Patents

Literature

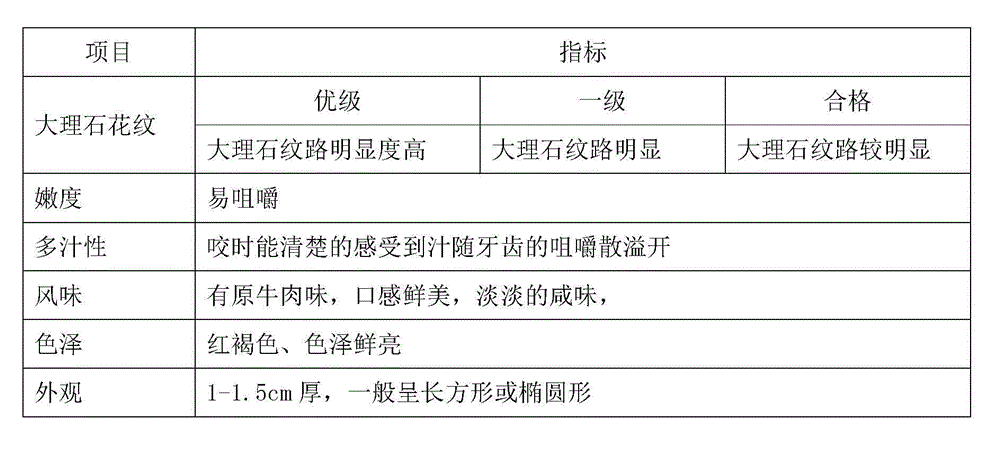

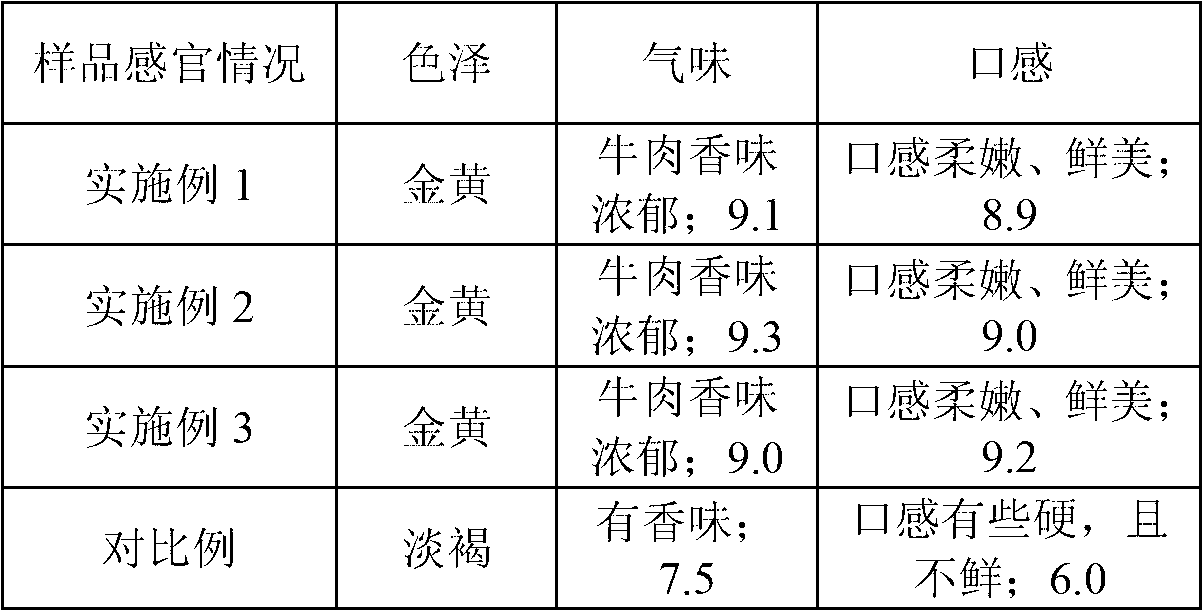

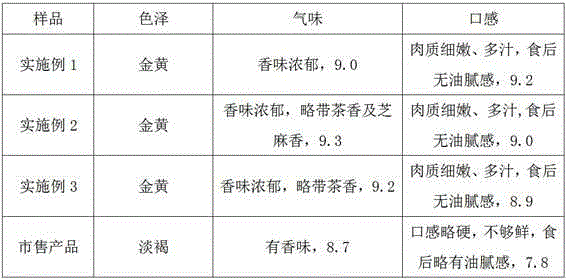

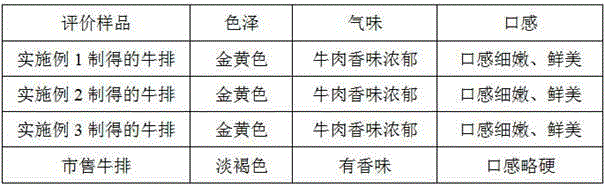

221 results about "Beef steak" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

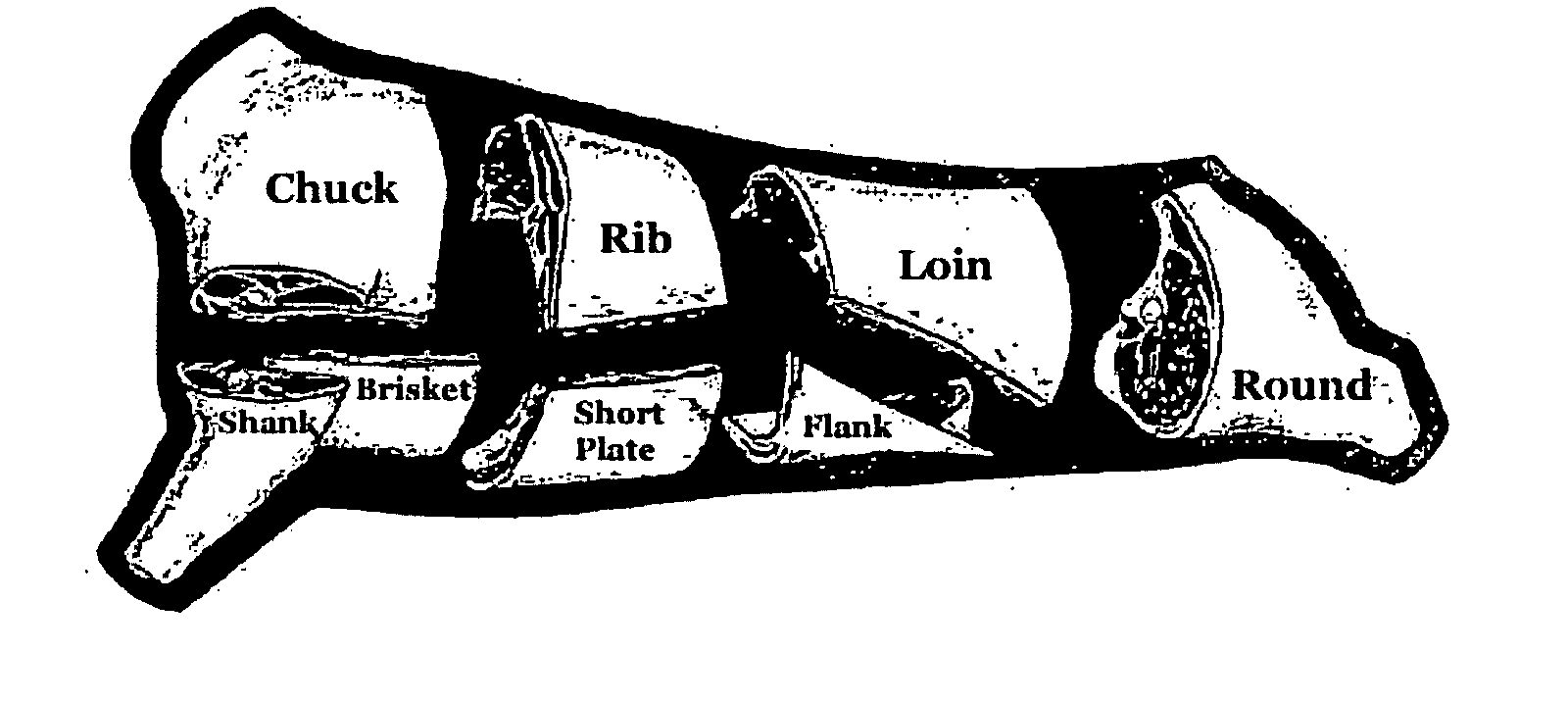

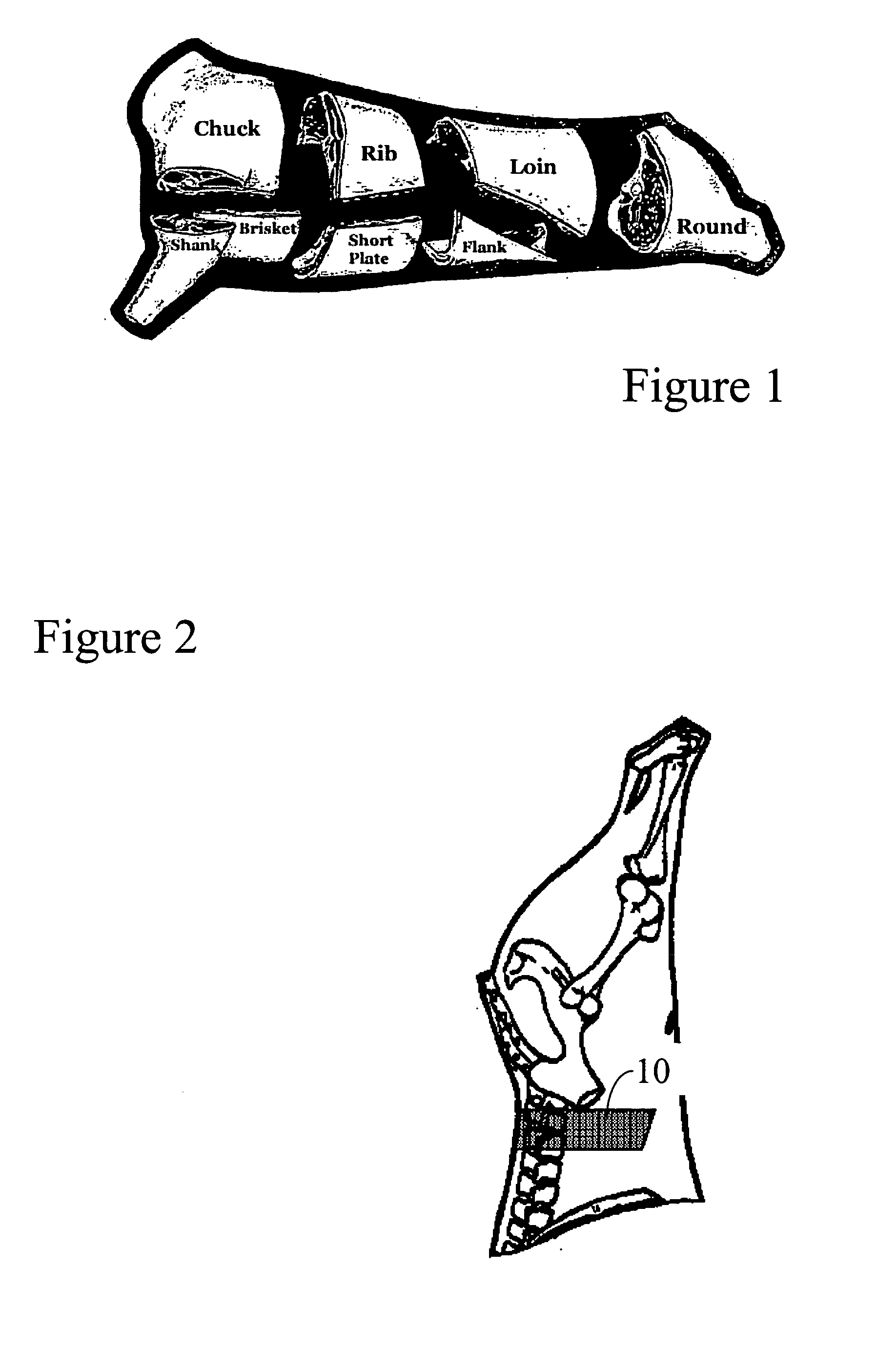

A beef steak is a flat cut of beef, with parallel faces spaced to a thickness of 1 to 5 centimetres (¹⁄₂ to 2 in), usually cut perpendicular to the muscle fibers, with a raw mass in common restaurant service ranging from 120 to 600 grams (4 to 21 oz). Beef steaks are usually grilled, pan fried, or broiled. The more tender cuts from the loin and rib are cooked quickly, using dry heat, and served whole. Less tender cuts from the chuck or round are cooked with moist heat or are mechanically tenderized (cf. cube steak).

