Patents

Literature

138 results about "Bright red color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yeast extract, preparation method and application thereof

InactiveCN101513246AFlavor coordinationTaste balanceFood preparationCaramel FlavorVegetable Proteins

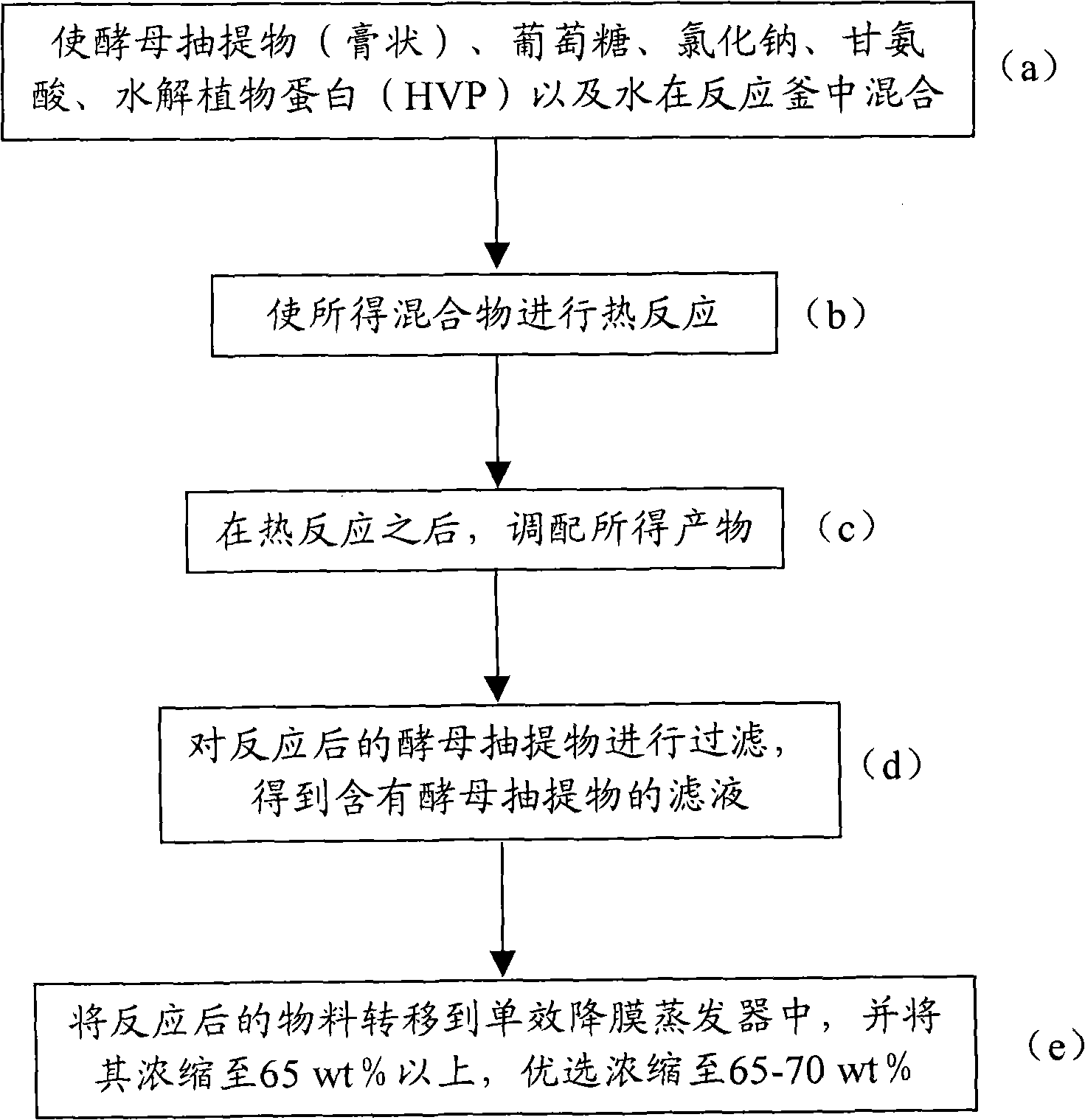

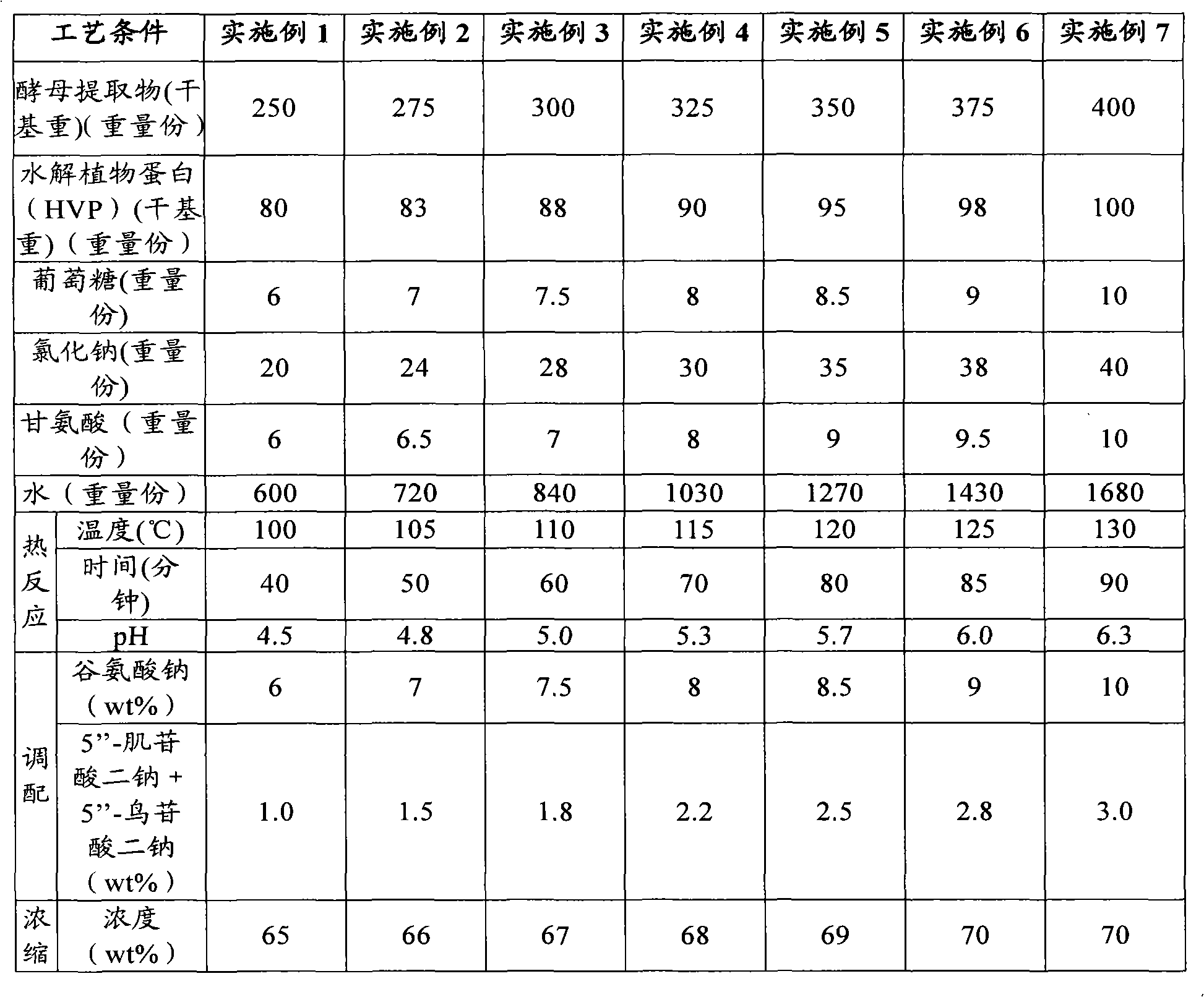

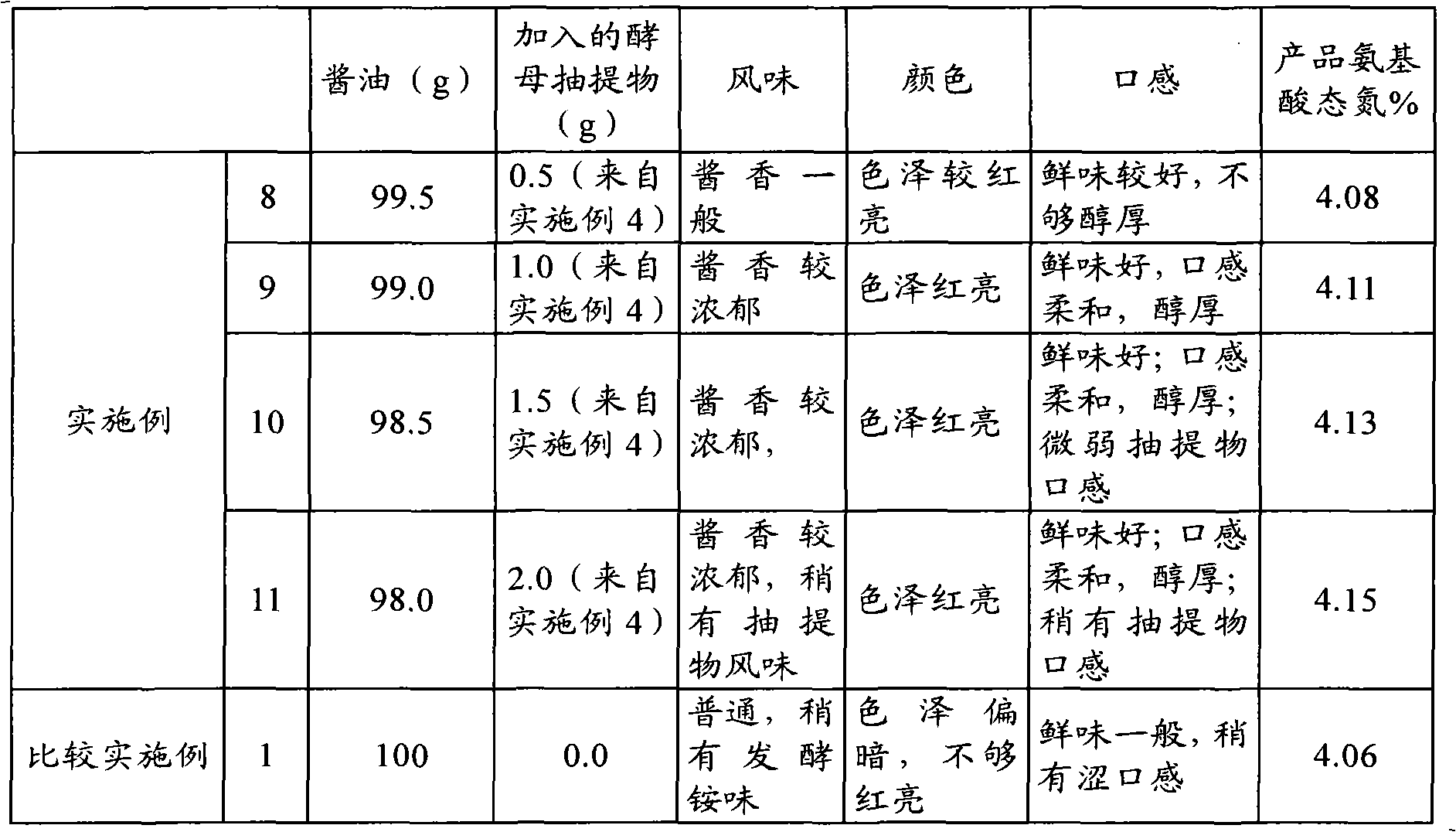

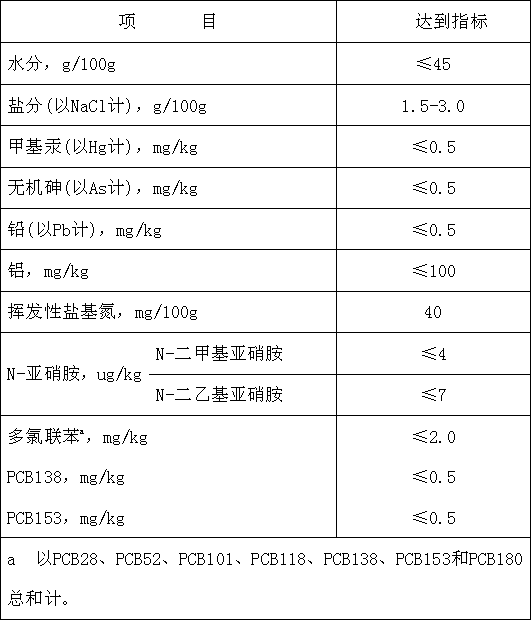

The invention provides a yeast extract, a preparation method and application thereof. The preparation method of the yeast extract comprises the following steps: (a) mixing the yeast extract, glucose, sodium chloride, glycin, hydrolyzed vegetable protein and water in a reaction kettle; (b) performing heat reaction on the mixture in step (a) for 40 to 90 minutes at a temperature of between 100 and 130 DEG C and pH of between 4.5 and 6.3; (c) after the heat reaction, adding 6 to 10 weight percent of sodium glutamate and 1.0 to 3.0 weight percent of disodium inosinate and disodium guanylate into an obtained product for preparation; (d) filtering the yeast extract after the reaction to obtain filtrate containing the yeast extract; and optional (e) transferring materials after the reaction to a single effect falling film evaporator, and concentrating the materials to more than 65 weight percent and preferably concentrating the materials to between 65 and 70 weight percent. The yeast extract prepared by the method has sauce fragrance and caramel like deep bright red color, and a water solution of the yeast extract has transparent bright red color and fresh and salty mouthfeel.

Owner:ANGELYEAST CO LTD

Special compound premix for Micropterus salmoides

ActiveCN102028122AIncrease weight gainReduce the bait coefficientFood processingClimate change adaptationBiotechnologyAnimal science

The invention discloses a special compound premix for Micropterus salmoides, belonging to the field of aquatic product feed and comprising compound vitamin, a complex mineral element, a yeast extract, chromium picolinate premix, bile acid premix and defatted rice bran. The invention can meet the nutrition requirements for healthy and rapid growth of the Micropterus salmoides. Compared with a control group, the use of the compound feed of the Micropterus salmoides can be prolonged to the adult fish period; the rate of body weight gain of the Micropterus salmoides is increased by 10-20 percent, and the bait coefficient is reduced by 10-15 percent; the liver has bright red color and is not swelling; the fat content is obviously reduced; the fish morbidity is obviously reduced; and the oxygen deficit resistance and the transport resistance are obviously increased. The special compound premix does not contain any antibiotic or forbidden drug and meets the national feed safety regulation. The raw material is easy to purchase and the production and the quality are easy to control.

Owner:FOSHAN XINTUN BIOLOGICAL SCI & TECH

Spicy stewing oil and preparation method thereof

