Regenerated cellulose-myofibrillar protein gel and preparation method thereof

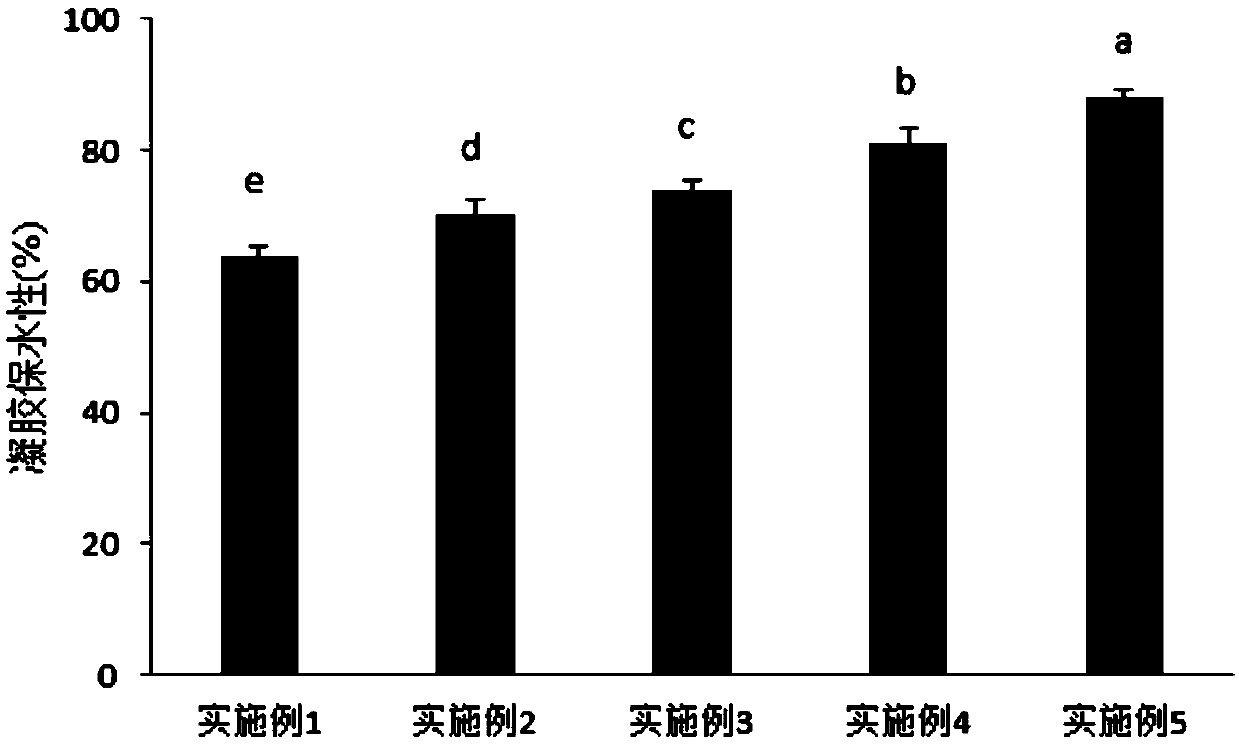

A technology of myofibrillar protein and regenerated cellulose, which is applied in the field of regenerated cellulose-myofibrillar protein gel and its preparation, and the application of regenerated cellulose to improve the quality of pork myofibrillar protein gel, which can solve the poor water retention of the gel , low hardness, gel quality decline and other problems, to achieve the effect of improving water retention, improving texture characteristics, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Myofibrillar protein gel

[0029] Step (1), the extraction of myofibrillar protein: remove pork hind leg connective tissue and fat, cut into small pieces and grind; Add 400mL standard salt solution (0.1mol / L NaCl, 20mmol / L Na 2 HPO 4 / NaH 2 PO 4 , 2mmol / L MgCl 2 , 1mmol / L EGTA, pH value 6.5), after homogenization, centrifuge at 2000g for 15min, repeat the homogenization and centrifugation twice; Then centrifuge at 2000g for 15min to obtain myofibrillar protein;

[0030] Step (2), the preparation of myofibrillar protein gel: adopt phosphate buffer solution (0.6mol / LNaCl, 50mmol / LNaCl 2 HPO 4 / NaH 2 PO 4 , pH=6.5) to prepare a solution with a myofibrillar protein concentration of 40mg / mL, homogenize at 6000rpm for 30s in an ice bath, repeat 3 times to ensure thorough mixing; take the mixed sample and place it in a 50mL centrifuge tube, and place it in a 2000g Centrifuge at a rotating speed for 5 minutes to remove air bubbles, then put the mixed sampl...

Embodiment 2

[0031] Example 2: Regenerated cellulose-myofibrillar protein gel

[0032] Step (1), the extraction of myofibrillar protein: remove pork hind leg connective tissue and fat, cut into small pieces and ground; Add 400mL standard salt solution (0.1mol / L NaCl , 20mmol / L Na 2 HPO 4 / NaH 2 PO 4 , 2mmol / L MgCl 2 , 1mmol / L EGTA, pH value 6.5), after homogenization, centrifuge at 2000g for 15min, repeat the homogenization and centrifugation twice; Then centrifuge at 2000g for 15min to obtain myofibrillar protein;

[0033] Step (2), preparation of regenerated cellulose: Wet 3 g of microcrystalline cellulose with 12 mL of deionized water, shake well, add 120 mL of 4° C. precooled 85% phosphoric acid, stir well, and obtain a milky white cellulose phosphoric acid suspension. Incubate in a low-temperature shaking incubator at 4°C and 200rpm for 24 hours to obtain a transparent and viscous cellulose phosphate solution, add 600mL deionized water to dilute, mix well, let stand for 2 hours,...

Embodiment 3

[0035] Example 3: Regenerated cellulose-myofibrillar protein gel

[0036] Step (1), extraction of myofibrillar protein: remove pig hind leg connective tissue and fat, cut into small pieces and grind; Add 400mL standard salt solution (0.1mol / L NaCl, 20mmol / L Na 2 HPO 4 / NaH 2 PO 4 , 2mmol / L MgCl 2 , 1mmol / L EGTA, pH value is 6.5), after homogenization, centrifuge at 2000g for 15min, and repeat the homogenization and centrifugation twice; Centrifuge at 2000g for 15min to obtain myofibrillar protein;

[0037] Step (2), preparation of regenerated cellulose: Wet 3 g of microcrystalline cellulose with 12 mL of deionized water, shake well, add 120 mL of 4° C. precooled 85% phosphoric acid, stir well, and obtain a milky white cellulose phosphoric acid suspension. Cultivate in a low-temperature shaking incubator at 4°C and 200rpm for 24 hours to obtain a transparent and viscous cellulose phosphate solution and let it stand for 2 hours, then add 600mL deionized water to dilute and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com