Patents

Literature

80 results about "Raw beef" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microwave western-style beefsteak and preparation method thereof

ActiveCN102715541AEasy to manufactureIn line with the rhythm of lifeFood preparationMicrowave ovenRaw beef

The invention discloses a microwave western-style beefsteak and a preparation method thereof. The preparation method comprises the steps of 1) selecting raw beef; 2) unfreezing the raw beef under conditions of temperature being 0-4DEG C and relative humidity being 80-90 percent; 3) salting; 4) shaping; 5) slicing, wherein the thickness of slices is 1.0-1.5cm; 6) placing and frying the slices on a frying pan with temperature being 220DEG C for 2 minutes; and 7) placing and quickly freezing the fried slices at negative 35DEG C for 45 minutes to obtain the microwave western-style beefsteak. The microwave western-style beefsteak which is prepared by adopting the technical scheme is simple and convenient to prepare and is suitable for industrial production, the microwave western-style beefsteak is only required to be heated for 40 seconds through big fire in a microwave oven, the operation is convenient to conduct and the microwave western-style beefsteak is compliant with rhythm of life of modern people. More importantly, the microwave western-style beefsteak provided by the invention is superior to the microwave beefsteak in the prior art in the aspects of tastes, flavor and color.

Owner:上海瑞轩食品有限公司

Method for producing spicy beef jerky

The invention discloses a method for producing spicy beef jerky, which comprises the following working procedures: thawing raw beef, cutting the raw beef, boiling or marinating, frying, mixing materials, vacuum-packaging and storing, wherein spice is added in the working procedure of mixing the materials, and the spice contains 45-50 parts by weight of anise, 16-18 parts by weight of fennel, 18-22 parts by weight of cassia twig, 8-10 parts by weight of licorice, 15-17 parts by weight of orange peel, 25-28 parts by weight of cinnamon, 5-8 parts by weight of pepper, 5-7 parts by weight of vanilla planifolia and 3-5 parts by weight of Chinese clematis root. Compared with the prior art, the method does not need to additionally add a preservative, the prepared spicy beef jerky has no air expansion during the storage period, and the bacterial colony indicator is in line with the stipulations.

Owner:褚先英

Preparation method of air-preserved yak meat

InactiveCN103271376AEasy accessGreat tasteClimate change adaptationFood preparationBiotechnologyMicroorganism

The invention relates to a food processing method and particularly relates to a preparation method of air-preserved yak meat. The method comprises the six steps of tenderization, fungi-reduced immersion, saline injection, vacuum tumbling, low-temperature pickling and hot air drying, wherein the tenderization treatment can be used for destroying muscle fiber structures and improving the pickling quality; by virtue of the fungi-reduced immersion on raw beef, the initial sanitation level of the raw beef can be greatly improved; the saline injection enables part of water-soluble pickling materials to enter into the deep layer of muscles rapidly so as to improve the pickling quality; the vacuum tumbling enables the pickling materials to enter into the deep layer of the muscles rapidly so as to improve the pickling quality, enables the meat to be tender, and can prevent oxidation; the low-temperature pickling can be used for restraining the growth and procreation of microorganisms, enables the yak meat to fully absorb various seasonings and nutrient components, can be used for effectively extracting proteins, and realizes thorough color development; and the hot air drying can be used for rapidly removing excess moisture in the meat, and enables the meat to be partially mature, fresh in taste, proper in salty, lingering in aftertaste, complete in color, aroma and taste, and rich in nutrition.

Owner:西藏牦牛王生态食品开发有限公司

Health-maintenance beef flavor seasoning powder

InactiveCN103005372ASpecial flavorCompatibility is reasonableFood preparationBiotechnologyMonosodium glutamate

The invention discloses health-maintenance beef flavor seasoning powder which consists of the following raw materials in parts by weight: 5 to 8 parts of composite spice, 3 to 5 parts of a composite nutrition extract, 3 to 5 parts of beef pure powder, 1 to 2 parts of pure cow oil, 3 to 4 parts of corn starch, 40 to 44 parts of monosodium glutamate, 28 to 30 parts of edible salt, 1 to 3 parts of I+G, 6 to 8 parts of white sugar, 1 to 3 parts of a yeast extract, 6 to 8 parts of maltodextrin, 0.1 to 0.3 part of disodium succinate, 0.3 to 0.5 part of hydrolyzed plant protein powder, 1 to 1.5 parts of strawberry freeze-dried powder and 0.5 to 1 part of robiniae pollen. The health-maintenance beef flavor seasoning powder has unique fragrance and rich nutrition; nori has special delicious fragrance; the composite nutrient extract is reasonable in formula; and the health-maintenance beef flavor seasoning powder has a health protection effect.

Owner:吴梦凡

Flavored beef tallow and preparation method thereof

The present invention relates to a flavored beef tallow and a preparation method thereof. Firstly water washing, drying, decolorizing, deodorizing, and filtering are carried out to process raw beef tallow into refined beef tallow butter and pepper and then refining, star anise and other spices. Then the refined beef tallow and Chinese prickly ash, star anises and other seasoning materials are subjected to four frying to obtain the flavored beef tallow. The beneficial effects of the prepared flavored beef tallow are as follows: in order to conveniently use the beef tallow and grant the refined beef tallow with an excellent taste, the flavored beef tallow integrates the unique flavors of beef tallow, Chinese prickly ash, fennel, thick broad-bean sauce, etc., and is rich in sauce fragrance, mellow in taste, and long in aftertaste.

Owner:泰安金冠宏油脂工业有限公司 +1

Processing method for refreshment dried beef slices

The invention discloses a novel production method for processing dried beef slices. Fresh beef is taken as a main raw material and is processed into novel dried beef slices. The method comprises the following processing steps of: cleaning the fresh beef, draining bloody water, and trimming into natural blocks; adding edible salt into a pot, frying the natural block beef until dryness, adding nitrous, galangal, angelica dahurica and tsaoko amomum fruit for salting, adding edible salt, galanga galangal seed, hawthorn, clove, resurrectionlily, round cardamom fruit, biond magnolia flower and orange for salting, and adding star anise, fennel, pepper, nutmeg, cassia and fructus amomi for salting; cleaning by using a meat washing machine, precooking and stewing beef by using spice, edible salt and gourmet powder, trimming completely, slicing, and baking and frying; and finally sterilizing and packaging the cooled beef. The novel dried beef slices can be produced massively; the nutritional value of the beef per se cannot be damaged in the production process; and the dried beef slices can be eaten by people of all ages and both sexes for a long time and are instant and delicious.

Owner:河南省金牛足食品有限公司

Method for tenderizing beef steak

Owner:福建佳客来食品股份有限公司

Preparation method of instant beef

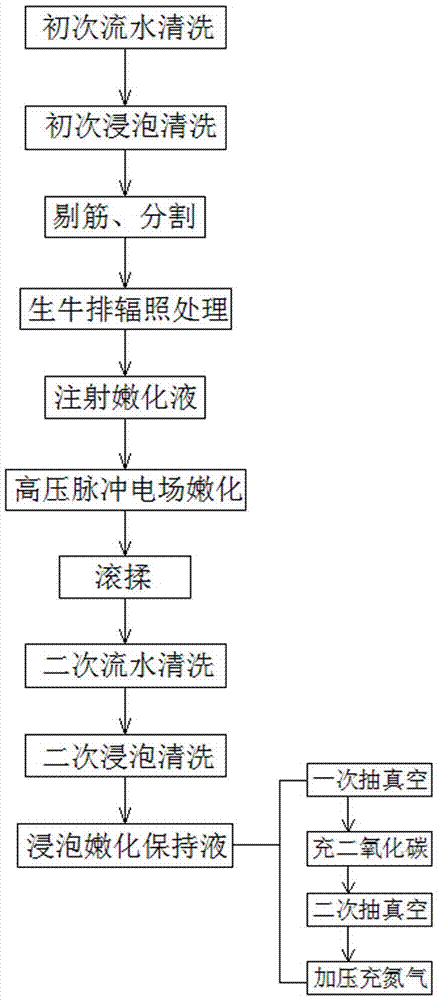

PendingCN107484969AGreat tasteExtended shelf lifeClimate change adaptationFood ingredient for microbe protectionRaw beefStarch

The invention relates to a preparation method of instant beef. The preparation method comprises the process steps of preparation of pickling liquid, pickling of raw beef and packaging. The pickling process of the raw beef comprises the following steps: (1) cleaning with running water: cleaning the raw beef with running water within 2-5s; (2) soaking and cleaning: adding 300-500g of starch into per 100kg of clear water to prepare cleaning liquid, and soaking the raw beef in the cleaning liquid for 10-20min, wherein the cleaning liquid is replaced after per 200-300kg of the raw beef is cleaned; (3) tendon removing and splitting: splitting the beef along the texture of the beef according to the standard of length x width x height = (40-50)cm x (5-15)cm x (2-3)cm; (4) drying: air-drying the split beef by using an air dryer, wherein the air-drying temperature is 40-60 DEG C; (5) injection pickling: pickling the dried beef with injection pickling liquid by adopting an injection machine; and (6) rolling and kneading: rolling and kneading the beef after injection pickling by adopting a vacuum rolling and kneading machine, wherein the speed range of the rolling and kneading machine is 1-4rpm, and the rolling and kneading time is 5-10min.

