Process for the filleting, treating, packaging, freezing, and thawing of varying types of tuna and other pelagic species

a technology for applied in the field of processing of varying types of tuna and other pelagic species, can solve the problems of less marketable and marginally profitable frozen tuna steaks, lower value products facing the same high cost of international air freight, and 30% to 80% of any given catch can be profitable, etc., to achieve the effect of efficient filleting, treating, freezing and thawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

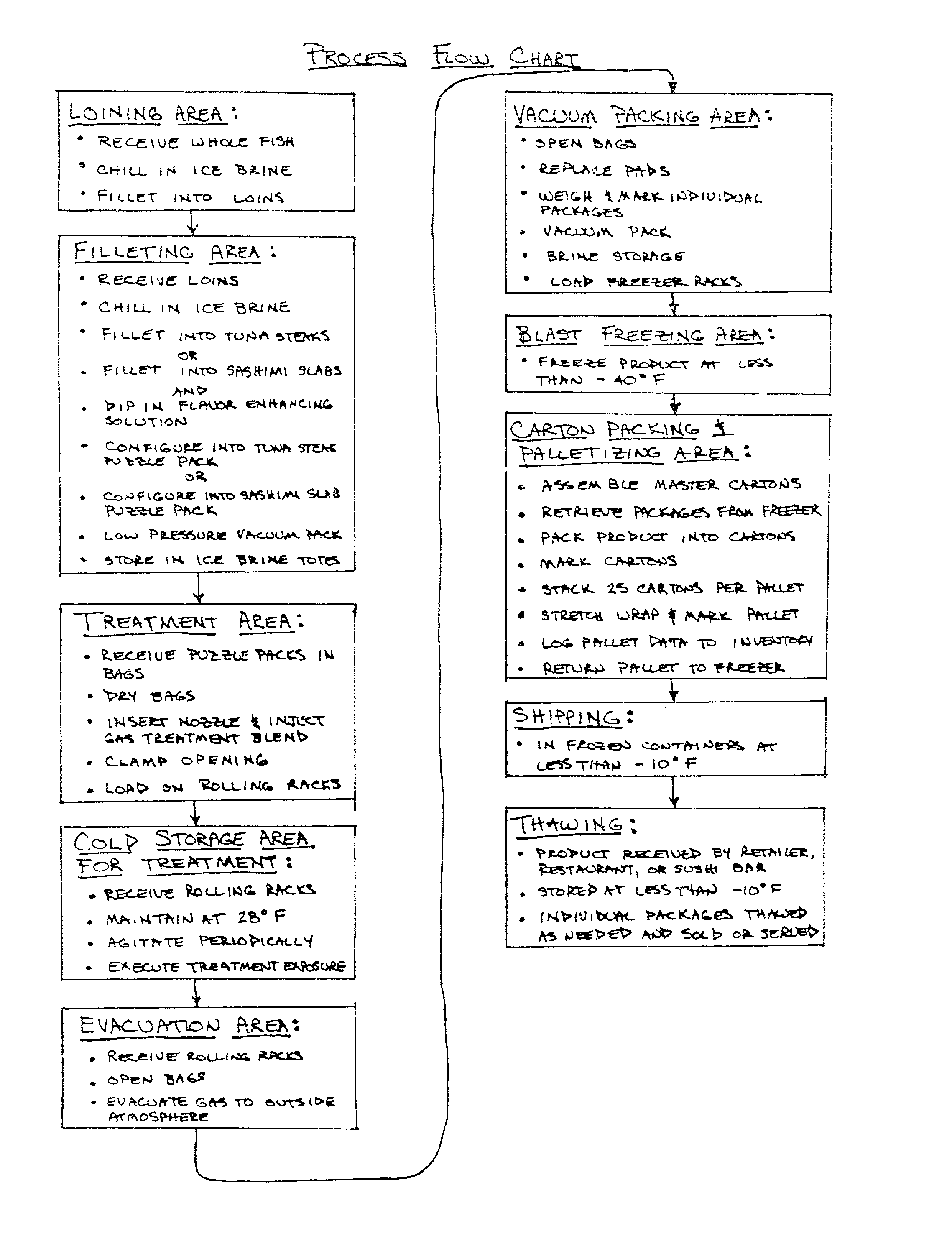

[0060] The best mode contemplated for carrying out the present invention is the preferred embodiments of the steps of the process illustrated by way of example in FIGS. 1 through 13.