Preparation method for edible fungus flavor food

The invention discloses a preparation method for an edible fungus flavor food. The edible fungus can be any one from edible agaricus bisporus, straw mushrooms, oyster mushrooms, shii-take, needle mushrooms, pleurotus nebrodensis, pleurotus eryngii, agrocybe aegerita, hypsizigus marmoreus, agaricus pratensis schaeff, spring mushrooms, stropharia rugoso-annulata, sparassis crispa, macrolepiota procera, tremellodon gelatinosum, black trumpet mushrooms, hericium erinaceus, pholiota nameko, lepista personata, mitake mushrooms, lactarius hatsudake, golden oyster mushrooms, pholiota adiposa, cantharellus cibarius, termitomyces albuminosus, tricholoma giganteum, pleurotus citrinopileatus, calocybe gambosa, truffle, amillariella mellea, fungus suillus, beef-steak fungus, lactarius deliciosus, tricholoma matsutake, agaricus bitorquis, pleurotus pulmonarius, toadstool and russula vinosa, and after treatment, the edible fungus is steeped into a steeping liquor prepared from red wine vinasse, high quality dry red wine and a flavouring agent in a vacuum and normal temperature and normal pressure combined condition, so as to obtain the flavor food; the edible fungus flavor food for leisure is prepared through oil-bath dewatering; a flavor food flavor puffed food is obtained through a swelling process, so as to meet consumers' hobbies and requirements.

Owner:徐州绿之野生物食品有限公司

Preparation method of western yak steak

Owner:SHANGHAI FOOD RES INST +1

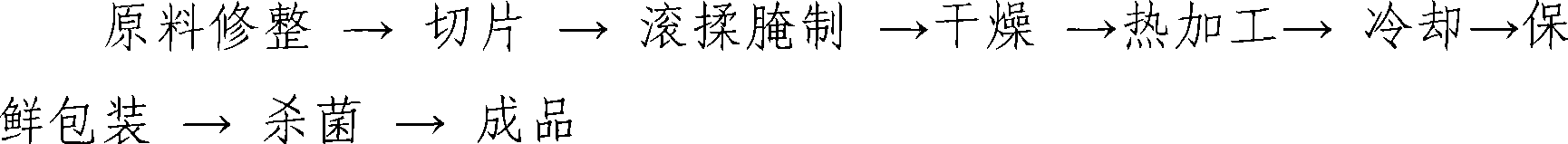

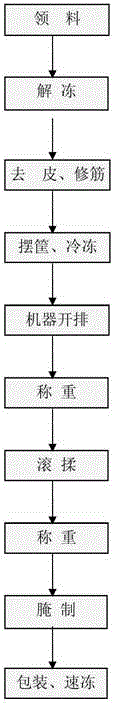

Conditioning steak processing process

ActiveCN103844275ARealize industrializationRealize standardized productionFood preparationRaw materialChemistry

The invention discloses a conditioning steak processing process, which comprises the following steps of removing contaminants, extravasated blood and thick tendon tissues from rear thick flank, cuboidless steak rump and silverside steak raw materials, preparing pickling fluid and black pepper pickling fluid, injecting the pickling fluid, pickling the raw materials after tumbling by the black pepper pickling fluid, and performing filling, standing, quick-freezing, slicing and vacuum packaging. According to the conditioning steak processing process, conditioning steaks are industrially produced in a standard way, the quality stability is improved, and the taste consistency of the conditioning steaks is ensured.

Owner:修武县伊赛牛肉有限公司

Beefsteak processing method

The invention relates to a beefsteak processing method and belongs to the technical field of food processing. The beefsteak processing method belongs to the improvement on the basis of the prior art and mainly comprises work procedures of beefsteak raw material cooling and acid discharge, biologic tenderization, rolling kneading tenderization, cutting package and finished product quality testing, wherein a, the biologic tenderization work procedure comprises the steps that through being metered by the meat weight, 0.4 percent of biologic tenderization agents are prepared into 8 percent water solution to be uniformly injected into meat blocks, and the biologic tenderization agents are prepared from 10 percent of papain, 30 percent of glucose, 10 percent of monosodium glutamate, 10 percent of table salt, 35 percent of starch and 5 percent of phosphate; b, the rolling kneading time of the beefsteak raw material meat in a rolling kneading machine is 30 minutes, the rotating speed is 30 to 35 turns per minute, and the temperature is 4 to 8 DEG C; and c, the thickness of the beefsteak subjected to cutting package is 1 to 1.5cm, the weight of each block is 150+ / - 5 g, and the vacuum packaging is carried out. The method has the advantages that 1, the method is simple and convenient, and the fresh and tender degree of the beefsteak can be improved; 2, the beefsteak eating is convenient, and the beefsteak is particularly suitable for mass consumption; and 3, the standard and industrial production of the beefsteak can be realized.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