Owner:福建佳客来食品股份有限公司

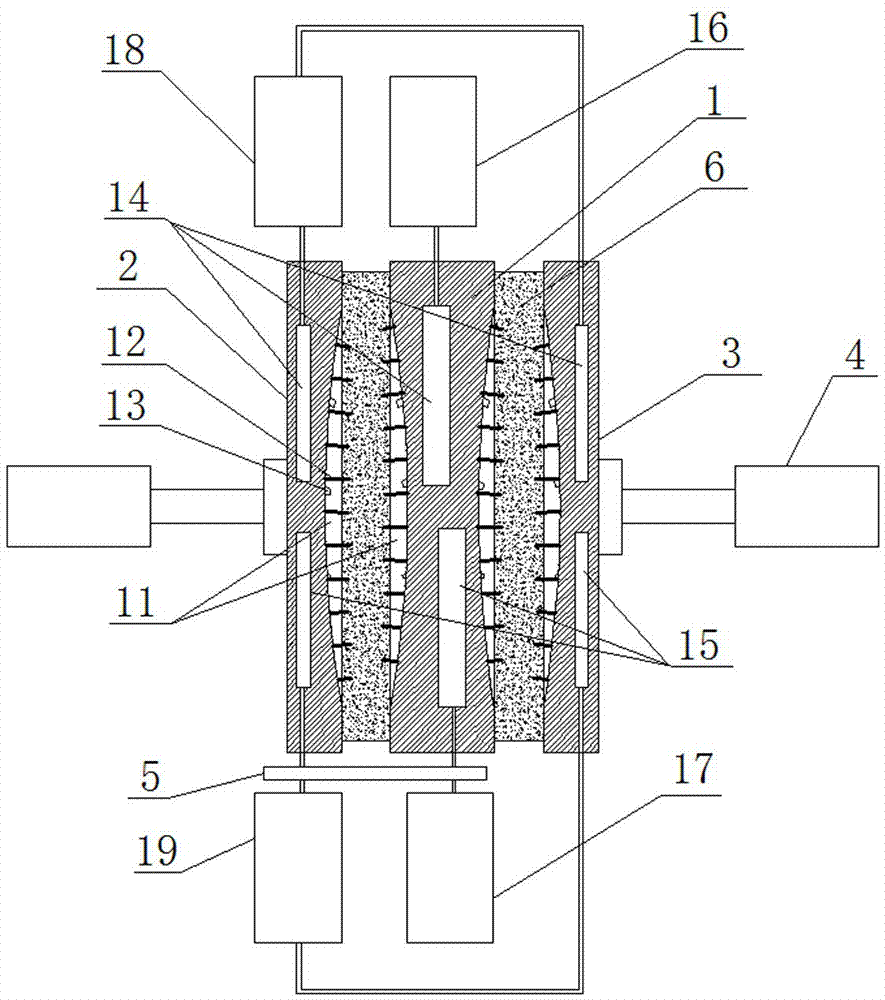

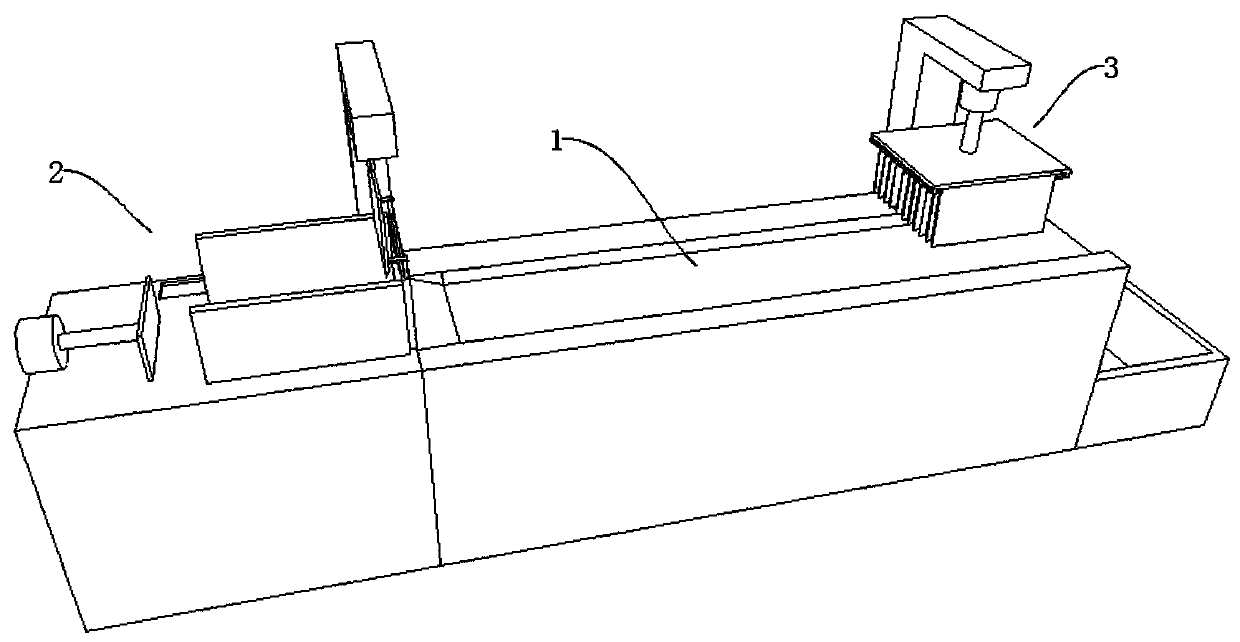

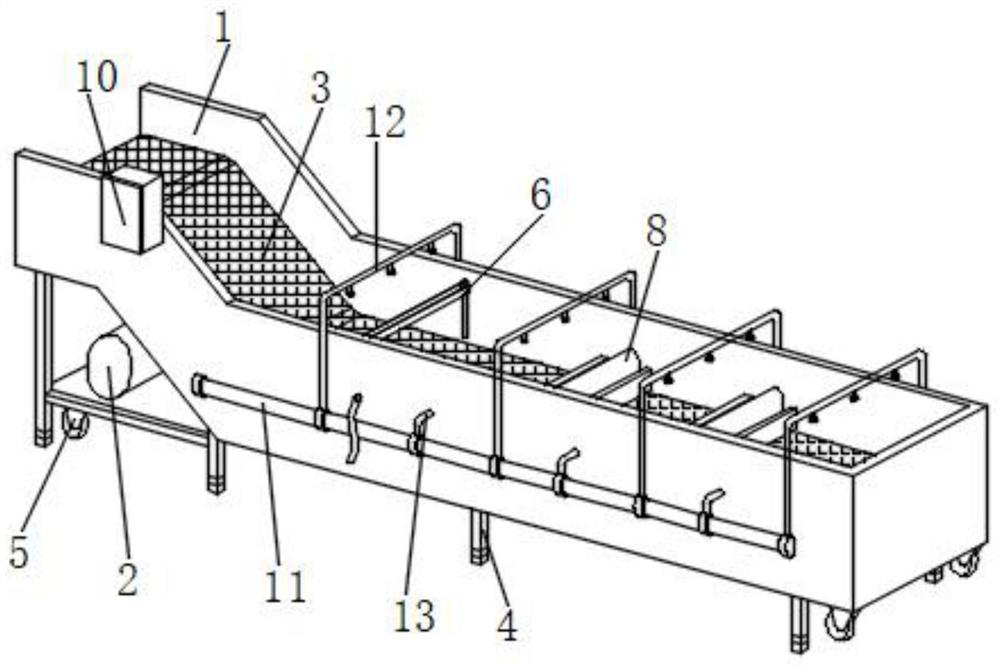

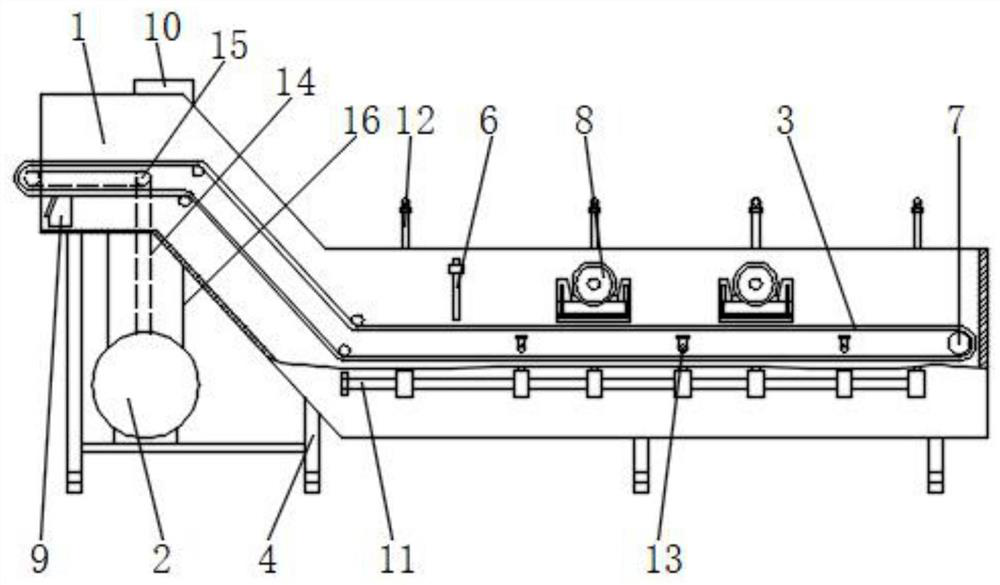

Raw beef cutting machine

PendingCN110574775AAvoid Manual LayingReduce manual labor intensityMetal working apparatusMeat shaping/cuttingRaw beefProduct processing

The invention relates to the technical field of meat product processing, and discloses a raw beef cutting machine. The raw beef cutting machine comprises a conveying mechanism, a slicing mechanism isarranged at the feeding end of the conveying mechanism, a strip-cutting mechanism is arranged between the slicing mechanism and the discharging end of the conveying mechanism, the slicing mechanism comprises a supporting table, a first cutter and a first driving device, and two longitudinal baffles and a transverse baffle are arranged on the top face of the supporting table, wherein the two longitudinal baffles are parallel to the motion direction of the conveying mechanism, and the transverse baffle is arranged on the sides, close to the conveying mechanism, of the longitudinal baffles; the first cutter is arranged on the upper part of a cavity and is parallel to the transverse baffle, and the first driving device drives the first cutter to move up and down along the inner wall of the cavity; and a groove provided with an upward opening and matched with the transverse baffle is formed in the top face of the supporting table, and the side, close to the transverse baffle, of the first cutter is connected with the transverse baffle through a connecting assembly. According to the raw beef cutting machine, slicing and strip cutting operation on raw beef can be achieved, the labor intensity of manpower is reduced, and strip beef is processed integrally and automatically.