The invention discloses spicy stewing oil and a preparation method thereof. The formula of the spicy stewing oil comprises salad oil, seasonings, fresh old ginger, fresh green Chinese onion, glutinous rice cake chilli, dry pepper, perfume, ligusticum chuanxiong, fructus tsaoko, fennel, fructus amomi, cinnamon, rhizoma kaempferiae, anise, Cape jasmine, Indian long pepper, cardamom fruit, semen myristicae, radix angelicae dahuricae, lemon grass, bay leaves, lysimachia sikokiana, clove, liquorice and rhizoma nardostachyos. The preparation method sequentially comprises the steps: preparation of raw materials, stewing, oil residue separation and cooling and packing. The spicy stewing oil has bright red color, pure flavor and attractive smell, realizes easy, quick and convenient preparation of stewed dishes; and the stewed dish has the advantages of oily color, rich and pure compound flavor, moderate spicy taste, long-lasting aftertaste and the like. The spicy stewing oil also can be used for making meat dishes, frying griddle cooked food and the like.

Owner:叶龙宝

Chilli sauce and preparation method thereof

The invention relates to chilli sauce and a preparation method thereof. The chilli sauce in the invention comprises the following raw materials in parts by weight: 100 parts of dried red chilli, 30-50 parts of cooking oil, 40-60 parts of vinegar, 8-12 parts of salt, 0-30 parts of garlic, 0-30 parts of ginger, 0-10 parts of chicken essence and 0-10 parts of five spice powder. The preparation method of the chilli sauce comprises the steps of preprocessing the raw materials and auxiliary materials, mixing, stewing and canning. The method for preparing the chilli sauce by utilizing the dried chilli as a raw material in the invention has simple operation, and the prepared chilli sauce has bright red color and luster and aromatic flavor, and integrates oil scent of oil chilli sauce, faint scentof water chilli sauce with tart flavor similar to that of fermented chilli sauce, thus having the fragrant, pungent and tart special taste, being capable of appetizing and having no preservative and longer shelf life.

Owner:JIANGSU UNIV

Processing method of instant lightly baked prawn

The invention relates to a processing method of an instant lightly baked prawn, and the method comprises the following steps that a fresh prawn with completed head and feelers and without damage is selected as a raw material; the prawn is cleaned, intestinal gland and internal organs are removed, the prawn is soaked in salt water and sterilized, so that the tissue is tight; then the prawn is cooked, uniformly mixed with seasoning, cured and baked until the water content of prawn meat is 40+ / -0.8 percent; and the prawn meat is packaged, sealed and sterilized to obtain an instant lightly baked prawn finished product. The processing method has reasonable procedures, is simple in preparation and easily realizes large-scale production. The seasoning for curing is mixed scientifically, so that the unique flavor and the dainty taste of the prawn product are improved. The lightly baked prawn product which is prepared through the method better maintains the nutrition ingredients of the prawn, the prawn meat has tight tissue, the product has bright red color, and the storage life is long. The instant lightly baked prawn can be eaten conveniently only after a package is opened, is chewy and elastic, has long aftertaste, is dainty in saline taste and sweetness, has delicious taste, has the special aroma of marine prawns, and is ideal leisure food.