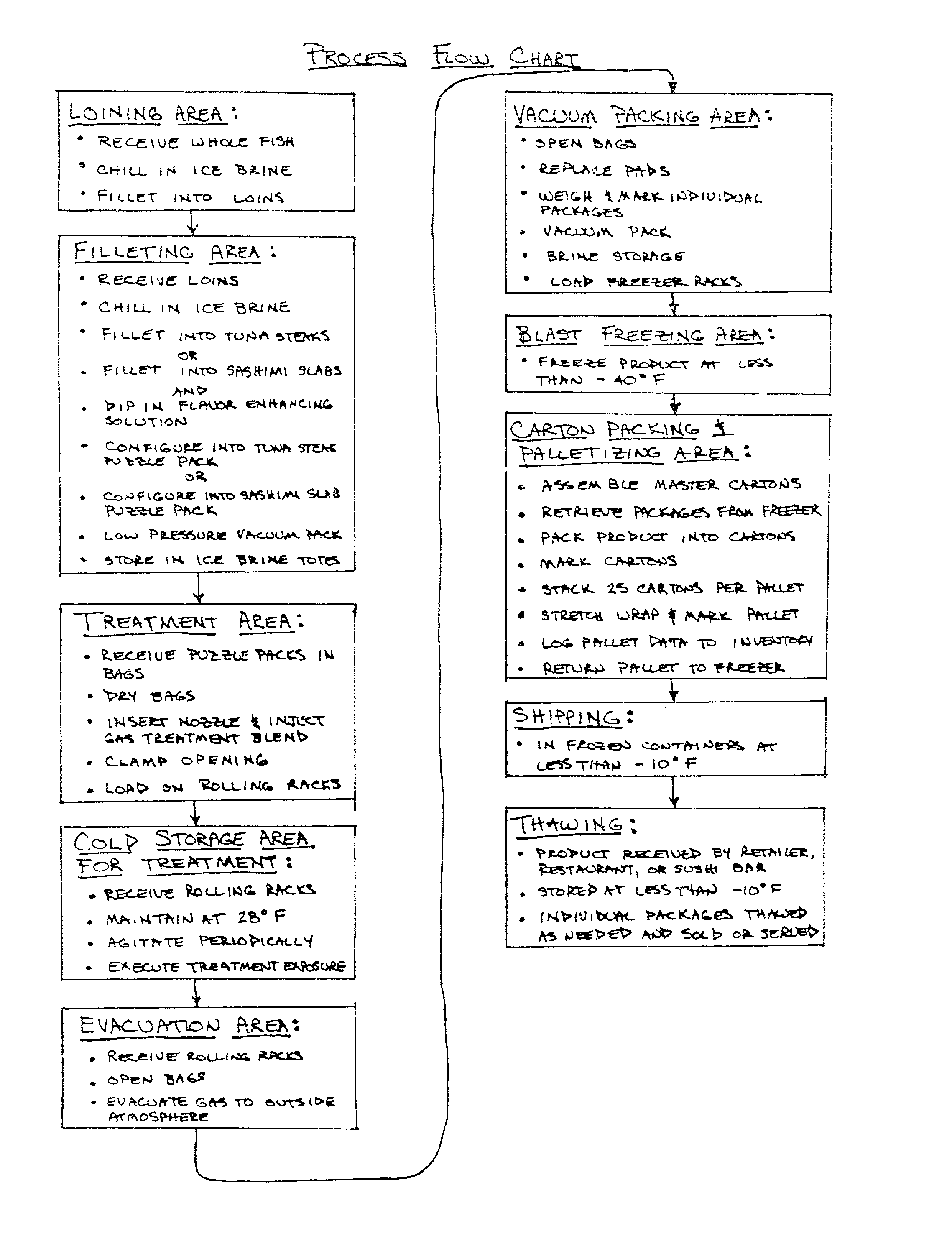

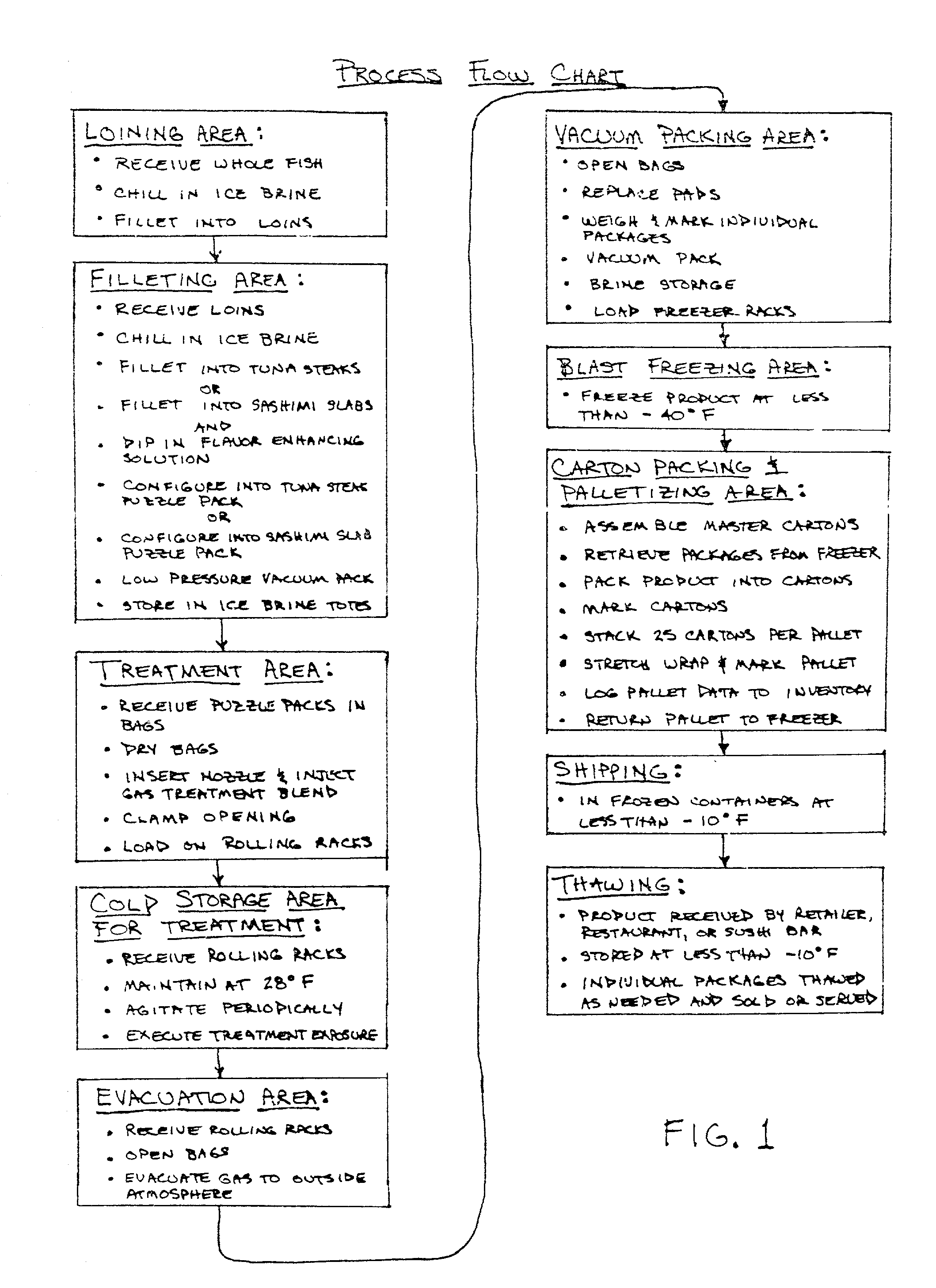

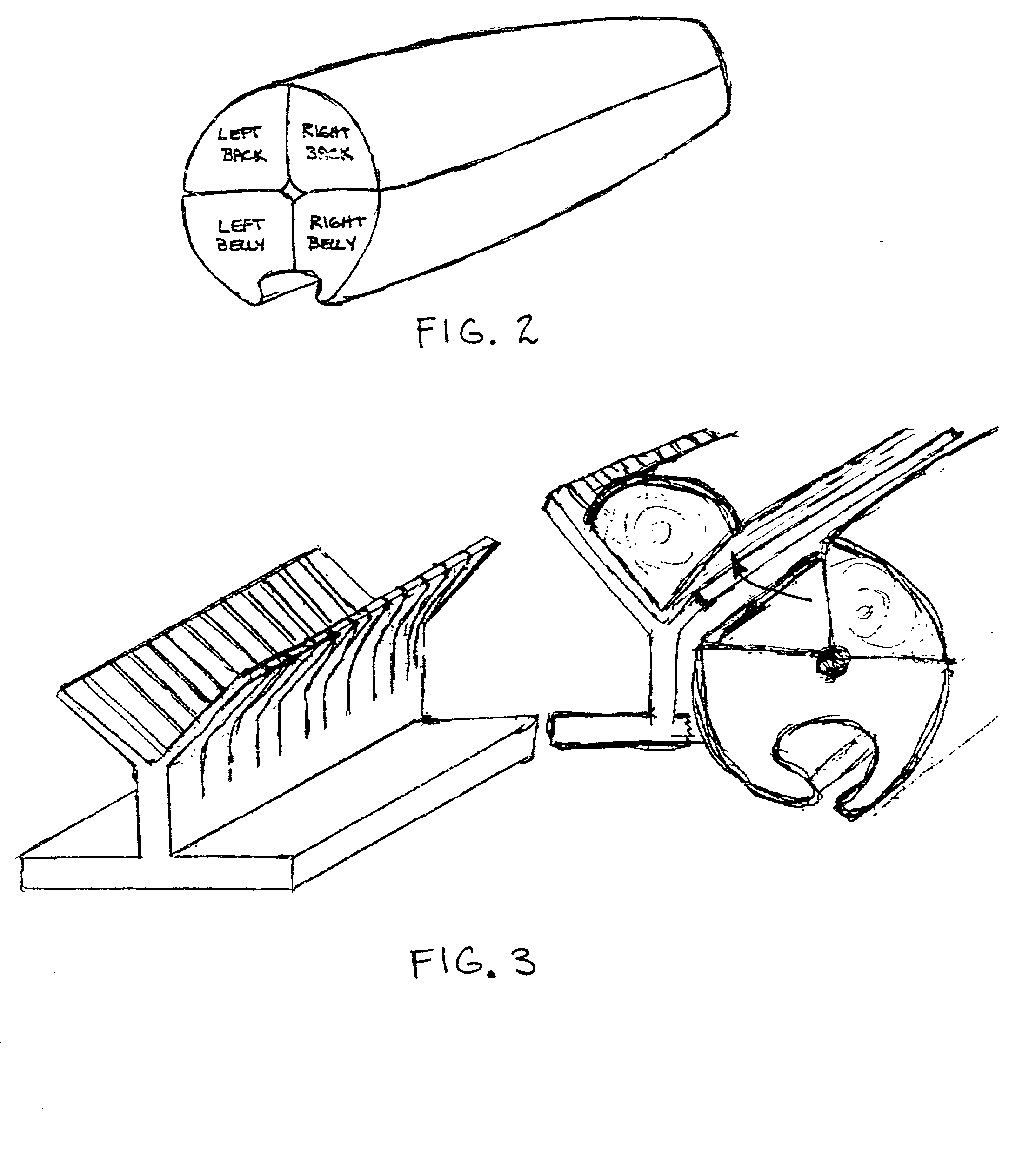

Process for the filleting, treating, packaging, freezing, and thawing of varying types of tuna and other pelagic species

InactiveUS20020012724A1Efficiently filletEffective treatmentReady-for-oven doughsMilk preservationSaline waterVacuum pack

A method of treating fish to maintain freshness after freezing and thawing. A whole fish is chilled and cut into four loins, each with two flat sides forming a corner. The loins are chilled and either sliced cross sectionally to form steaks or sliced parallel to one of the flat sides to form sashimi slabs. If sashimi slabs are formed, the slabs are then preferably dipped in a warm flavor enhancing solution. The steaks or slabs are then sealed in non-permeable bags, preferably in a "puzzle pack" configuration that maximizes density and minimizes interstices. The bag with the steaks or sashimi slabs is then submerged in a brine solution. A treatment gas is then injected into the bag. After a treatment time, the gas is removed and the bag is vacuum packed. The bags are then frozen for shipping and storage. When needed, the bags can be thawed in a brine solution.

Owner:KOWALSKI WILLIAM R

Processing method of beefsteak

The invention provides a processing method of beefsteak. The processing method of the beefsteak comprises the following steps: defrosting, cutting, curing, packaging, vacuum sealing, quick-freezing, binning and cold storaging, wherein ingredients used in the preparation comprise carrots, celery, pimiento, heads of garlic, onions, beef powder, chicken powder, five spice powder, oyster sauce, soy sauce, brandy, potato starch and soybean oil. For every 500 grams of the beefsteak, the ingredients preferably comprises 1.71 grams of beef powder, 2 grams of chicken powder, 0.57 grams of five spice powder, 1.4 2 grams of oyster sauce, 3.28 grams of soy sauce, 1.71 grams of brandy, 5.71 grams of potato starch and 2 grams of soybean oil of the optimized used ingredients. The processing method of the beefsteak is simple, convenient, and capable of greatly improving the freshness and delicacy of the beefsteak and achieving standardized processing.

Owner:FUJIAN SHENG SHI JING DIAN RESTAURANT MANAGEMENT

Processing method of grilled steak

The invention discloses a processing method for grilled steak. The method comprises the following steps of: injecting material water after material sorting, defreezing and trimming, wherein the water injection rate is 20%; standing and curing for 24 hours; quickly freezing, wherein the center temperature of the quickly-frozen steak is -2 DEG C and the surface temperature is -8 DEG C; slicing and grilling, wherein the slice thickness is 18-20 mm, the weight is 200 grams, and the grilling temperature is 140-160 DEG C. The steak grilled by the invention has multiple flavors and tastes fresh, tender and succulent. The invention has the advantages of novel technique, unique effect, being suitable for industrial production, and the like.

Owner:马鞍山雨润食品有限公司 +1

Microwave western-style beefsteak and preparation method thereof

ActiveCN102715541AEasy to manufactureIn line with the rhythm of lifeFood preparationMicrowave ovenRaw beef

The invention discloses a microwave western-style beefsteak and a preparation method thereof. The preparation method comprises the steps of 1) selecting raw beef; 2) unfreezing the raw beef under conditions of temperature being 0-4DEG C and relative humidity being 80-90 percent; 3) salting; 4) shaping; 5) slicing, wherein the thickness of slices is 1.0-1.5cm; 6) placing and frying the slices on a frying pan with temperature being 220DEG C for 2 minutes; and 7) placing and quickly freezing the fried slices at negative 35DEG C for 45 minutes to obtain the microwave western-style beefsteak. The microwave western-style beefsteak which is prepared by adopting the technical scheme is simple and convenient to prepare and is suitable for industrial production, the microwave western-style beefsteak is only required to be heated for 40 seconds through big fire in a microwave oven, the operation is convenient to conduct and the microwave western-style beefsteak is compliant with rhythm of life of modern people. More importantly, the microwave western-style beefsteak provided by the invention is superior to the microwave beefsteak in the prior art in the aspects of tastes, flavor and color.

Owner:上海瑞轩食品有限公司

Low-cholesterol beefsteak and preparing method thereof

The invention discloses low-cholesterol beefsteak and a preparing method thereof. The preparing method includes the steps that raw material unfreezing, filling, rolling, kneading, sousing, breading, bag filling, quick-freezing, sliding and packaging are performed on frozen beef to obtain the low-cholesterol beefsteak. Various ingredients such as haw juice and kelp extract are used for sousing the beef, the beefsteak can be eaten after being fried or heated through microwaves, and is delicate, succulent and easy to digest, the cholesterol in the body will not be increased after people eat the beefsteak, and people with poor intestines and stomach digestive functions and high cholesterol can eat the beefsteak. The preparing method is high in standardization degree and suitable for industrial production of black pepper beefsteak and filet beefsteak.

Owner:FUJIAN JUYUAN FOOD CO LTD

Low temperature curing beefsteak and processing method

The invention discloses a low temperature curing beefsteak and a processing method. Beef is unfrozen and cut into beefsteak, then pickling, seasoning, low-temperature curing and packaging are carried out, and low temperature curing beefsteak is prepared. The beefsteak prepared through the method can reserve original color and fragrance of beef and most water in beef furthest, the prepared beefsteak has tender and delicious mouthfeel, nutritional ingredients in beef can be reserved effectively, harmful substances generated from high temperature processing are avoided, the beefsteak can be eaten after simple heating without additional seasoning, which is convenient.

Owner:福建佳客来食品股份有限公司

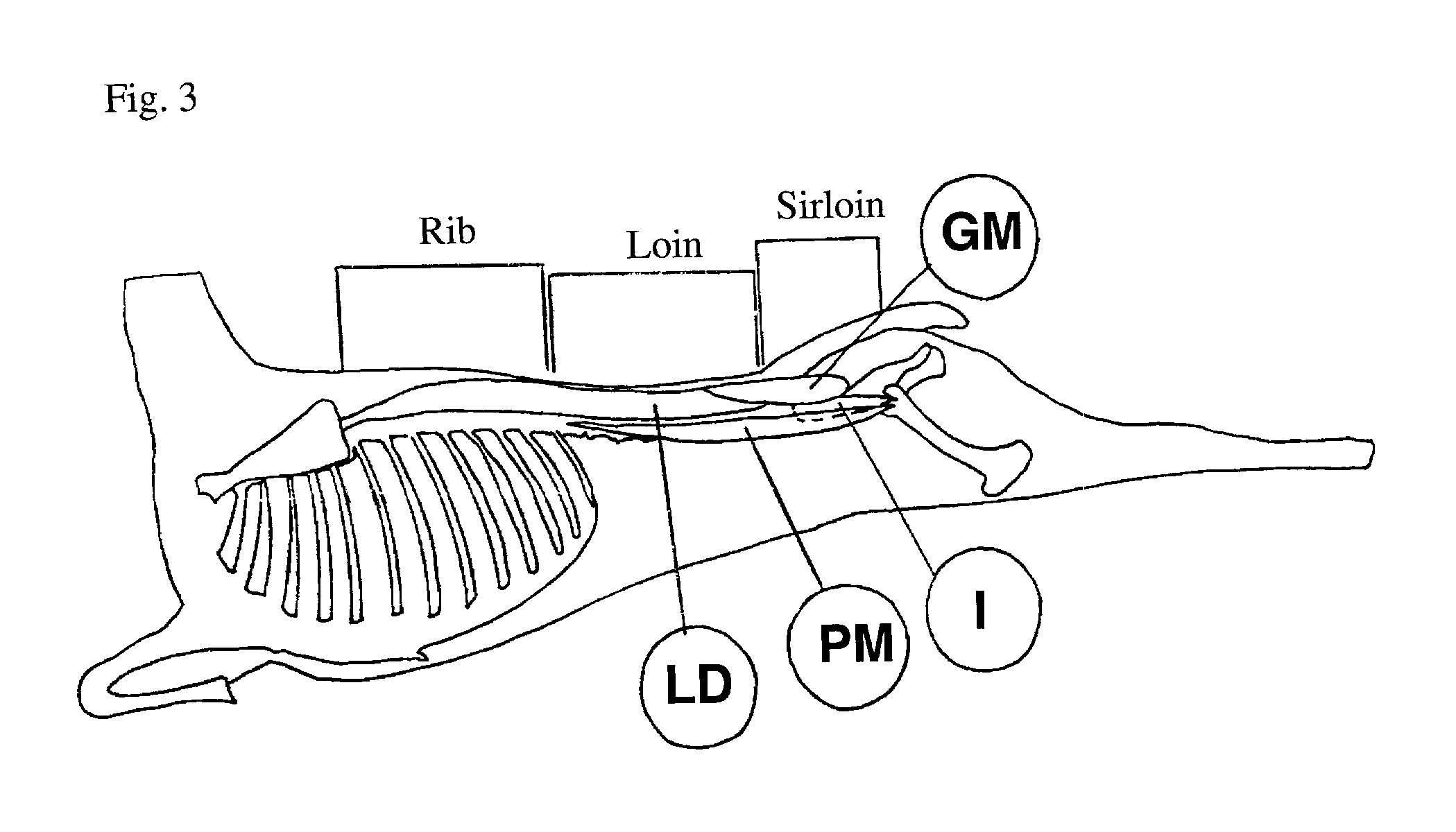

Beef steak cutting and preparation process and products

A tenderloin steak product comprises a tenderloin beef section with at least a portion of attached bone. The steak is essentially a Porterhouse steak from which the top loin portion has been removed. A portion of the bone non-contiguous with the top loin is also preferably removed. The top loin and a portion of the bone can be removed by cutting the bone lengthwise along the long dimension of the tenderloin, to separate the two meat portions.