Owner:XICHANG SIQIXIANG FOOD CO LTD

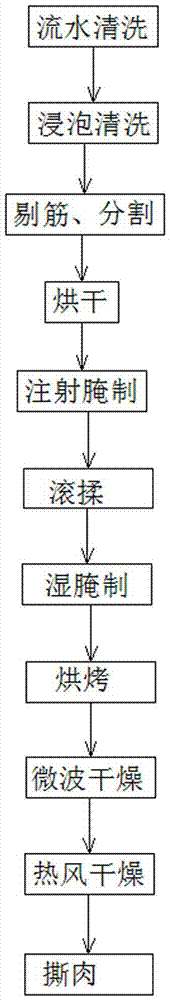

Processing method of fried dried beef

The invention provides a processing method of fried dried beef, and belongs to the technical field of processing of meat products. The processing method comprises the following steps of (1) performing pretreatment: performing acid discharge treatment on beef; (2) performing tenderization and pickling: injecting tenderization fluid into raw beef blocks, performing tenderization, and then performing seasoning and pickling, wherein the tenderization fluid contains suberect spatholobus stem protease of which the mass concentration is 0.3-0.4%, rhizopus of which the mass concentration is 0.01-0.02%, and tea polyphenols of which the mass concentration is 0.03-0.05; (3) performing fermentation treatment: fermenting pickled beef and pickled vegetable juice together; (4) performing roasting treatment; and (5) performing air-drying treatment. According to the processing method disclosed by the invention, a technology is improved, so that a new fried dried beef product which is tender in mouth feel, brownish red in color, rich in fragrance and healthy to eat is obtained.

Owner:广西乐业康辉生态养殖专业合作社

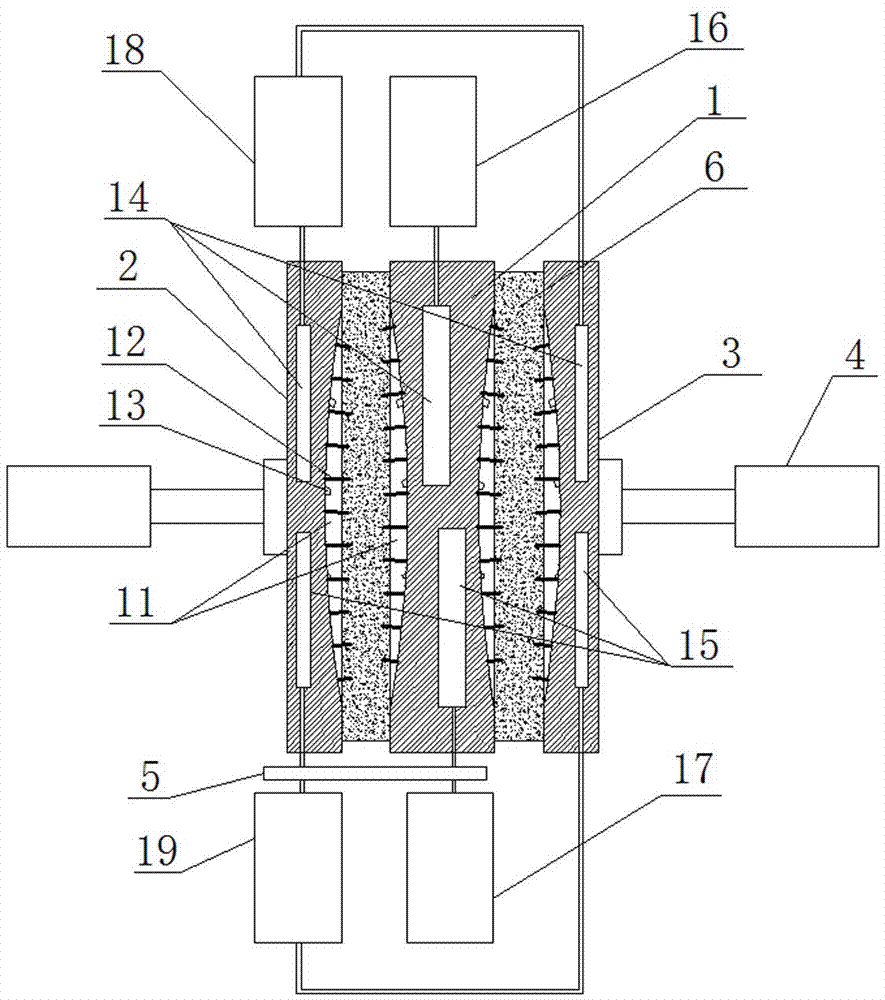

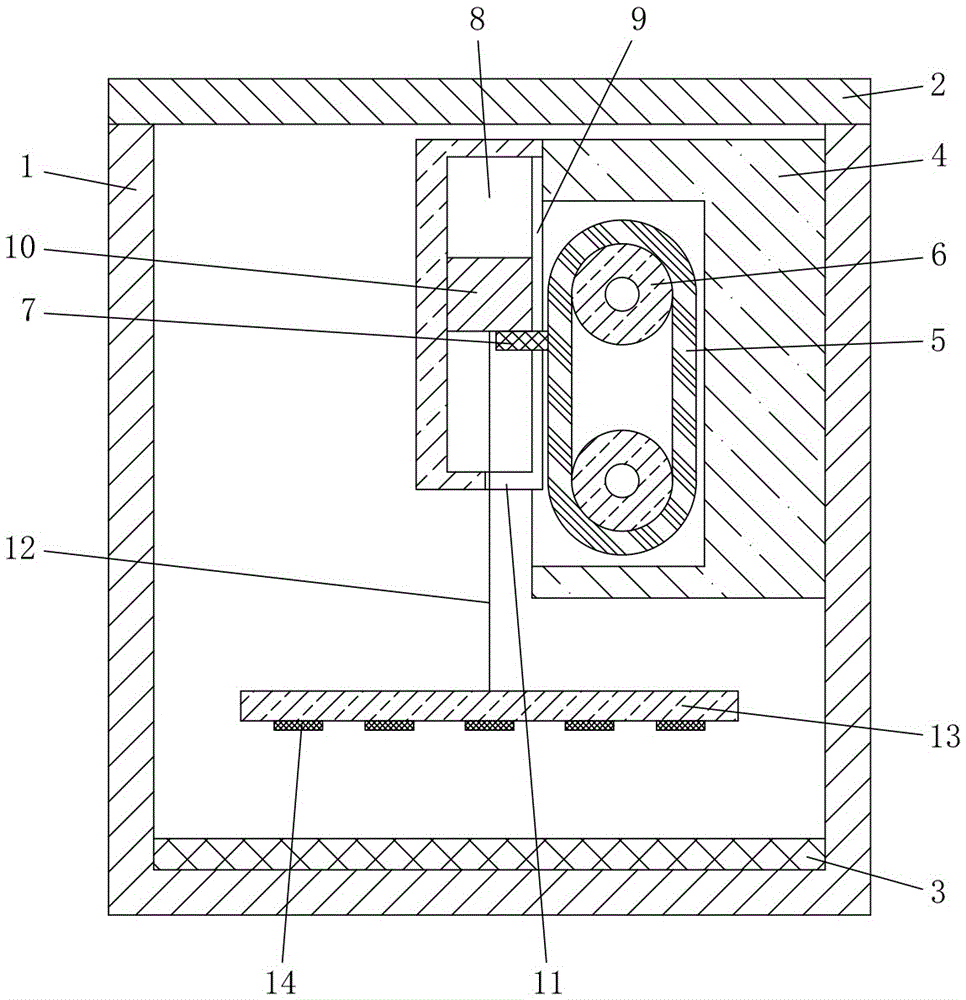

Beef knocking box used for beef barbecue

InactiveCN105557960AHit evenlySolve environmental problemsBeating-based meat tenderisingRaw beefElectric machinery

The invention discloses a beef knocking box used for a beef barbecue. The beef knocking box comprises a closed cylindrical box body; the side wall of the cylinder box body is provided with a movable openable and closeable door; the movable openable and closeable door is connected with the cylindrical box body through a hinge; a round turntable used for carrying raw beef is arranged in the cylindrical box body; a round cavity is formed in the round turntable; the side edge of the round turntable is provided with a rectangular cavity window; the round cavity is connected with outside through the cavity window; a length size of the cavity window is equal to a diameter size of the round cavity; ice is held in the round cavity; a knocking mechanism is arranged above the round turntable; the knocking mechanism comprises a support fixed on the inner wall face of the cylinder box body; the support is provided with a chain, chain wheels and a motor, wherein the chain wheels are connected with the chain, and the motor is used for driving the chain wheels; the chain is provided with a stopper. A beef knocking problem under a field environment is solved by the beef knocking box used for a beef barbecue provided by the invention.

Owner:重庆市老川牛食品有限公司

Fermented beef jerky product and manufacturing method thereof

InactiveCN106071913ASolve the shortcomings of hard textureTextured hard imperfections to avoidFood sciencePutrefying bacteriaNitrite

The invention discloses a fermented beef jerky product and a manufacturing method thereof. The fermented beef jerky product is prepared from 10 kg of tendon beef, 50 g of salt, 50 g of white sugar, 10 g of glucose, 50 g of ground black pepper, 10 g of ajinomoto, 50 g of fresh ginger, 50 g of onion, 50 g of light soy sauce, 0.02 g of nitrite and 20 g of papain. The manufacturing method comprises the steps of raw beef trimming, leavening agent preparation and activation, raw beef curing, raw beef fermentation, fermented beef jerky drying, fermented beef jerky maturing, fermented beef jerky aseptic packaging and storage and the like. The fermented beef jerky product has the advantages that the traditional beef jerky quality, taste and flavor are improved, the color is more bright, original color and taste are kept, the beef jerky normal temperature preservation time is prolonged, nutritional ingredients can be easily absorbed by people in the fermentation process, putrefying bacteria are effectively retrained from growing, and production and processing are not limited by seasonality.