Owner:RONGCHENG HONGWEI FOOD

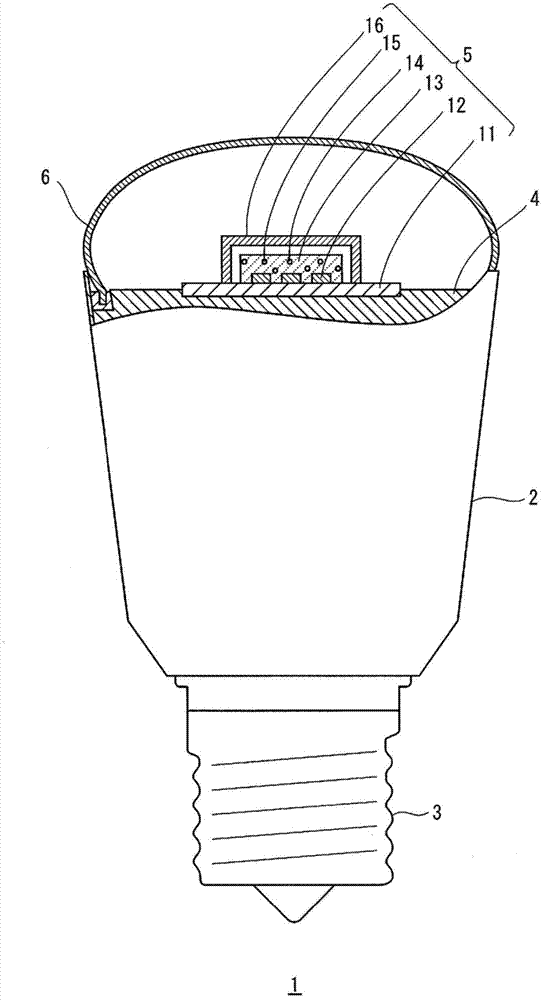

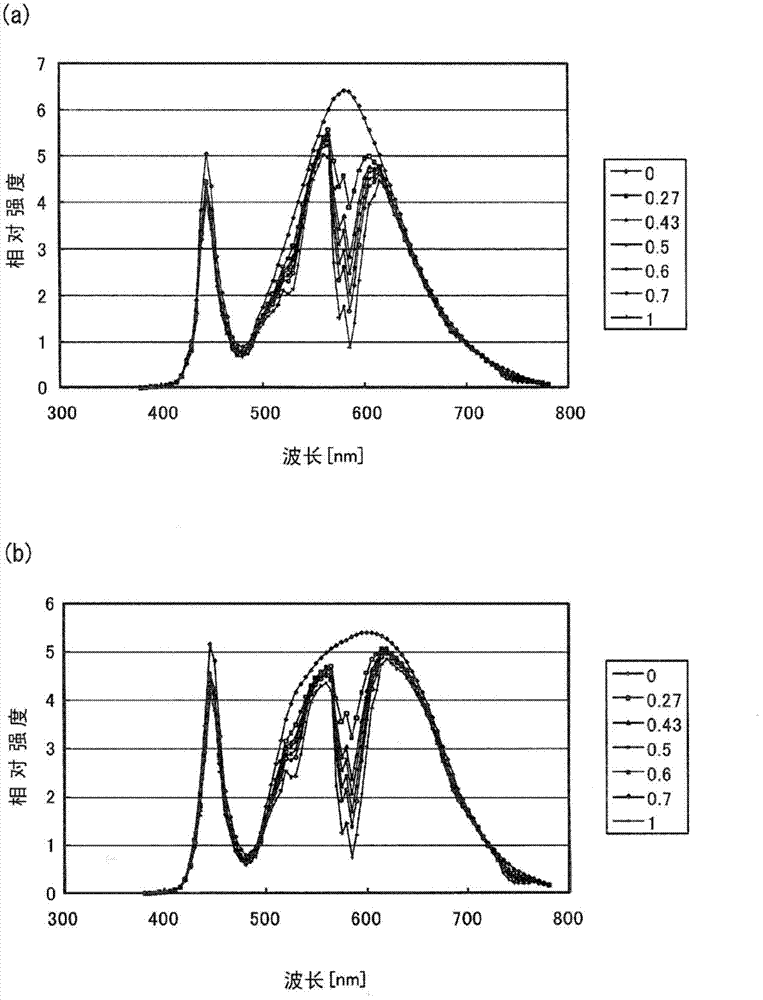

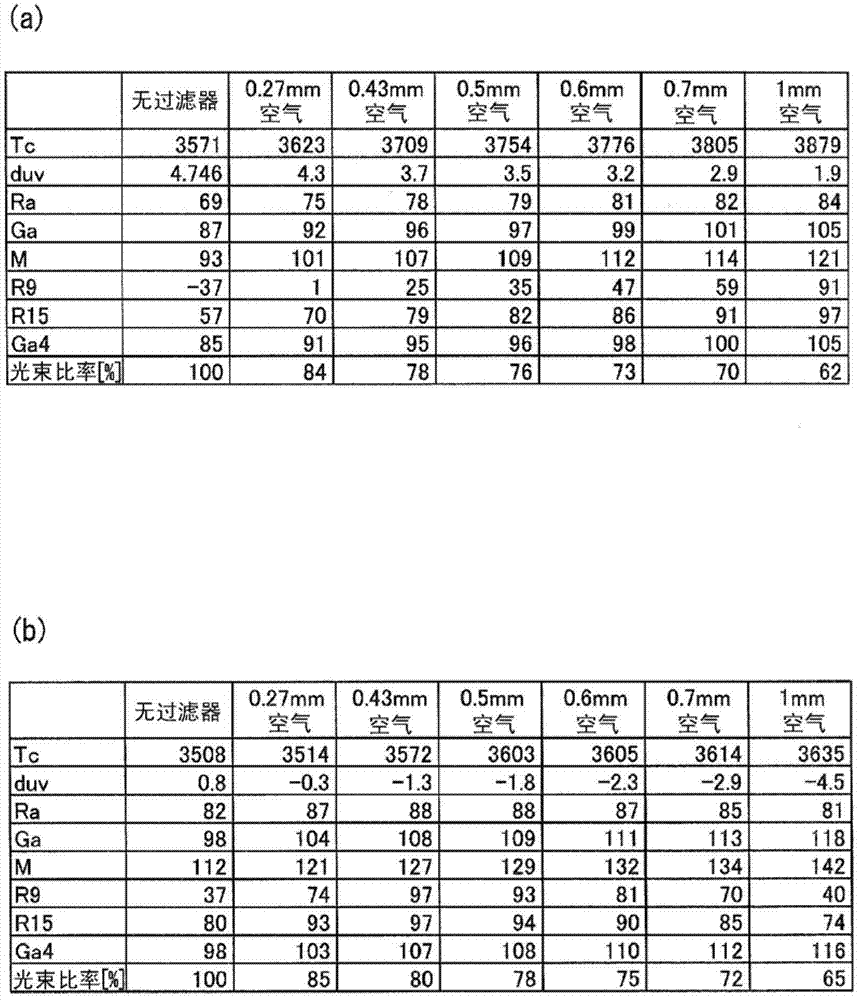

LED lamp, LED illumination device, and LED module

ActiveCN102782396ADecreased spectral radiation intensityPoint-like light sourceElongate light sourcesPhosphorBright red color

Disclosed is an LED lamp which is capable of having a bright red color look natural. Specifically disclosed is an LED lamp (1) which comprises: an LED module (5) comprising a blue LED (12) that has a main emission peak within the wavelength range of 440-460 nm, a green or yellow phosphor (14) that is excited by the light emitted from the blue LED (12), and a red phosphor (15) that is excited by the light emitted from the blue LED (12) and / or the green or yellow phosphor (14); and a filter (16) that reduces the spectral radiation intensity of at least a part of the wavelength range of 570-590 nm among the light emitted from the LED module (5).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Saffron crocus health-care drinks and making method thereof

The invention provides saffron crocus health-care drinks and a making method thereof. The method is to treat a saffron crocus Chinese herbal medicine by techniques of microwave extraction, membrane separation, ultrahigh-temperature sterilization, sterile filling and the like. In the invention, by adopting low-temperature microwave extraction and instant ultrahigh-temperature sterilization, the flavor, nutrients and active ingredients of medicine solution is protected to a maximum degree; and the made drinks do not require refrigerating and adding preservative, the quality, freshness and nutrients of the drinks can be kept for a long term, and health-care drinks with bright red color can be make. The making process is short in flow, low in cost, labor-saving, and time-saving, the content of active ingredients is high, and the damage and loss of nutrients and flavor materials in the drinks are reduced. When taken for a long time, the saffron crocus health-care drinks can subside swelling, relieve pains, cool blood, detoxify, resist cancer and aging, and improve the immunity in human bodies completely.

Owner:朱彩凤

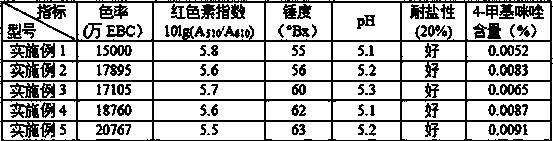

Preparation process of low 4-methylimidazole caramel pigment

The invention discloses a preparation process of low 4-methylimidazole caramel pigment, wherein an ammonium carbonate catalyst is added step by step, the reaction temperature and reaction time are controlled strictly, a caramel reaction is carried out stage by stage, the prepared caramel pigment has a bright red color (the haematochrome index is higher than 5.5), the 4-methylimidazole content is low (smaller than 100 ppm), and all the physical and chemical indexes reach the GB8817-2001 national standard.

Owner:广州华糖食品有限公司 +1

Chilli sauce and preparation method thereof

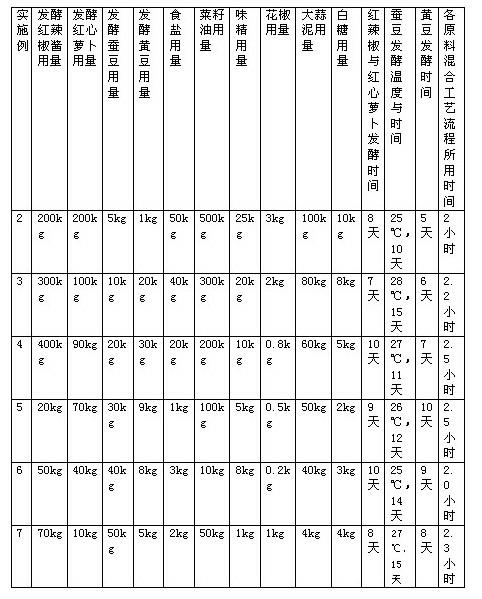

InactiveCN101904487ARadish red pigment highIncrease contentFood preparationBiotechnologyNatural product

The invention discloses chilli sauce, which is prepared by mixing raw materials of chilli, red heart radish, broad bean, soybean, aginomoto, salt and oil according to an effective ratio. The chilli, the red heart radish, the broad bean and the soybean are all fermented. The chilli sauce has the advantages of simple preparation method, simple equipment and convenient industrial production on a large scale; the chilli sauce has the quality guarantee period between 12 and 18 months at normal temperature, crisp mouthfeel, bright red color and authentic biting taste, and is pure natural product according to the raw materials and the process flow, is not added with any additive or pigment, has rich nutrients and more effectively ensures the health of consumers.

Owner:周红

Copper-red glaze and preparation method thereof

The invention relates to copper-red glaze and a preparation method thereof. The copper-red glaze comprises, by weight, 5-10 parts of kaolin, 18-35 parts of quartz, 10-16 parts of calcium phosphate, 15-22 parts of albite, 15-24 parts of potassium feldspar, 2-9 parts of talcum, 1-2 parts of cupric oxalate, 0.5-1.5 parts of tin oxide, 8-16 parts of calcite, 0.5-1.5 parts of zinc oxide and 10-13 parts of borax. The copper-red glaze has the advantages that the glaze is even in color and good in glossiness, and porcelain processed by the copper-red glaze is even in color and thick in glaze, has an unique artistic effect, gives an impression of depth, steadiness, dignity and elegance to people, has a bright red color and is even in glaze color distribution and high in yield.

Owner:崔松伟

Summer black tea production technology

InactiveCN103828947ATight and thinBlack and oily in colorPre-extraction tea treatmentCooking & bakingEconomic benefits

The invention relates to a summer black tea production technology and especially relates to a technology for preparing black tea from summer raw materials. Summer raw materials harvested in June, July, and August are selected, the summer raw materials are re-withered by specific processes of the technology in specific time, the re-withered summer raw materials are rolled, the rolled summer raw materials are re-fermented by specific processes of the technology in specific time, and the re-fermented materials are subjected to unique production processes such as gross fire, complete fire and long-time re-baking. The produced black tea strips are tightly shrunk, are fine and have a black color, oily touch, and sugar and honey fragrances. The soup of the summer black tea has a bright red color, a mellow and mild taste, no bitter taste, and even and orderly tea bottom. The summer black tea production technology reduces a bitter taste of the summer black tea, realizes a sweet taste of the summer black tea and improves economic benefits of the summer black tea.

