Method for making vacuum freeze drying watermelon slices

A technology of vacuum freeze-drying and production method, which is applied in the fields of food preservation, fruit and vegetable preservation, food science, etc., to achieve the effect of bright red color, promoting agricultural efficiency, and convenient eating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

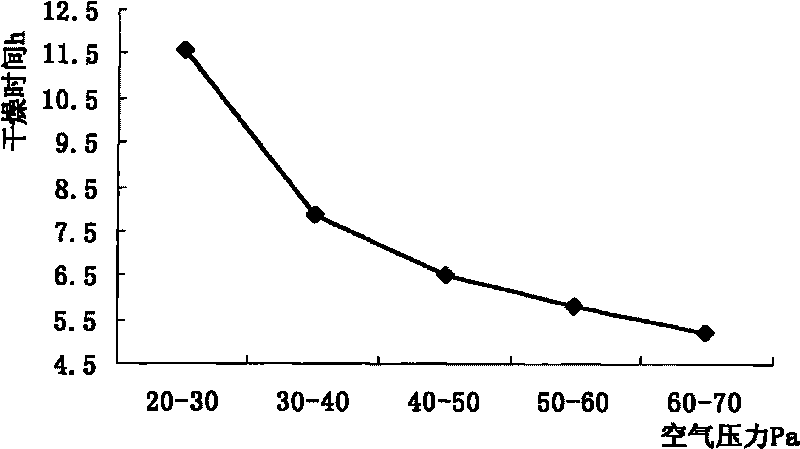

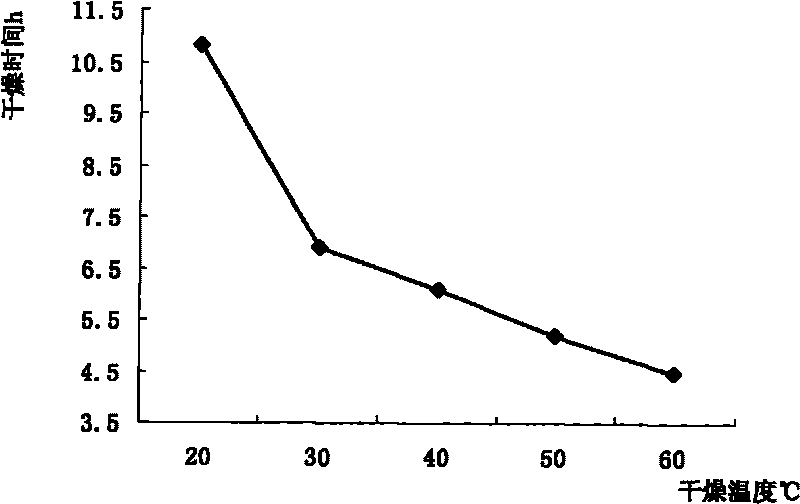

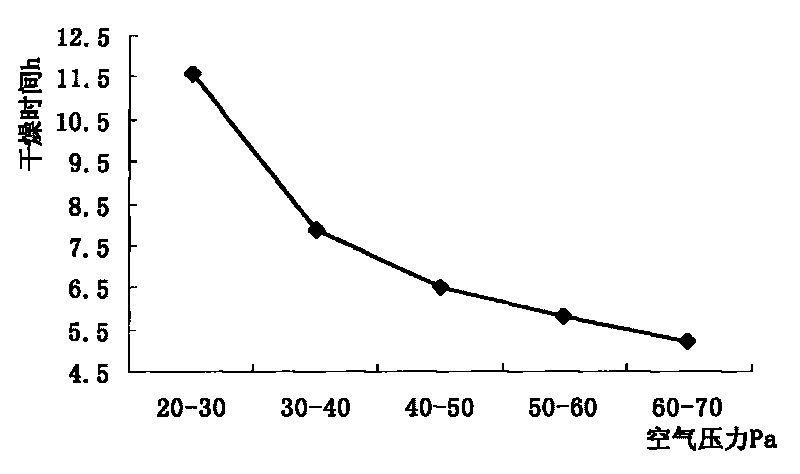

Embodiment 1

[0037] A method for making vacuum freeze-dried watermelon slices, including a slicing process, a hardening and color protection process, a film covering process, a pre-freezing process, a drying process, and a nitrogen-filled packaging process; , the watermelon pulp is cut into thin slices with a thickness of 2mm, and the thin slices are vibrated to make the watermelon seeds fall off automatically; Soak good watermelon slices in calcium lactate solution at a temperature of 55°C for 30 minutes; during the coating process, first gelatinize the starch, add 35g of potato starch to 1000ml of cold water, then heat the cold water to 95°C, while heating Stir until a uniform translucent viscous solution is formed; completely immerse the soaked watermelon slices in the translucent viscous starch solution that has been gelatinized and cooled to 30°C, and take it out quickly, the surface of the watermelon slices is attached A layer of gelatinized starch film; during the pre-freezing proce...

Embodiment 2

[0039] A method for making vacuum freeze-dried watermelon slices, including a slicing process, a hardening and color protection process, a film covering process, a pre-freezing process, a drying process, and a nitrogen-filled packaging process; , the watermelon pulp is cut into thin slices with a thickness of 4mm, and the thin slices are vibrated to make the watermelon seeds fall off automatically; The good watermelon slices are soaked in calcium lactate solution at 40°C for 35 minutes; during the coating process, starch gelatinization is performed first, 30g of potato starch is added to 1000ml of cold water, and then the cold water is heated to 95°C, while heating Stir until a uniform translucent viscous solution is formed; completely immerse the soaked watermelon slices in the translucent viscous starch solution that has been gelatinized and cooled to 25°C, and take it out quickly, the surface of the watermelon slices is attached A layer of gelatinized starch film; during th...

Embodiment 3

[0041] A method for making vacuum freeze-dried watermelon slices, including a slicing process, a hardening and color protection process, a film covering process, a pre-freezing process, a drying process, and a nitrogen-filled packaging process; , the watermelon pulp is cut into thin slices with a thickness of 3mm, and the thin slices are vibrated to make the watermelon seeds fall off automatically; Soak good watermelon slices in calcium lactate solution at 47.5°C for 40 minutes; during the coating process, starch gelatinization is performed first, and 40g of potato starch is added to 1000ml of cold water, and then the cold water is heated to 95°C, while heating Stir until a uniform translucent viscous solution is formed; completely immerse the soaked watermelon slices in the translucent viscous starch solution that has been gelatinized and cooled to 35°C, and take it out quickly, the surface of the watermelon slices is attached A layer of gelatinized starch film; during the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com