Owner:额敏县新大同创生物工程有限责任公司

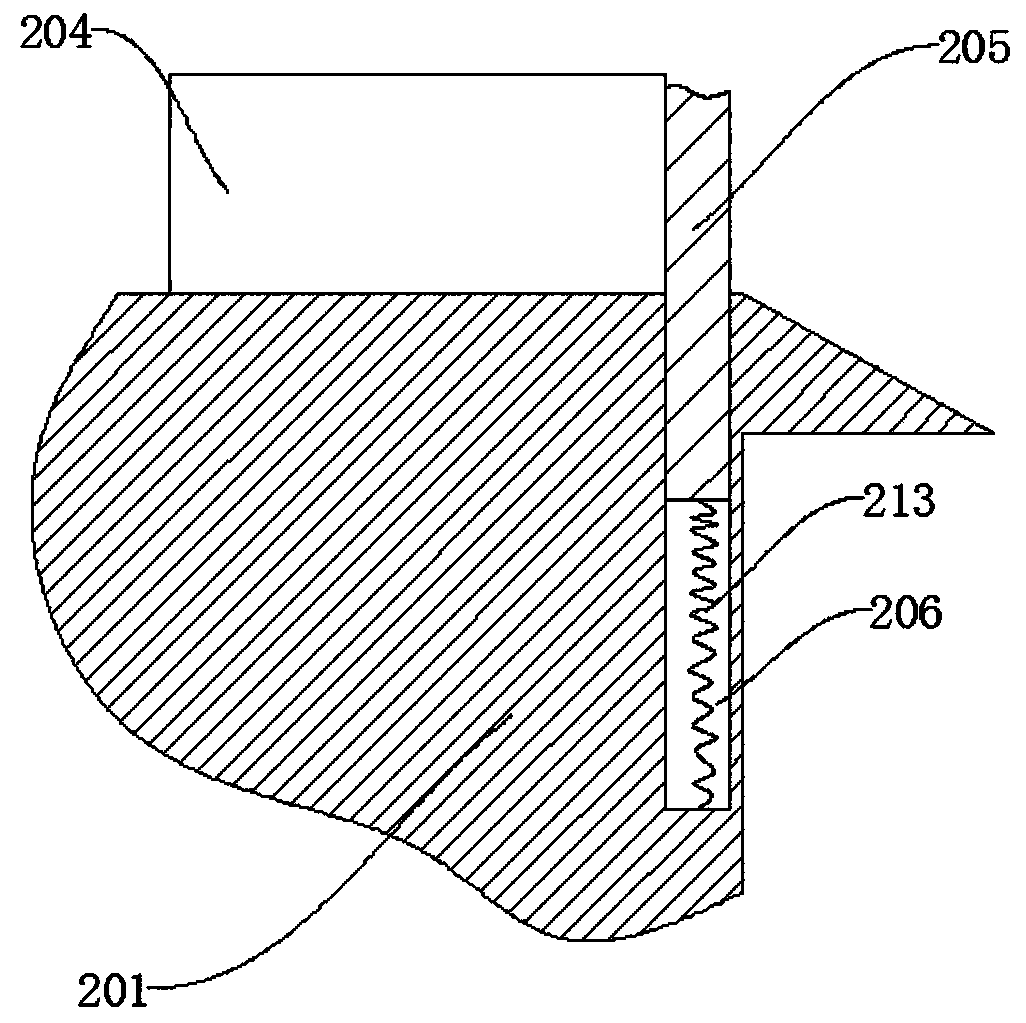

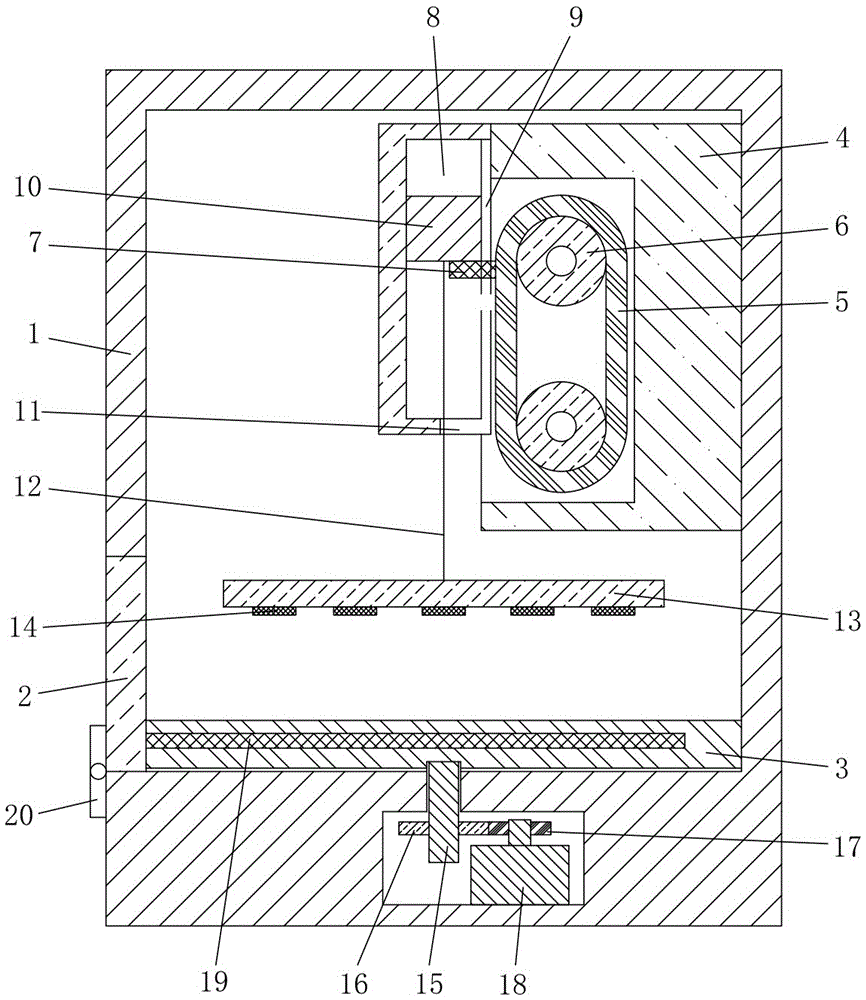

Beef beating box for beef barbecue

The invention discloses a beef beating box for beef barbecue.The beef beating box for beef barbecue comprises a closed square box body, a door openable and closeable freely is arranged on the upper portion of the square box body, a beef containing disk is arranged in the square box body and contains raw beef, and a beating mechanism is arranged above the beef containing disk and comprises a support which is fixed on the inner wall surface of the square box body and is provided with a passage.A chain, chain wheels connected with the chain and a motor driving the chain wheels are arranged on the support, a stopper is arranged on the chain, the chain is perpendicularly erected beside the passage and clings to the passage, an elongated window is formed in a position, facing the chain direction, of the passage wall, the stopper passes through the elongated window to extend into the passage, a bearing block is arranged in the passage, a flexible cord is connected at the lower end of the bearing block and penetrates through a small window, an oblate heavy block is fixed at the other end of the flexible cord, and a plurality of projecting transverse bars are arranged on the lower surface of the heavy block.The beef beating box for beef barbecue solves the problem of beef beating in a field environment.

Owner:中山市骏佳电器有限公司

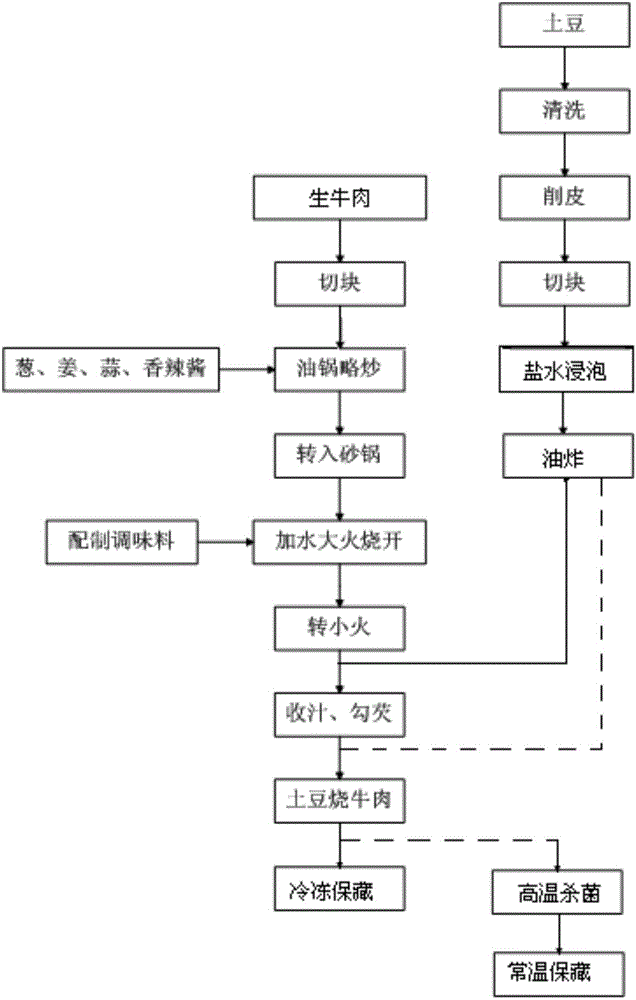

Processing method for braised potatoes and beef as main meal dish

InactiveCN104886610AFull of nutritionStrong fragranceClimate change adaptationFood preparationNutritive valuesMonosodium glutamate