Owner:LISHUI AGRI SCI

Method for prolonging bouilli expiration data through low-frequency ultrasonic-assisted high-temperature and high-pressure combined sterilization

InactiveCN106797996AEfficient killingReduce order of magnitudeMeat/fish preservation by heatingFood ultrasonic treatmentLean meatEngineering

The invention provides a method for prolonging bouilli expiration data through low-frequency ultrasonic-assisted high-temperature and high-pressure combined sterilization and belongs to the technical field of meat product processing. The method disclosed by the invention comprises the steps of firstly vacuum packaging cooked bouilli with cooking liquor through high-temperature-resistant retort pouches, then performing high-temperature and high-pressure sterilization, quickly cooling and then performing low-frequency ultrasonic-assisted sterilization. Compared with traditional high-temperature and high-pressure sterilization, a product obtained through the invention has brighter red color and luster pork skin, has deep-red and glossier lean, has peculiar mellow flavor of bouilli, has no cooking taste and has moderate mouthfeel; the lean meat is soft, moderate and not hard and dry; the fat can be melted instantly after being eaten; the port skin is soft and glutinous; furthermore, a fat oxidizing degree is greatly reduced, and a product is not prone to oxidizing or going bad. Therefore, the method disclosed by the invention solves the problem that traditional high-temperature and high-pressure sterilization can damage product appearance and nutrition quality and solves the problem that pure ultrasonic wave sterilization strength is insufficient at the same time. In the premise that no corrosion remover is added, compared with before being sterilized, the preserving rate of bouilli flavor is kept by 93% or more, and normal-temperature high-quality shelf life of the bouilli can reach 12 months.

Owner:JIANGNAN UNIV

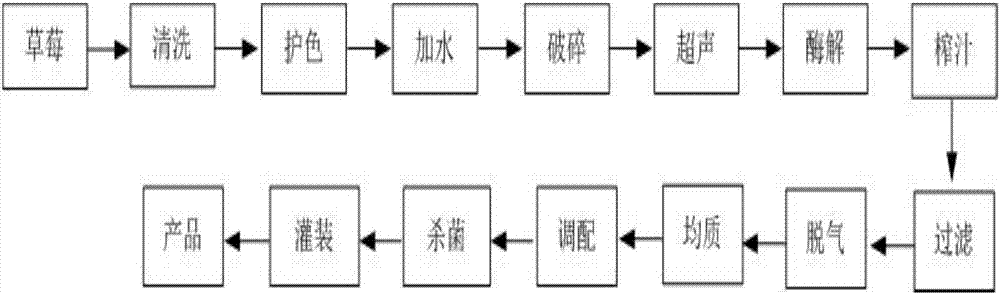

Preparation method of strawberry juice

ActiveCN107568520AImprove enzymatic hydrolysis efficiencyImprove stabilityFood sciencePectinaseFragaria

The invention discloses a preparation method of strawberry juice. The method includes the following steps: firstly removing the stalks and pedicels of strawberries and performing cleaning; performingcolor protection; adding drinking water and performing breaking; after performing ultrasonic wave treatment, adding pectinase and cellulase and performing enzymolysis; performing squeezing, filtration, degassing and homogenization on the strawberry pulp after the enzymolysis so as to obtain strawberry juice; adding granulated sugar, citric acid, apple pectin, vitamin C and lactein into the strawberry juice; performing homogenization on the mixed strawberry juice, performing sterilization with ultra-high pressure homogenization and then performing aseptic filling so as to obtain finished strawberry juice products. The strawberry juice prepared through the process and formula provided by the invention has high strawberry juice yield, has little nutrient loss, has an outstnding fruit aroma ofthe strawberries, has a bright red color and a mellow and thick taste of proper sourness and sweetness, does not have the phenomenon of suspension or delamination, contains no preservative and has along storage period.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

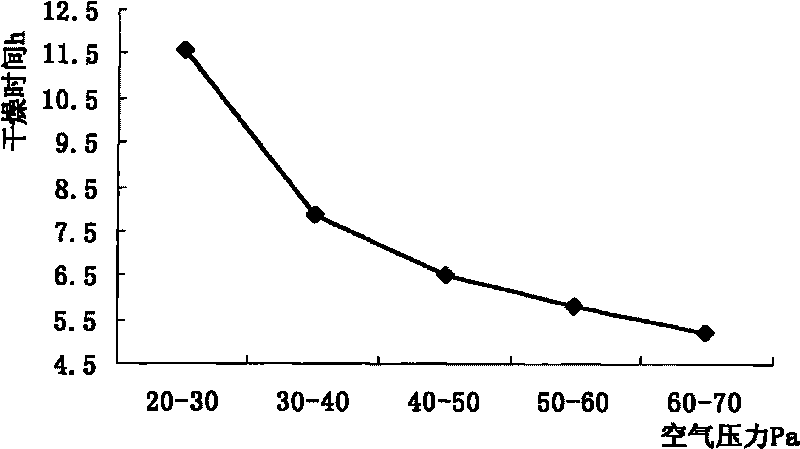

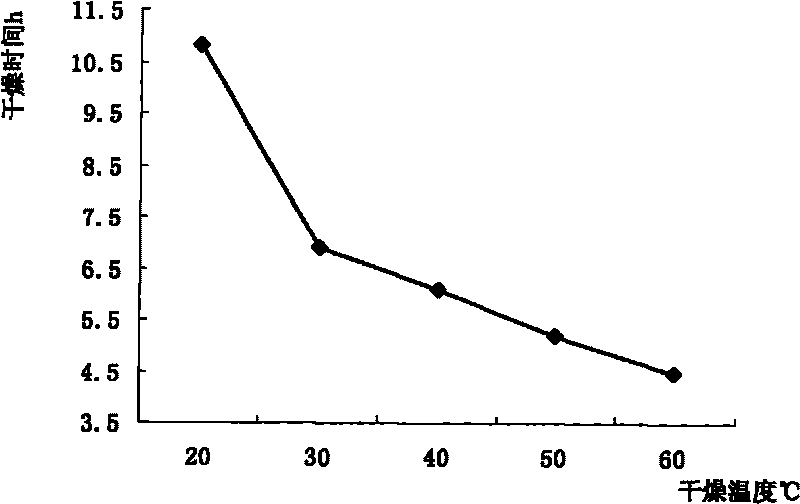

Method for making vacuum freeze drying watermelon slices

InactiveCN101692846AAchieve long-term storageBright red colorFruit and vegetables preservationFlavorLife quality

The invention relates to the deep processing method of watermelon, in particular to a method for making vacuum freeze drying watermelon slices, solving the problem that the watermelon cannot be stored for a long tine on the premise of keeping original flavor and nutrition value of the watermelon by the traditional deep processing method of the watermelon. The method comprises the following steps: slicing, curing and conserving color, coating membranes, pre-freezing, drying, charging nitrogen gas and packaging. The invention realizes that the watermelon can be stored for a long time on the premise of keeping the original flavor, the nutrition value and medicinal value of the watermelon. The watermelon slices made by the method have bright red color, scour and sweet taste, and special fresh taste of the fresh watermelon. The surfaces of the watermelon slices are smooth but not adhesive, and are not nearly contractive. The application of the invention has great signification on promoting the agriculture synergism and the farmer increment and improving the life quality of people.

Owner:山西师范大学

Red sugarbeet beer and its brewing method

The present invention relates to red sugar beet beer and its brewing process. The process includes preparing malt juice with malt, hop and water, and pre-fermentation to obtain beer liquid; preparing red sugar beet slurry with red sugar beet and water and filtering to obtain red sugar beet juice, sterilizing, and cooling and fermenting to obtain fermented red sugar beet liquid; mixing fermented red sugar beet liquid and beer liquid in the weight ratio of 1 to 3-6, post-fermentation at 5-7 deg C for 36-48 hr and at 0 deg C for 48-96 hr, and filtering to obtain the red sugar beet beer. The present invention has the following advantages: common beer flavor, increased slight sour and sweet mouth feeling, natural attractive bright red color and health functions of invigorating kidney, strengthening physique, nourishing blood, etc.

Owner:章传华

Persimmon vinegar with effects of promoting blood circulation and removing blood stagnation

InactiveCN102302140ASweet and sour tasteRuddy colorVinegar preparationFood preparationSalvia miltiorrhizaLiver and kidney

The invention discloses persimmon vinegar with effects of promoting blood circulation and removing blood stagnation. The persimmon vinegar is brewed from persimmon in conjunction with the following traditional Chinese medicines: salvia miltiorrhiza, Chinese Angelica, creeping liriope, ligusticum wallichii, wolfberry fruit and hawthorn fruit by the process of fermentation. By virtue of synergism of the traditional Chinese medicines, the persimmon vinegar has the effects of promoting blood circulation and removing blood stagnation, cooling blood and eliminating mass, and tonifying the liver and kidneys. The persimmon vinegar provides a human body with acetic acid, lactic acid, succinic acid, gluconic acid, malic acid and amino acids while taking full advantage of medical effects, which can enhance the health-care effect of promoting blood circulation and removing blood stagnation. The invention has the benefits that the prepared persimmon vinegar has a sour-sweet taste, a bright red color and a mild fragrance of traditional Chinese medicines, is free of adverse and toxic effects, can be eaten together with other foods or separately, and is significant in the effects of promoting blood circulation and removing blood stagnation.

Owner:王学文

Method for manufacturing canned crabmeat

InactiveCN105361016ASolve the darkening of colorSolve the problem of blue changeMeat/fish preservation using chemicalsFlavorHeat sensitive

The invention provides a method for manufacturing canned crabmeat. The method includes whole crab cleaning and disinfection, preparation of crabmeat, color retention treatment, preparation of a soup, canning, exhausting, sealing, and sterilization. The invention has the advantages that the method effectively solves the problem of bluing canned crabmeat, and the finished crabmeat has bright red color; at the same time, the method solves the problem of meat hardening and weak elasticity and chewiness after high temperature steaming, effectively shortens the sterilization time after canning, realizes low-temperature sterilization, and keeps the original elasticity and flavor of meat, maximizes the retention of heat sensitive nutrients, and prevents moisture loss. The prepared canned crabmeat is convenient to eat, tender and smooth in mouth feel, delicious in taste, and long in shelf life. The manufacturing process is scientific, reasonable, strong in operationality and applicable to industrial production.

