma irradiation, which is applied to the radiation processing technology of agricultural products and the processing of agricultural and sideline products to achieve the effect of ensuring edible quality, improving edible quality, and the method being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, concrete steps are as follows:

[0021] 1) Take fresh sea bass, wash, remove the head and tail, gills, viscera and then cut into meat pieces with a thickness of 1cm;

[0022] 2) Pickling: add 0.1% salt and 0.5% monosodium glutamate according to the quality of sea bass, and marinate at 10°C for 90 minutes;

[0023] 3) In the last 25 minutes of the pickling process in step 2), an antioxidant was added to carry out antioxidant impregnation to the perch pieces; the antioxidant formula was: Vc:Ve=1:1, and the antioxidant dosage was 0.1 g / Kg;

[0024] 4) Wash and drain the perch marinated in step 3), steam for 3 minutes, and steam the perch until 7 minutes;

[0025] 5) Carry out vacuum packaging to the perch after step 4) steam cooking;

[0026] 6) Carry out the absorption dose of 2.72kGy to the perch that has been vacuum-packed in step 5) at a temperature of 0°C. 60 Co-γ irradiation treatment.

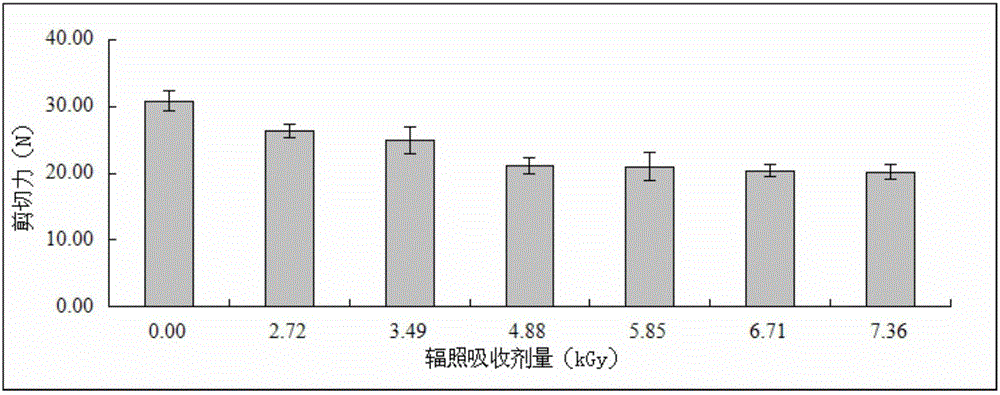

[0027] The perch sample after irradiation is measured with a t...

Embodiment 2

[0028] Embodiment 2, with embodiment 1, difference is,

[0029] 2) Pickling: Add 0.5% salt and 0.5% monosodium glutamate according to the quality of sea bass, and marinate at 8°C for 75 minutes;

[0030] 3) In the last 15 minutes of the pickling process in step 2), an antioxidant is added to impregnate the perch pieces with antioxidant; the antioxidant formula is: Vc:Ve=1:1, and the antioxidant dosage is 0.15g / Kg;

[0031] 4) Wash and drain the perch marinated in step 3), steam for 5 minutes, and steam the perch until 8 minutes are cooked;

[0032] 6) Put 3 per sample of perch vacuum-packed in step 5) in parallel, and pack them into cartons one by one, and isolate each sample with a water bag with a thickness of 2 cm. After the carton is sealed, it is sent to the Hubei Provincial Irradiation Engineering Center for treatment. At a temperature of 5°C, the absorbed dose is 3.49kGy 60 Co-γ irradiation treatment.

[0033] Perch sample after irradiation, its shear force measured ...

Embodiment 3

[0034] Embodiment 3, with embodiment 1, difference is,

[0035] 2) Pickling: add 1% salt and 0.5% monosodium glutamate according to the quality of sea bass, and marinate at 6°C for 60 minutes;

[0036] 3) In the last 10 minutes of the pickling process in step 2), an antioxidant is added to carry out antioxidant dipping of the fish pieces; the antioxidant formula is: Vc:Ve=1:1, and the antioxidant dosage is 0.2g / Kg;

[0037] 4) Wash and drain the perch marinated in step 3), and steam for 8 minutes to steam the perch until 9 minutes are cooked;

[0038] 6) Put 3 per sample of perch vacuum-packed in step 5) in parallel, and pack them into cartons one by one, and isolate each sample with a water bag with a thickness of 2 cm. After the carton is sealed, it is sent to the Hubei Provincial Irradiation Engineering Center for treatment. At a temperature of 10°C, the absorbed dose is 4.88kGy. 60 Co-γ irradiation treatment.

[0039] The perch sample after irradiation is measured with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com