The present invention discloses a processing method for braised potatoes and beef as main meal dish and the processing method comprises the following steps: dicing 250-1500 parts of raw beef and 100-600 parts of potatoes, soaking the diced potatoes with 1% mass concentration of saline for 30 minutes; heating 50- 300 parts of oil until the oil is medium hot, adding and stir-frying 10-60 parts of scallions, 10-60 parts of ginger, 10-60 parts of garlic and 30-180 parts of fragrant and spicy sauce until the above materials are fragrant, adding beef, and oil-frying for 5-20 minutes; oil-frying potatoes with oil use amount 5-10 times of the potato weight at an oil temperature of 170-200 DEG C for 2-3 minutes; preparing seasoning which includes 20-120 parts of cooking wine, 40-240 parts of soy sauce, 10-60 parts of salt, 4-24 parts of monosodium glutamate, 4-24 parts of chicken essence, 2-12 parts of pepper and 15-90 parts of white sugar; adding and boiling water, adding beef and seasoning, stewing and cooking the beef until the beef is well-done with a low heat, adding oil-fried potatoes, stewing the potatoes into until the potatoes are soft, obtaining the braised potatoes and beef, and conducting cryopreservation for the braised potatoes and beef, or stewing the beef until the beef is medium done, packaging the beef, oil-fried potatoes and soup, high-temperature sterilizing and storing the sterilized braised potatoes and beef at room temperature. The nutritional values of beef and potatoes can complement each other, and the flavor and mouth feel can be obtained repeatedly. The obtained products are stored at room temperature or at frozen temperature.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Method for preparing high-nutrition beef marinated eggs

The invention discloses a method for preparing high-nutrition beef marinated eggs. The method comprises the following steps: step I, firstly steaming raw eggs until the yolk is not completely coagulated and then air-curing the eggs at room temperature and shelling the eggs, thus obtaining steamed eggs; step II, putting raw beef in a marinating pot, heating to marinate the raw beef, then fishing out and mincing the raw beef and adding starch to obtain marinated beef; obtaining marinated beef broth after fishing out the beef; step III, injecting the marinated beef into each egg, then putting the eggs in the marinating pot, marinating, fishing out the eggs after completing marinating, transferring the eggs to a low-temperature condition and insulating and air-curing the eggs, thus obtaining marinated eggs; and step IV, carrying out vacuum bag sealing, sterilizing and outer packaging on the marinated eggs, thus completing preparation of the high-nutrition beef marinated eggs. The marinated eggs prepared by the method are tasty, have strong fragrance, are chewy, have resilience, high protein contents and high nutritive values and are safe and healthy.

Owner:RUZHOU LONGZHONGMAO FOOD

Beef product for breakfast and processing method thereof

PendingCN106579036AEnlarging the molecular gapSimple internal structureFood freezingFood thermal treatmentRaw beefDigestion

The invention provides a beef product for a breakfast and a processing method thereof, and relates to the technical field of food processing. The processing method of the beef product for the breakfast comprises the following steps that raw beef is taken, the raw beef is punched, then, the raw beef is cut into beef blocks, then, the beef blocks are placed under the temperature of subzero 18 DEG C to subzero 20 DEG C to be frozen for 2-2.5 h, the beef blocks are placed over boiling water, and the beef blocks are steamed for 20-30 min. The beef product obtained through the processing method for the beef product for the breakfast can be soft in beef quality and suitable for digestion of people in the morning.

Owner:SOUTHWEST UNIVERSITY

Refrigerating marinating method of raw beef and Huobianzi beef produced by the method

A refrigerating marinating method of raw beef includes beef treatment, spices treatment and marinating treatment. The Huobianzi beef prepared from the marinated beef provided by the invention has tender meat quality and delicious taste. The method can effectively play the bactericidal and anti-bacteria effects, extend the storage time, greatly reduce loss of nutrients in the product, improve product yield and reduce production costs.

Owner:ZIGONG CITY TIANJING FOOD CO LTD

Convenient instant rocker foot beef and preparation method thereof

ActiveCN107549670AIncrease awarenessFew types of ingredientsClimate change adaptationMeat/fish preservation by irradiation/electric treatmentFlavorRaw beef

The invention discloses convenient instant rocker foot beef. A beef pre-making bag is prepared through the steps of pickling raw beef, performing marinating, performing shaping, performing baking, performing subpacking, performing sterilization and the like; a seasoning bag is prepared through the steps of compounding raw materials, performing mixing, performing packaging and the like; a soup bagis prepared through the steps of performing bone crushing, performing stewing, performing seasoning, performing subpacking, performing sterilization and the like; and a vegetable bag is prepared through the steps of processing vegetables, performing blending, performing subpacking, performing sterilization and the like. According to the convenient instant rocker foot beef disclosed by the invention, based on the making and eating requirements of instant foods, under the precondition of guaranteeing the flavor of the product, the beef pre-making bag, the seasoning bag, the soup bag and the vegetable bag are prepared in batches by a standardized process; through operations of the salinity, packaging and physical sterilization of each bag, the product has a longer quality guarantee life; besides, through assisting by a conventional self-heating meal box packaging technology, and the sterilized bagged packets are further packaged, so that consumers can conveniently carry and eat the rockerfoot beef and popularization of the rocker foot beef as a local favor food is facilitated.

Owner:CHENGDU SHIWEITIAN TECH CO LTD

Processing method of natural preservative sauced beef

PendingCN110521943AFull of flavorLong storage timeFood preservationFood ultrasonic treatmentMeat tendernessEssence oil

The invention discloses a processing method of natural preservative sauced beef. The processing method comprises the following steps: (1) decontaminating and cleaning raw beef; (2) pretreating raw meat; (3) injecting and pickling; (4) tumbling; (5) marinating; and (6) air-drying, vacuum-packaging and sterilizing. The sauced beef is prepared on the basis of traditional preparation; pretreating is carried out the raw material meat with calcium chloride; the meat tenderness is improved, a compound injection is used; natural preservative components such as cinnamon essential oil are added; the seasoning liquid is used for enhancing the taste; the beef is tasteful; an ideal preservative and fresh-keeping effect is achieved; meanwhile, traditional processing procedures are optimized, processingtechnological parameters are defined, the product safety is improved, antiseptic treatment and vacuum packaging sterilization are matched, the shelf life and stability of the product can be effectively improved, the storage time of the sauced beef is prolonged, the production benefits of the sauced beef are comprehensively improved, and good application prospects are achieved.