Owner:STOCKMAN ROBERT

Preparation method of ready-to-eat grilled beef steak

InactiveCN102090644ASimple production processSuitable for industrial productionFood preparationReady to eatFlavor

The invention discloses a preparation method of ready-to-eat grilled beef steak. The process flow comprises the following steps: selecting, mixing and pickling materials; packing, boiling with water, decocting, and cooling; and packing, quick-freezing, boxing and storing in frozen storehouse. The preparation method disclosed by the invention is simple in production process and suitable for industrial production; and the prepared ready-to-eat grilled beef steak has the characteristics of unique flavor and good taste.

Owner:吴玉华

Tomato sauce for beefsteak

The invention discloses tomato sauce for a beefsteak. The tomato sauce contains the following ingredients in parts by weight: 10-20 parts of ketchup, 20-30 parts of soybean sauce, 30-50 parts of water, 0.5-1.5 parts of common salt, 0.5-1.5 parts of white granulated sugar, 0.2-0.4 part of five-spice powder, 0.4-0.8 part of monosodium glutamate and 10-20 parts of oyster sauce. After the beefsteak is subjected to sousing pretreatment by using the tomato sauce for the beefsteak, disclosed by the invention, the prepared beefsteak is high in freshness and tenderness, each to cook, fine in taste and good in flavor, can be used for removing offensive smells, can also be used for carrying out coloring, improving freshness and enhancing the flavor and meanwhile is rich in amino acids and vitamins.

Owner:上海珍馨化工科技有限公司

Selenium-enriched edible mushroom soup and cooking method thereof

The invention relates to selenium-enriched edible mushroom soup and a cooking method thereof. The manufacture method comprises the steps of: cleaning one or various selenium-enriched edible mushrooms and eliminating impurities; cutting up the mushrooms, and cooking the mushrooms with one or various meat foods such as chicken shell, duck bone, goose bone, pork chop, beefsteak, mutton chop, pig bone, ox bone, goat bone, chicken, duck meat, goose meat, and the like, and one kind of or various kinds of fennel, star anise, Chinese cinnamon, peppermint, cooking wine, bean paste, milk vetch, angelica, pseudo-ginseng, radix pseudostellariae, American ginseng, sugar, lemon, orange peel, ginger, and the like for a long time to stew the soup; filtering the soup to obtain puree; mixing the puree with one kind of or various kinds of powder ground from barley and cooked brown, potato, root of lotus, caltrop starch, tianli powder, starch, soy sauce, selenium-enriched yeast, lard, butter, mutton fat, chicken fat, duck fat, goose fat, edible oil, monosodium, salt, food additive and food preservative; cooking the materials together, recovering water, and mixing the materials with one kind of or various kinds of garlic dry powder, dried green onion sections, dried vegetable pieces, paprika, Sichuanese pepper corn, pepper, curry powder, tea powder, bean vermicelli cut into sections, and the like; and packaging equivalently, and then carrying out sterilization treatment.

Owner:金勇

Self-heating instant steak and processing method thereof

The invention relates to the field of food processing, in particular to self-heating instant steak and a processing method thereof. The processing method of the self-heating instant steak comprises the following steps of frying the tenderized and pickled steak with the thickness of 1.0-2.0cm for 30-50 seconds at the temperature of 150-200 DEG C; baking the fried steak for 15-20 minutes at the temperature of 200-210 DEG C; cooling down the baked steak to the temperature of 10-20 DEG C; packaging the steak in a vacuum state; and quickly freezing the packed steak to the temperature of minus 18 DEG C to minus 15 DEG C in an environment with the temperature of minus 40 DEG C to minus 36 DEG C. By the method, the steak is tenderized and pickled at first and then is fried and baked, the baked steam is cooked eighty to ninety percent and is frozen quickly, and the processed steak can be eaten instantly after being placed in boiling water, tastes good, tender and crisp, is delicious and has developmental nutrition; and moreover, the steak is convenient to carry and eat and is convenient and instant, and people can eat the steak in any outdoor places such as fields and trains except for airplanes.

Owner:GUIZHOU FENGGANG CHANGBO FOOD CO LTD

Additive for meat product, meat product and method for making same

InactiveUS20070110884A1Extended shelf lifeImprove water retentionFood preparationSodium lactateCarrageenan