Owner:GUANGXI LIYANG BUILDING DECORATION ENG CO LTD

Making method of defatted stewed pork with brown sauce

InactiveCN105901472ABright red colorMeaty and softFood ingredient as flavour affecting agentFood ingredient as mouthfeel improving agentBamboo shootEngineering

The invention relates to a making method of defatted stewed pork with brown sauce, and belongs to the technical field of food processing. The method adopts a chickens' extract-free defatting cooking technology comprises the following steps: pressing streaky pork with a weight, and steaming the streaky pork; cutting the steamed streaky pork with a knife to form square port, and cutting remaining parts to form minced pork; arranging a bamboo pad at the bottom of a pot, adding ginger and scallion, arranging the square pork on the bamboo pad, adding cold water until the square pork is immersed, adding high-grade Shaoxing wine, red wine, soy sauce and white sugar, and boiling the cold water with strong fire; changing to weak fire, boiling until the pork is loose and bright red, and taking out the pork with a dense sauce; adding the minced pork to the pot, cooking the minced pork, taking out the cooked minced pork, and reserving the obtained pork juice without oil; selecting a ceramic pot, adding dried bamboo shoot and the cooked square pork, filling with small strips of the minced pork, adding dry black carps, and pouring the pork juice; and carrying out secondary steaming on the panned stewed pork with brown sauce to obtain the defatted stewed pork with brown sauce. The stewed pork with brown sauce, made in the invention, has the advantages of bright red color, soft meat, thinness without skinniness, and special delicate fragrance mouthfeel formed through mutual fusion of various fragrances.

Owner:崔新民

Concrete penetrating coloring agent and application thereof

The invention relates to a concrete penetrating coloring agent and application thereof. The concrete penetrating coloring agent is prepared from the following components of organic pigment, a solvent,a penetrant, a wetting agent, an emulsifier, a silane coupling agent and a thinner. The concrete penetrating coloring agent has the advantages that the penetrating property is strong, the coloring agent can effectively penetrate into a concrete surface layer and generate chemical reaction with a concrete substrate, and a colorful concrete whole structure with stable color can be formed; the operation is simple, the convenience in use is realized, the colorful effect is realized, more than twenty conventional colors can be formed, and the required other colors can be blended by the existing colors; the conventional colors include golden yellow color, orange yellow color, camel color, brown color, coffee color, orange red color, claret color, bright red color, garnet color, purple color, bright green color, jade green color, dark green color, water gray blue color, bright blue color, peacock blue color, deep blue color, light gray color, medium gray color, pure black color and the like,and every two colors or more colors can be mixed to form other colors.

Owner:苏州金润新材料科技有限公司

Common yam rhizome-mushroom oil pepper and preparation method thereof

InactiveCN107183598ABright red colorStrong fragranceFood ingredient functionsMonosodium glutamateHot peppers

The invention discloses a common yam rhizome-mushroom oil pepper, which is prepared from the following raw materials by weight: 24.5-25.5 parts of edible oil, 9.5-10.5 parts of hot pepper, 4.5-5.5 parts of common yam rhizome, 20-25 parts of mushroom, 1.5-2 parts of soybeans, 1-1.5 parts of edible salt, 1-3.5 parts of monosodium glutamate, 0.5-0.8 part of white granulated sugar, 0.4-0.6 part of spice, 0.1-0.15 part of fructus amomi rotundus, and 0.1-0.15 part of amomum tsaoko. The common yam rhizome-mushroom oil pepper of the present invention has characteristics of bright red color, spicy and delicious taste, pure taste, elegant and delicate taste, long aftertaste, and high nutritional value. The invention further discloses a preparation method of the common yam rhizome-mushroom oil pepper, wherein fresh red pepper, common yam rhizome, mushroom, edible oil and the like are used as the raw materials, and raw material pretreatment, frying, stir-frying and other processes are performed to prepare the common yam rhizome-mushroom oil pepper. The common yam rhizome-mushroom oil pepper prepared by using the process method of the present invention has characteristics of bright red color, no blackening, no coking, long-term storage, and health preserving effect.

Owner:宝鸡同盛食品有限公司

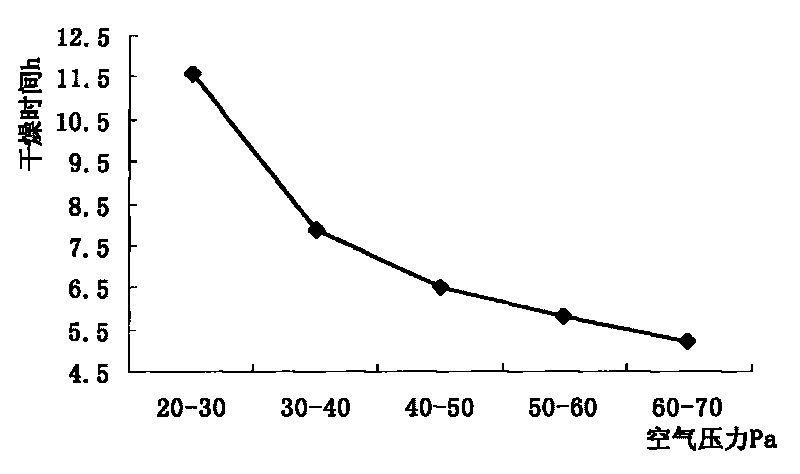

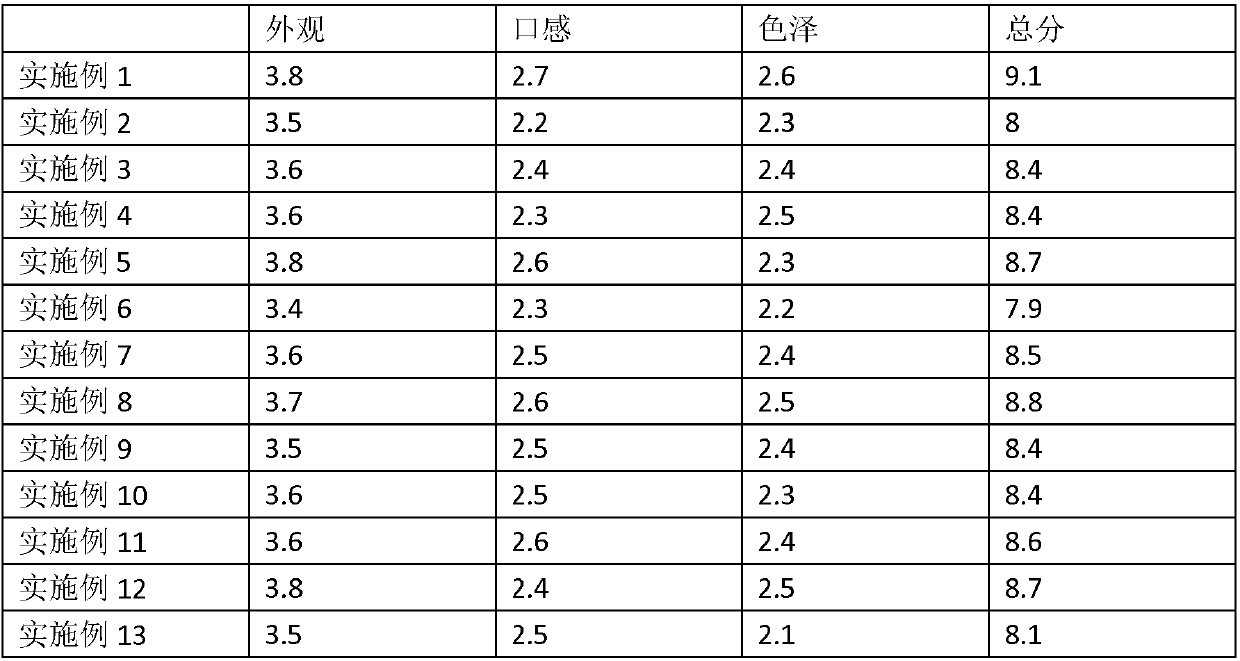

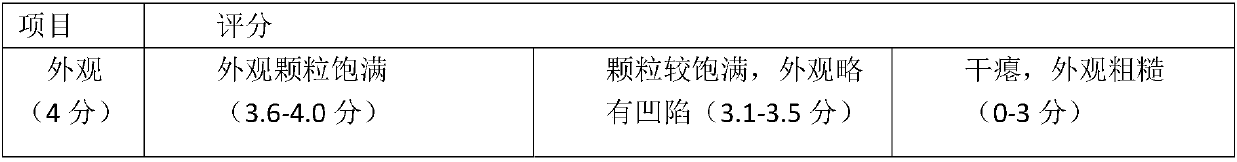

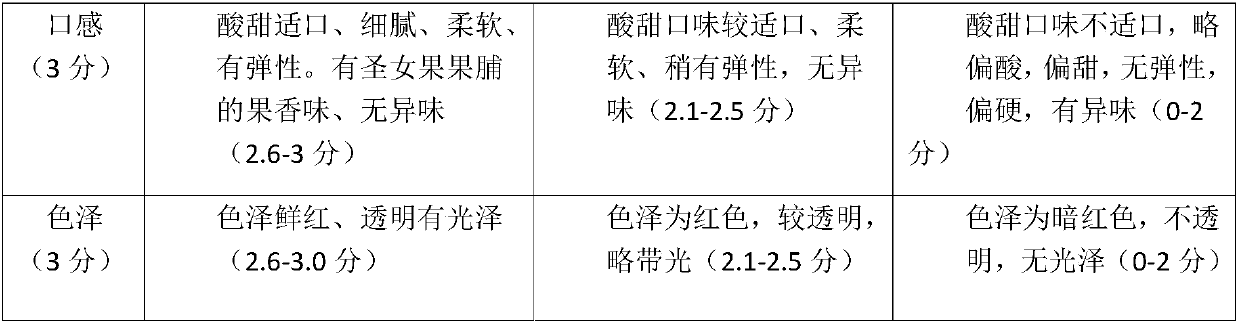

Production method of sulfur-free fermented preserved cherry tomato

ActiveCN107712235ASoft textureBright red colorFood thermal treatmentConfectioneryLactobacillus acidophilusPermeation

The invention discloses a production method of sulfur-free fermented preserved cherry tomato. The healthy novel preserved cherry tomato obtained through weakly acidic potential water cleaning, Lactobacillus bulgaricus, Lactobacillus acidophilus and Lactobacillus plantarumc composite bacterium fermentation, a best color protecting agent ratio and an ultrasonic sugar permeation process has the advantages of soft texture, bright red color and unique taste. Added oligosaccharides can promote the growth and the reproduction of probiotics, and also can inhibit the growth of harmful bacteria in the intestine, promote the intestine moistening and bowel relaxing of human bodies to realize safe detoxification, enhance the immunity, reduce the blood fat and cholesterols and promote mineral matter absorption.