Owner:ANHUI HENGSHENG IND

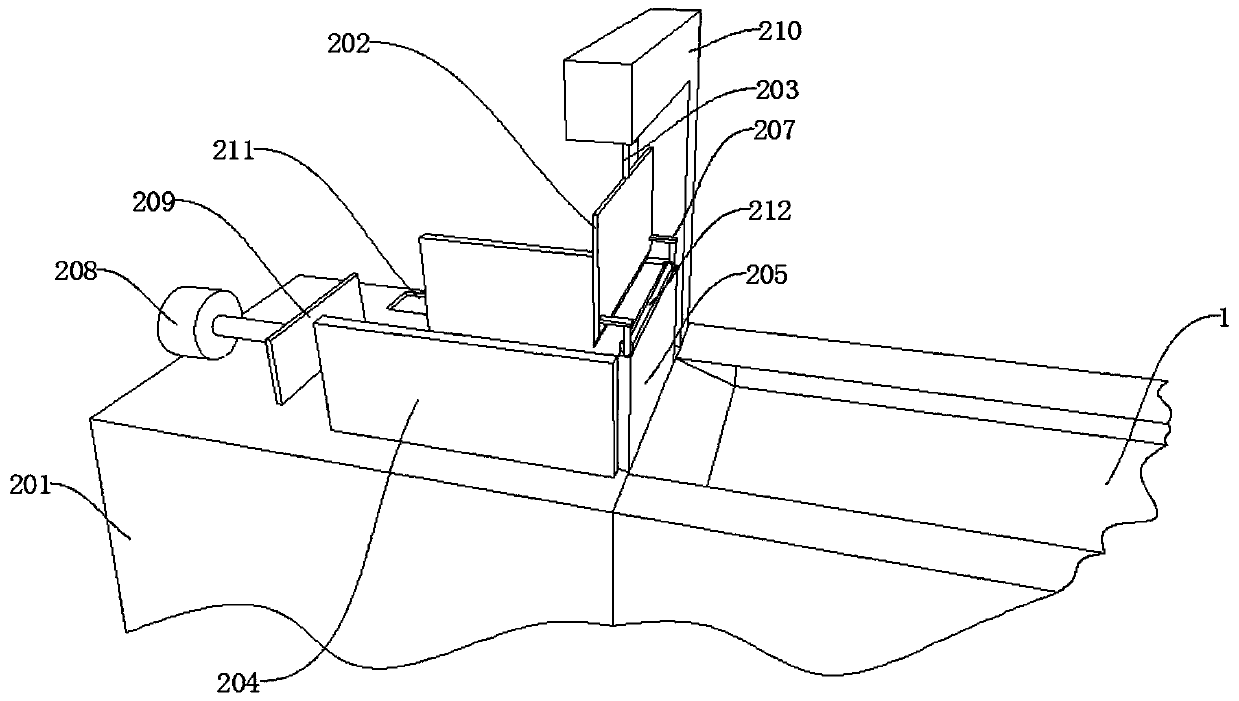

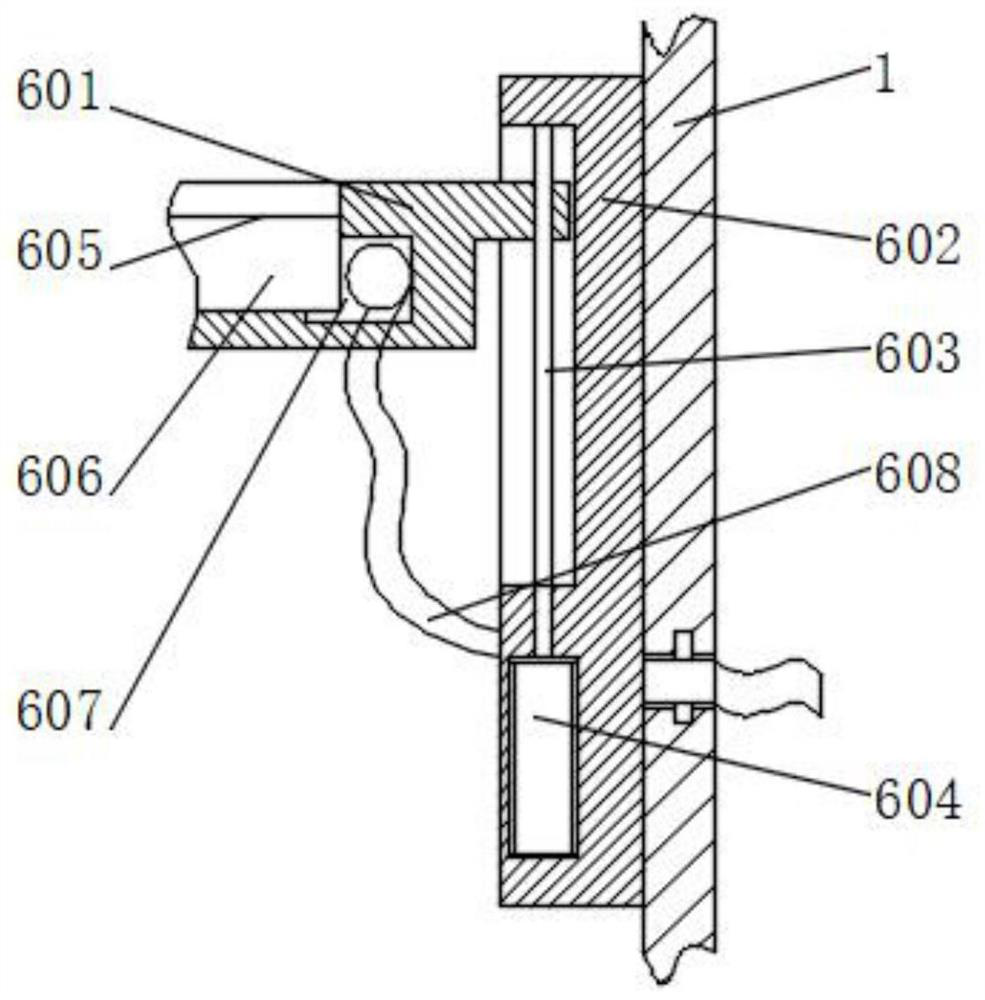

Raw beef cleaning device for making beef jerky

InactiveCN112425635AReduce decreaseResidue reductionMeat processing devicesRaw beefProcess engineering

The invention discloses a raw beef cleaning device for making beef jerky. The device comprises a cleaning water tank and supporting legs, the cleaning water tank is located above the supporting legs,a conveyor belt net is arranged in the cleaning water tank, a vibration device is arranged in one end of the cleaning water tank and located below the conveyor belt net, the vibration device makes contact with the lower surface of the conveyor belt net, and two cleaning structures are arranged in the cleaning water tank and located above the conveyor belt net. The raw beef cleaning device for making beef jerky belongs to the field of making of beef jerky, can enable floating oil in the conveyor belt net to flow out from a storage tank and an output pipe, reduces the floating oil in the conveyor belt net, enables beef on a lifting plate to be in contact with a cleaning brush through a telescopic electric push rod, and thus cleaning the beef. Compared with manual cleaning, the device is convenient, the beef left on the conveyor belt net is cleaned, the beef left on the conveyor belt net is reduced, and the beef cleaning device is practical.

Owner:山东鲁拓畜产品有限公司

Production process for spicy beef jerky

The invention discloses a production process for spicy beef jerky. The production process comprises the following steps of: unfreezing raw beef, cutting the raw beef, boiling or marinating, frying, adding seasonings, performing vacuum packaging, and storing. The production process is characterized in that added spices in the seasoning adding process are prepared from the following raw materials in parts by weight: 20-25 parts of peppers, 30-35 parts of anise, 30-35 parts of bay leaves, 15-20 parts of hot peppers, 5-8 parts of dry ginger, 5-10 parts of gardenia jasminoides, 5-10 parts of liquorice, 5-10 parts of radix curcumae longae, 5-10 parts of hawthorns, 3-5 parts of alpinia katsumadai, 3-5 parts of radix angelicae, 3-5 parts of scutellaria baicalensis and 3-5 parts of honeysuckle. According to the production process, the raw materials can be used for ensuring that the beef jerky does not easily go bad in the quality guarantee period, a preservative does not need to be additionally added, the produced spicy beef jerky cannot be swelled in the storage period, and the bacterial colony indexes meet the specification.

