Method for regulating adsorption capacity of sea-fish myofibrillar protein to flavor compound

A technology of myofibrillar protein and adsorption capacity, which is applied in fish protein components, protein food processing, animal protein processing, etc. It can solve the problems of low modification efficiency, damage to food quality, and limited improvement of food flavor, etc., to achieve Effect of changing adsorption and improving food properties and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

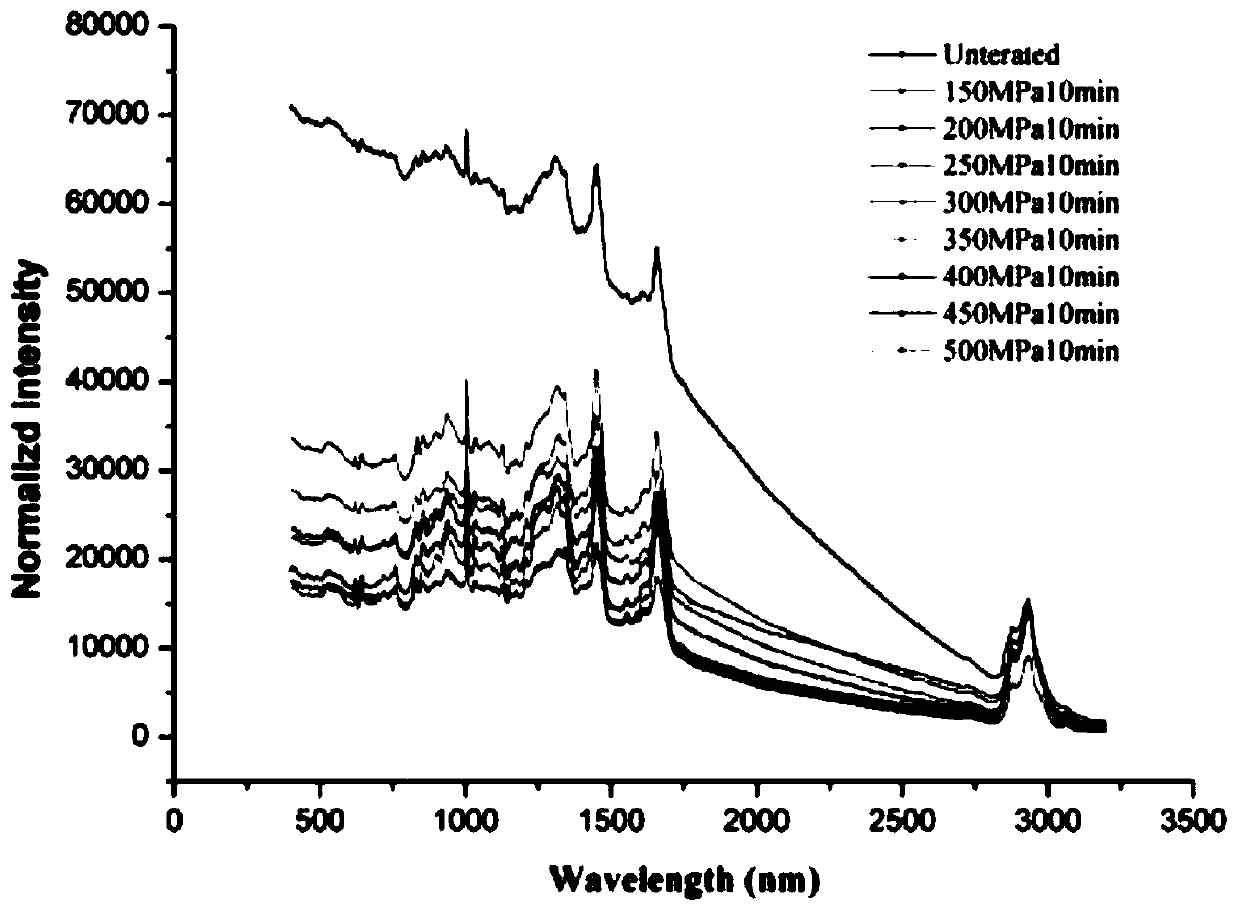

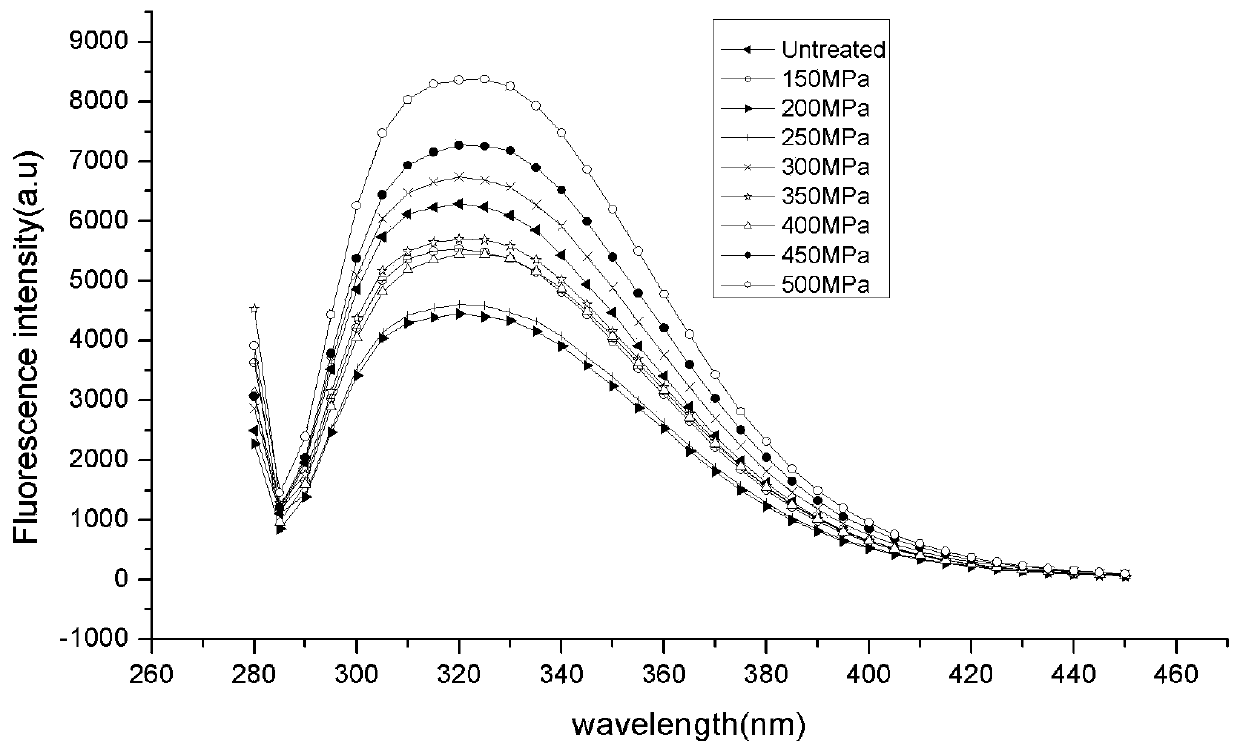

Image

Examples

Embodiment 1

[0040] (1) Extraction of myofibrillar protein: peel the cultured large yellow croaker, remove the bone, and remove the viscera, take the fish meat on both sides, place the fish meat in a meat grinder, and grind it into minced meat. Add four times the volume of ice extract, homogenize with a homogenizer, refrigerate and centrifuge, discard the supernatant and save the precipitate, then add ice extract, repeat the above operation twice to obtain crude protein, and mix the obtained crude protein with 4 times the volume of ice The washing liquid was mixed, homogenized by a high homogenizer, refrigerated and centrifuged, and the supernatant was removed, and the homogenized centrifuged was repeated once. Add 4 times the volume of ice-washing solution to homogenate, filter with 2 layers of gauze, and centrifuge the filtrate. The resulting precipitate is myofibrillar protein, which is stored in a -40°C refrigerator for later use.

[0041] (2) Preparation of myofibrillar protein gel: Myo...

Embodiment 2