Owner:ZHEJIANG UNIV

Technology for producing marinating water for marinated products

InactiveCN107801969ABright red colorRich and long fragranceNatural extract food ingredientsFiltrationPeppermints

The invention provides a technology for producing marinating water for marinated products, and relates to the field of food processing. The technology comprises the following steps: taking 70-80 partsby weight of soup stock, adding, by weight, 8-12 parts of chili, 3-6 parts of shrimp meat, 5-8 parts of Chinese prickly ash, 5-8 parts of old ginger, 10-15 parts of fresh ginger, 7-9 parts of garlic,5-8 parts of scallion, 3-4 parts of aniseed, 2-3 parts of Kaempferia galanga L., 2-3 parts of anise, 2-3 parts of cinnamon bark, 2-3 parts of Fructus Amomi, 2-3 parts of Java amomum fruit, 2-3 partsof Syzygium aromaticum, 1-2 parts of wrinkled gianthyssop, 1-2 parts of Ligusticum wallichii, 1-2 parts of Fructus Tsaoko, 1-2 parts of Common jasmin orange, 2-3 parts of Folium Perillae, 1-2 parts ofdried orange peel and 1-2 parts of peppermint leaves, performing decoction for 4-6 h, and performing filtration to obtain a filtrate which is the marinating water. The marinating water produced through carefully choosing all above raw materials and using the cooperative coordination effects of the raw materials has the advantages of bright red color, heavy and long flavor, fresh and delicious taste, strong fish or mutton smell removal ability, guaranteeing of good quality of marinated products produced by using the marinating water, high controllability, stable taste and long shelf life; andthe technology has the advantages of simplicity, short production period, high production efficiency, and facilitation of large-scale production.

Owner:绵阳市云阳食品有限公司

Method for preparing high-nutrition pickled dried beef

InactiveCN101731637AHigh utility valueGood for healthFood preparationAdditive ingredientBright red color

The invention relates to a food processing method, in particular to a method for preparing high-nutrition pickled dried beef, which comprises five steps of pickling roughly, cooking thoroughly, adding plant soot, sealing by a clay jar and drying and packaging, wherein the step of coating the black plant soot on the boiled beef is to set the meat quality off to a bright red color, without blotting a mouth and harming a human body; the step of pickling is to remove meat smell; and the step of sealing by the clay jar is to make the beef completely absorb nutrient components. The dried beef is dry instead of tough, smooth instead of soft, ruddy and bright, delicious in taste, moderate in appetite, lingering in aftertaste, full in color, fragrance and taste and rich in nutrition. The dried beef is black on the surface and red in the center, which makes a person free the imagination to associate the dried beef with Zhang Fei, who is a valiant general in Shu Han during the three kingdoms period, so that eating the beef contains a historical flavor. Compared with the conventional production technology of the air-dried beef, the air-dried beef is produced by pickling by dry-powder ferment so as to shorten the fermentation time and have a good application prospect.

Owner:CHENGDU FANXINJIA TECH

Formula and making method of high-nutrition spicy chili sauce

InactiveCN106262716AImprove edibleHigh medicinal valueFood ingredient as mouthfeel improving agentChilli con carnePreservative

The invention discloses a formula and making method of high-nutrition spicy chili sauce, and belongs to the field of food. The high-nutrition spicy chili sauce is made from, by mass, 50-60 parts of fresh chilies, 10-18 parts of snail meat, 3-8 parts of fresh ginger, 2-7 parts of medicinal liquor, 3-8 parts of fresh cucumber peel, 4-10 parts of olive oil, 2-8 parts of rod chilies, 2-7 parts of perilla leaves, 6-10 parts of garlic, 4-10 parts of butter and 3-8 parts of table salt. According to the formula and making method of the high-nutrition spicy chili sauce, natural food materials are adopted, no chemical additive is added, and reasonable matching, rich nutrition and the effects of promoting appetite and caring health are achieved; the method is easy to operate and popularize, the chili sauce made through the method has the bright red color and luster, rich nutrition, strong fragrance, spicy taste and chewiness and is free of preservatives and long in quality guarantee period, and the longer the chili sauce is preserved in the quality guarantee period, the better mouthfeel the chili sauce has.

Owner:湖南省辣味源农业有限公司

Making method of Dancong strip-shaped black tea

InactiveCN107372925AImprove qualityThe shape is tight and beautifulPre-extraction tea treatmentBlack teaEconomic benefits

The invention provides a making method of Dancong strip-shaped black tea. The method mainly comprises the following steps: fresh leaf picking, withering, rolling, fermentation, drying, re-fermentation and re-drying. Devices are combined in the making process to optimize withering and fermentation technologies in order to improve the processing quality, the processing efficiency and the economic benefit of Dancong black tea. The obtained Dancong black tea has high and brisk endoplasmic aroma and has nectar aroma, a tea soup obtained by using the tea has a bright red color, a mellow, brisk and sweet taste and plump mouthfeel, is unique, and is incomparable to general black tea .

Owner:饶平县兴记茶厂

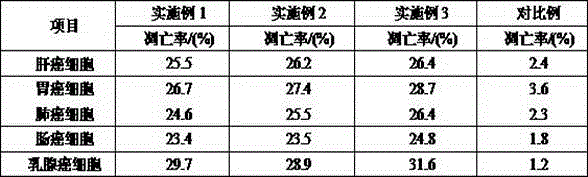

Antitumor red bean curd

The invention discloses an antitumor red bean curd. The antitumor red bean curd is made from, by weight, 120-130 parts of soybeans, 22-24 parts of skim milk, 6-8 parts of bell pepper, 6-8 parts of strawberries, 6-8 parts of gooseberries, 1.6-1.8 parts of camellia sinensis flowers, 1.4-1.6 parts of licorice root, 1.4-1.6 parts of health preserving grass, 1.4-1.6 parts of Semen Impatientis, 0.6-0.8 parts of Brucea javanica, 2.2-2.4 parts of lactic acid bacteria, 4-5 parts of lactosucrose and 0.2-0.3 parts of lycopene. The antitumor red bean curd has the advantages of abundant raw materials, fine and tender mouthfeel, rich fragrance, bright red color, balanced nutrition, easy absorption and comprehensive health functions, and can protect heart and cerebral vessels, prevent ageing, tranquilize mind, help sleep, promote intestinal functions and prevent tumors to reach a life prolongation health effect; various Chinese herbal medicines and soybean milk are boiled, and components are fully fused, so toxicity of the traditional Chinese medicines is eliminated, and the beany flavor is weakened.

Owner:张保义

Special spice chilli sauce

The invention discloses special spice chilli sauce, which is prepared by the following steps: taking 100kg of fresh chilli as a raw material, adding 2kg of ginger, 2kg of shallot, 1kg of garlic and 0.2kg of litsea cubeba, grinding into thick liquid, adding 10kg of table salt, performing fermentation for 30 days, and stirring every 3 to 5 days; and after the fermentation, adding 2kg of white spirit with 52 alcoholic strength into each 100kg of the chilli sauce, evenly stirring, packaging into a package barrel, sealing the opening of the barrel by a food grade plastic film, making the film closely contacted with the liquid level of the chilli sauce in the barrel and form a concave space with the upper edge of the opening of the barrel, pouring white spirit with more than 52 alcoholic strength into the concave space, and screwing the upper cover of the package barrel for sealing and disinfection so as to realize long-term storage. The special spice chilli sauce has stable quality, bright red color, no deterioration and blackening, consistent taste and more than 3-year quality guarantee period.

