Raw beef soup, processing method of raw beef soup and beef cooking bag prepared by using raw beef soup

A processing method and beef soup technology, which are applied in the field of beef cooking bags, can solve the problems of fishy beef bones, insufficient umami taste of natural beef soup, unable to obtain the original taste, etc., and achieve pure and mellow soup flavor and excellent gelatinous texture. and the effect of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

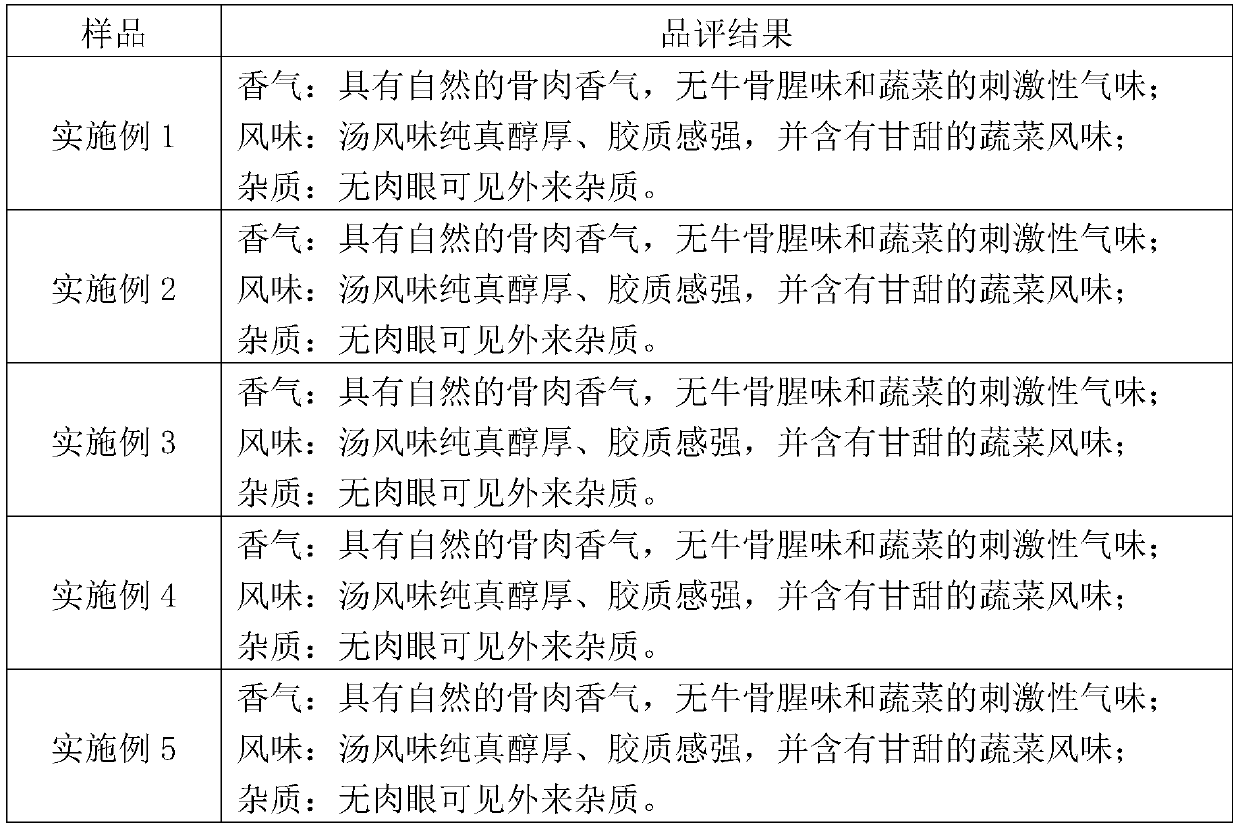

Examples

Embodiment 1

[0028] Including the following preparation steps:

[0029] Step 1) pretreatment: thaw the refrigerated bovine bone and put it into the bone crusher for crushing to obtain bovine bone blocks with a block diameter of 8 cm or less; then clean the bovine bone blocks and set aside;

[0030] Thaw the refrigerated beef and clean it, set aside;

[0031] Step 2) Make soup: put 1400g of the above-mentioned pretreated beef bones into a pressure cooker, add 7200g of water, 200g of radish pieces, 100g of ginger and 100g of scallions, and then cook under a pressure of 0.1 to 0.23 Under the conditions of MPa and temperature of 130-135°C, high-pressure cooking for 60 minutes;

[0032] Then open the lid of the pressure cooker to release the pressure, and add 1000g of beef, and then continue to cook for 4 hours under normal pressure at a temperature of 95 to 100°C; thick beef broth and cooked beef are obtained;

[0033] Step 3) Filtration and separation: after the gained cooked beef is pulled...

Embodiment 2

[0036] Including the following processing steps:

[0037] Step 1) Pretreatment: thaw the refrigerated beef bone and put it into a bone crusher for crushing to obtain a beef bone block with a diameter of less than 8cm; then clean the beef bone block and put it into boiling water for 5-5 After 10 minutes, the blood after blanching can be drained, or filtered and poured into the pressure cooker in step 2); set aside;

[0038] Thaw the refrigerated beef and clean it, then put it into boiling water for 5-10 minutes, the blood after blanching can be drained, or filtered and poured into the pressure cooker in step 2); set aside;

[0039] Step 2) Make soup: put 1800g of the above-mentioned pretreated beef bones into a pressure cooker, add 7199.8g of water, 400g of radish pieces, 50g of ginger, 50g of green onions, 50g of onions, and 50g of peppers , 0.1g of orange peel and 0.1g of Angelica dahurica, and then high-pressure cooking for 100min at a pressure of 0.1-0.23MPa and a temperat...

Embodiment 3

[0045] Including the following processing steps:

[0046] Step 1) pretreatment: thaw the refrigerated bovine bone and put it into the bone crusher for crushing to obtain bovine bone blocks with a block diameter of 8 cm or less; then clean the bovine bone blocks and set aside;

[0047] Thaw the refrigerated beef and clean it, set aside;

[0048]Step 2) make soup: put 1200g of the above-mentioned pretreated beef bones into a pressure cooker, add 7500g of water, 100g of radish pieces, 50g of ginger, 50g of green onions, 50g of onions and 50g of peppers, Then, under the conditions of pressure of 0.05-0.1MPa and temperature of 125-130°C, high-pressure cooking for 90 minutes;

[0049] Then open the lid of the pressure cooker to release the pressure, and add 700g of beef, 100g of spices and 200g of butter, and then continue to boil for 8 hours at a temperature of 95 to 100°C under normal pressure; liquid and cooked beef;

[0050] Step 3) Filtration and separation: after the gained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Block diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com