[0061] Referring specifically to FIG. 1, each tuna is brought fresh to the processing facility joining room where the air temperature is kept within an operability range of 32 to 45 degrees Fahrenheit, a preferred range of 36 to 40 degrees and an optimal temperature of 38 degrees Fahrenheit. Each tuna comes in on crushed ice or in a tote of a brine solution and is placed in a salt brine chilling tank with water, ice, and sufficient salt to keep the solution temperature at an operability range of 28 to 36 degrees Fahrenheit, a preferred range of 30 to 32 degrees Fahrenheit and an optimal temperature of 31 degrees Fahrenheit.

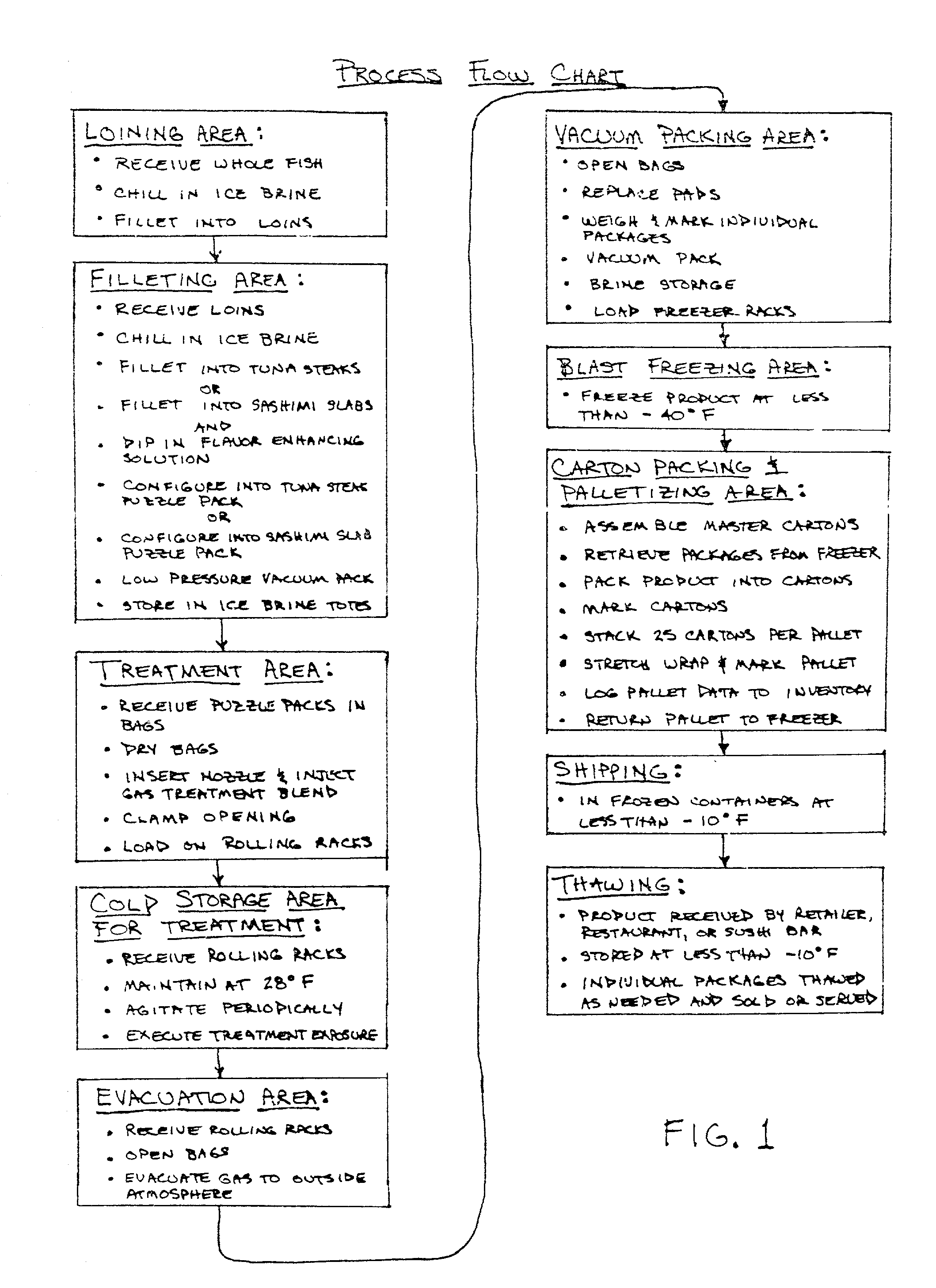

[0062] Referring to FIG. 2, after chilling, each tuna is cut into four loins--left back, right back, left belly, right belly--with skin removed and partial red bloodline remaining at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com