Owner:务川山仙东升食品有限责任公司

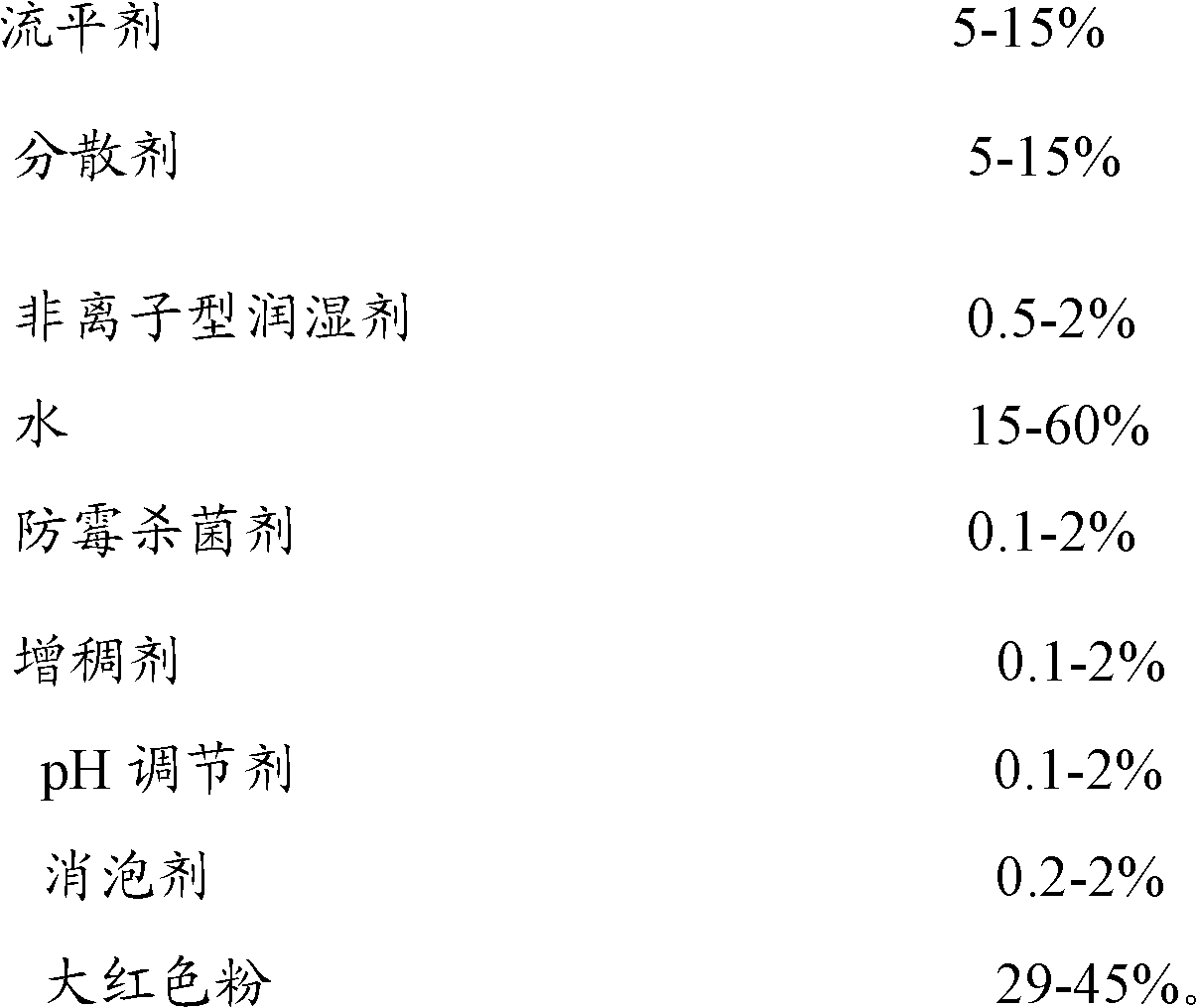

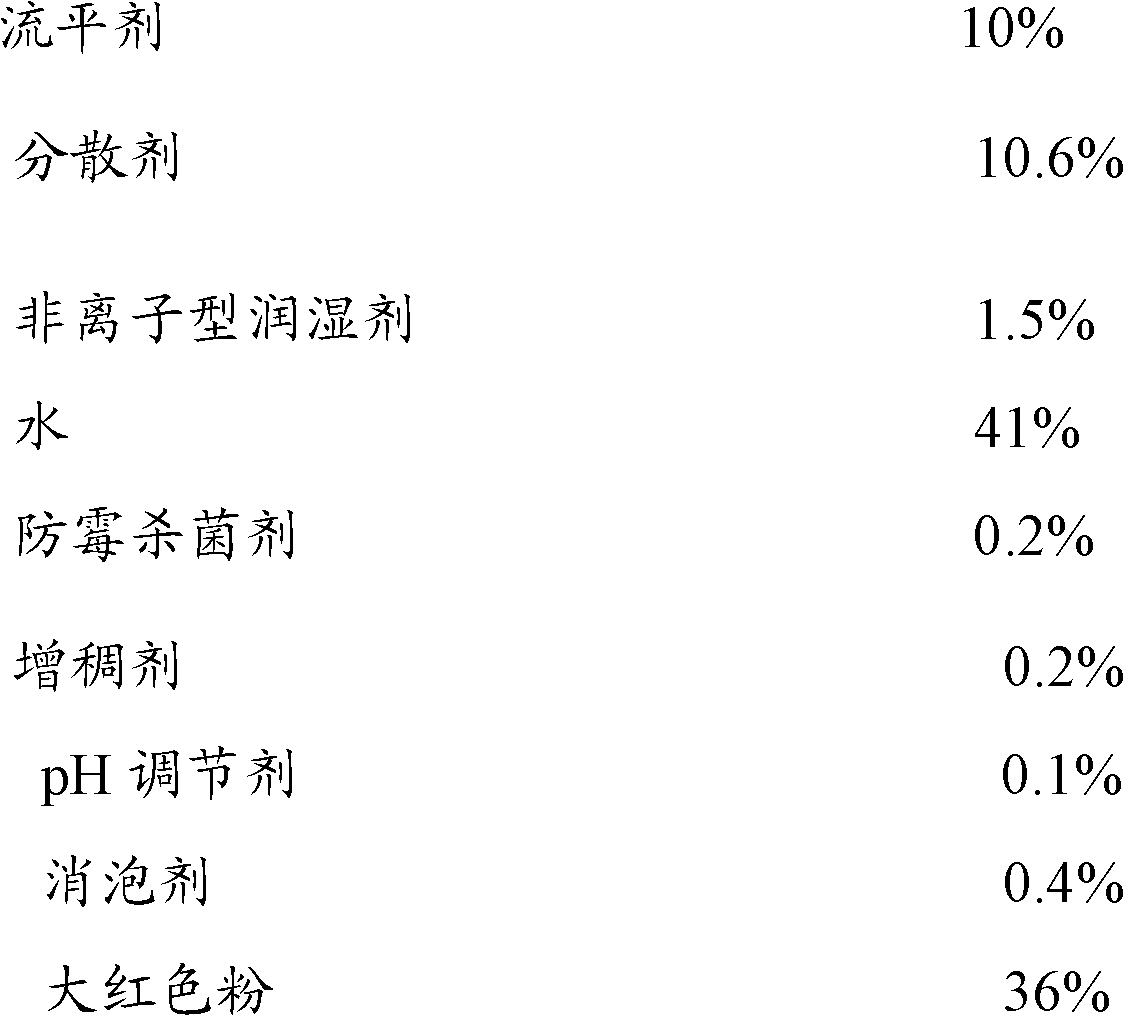

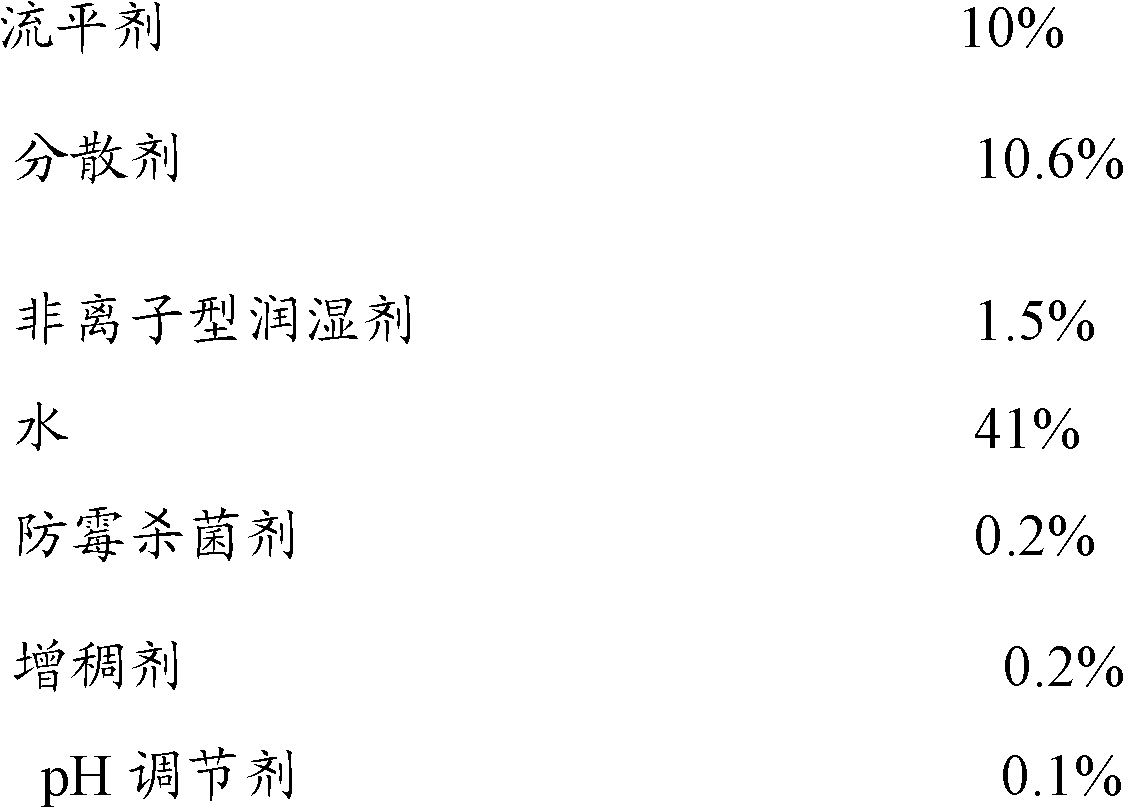

Environment-friendly water-based universal bright red color paste and preparation method for same

The invention provides water-based universal bright red color paste, which comprises, by weight, 5-15% of leveling agent, 5-15% of dispersing agent, 0.5-2% of nonionic wetting agent, 15-60% of water, 0.1-2% of mouldproof fungicide, 0.1-2% of thickening agent, 0.1-2% of pH (potential of hydrogen) regulator, 0.2-2% of defoaming agent and 29-45% of bright red powder. The water-based universal bright red color paste is prepared by means of reasonable match of the leveling agent, the dispersing agent and the specific wetting agent, is high in university, does not contain APEO (alkylphenol ethoxylates) but contains ultra-Low VOC (volatile organic compounds) (VOC<=2G / L), and can be used for color matching of emulsion paint and water-based wood lacquer.