[0048] (1) Extraction of myofibrillar protein: peel the cultured large yellow croaker, remove the bone, and remove the viscera, take the fish meat on both sides, place the fish meat in a meat grinder, and grind it into minced meat. Add four times the volume of ice extract, homogenize with a homogenizer, refrigerate and centrifuge, discard the supernatant and save the precipitate, then add ice extract, repeat the above operation twice to obtain crude protein, and mix the obtained crude protein with 4 times the volume of ice The washing liquid was mixed, homogenized by a high homogenizer, refrigerated and centrifuged, and the supernatant was removed, and the homogenized centrifuged was repeated once. Add 4 times the volume of ice-washing solution to homogenate, filter with 2 layers of gauze, and centrifuge the filtrate. The resulting precipitate is myofibrillar protein, which is stored in a -40°C refrigerator for later use.

[0049] (2) Preparation of myofibrillar protein gel: t...

Embodiment 3

[0056] (1) Extraction of myofibrillar protein: peel the cultured large yellow croaker, remove the bone, and remove the viscera, take the fish meat on both sides, place the fish meat in a meat grinder, and grind it into minced meat. Add four times the volume of ice extract, homogenize with a homogenizer, refrigerate and centrifuge, discard the supernatant and save the precipitate, then add ice extract, repeat the above operation twice to obtain crude protein, and mix the obtained crude protein with 4 times the volume of ice The washing liquid was mixed, homogenized by a high homogenizer, refrigerated and centrifuged, and the supernatant was removed, and the homogenized centrifuged was repeated once. Add 4 times the volume of ice-washing solution to homogenate, filter with 2 layers of gauze, and centrifuge the filtrate. The final precipitate is myofibrillar protein, which is stored in a -40°C refrigerator for later use.

[0057] (2) Preparation of myofibrillar protein gel: take ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com