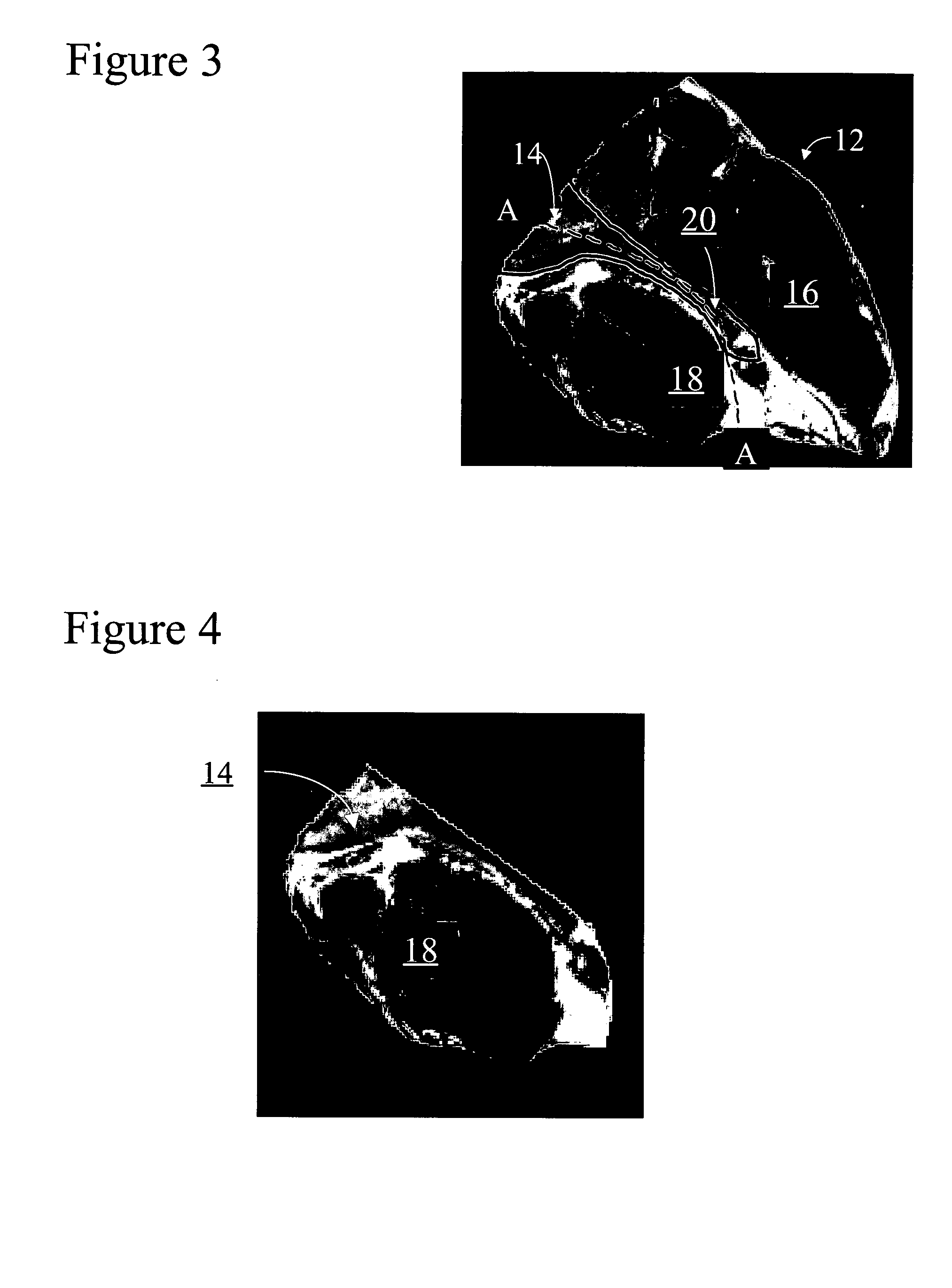

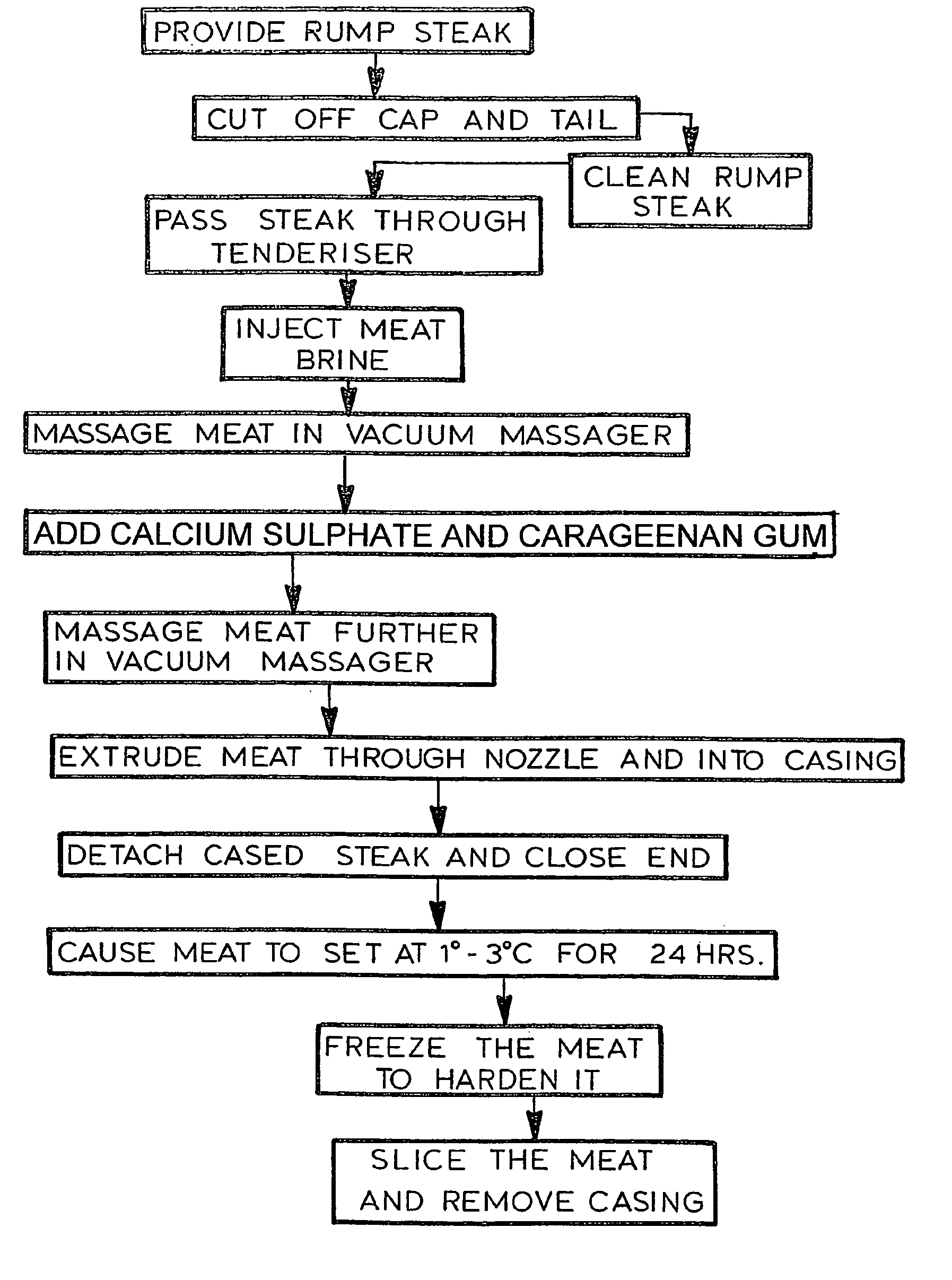

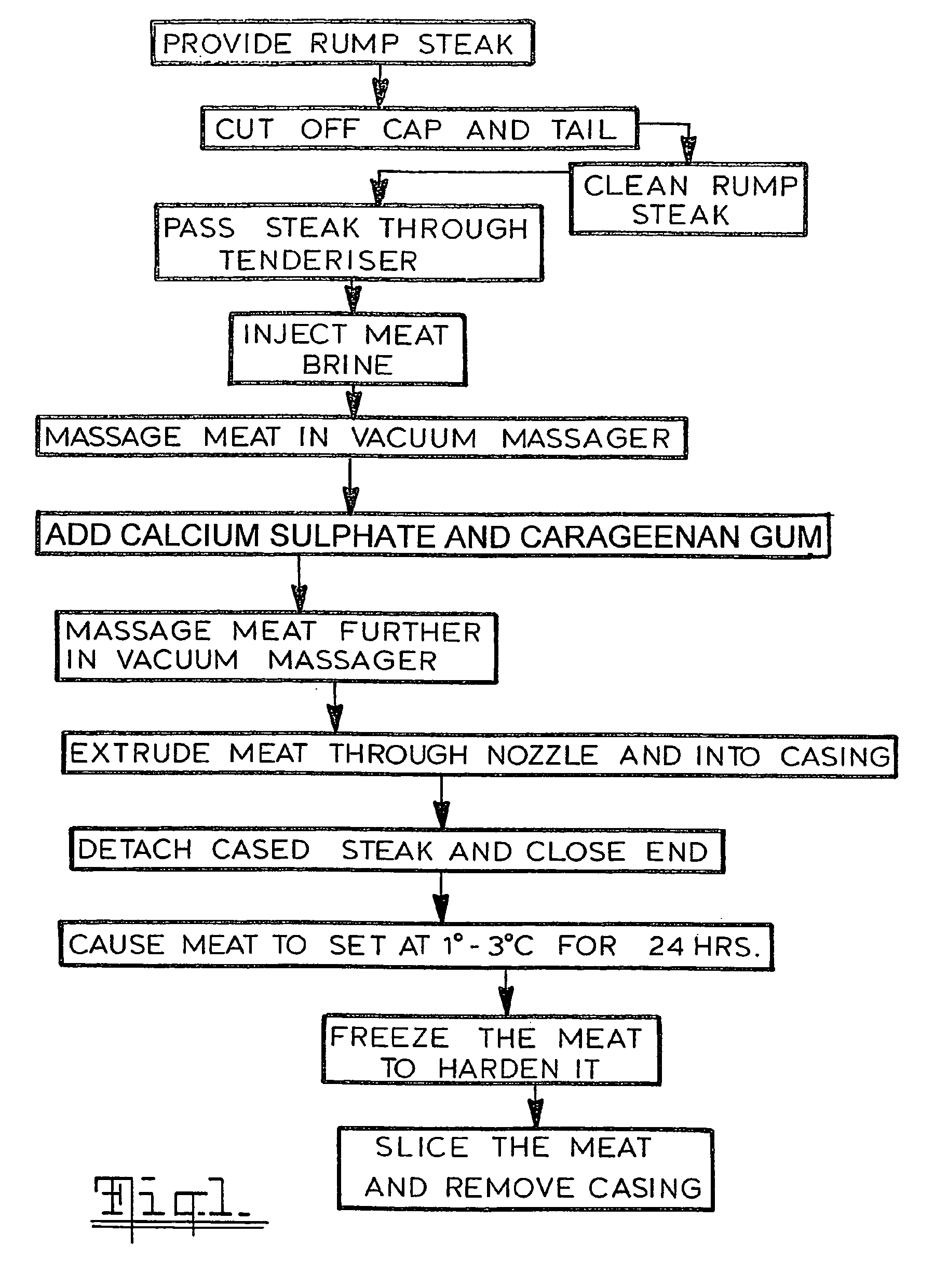

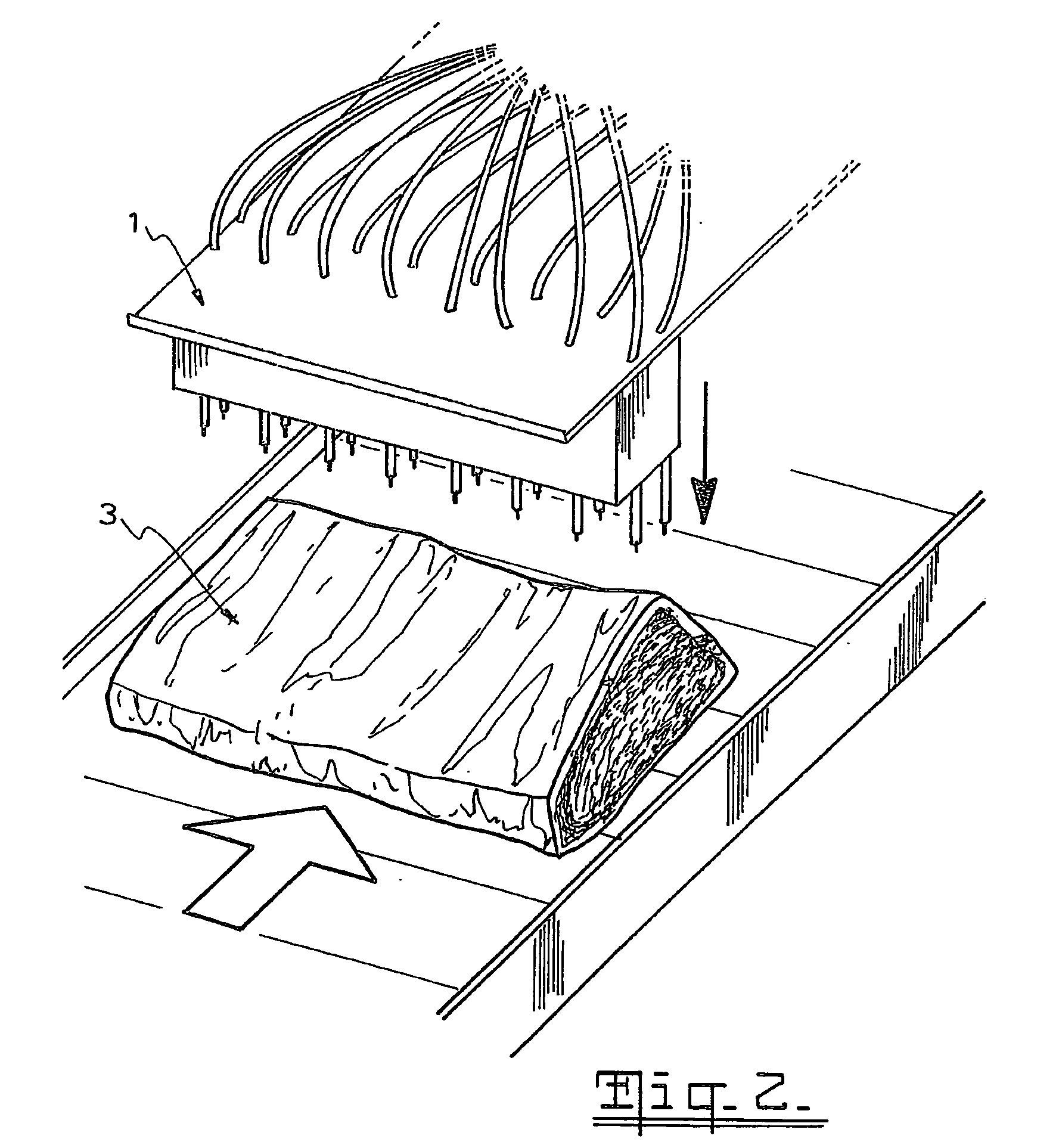

A process of treating a slab of steak is disclosed. The process comprises cleaning the steak and then placing the steak in a tenderiser to tenderise the steak. The process then includes pumping a meat additive into the slab of steak. The meat additive comprises sodium alginate; at least one of sodium lactate, sodium citrate and citric acid; and water and optionally also slats and vegetable protein. Thereafter the slab of steak is placed into a vacuum massager and massaged for a period of time. An amount of hydrolysed calcium sulphate and / or carrageenan is added to the slab of steak before or after said vacuum massaging step. The next step involves forcing the meat through an orifice and into a meat casing having at least one open end to form a cased meat product. Thereafter any open ends of the meat casing are closed. The cased meat product is then stored at a temperature of 1° C. to 10° C. for at least 12 hours to allow the steak and the additive pumped into it to set. The cased meat product is then frozen to crisp and harden it. It is then sliced using a slicer, to yield a plurality of slices of steaks. In one form the slab of meat is a rump. And the steak slices are used as steak patties in steak burgers. The process enables a substantially reproducible size and shape of steak slice to be obtained.

Owner:MOIST & TENDER TECH

Low temperature beef steak and preparation method thereof

The invention provides low-temperature beefsteak which is obtained by thermally processing the following raw materials and auxiliary materials at low temperature. The raw materials comprise the following ingredients by weight parts: 100 parts of beef and 10-15 parts of water; the auxiliary materials comprise the following ingredients by weight parts: 1.5-2.3 parts of common salt, 0.5-1.5 parts of white sugar, 0.1-0.3 part of tripolyphosphate, 0.2-1 part of soybean protein, 0.2-0.4 part of flavor essence, 0.5-1 part of smoke solution, 0.3-0.5 part of white pepper powder, 0.15-0.3 part of nutmeg powder, 0.3-0.5 part of onion powder and 0.1-0.3 part of red pigment. Simultaneously, the invention further provides a preparation method of the low-temperature beefsteak. The beefsteak is processed by the processing method of the low-temperature meat product. As the fumeol is used and the temperature of heat processing is relatively low, the method not only preserves the tenderness and flavor of the high-temperature beefsteak, but also avoids carcinogen, thus providing wider means for beef deep-processing.

Owner:CHINA MEAT RES CENT

Method for tenderizing beef steak

Owner:福建佳客来食品股份有限公司

Low-salt conditioning steak product

InactiveCN105982223AReduce contentMake up for quality deficienciesMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingBiotechnologyNutrition

The invention relates to a low-salt conditioning steak product. In the method, food-grade potassium chloride partially replaces the sodium salt in a conditioning steak formula; and through the auxiliary yeast extract and papain of certain amount and with the synergistic sodium alginate film (20g / L) for preservation, the quality of the low-salt conditioning steak is improved. The specific processing steps are as follows: (1) pretreatment of raw material meat; (2) slicing; (3) salting; (4) preservation with a sodium alginate film, etc. The low-salt conditioning steak provided by the invention has the characteristics of convenience in eating, high added value, small capacity and the like; the sodium salt content is lower than or equal to 1.5%, and the table salt content of the product is remarkably reduced; and the flavor, texture and shelf life of the product can be maintained. The low-salt conditioning steak product meets the food consumption needs for health, nutrition and convenience of current people and has a broad market prospect.