Owner:东莞大宝化工制品有限公司 +1

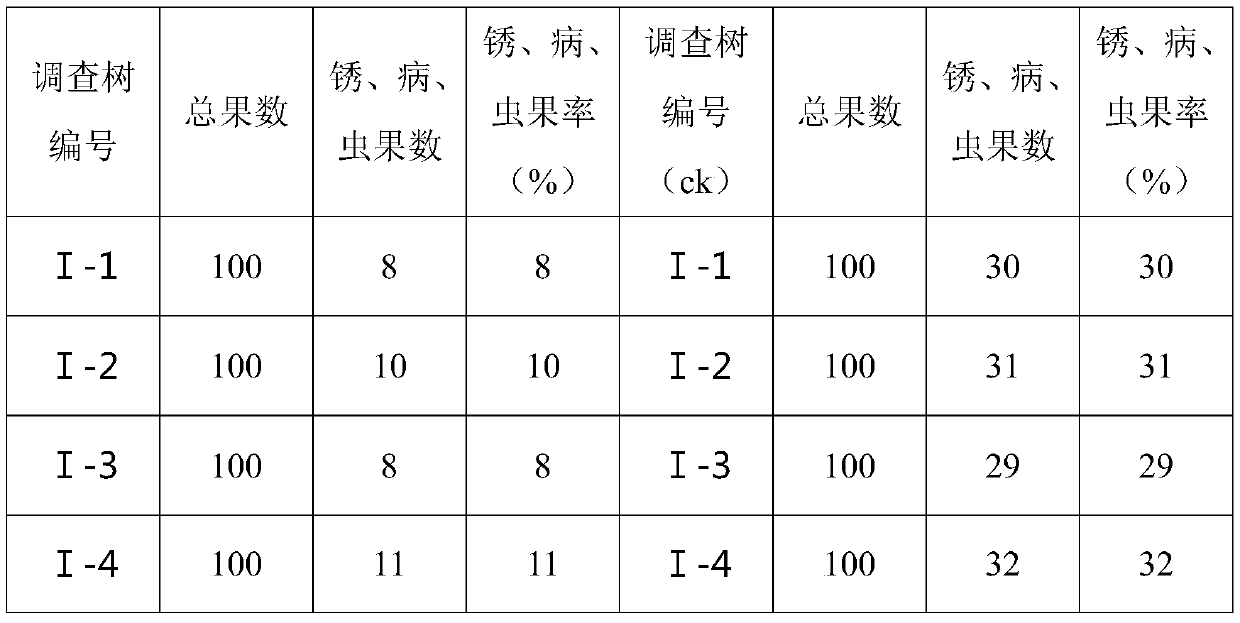

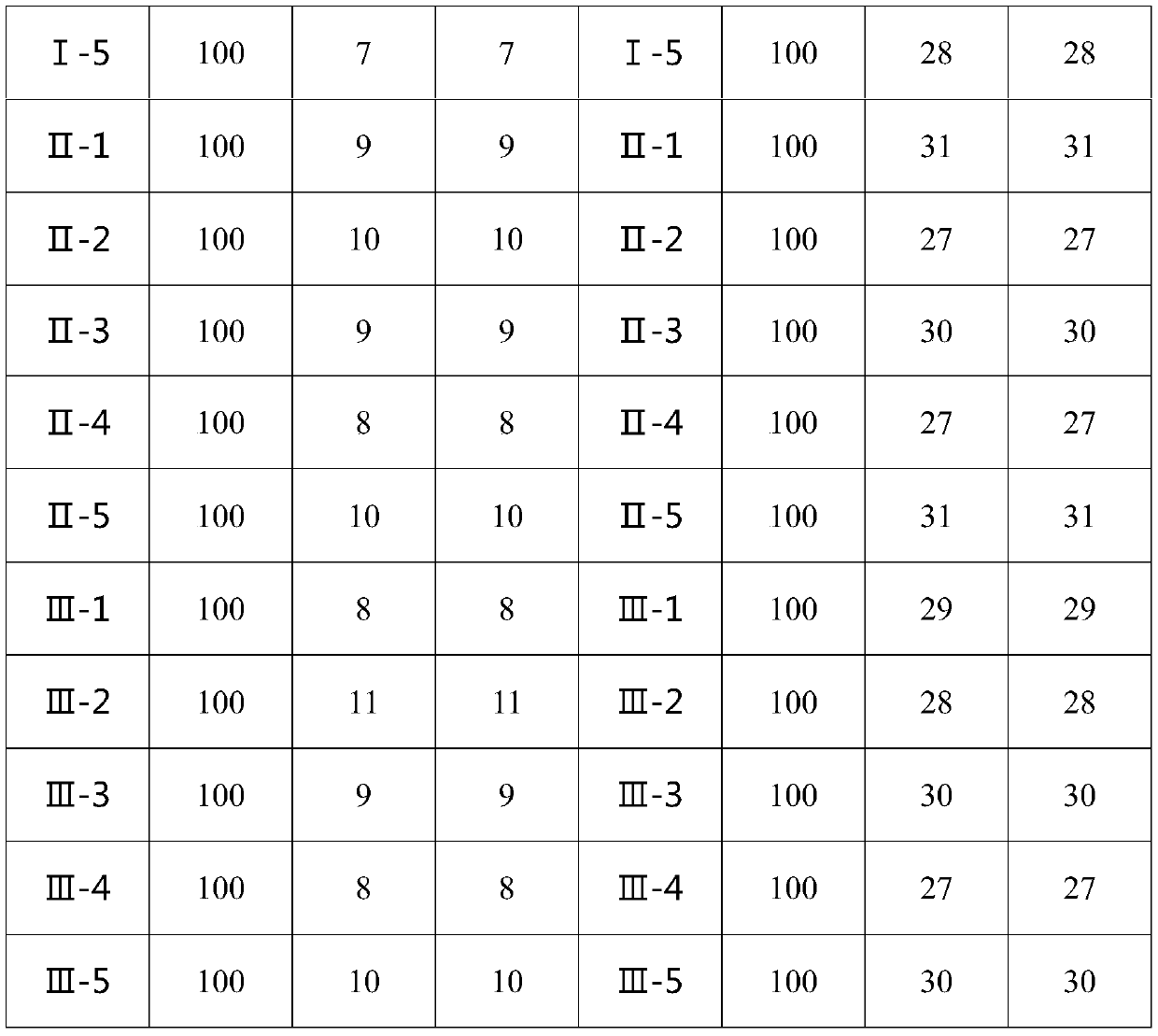

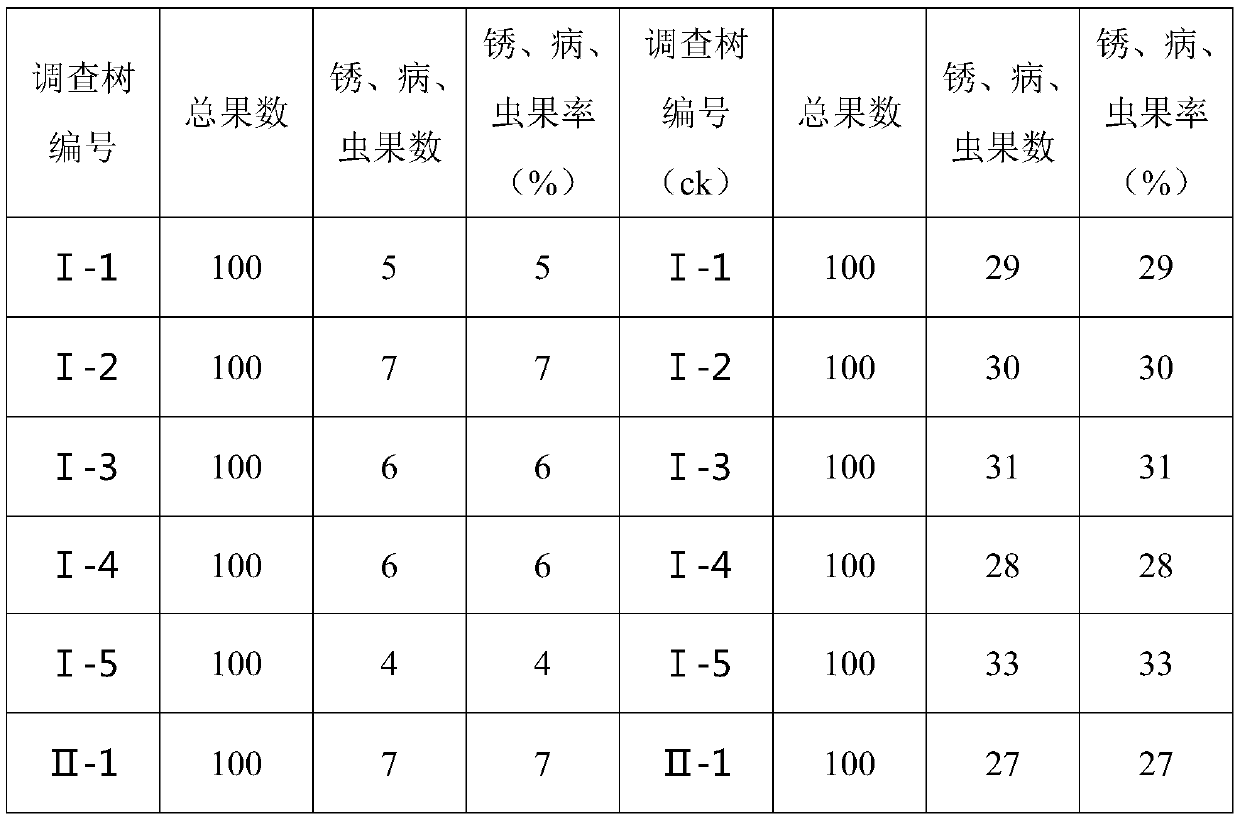

Method for improving surface cleanness and color brightness of apples

InactiveCN110692417APrevent rustFlat surfaceCultivating equipmentsHorticulture methodsFruit treeFruit maturation

The invention discloses methods for improving apple appearance quality, particularly relates to a method for improving the surface cleanness and color brightness of apples, and belongs to the technical field of fruit tree planting. The method includes: in early June, spraying a pesticide, a bactericide, a surface cleaning agent and fruit and vegetable calcium to the apples for 4 times from the early fruit-setting period of the apples to the time before bagging, bagging the apples after the spraying to prevent fruit rust, bitter pit and other diseases and pests, and removing the bags 15 days before fruit maturity to achieve centralized coloring until harvesting. By the method, the surfaces of the applies are clean and smooth, and the apples have a bright red color.

Owner:辽宁省果树科学研究所

Raspberry drink with slimming and beautifying functions and preparation method thereof

ActiveCN106343295AReduce flocStimulate the desire to drinkFood ingredient functionsYellow raspberryBright red color

The invention relates to the technical field of food processing, in particular to a raspberry drink with slimming and beautifying functions and a preparation method thereof. The raspberry drink is mainly prepared from the following raw materials in parts by weight: 50-60 parts of red raspberry, 10-20 parts of yellow raspberry, 5-10 parts of black raspberry, 5-10 parts of dragon fruit, 2-5 parts of aloe, 3-5 parts of honeysuckle, 2-4 parts of chrysanthemum, 2-5 parts of rose, 1-3 parts of mint, 3-7 parts of lycium barbarum, 5-10 parts of longan, 2-7 parts of lily, 1-4 parts of red dates, 1-4 parts of fragrans, 2-4 parts of roselle, 1-3 parts of lemons, 20-40 parts of a sweetening agent and 240-300 parts of water. The raspberry drink provided by the invention is sour and sweet in taste and is fresh and fragrant, and has healthcare effects of slimming and fitting bodies and beautifying faces. The drink prepared by using the method provided by the invention has an attractive and bright red color and is clear and bright.

Owner:河南生命果绿色食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com