Owner:蒋健

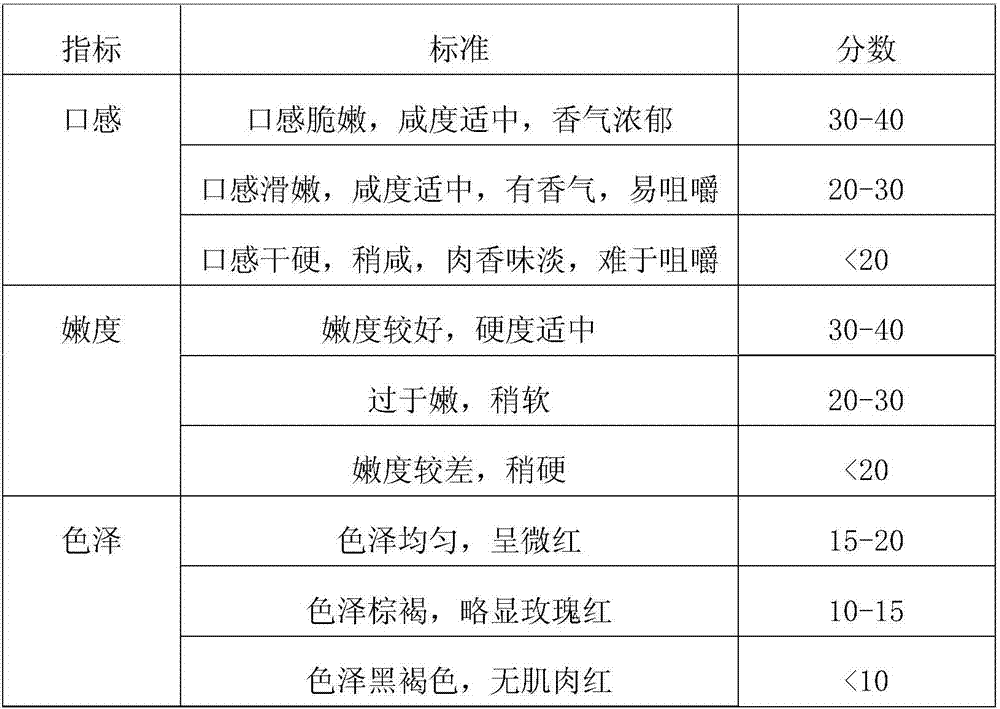

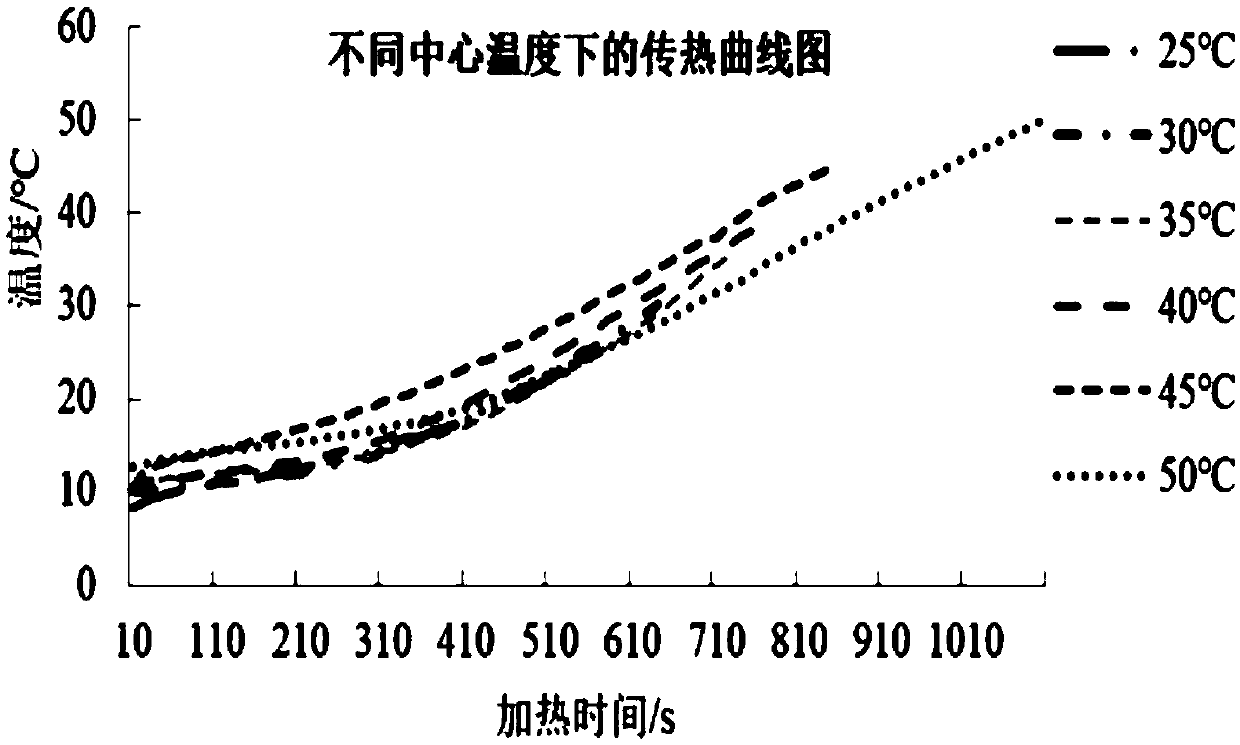

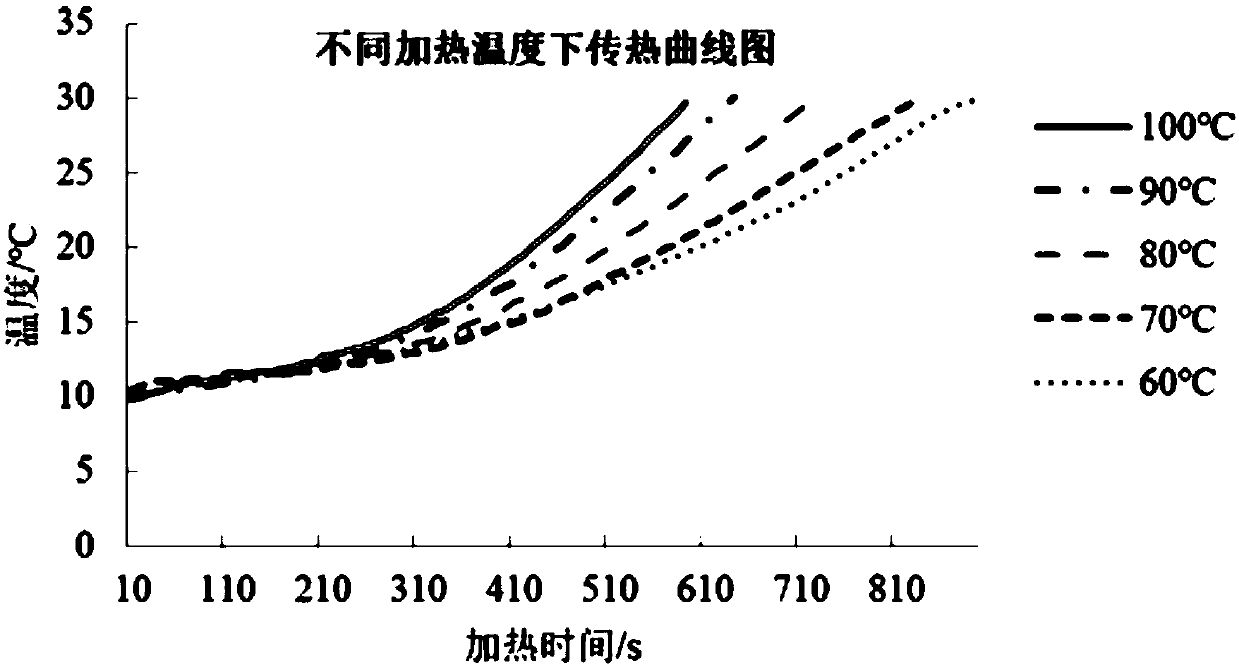

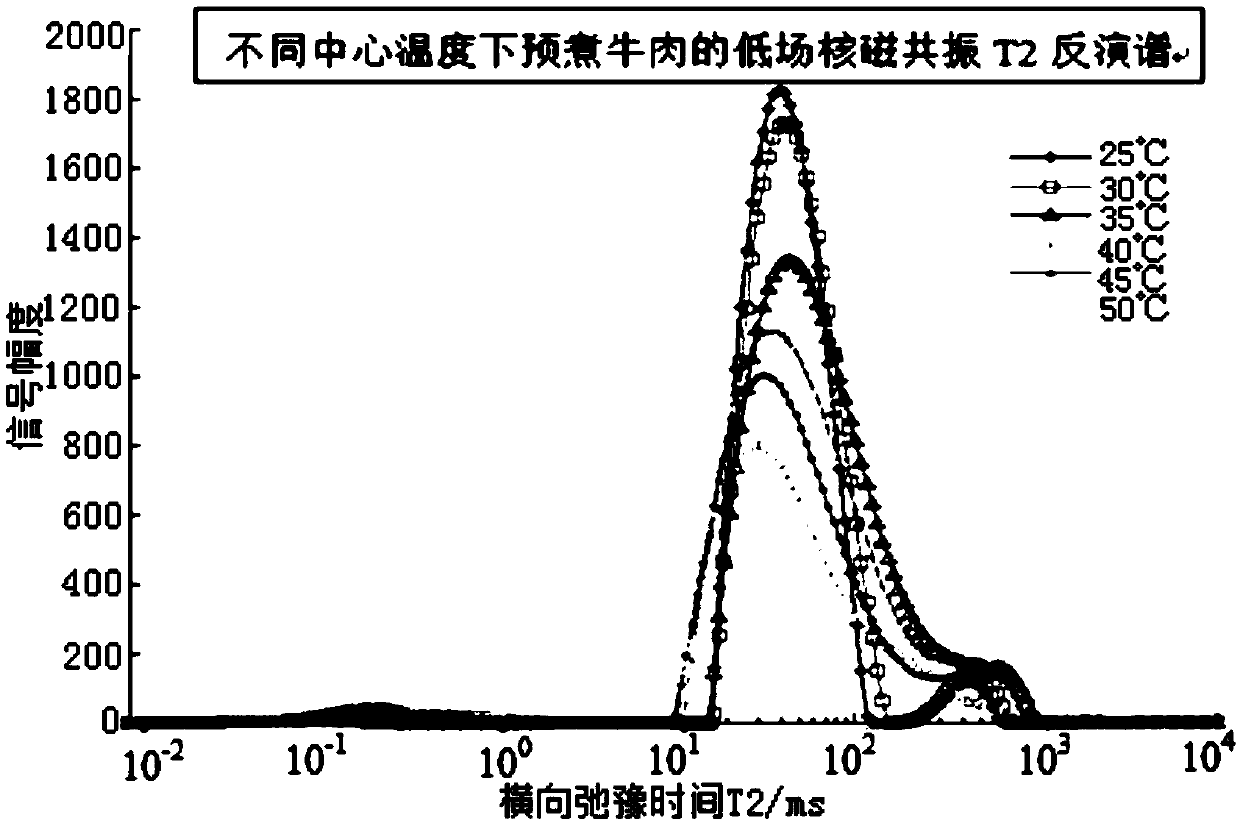

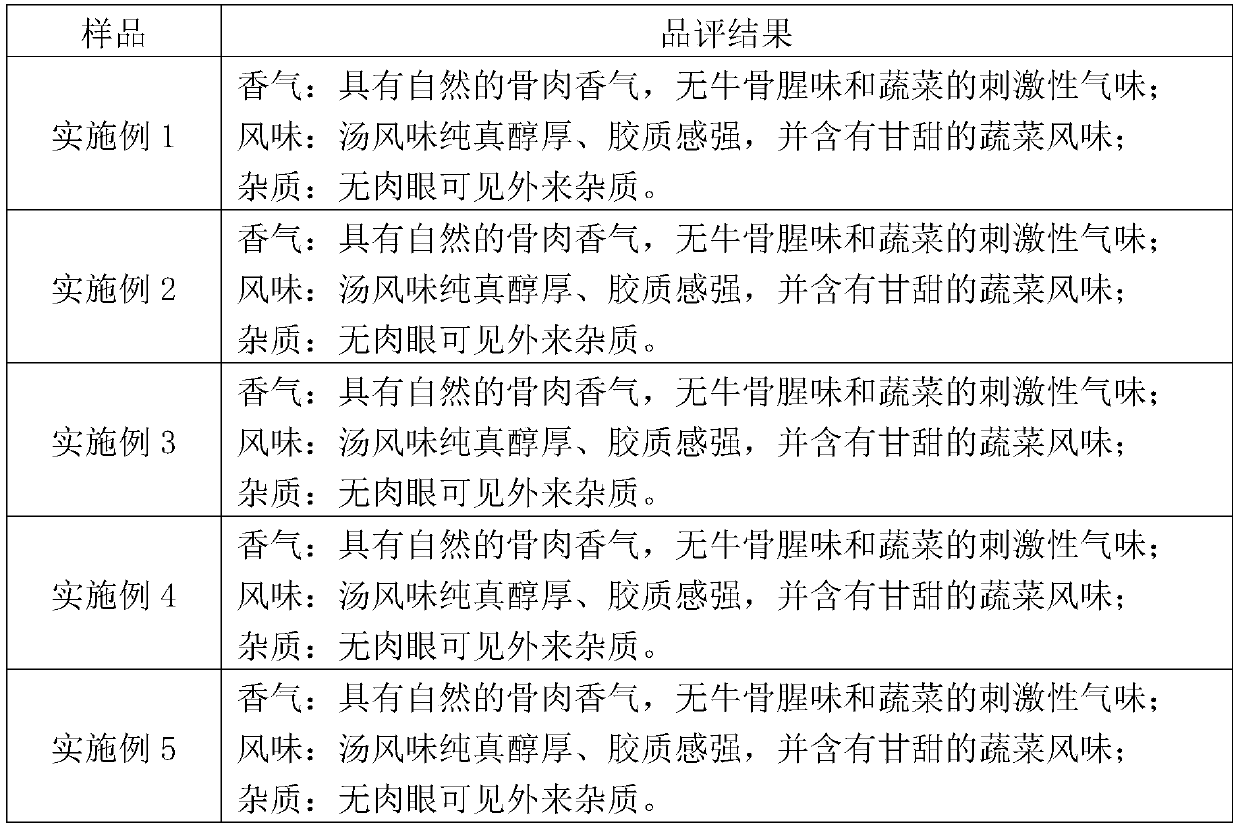

Optimizing method for conditioning beef product pre-cooking process

ActiveCN109673958ABreaking down the technical barriers of precookingReduce the risk of importingData processing applicationsDesign optimisation/simulationWater bathsSurface moisture

The invention discloses an optimizing method for a conditioning beef product pre-cooking process. The optimizing method comprises the following steps: unfreezing beef blocks in a 25-DEG C ice bath, absorbing surface water by water absorbing paper when centre temperature is 10 DEG C, and weighing; putting the beef with the centre temperature of about 10 DEG C into a 90-DEGC water-bath pot, recording temperature changes, immediately taking out when the centre temperatures are separately 25 DEG C, 30 DEG C, 35 DEG C, 40 DEG C, 45 DEG C and 50 DEG C, and cooling; using the water absorbing paper toabsorb surface water, and weighing M2; measuring shearing force and a water distribution state of a pre-cooked meat sample; and utilizing a differential type scanning calorimetric method to measure the degeneration degree of protein at different depth of the pre-cooked meat sample. The pre-cooking optimal process performs temperature treatment on beef according to different procedures, so that aconditioning pre-prepared beef product which can be independently sold and is suitable for secondary processing is obtained, and the technical barrier of raw beef pre-cooking is broken through; and moreover, international trade possibility is increased, and the raw beef import risk is reduced.