Owner:HEFEI UNIV OF TECH

Pan-fried beef steak with black pepper and preparation method thereof

The invention discloses a pan-fried beef steak with black pepper and a preparation method thereof. The pan-fried beef steak with black pepper comprises the following components in parts by weight: 100 parts of beef, 3-5 parts of starch, 1-2 parts of dark soy sauce, 1-3 parts of black pepper powder, 1-2 parts of white granulated sugar, 0.3-0.9 part of edible salt, 0.3-0.9 part of sodium glutamate and 0.1-0.5 part of white pepper powder. The pan-fried beef steak with black pepper tastes good, and is easy to cook and long in anti-corrosion time; preservatives in use are natural extracts, healthy and safe, and have a certain seasoning effect.

Owner:上海珍馨化工科技有限公司

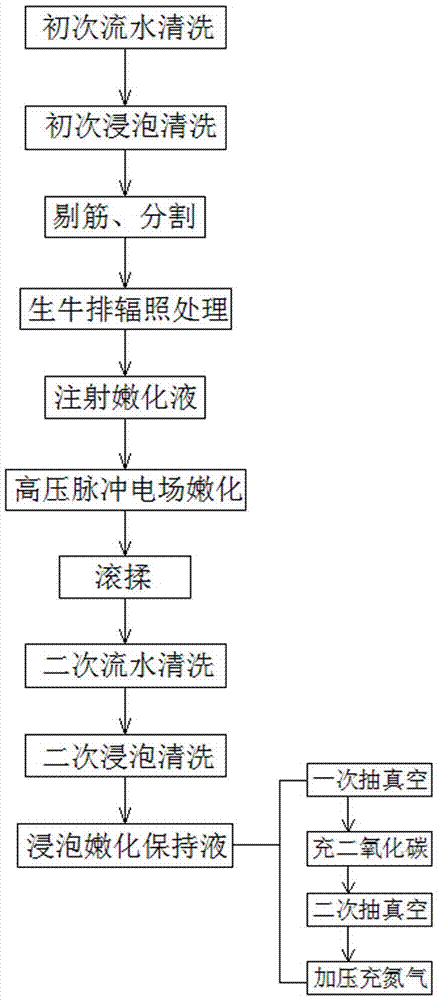

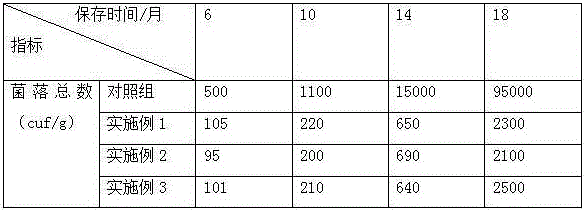

Processing method for prolonging quality guarantee period of beefsteaks

PendingCN107348307AExtended shelf lifeKeep freshFood ingredient as antioxidantFood preservationBeef steakClean water

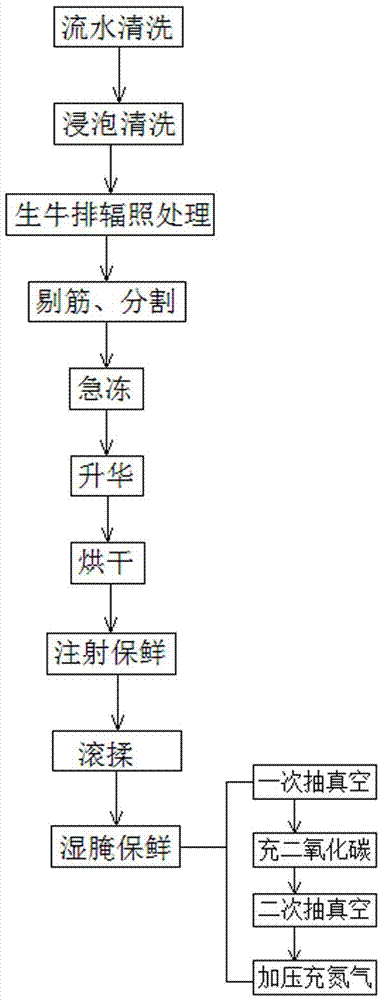

The invention relates to a processing method for prolonging the quality guarantee period of beefsteaks. The processing method comprises the following process steps of: preparing fresh-keeping liquid, carrying out fresh-keeping processing on beefsteaks, and packaging. The fresh-keeping processing process of raw beefsteaks comprises the steps of: (1) washing with flowing water: washing the raw beefsteaks for 2-5 seconds by using flowing water; (2) soaking and washing: adding 300-500g starch into every 100kg clean water to prepare washing liquid, and soaking the raw beefsteaks in the washing liquid for 10-20 minutes; and replacing the washing liquid after washing every 200-300kg raw beefsteaks; (3) carrying out irradiation treatment onthe raw beefsteaks: carrying out irradiation treatment on the raw beefsteaks, wherein the total average dosage of irradiation is 5-7kGY; and (4) carrying out muscle picking and cutting: according to the beefsteak cutting standard that the length, the width and the height are 40-50cm, 15-30cm and 2-3cm respectively, cutting along the texture of the beefsteaks.

Owner:福建佳客来食品股份有限公司

Preparation process of beefsteak for children

InactiveCN104872690AFresh tasteTo tasteFood ingredient functionsFood preparationBiotechnologyAnimal science

The invention belongs to the field of meat product processing and specifically relates to a preparation process of a beefsteak for children. The preparation method comprises the steps of taking a fresh and tender beefsteak, cleaning, removing broken bone and extravasated blood, cutting the beef into a square beefsteak and draining, next, soaking the beefsteak in milk of 30-40 DEG C for 3-5 minutes, taking out, cooling and draining, next, spreading prepared curing powder on the beefsteak evenly, rolling for 10-20 minutes and placing at a temperature within the range of 0-4 DEG C for 6-8 hours, and finally, treating the beefsteak in a tenderizing liquid for 20-30 minutes, packaging in vacuum and quick-freezing for storage. The obtained beefsteak is fresh and tender in taste, suitable for children, and capable of enhancing the immunity of children, supplementing calcium, vitamins and the like.

Owner:福建佳客来食品股份有限公司

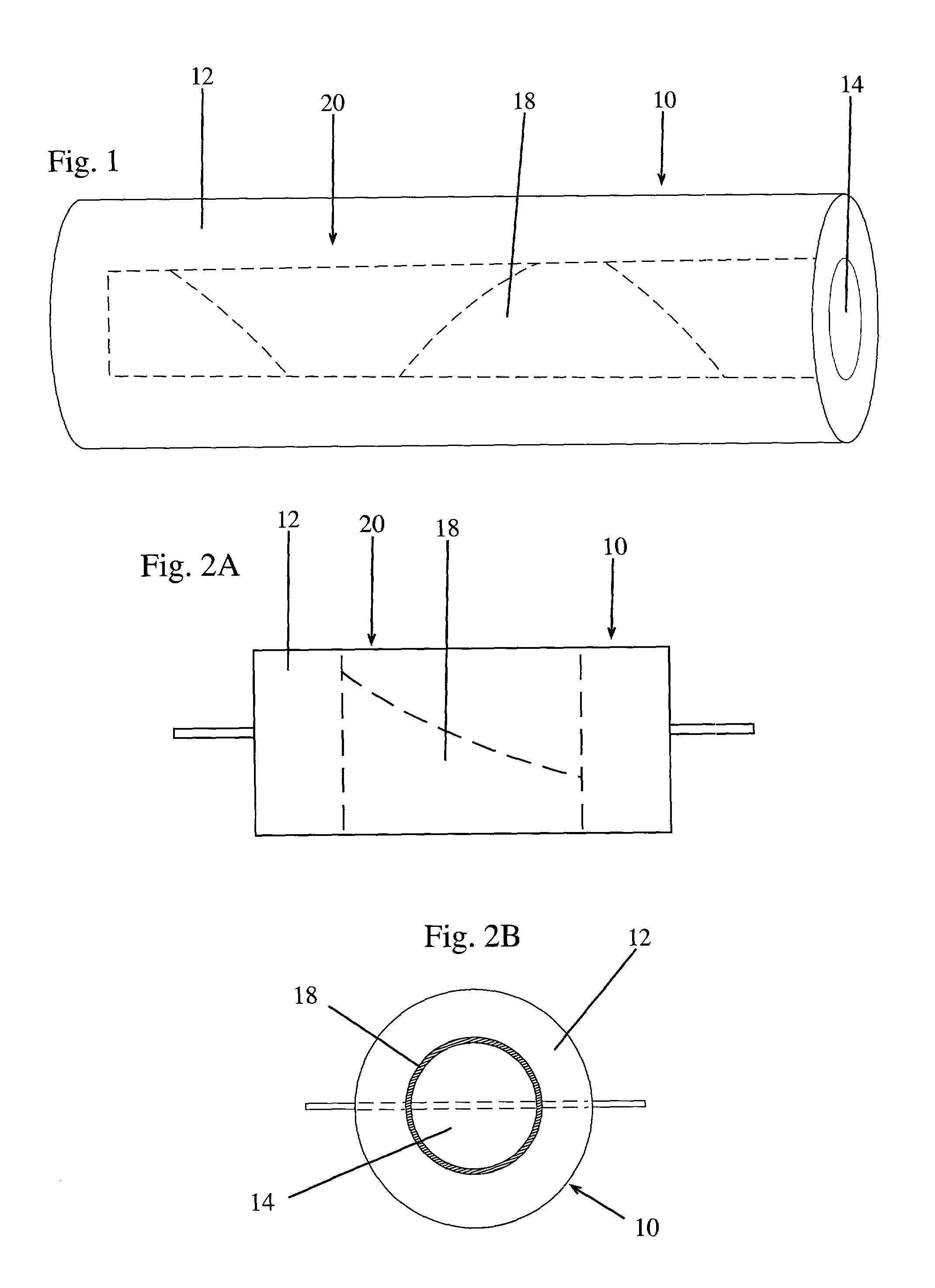

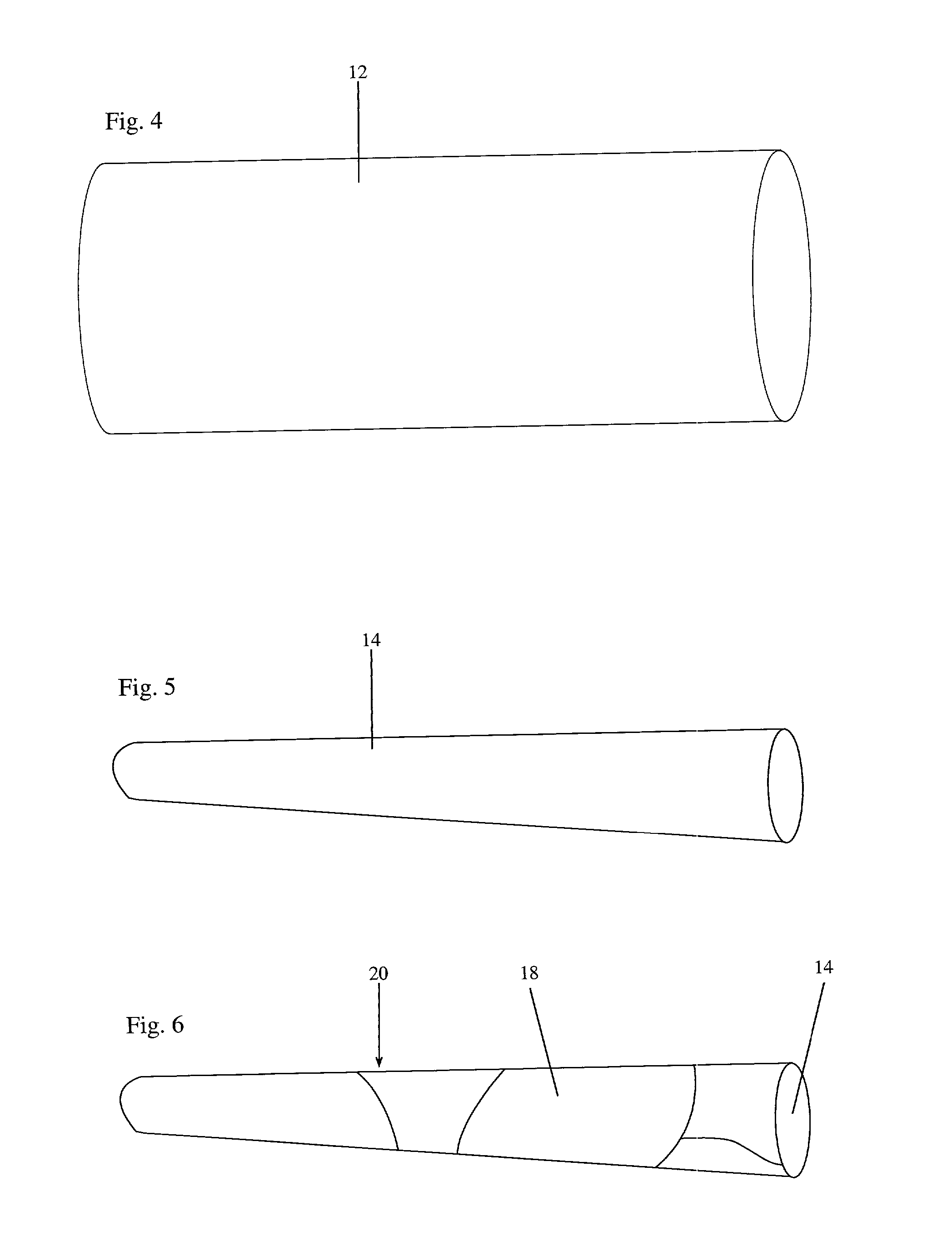

Coaxially combined meat roast with steaks or chops cut from same

A coaxially combined meat roast (10) is disclosed which comprises a first solid elongated meat mass (12) encasing as a core element along substantially the longitudinal axis thereof within a longitudinal slit-like aperture incised therethrough, a vegetably veneered second solid elongated muscle meat mass (20).

