Meat tenderizing method for improving pyrolysis of myofibril

A technology for myofibrils and meat products, applied in the field of tenderization of poultry and livestock meat, can solve the problems of difficulty in exerting dissociated actomyosin, inability to effectively improve tenderness, etc., so as to improve freshness and nutritional value, and improve meat quality. Product quality, improve the effect of color and luster

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

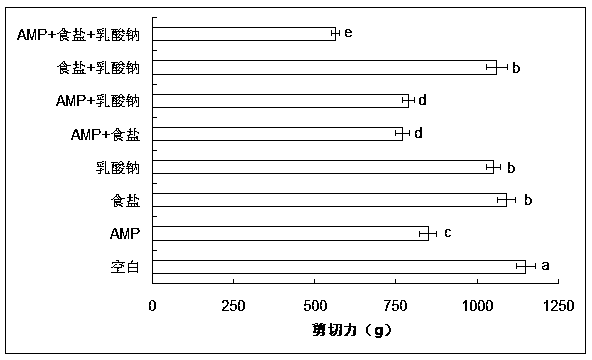

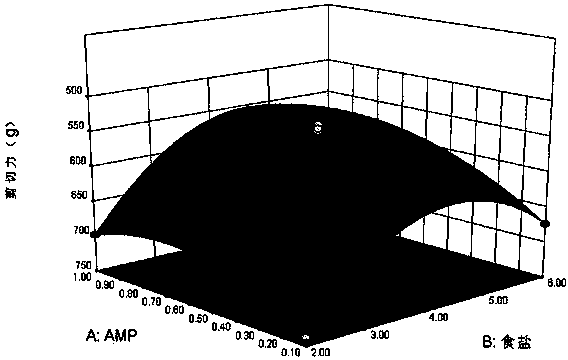

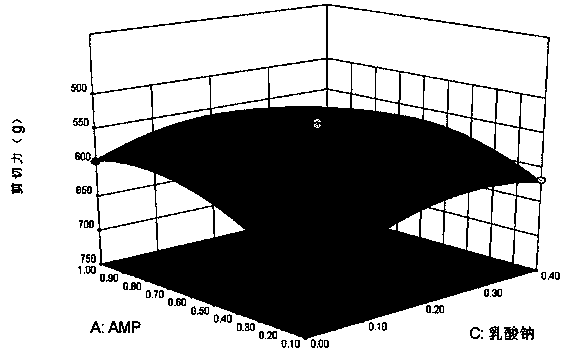

[0026] Example 1: Take 0.6 kg of adenine nucleotide (AMP), 4 kg of salt and 0.2 kg of sodium lactate to prepare a meat tenderizer.

[0027] Clean the fresh or thawed raw pork, chop it, put it into clean water 1.0 times the weight of the raw pork, and add meat tenderizer according to 6% of the weight of the raw pork, stir it evenly, and put it in a room at a temperature of 15°C. Soak for 8 hours under the same conditions, and stir once every 60 minutes, and drain after soaking to obtain tenderized raw pork.

Embodiment 2

[0028] Example 2: Take 1 kg of adenine nucleotide (AMP), 5 kg of salt and 0.3 kg of sodium lactate to prepare a meat tenderizer.

[0029] Clean the fresh or thawed raw beef, chop it, put it into clean water 1.2 times the weight of the raw beef, and add meat tenderizer according to 8% of the weight of the raw beef, stir it evenly and put it under the condition of 15℃ Soak for 8 hours and stir once every 60 minutes, and drain after soaking to get tenderized raw beef.

Embodiment 3

[0030] Example 3: Take 0.8 kg of adenine nucleotide (AMP), 4 kg of salt and 0.1 kg of sodium lactate to prepare a meat tenderizer.

[0031] Clean the fresh or thawed raw mutton, chop it, put it into clean water 1.0 times the mass of raw mutton, and add meat tenderizer according to 8% of the mass of raw mutton, stir evenly and put it under the condition of 15 ℃ Soak for 8 hours and stir once every 60 minutes, and drain after soaking to get tenderized raw mutton.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com