Owner:HENAN AGRICULTURAL UNIVERSITY

Process for producing beef and tendon composite food

The invention relates to a production process of a food, in particular to a process for producing a tendon flower beef food adopting beef and ligaments as raw materials. The production process comprises the following three steps: the first step: (1) soaking ligaments in clean water; (2) boiling the ligaments in clean boiling water; taking out; pickling in plant spices and sodium nitrite; (3) boiling the ligaments in clean boiling water; taking out; adding common salt, seafood sauce, soy sauce and sugar to boil again; and (4) putting the boiled ligaments and edible vegetable oil in a roller kneading machine to uniformly stir; the second step: (1) firstly, soaking raw beef; (2) boiling in clean boiling water; (3) removing dirt, blood splashes, fat and tendon films; and then, slicing; the third step: (1) attaching the alternative tendons and the beef according to a certain proportion; (2) vacuumizing; bagging and sealing; (3) sterilizing at high temperature and high pressure; and (4) trimming, forming, bagging and cooling. The invention has the advantage that beef and ligaments are made into a tasty beef and tendon composite food which fills a food gap and is easy to store and popularin the old and the young.

Owner:河南省金牛足食品有限公司

Making method of instant beef soup sauce packet

InactiveCN106983127ANo change in nutritional valueDoes not change the tasteFood preservationMonosodium glutamateHydrolysate

The invention discloses a making method of an instant beef soup sauce packet, comprising the steps of chopping raw beef, adding bromelain and five-spice salt water in the chopped beef, curing, adding transglutaminase solution, rubbing, allowing standing at room temperature, heat-insulating, heating for enzyme deactivation, cooling to room temperature, steaming in a steaming room for a period of time, and cooling for use; adding washed bovine bone into water, adding a spice pack, spring onion and ginger, boiling on slow fire, removing scum, boiling with medium heat, boiling with slow fire until certain soup weight is obtained, scooping out solid in the soup, adding tallow and monosodium glutamate to the soup, and cooling for use; mixing beef extract and the concentrated soup in a certain mass ratio, enzymatically hydrolyzing with glucolase, packing each part of the hydrolysate of certain mass into a sealed bag, and drying and sterilizing in a microwave drying sterilizer at certain temperature for a period of time to obtain the sauce packet. The microwave sterilizing technique used herein is short in sterilizing time and high in speed, the equipment is simple, and controlling is facilitated.

Owner:HUAINAN YISHENG FOOD

Raw beef soup, processing method of raw beef soup and beef cooking bag prepared by using raw beef soup

InactiveCN110771842AThe aroma of flesh and blood is naturalPure and mellow flavorFood scienceBiotechnologyRaw beef

The invention discloses a raw beef soup, a processing method of the raw beef soup and a beef cooking bag prepared by using the raw beef soup. The processing method of the raw beef soup comprises the steps that refrigerated beef bone is unfrozen and broken into beef bone pieces, and the beef bone pieces are cleaned for standby application; then pretreated beef bone pieces are put into a pressure cooker, water, radish pieces, ginger and green Chinese onions are added, and the mixture is cooked under high pressure at the pressure of 0.025-0.23 MPa and a temperature of 105-140 DEG C; and then a lid of the pressure cooker is opened, beef is added, and then the mixture is continuously cooked under normal pressure and at a temperature of 95-105 DEG C to obtain crude beef broth and cooked beef; the obtained cooked beef is removed, and the obtained crude beef broth is filtered and separated to obtain the raw beef soup. The processing method is simple and safe to operate. The raw beef soup prepared by the processing method has the characteristics of natural bone aroma, no fishy smell, no pungent odor of vegetables, pure and mellow soup flavor, sweet vegetable flavor, strong texture, high nutrient content and the like.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

Osmanthus tea flavored dried beef and processing process thereof

The invention discloses osmanthus tea flavored dried beef and a processing process thereof and belongs to the field of foods. The osmanthus tea flavored dried beef is composed of the following raw materials: 11kg of fresh beef, 260g of table salt, 530g of white sugar, 200g of osmanthus tea powder, 30g of ginger, 130g of white spirit, 55g of monosodium glutamate, 17g of cinnamon, 26g of star anise, 17g of zanthoxylum bungeanum maxim, 13g of syzygium aromaticum, 80g of chili sauce and 70g of red pepper flour. All the raw materials are further processed to obtain the final product. The osmanthus tea flavored dried beef has the beneficial effects that the problem that an existing beef processing process can not easily remove the smell of raw beef and thus the beef is not easily accepted by some people is solved, and the previous beef with the smell can be processed into the dried beef with good color, aroma and taste.

Owner:马国丰

Salted and fermented soya paste beef and its production method

A method for cooking the soya paste-beef includes such steps as immersing raw beef in water, brushing, removing bone, cutting to become blocks whose thickness is not greater than 30 mm, mixing the beef blocks with water and salted and fermented soya paste, boiling for one hour, adding flavouring, and stewing while adding meat soup every one hour 2-4 times. Its advantages are strong paste flavour, agreeable fat, and soft mass.

Owner:TIANJIN CHINESE & BRITISH NANOMETER TECH DEV

Bone-strengthening and stomach-warming soup

InactiveCN106562364APromote leachingFacilitated releaseNatural extract food ingredientsFood ingredient functionsSpleenFermentation

The invention mainly relates to the technical field of food processing, and discloses a bone-strengthening and stomach-warming soup, which is prepared from the following raw materials: raw beef, beef bone, anise, black pepper, cortex cinnamomi, pericarpium citri reticulatae, foeniculum vulgare, rhizoma kaempferiae, fructus tsaoko, herb of rose pelargonium, radix angelicae dahurioae, fructus amomi, murraya paniculata, alpinia katsumadai hayata, Chinese cumin seed, rhizoma atractylodis macrocephalae, lycoperdon pusillum, ficus carica, toona sinensis seedlings, bruised ginger, chopped green onion, shredded kelp, small gluten cubes, rock candy, iodised salt and lactic acid bacteria; the bone-strengthening and stomach-warming soup is delicious and intense in flavor, and is added with various Chinese herbal medicines for resisting germs and insects, so that the shelf life is prolonged; after fermentation through the lactic acid bacteria;, effective constituents are promoted to be leached so as to increase the fragrance and be antibacterial and anti-inflammation, so that the human immunity is enhanced, the metabolism is promoted, the stomach is warmed, the spleen is replenished, and the heart and cerebral vessels are protected; the beef and the beef bone are added, and secondary fermentation is carried out, so that the fragrance is increased, the beef is fine and tender, the calcium release of the beef bone is accelerated, growth and development are promoted, and bones are strengthened; and the bone-strengthening and stomach-warming soup is prevented from causing adverse effect on the heart and cerebral vessels, and is convenient to carry and eat, the sales volume is improved by 9.3 percent, and the economic income is improved by 11.4 percent.

Owner:李科羽

Production process for mint-flavor beef jerky

InactiveCN103431432AHas a bactericidal effectNot perishableFood preparationMint FlavorGLYCYRRHIZA EXTRACT

The invention discloses a production process for mint-flavor beef jerky. The production process comprises the following steps: unfreezing raw beef, cutting the raw beef, boiling or marinating, frying, adding seasonings, performing vacuum packaging, and storing. The production process is characterized in that added spices in the seasoning adding process comprise the following raw materials in parts by weight: 30-35 parts of mint, 20-25 parts of anise, 20-25 parts of bay leaves, 5-10 parts of sand ginger, 5-10 parts of liquorice, 3-5 parts of gardenia jasminoides, 3-5 parts of radix angelicae, 3-5 parts of radix curcumae longae, 3-5 parts scutellaria baicalensis and 3-5 parts of honeysuckle. According to the production process, the raw materials can be used for ensuring that the beef jerky does not easily go bad in the quality guarantee period, a preservative does not need to be additionally added, the produced mint-flavor beef jerky cannot be swelled in the storage period, and the bacterial colony indexes meet the specification.

Owner:蒋健

Preparation method of beef and corn vermicelli

The invention discloses a preparation method of beef and corn vermicelli. The preparation method comprises the following steps: (1) getting raw materials ready, specifically, preparing corn starch, water, egg white, raw beef and salt according to a weight ratio; (2) carrying out pretreatment, specifically, cooking the raw beef thoroughly, removing 90% of water in the cooked beef, grinding the cooked beef into powder, and then drying the beef powder; (3) mixing, specifically, firstly adding the egg white and the salt into the water and evenly mixing, then adding the beef powder and the corn starch into the water and evenly mixing so as to finally obtain a dough; (4) forming vermicelli, specifically, putting the dough into a vermicelli extruding machine, extruding the vermicelli with a fixed length, putting the extruded vermicelli into a boiling pot and cooking for 3-6min, fishing out the cooked vermicelli from the pot and drying in the air, and finally, packaging the vermicelli by using plastic bags. The method mainly has the beneficial effects that 1, the connection closeness of the corn starch can be improved, so that the produced vermicelli has better toughness; 2, the corn vermicelli has fragrance and higher nutritional and health care values, so that the aim of prompting the appetitive of people is achieved.

Owner:邓勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com