Owner:GUESS WILLIAM YOUNGER

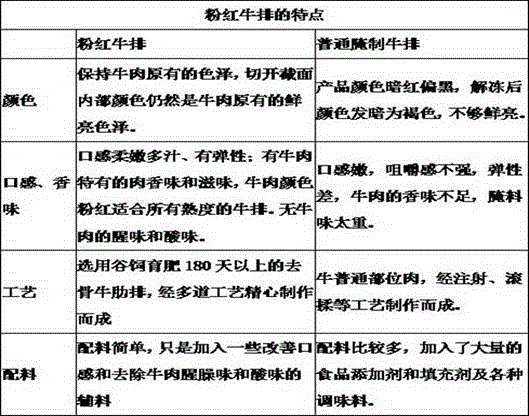

Preparation method of pink western-style beef steak

The invention provides a preparation method of pink western-style beef steak. A frozen beef steak piece with a certain fat content is selected and used as a raw material; the raw material steak piece is unfrozen at 0-4 DEG C under the relative humidity being 80-90%; then a marinade is injected into the raw material steak piece for compression, and rolling and rubbing last for 15-25 minutes; a high temperature resisting steaming and boiling bag is adopted for vacuum package; afterwards, boiling lasts for 20-30 hours in constant circulating water; boiled beef is put into ice water at 0-5 DEG C until the center temperature of the beef is reduced to be 5 DEG C or lower; the bag is opened and dirt on the surface of beef is washed away; the processed beef is put into quick-freezing equipment below subzero 35 DEG C to be quickly frozen for 20-30 hours; afterwards, slitting quantification, vacuum package, and boxed warehousing are carried out. The pink western-style beef steak exceeds the beef steak in the prior art in aspects of taste, fragrance, mouthfeel, and particularly color. The preparation method is simple and convenient in technological preparation, and is suitable for industrial production.

Owner:上海瑞轩食品有限公司

Lower calorific value beefsteak and processing method thereof

ActiveCN104687076AHigh nutritional valueRich in nutritional valueFood preservationFood preparationCaloric valuesProcess engineering

The invention relates to the technical filed of food processing, in particular to a lower calorific value beefsteak and a processing method thereof. The lower calorific value beefsteak is obtained by the steps of beef processing, unfreezing, salting, sterilizing, plate arranging, quick-freezing, packaging and refrigerating, therefore, the caloric intake of the beefsteak is reduced, and people can enjoy the great taste and meanwhile enjoy the healthy life. The calorific value ingested by people is reduced mainly by adding specific ingredients in the salting process and through the mutual cooperation and synergistic effects of the ingredients, vitamin and mineral contents are increased, and therefore digestion, gastrointestinal health and caloric control are facilitated after the intake.

Owner:FUJIAN JUYUAN FOOD CO LTD

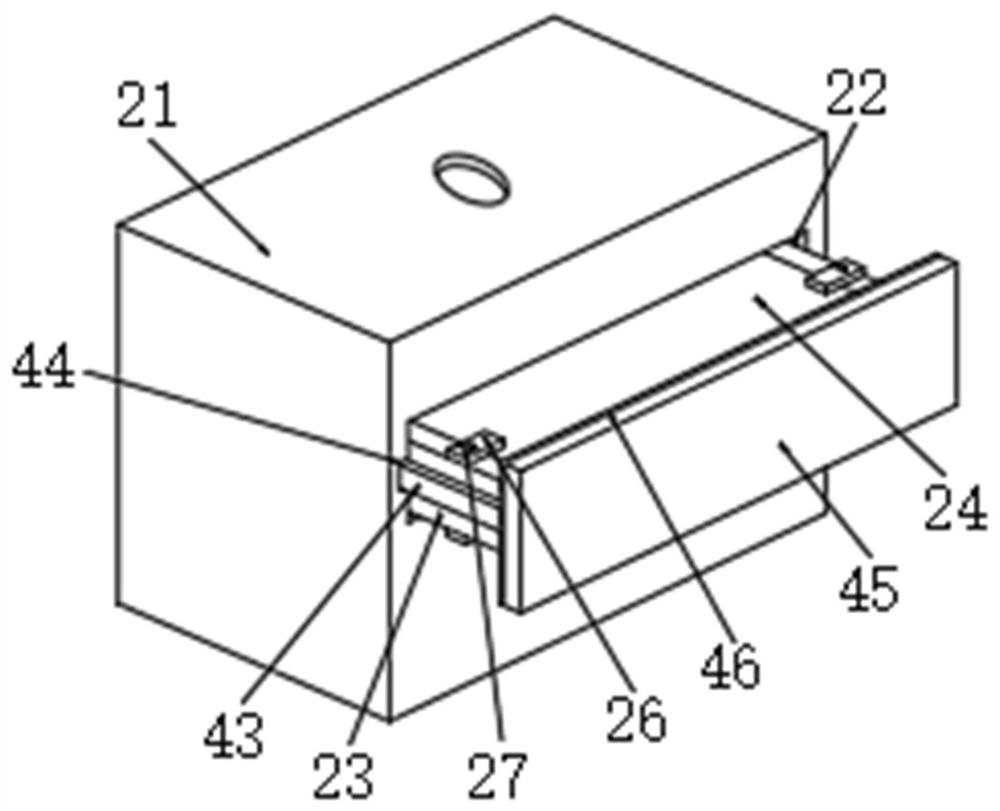

Cleaning equipment used before beefsteak processing and using method thereof

InactiveCN112544674AAvoid wastingGuaranteed recyclingGas treatmentFatty/oily/floating substances removal devicesOil and greaseRinse water

The invention discloses cleaning equipment used before beefsteak processing, and belongs to the technical field of beefsteak processing. The cleaning equipment comprises a cleaning box body and a sealing door; the surface of the sealing door is provided with a transparent window, and the sealing door is hinged to the cleaning box body; a containing plate is horizontally arranged inside the cleaning box body; a plurality of first beating hammers and second beating hammers are arranged above the containing plate in a staggered mode; and a driving assembly used for driving the first beating hammers and the second beating hammers to move relatively is installed on the cleaning box body, so that beef can be beaten and the good toughness of the beef can be guaranteed. Water in a water tank is pumped by a water pump and sprayed out through a spray head to be cleaned, the flushing water is received by a water receiving cover and flows back into the water tank, and impurities and grease are filtered out through a first filter screen and a grease filter membrane on a mounting frame, so that the water can be treated, recycling is guaranteed, and water resource waste is avoided; and a drawingplate is matched with a sealing gasket, so that the mounting frame can be conveniently pulled out to clean and replace the first filter screen and the grease filter membrane, the structure is simple,and the operation is convenient.

Owner:安徽荷金来农业发展股份有限公司

Canned grilled beef steak and preparation method thereof

The invention relates to a processing method of foods, in particular to a preparation method of grilled beef steak, which comprises cutting frozen beef steak into beef steak sections, flushing, soaking and unfreezing the beef steak cut into sections, adding condiments into the water-drained beef steak sections, evenly mixing, curing for 5-6h, steaming the beef steak sections with a steam-boiler for 5min, taking out the beef steak sections, placing and cooling, clearing up the beef steak sections into single pieces, baking the single pieces of steak, directly canning, vacuumizing cans accommodating the steak under the condition of 2.5-3 MP, sealing openings, sterilizing the cans accommodating the steak in a pressure cooker for 50min, taking out the cans, cleaning can bodies, waxing the cans, storing the cans for 10 days at a storehouse temperature of 37 DEG C, taking the cans out of the storehouse, cleaning oil on the can bodies, storing the cans for 10-15 days at the storehouse temperature under normal-temperature conditions to obtain finished products. The canned grilled beef steak has the advantages of being convenient to carry and store and capable of being instantly eaten after a bag is opened.

Owner:河南省金牛足食品有限公司

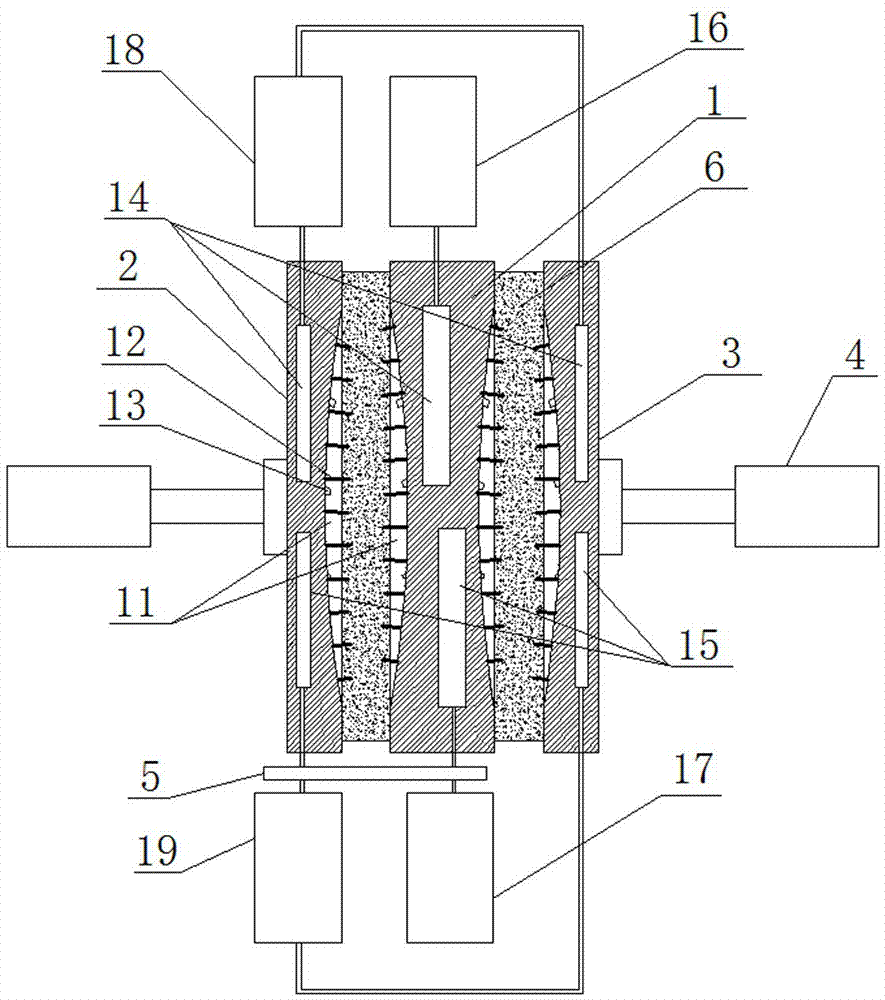

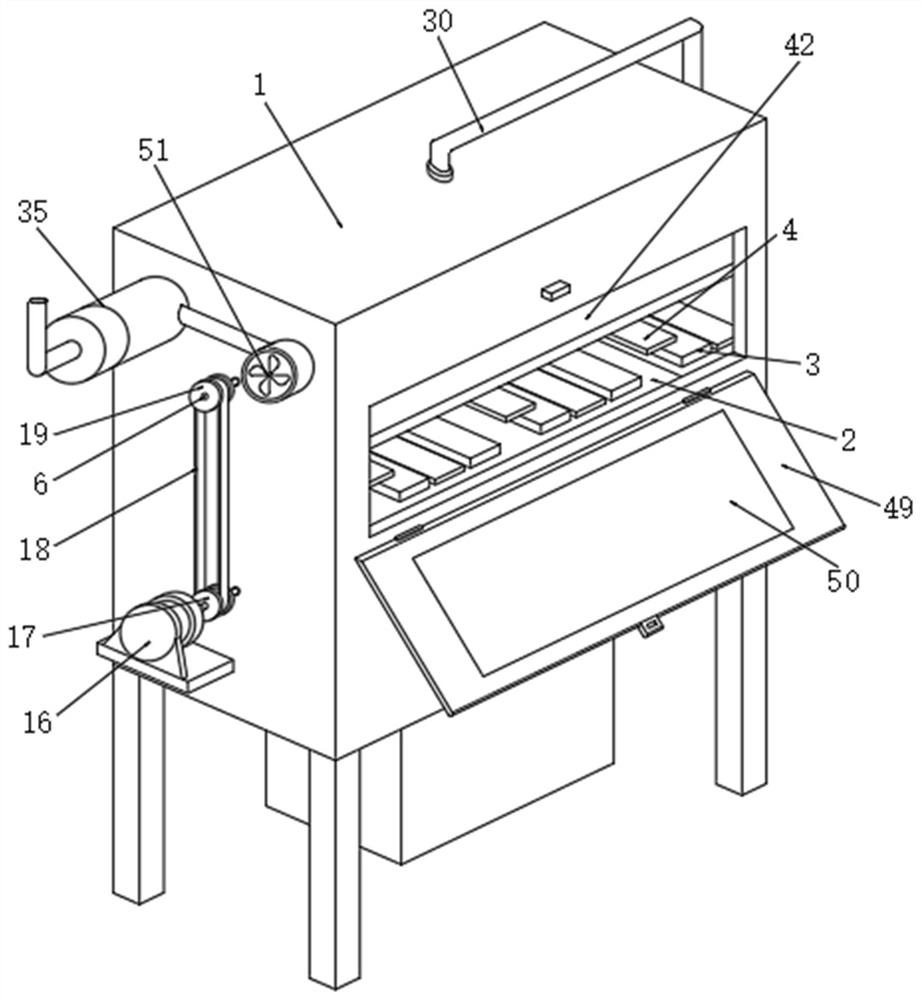

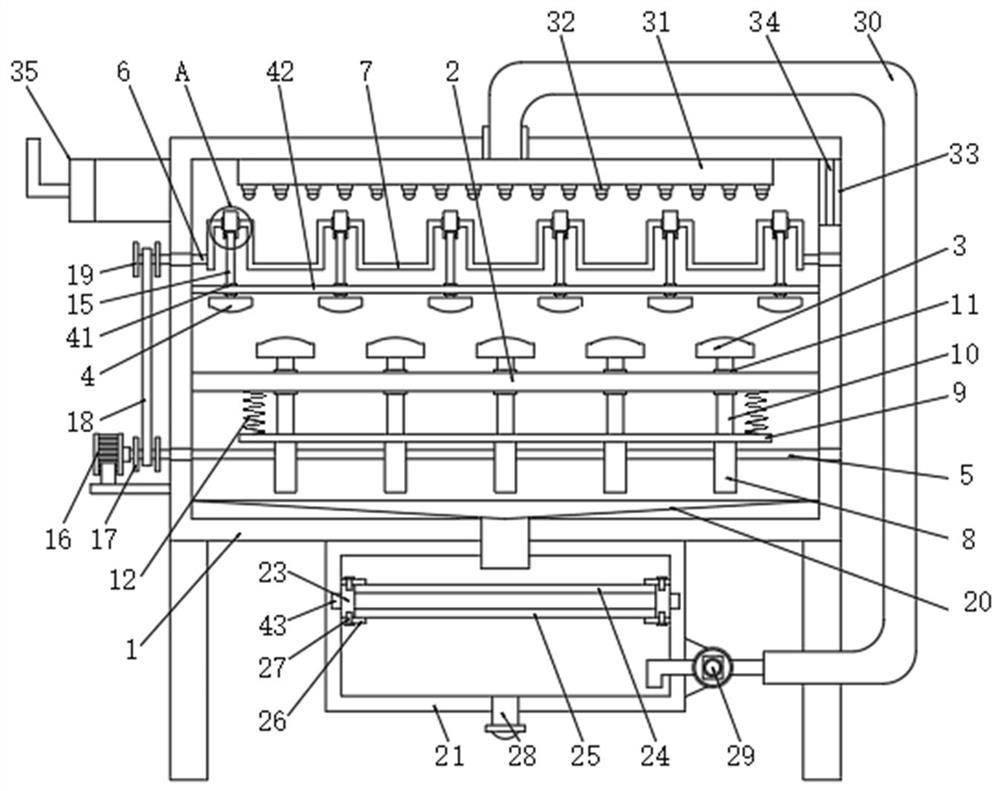

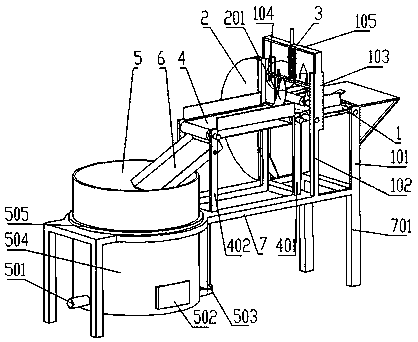

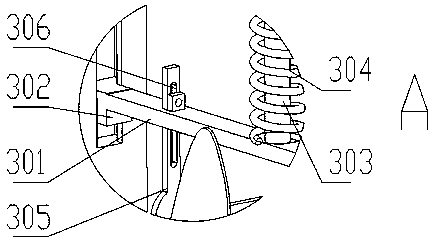

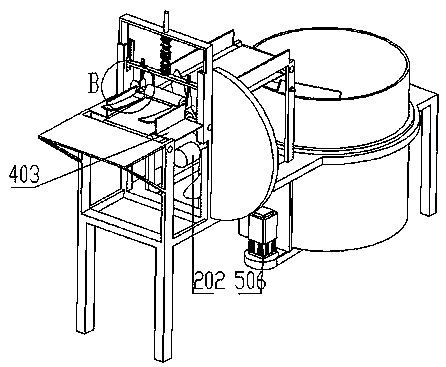

Preparation method and production device of Chinese style beef steak

InactiveCN110150573AImprove production efficiencyFood ingredient as colourLipidic food ingredientsSugarBeef steak

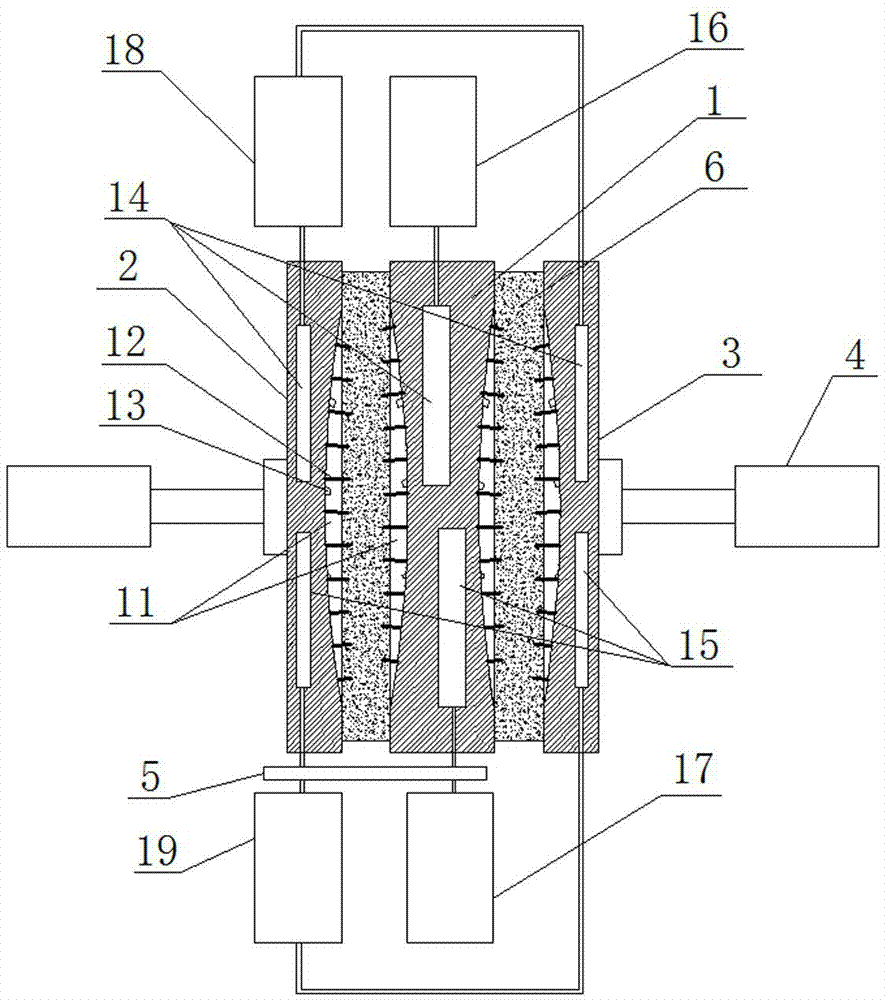

The invention discloses a preparation method and production device of a Chinese style beef steak, and relates to the technical field of food. According to the technical scheme, the Chinese style beefsteak is characterized by being prepared from a main material and boiling auxiliary materials, wherein the main material is 300-500 parts, by weight, of beef brisket, and the boiling auxiliary materials comprise, by weight, 3.2-3.5 parts of salt, 3.0-3.2 parts of sugar, 0.8-1.0 part of soy sauce, 3-4 parts of cooking wine, 0.2-0.3 part of cortex cinnamomi, 0.05-0.06 part of cloves, 0.1-0.2 part ofsemen myristicae, 0.5-0.6 part of anises, 0.2-0.3 part of Sichuan peppers, 10-20 parts of green Chinese onions and 10-15 parts of ginger. The invention provides the new-taste Chinese style beef steakand the preparation method thereof, and designs the device for improving the production efficiency.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Double-benefit beefsteak and preparation method thereof

The invention relates to double-benefit beefsteak and a preparation method thereof. The double-benefit beefsteak is mainly prepared from the following components in part by weight: 950 to 1,050 parts of main material beef, 15 to 20 parts of starch, 14 to 18 parts of chicken essence, 15 to 20 parts of light soy sauce, 6 to 8 parts of tasty king, 14 to 16 parts of white granulated sugar, 1.5 to 2 parts of salt, 15 to 18 parts of dark soy sauce, 3 to 4 parts of five spice powder, 6 to 8 parts of cumin powder, 1.5 to 2 parts of white pepper powder, 15 to 18 parts of oyster sauce and 5 to 8 parts of auxiliary material sodium bicarbonate. According to the raw material standardization, product standardization and process standardization of the double-benefit beefsteak can be realized.

Owner:SUZHOU HAODELAI FOOD

Beefsteak fresh-keeping method

InactiveCN105341135AHeat-clearingImprove the immunityMeat/fish preservation by coatingMeat/fish preservation by freezing/coolingBiotechnologyAnimal science

The invention belongs to the meet food processing field, and concretely relates to a beefsteak fresh-keeping method. Fresh beefsteak is taken and cleaned, crushed bone and extravasated blood are removed; the beefsteak is allowed to stand for 12-24h at a temperature of 0-4 DEG C, and then is taken out, the beef is cut into square beefsteak, and the square beefsteak is drained; the surface of the beef is coated with prepared fresh-keeping powder uniformly, then rolling is carried out for 5-10min, and the beefsteak is allowed to stand for 3-6h at a temperature of 0-4 DEG C; the beefsteak is immersed in a fresh-keeping solution and processed for 20-30min, then the beefsteak is taken out and drained, and vacuum package and quick-frozen preservation are carried out. The method is simple, the cost is low, the prepared beefsteak has a better fresh-keeping effect than the prior art, and the beefsteak tastes fresh and tender, can enhance human body immunity, and supplements calcium, vitamins and the like.

Owner:福建佳客来食品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com