Preparation method of freeze-dried powder soluble microneedle

A freeze-dried powder and microneedle technology, applied in the field of microneedles, can solve the problems of reducing the deliverable amount of freeze-dried powder, failing to form a needle structure, and insufficient mechanical strength of freeze-dried powder, so as to achieve long-term storage, avoid waste, Realize the effect of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

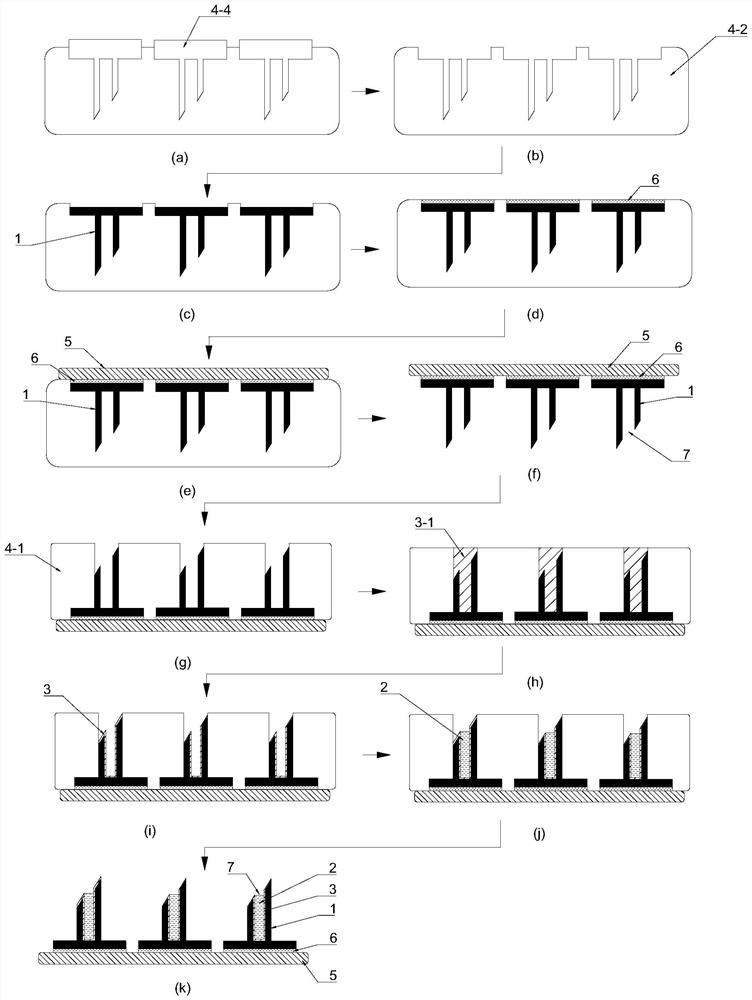

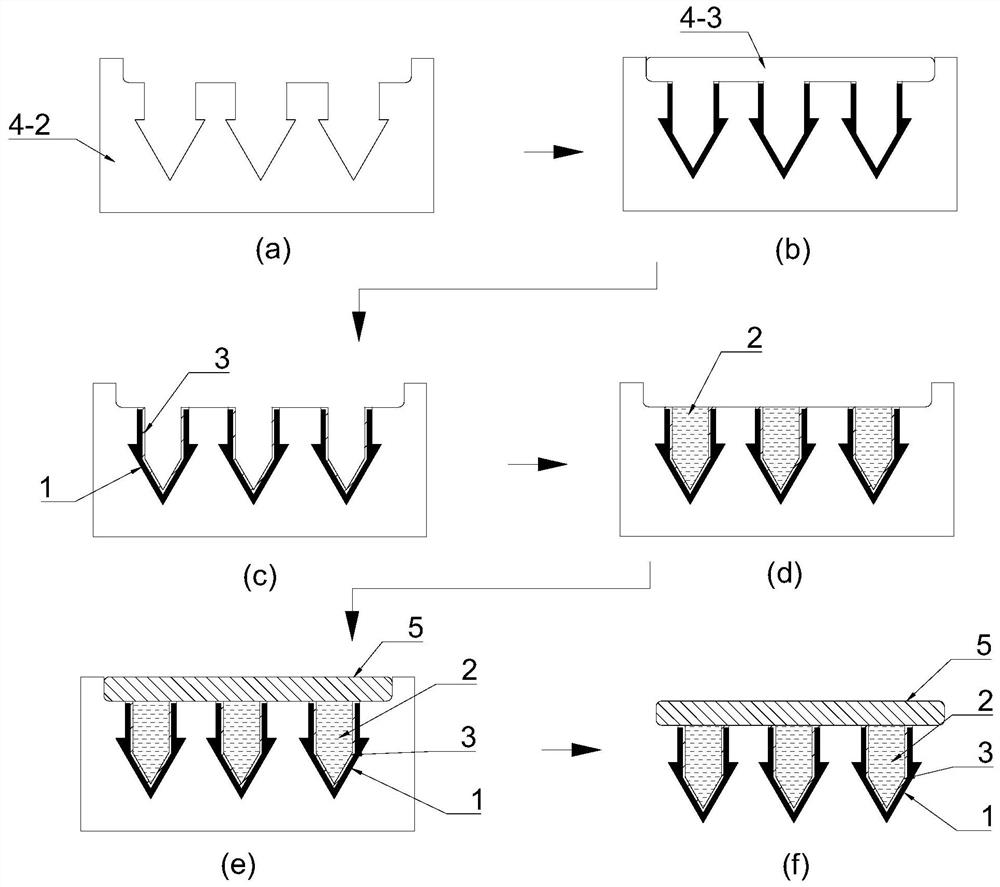

[0032] Example 1, as figure 1 As shown in K, a lyophilized powder soluble microneedle includes a plurality of soluble hollow needles 1 and a substrate 5, and the soluble hollow needles 1 are detachably fixed on the substrate 5 to form a microneedle array. Specifically, the substrate There is an effervescent separation layer 6 between 5 and the soluble hollow needle body 1 , and the soluble hollow needle body 1 is detachably fixed on the base 5 through the effervescent separation layer 6 . An oil-soluble protective layer 3 is provided on the inner surface of the soluble hollow needle body 1 , and freeze-dried powder 2 is filled in the inner cavity of the soluble hollow needle body 1 . The dissolvable hollow needle body 1 can also be detachably fixed on the substrate 5 using other solutions, such as the solution disclosed in Chinese Patent Document CN104069585A for detachable fixing.

[0033] The material of the soluble hollow needle 1 can be hyaluronic acid, collagen, silk pro...

Embodiment 2

[0050] Example 2 is basically the same as Example 1, except that the oil-soluble protective layer 3 is a polylactic acid waterproof protective layer. The method for preparing the polylactic acid waterproof protective layer on the inner surface of the soluble hollow needle body 1 made of hyaluronic acid is as follows: pour the ethyl acetate solution dissolved in polylactic acid into the upper port of the micropores of the drying mold 4-1, and the concentration is 0.5% , by heating the solution to evaporate the ethyl acetate solvent to dryness, the hyaluronic acid microneedle film will deposit a layer of polylactic acid waterproof protective layer.

Embodiment 3

[0051] Example 3, compared with the lyophilized powder soluble microneedle in Example 1, is different in that the needle opening 7 of the soluble hollow needle body 1 is on the side of the soluble hollow needle body 1 . And in the process of preparing the microneedle with the soluble hollow needle body 1, the filling of the lyophilized powder is completed.

[0052] The preparation method of the lyophilized powder soluble microneedle specifically includes the following steps:

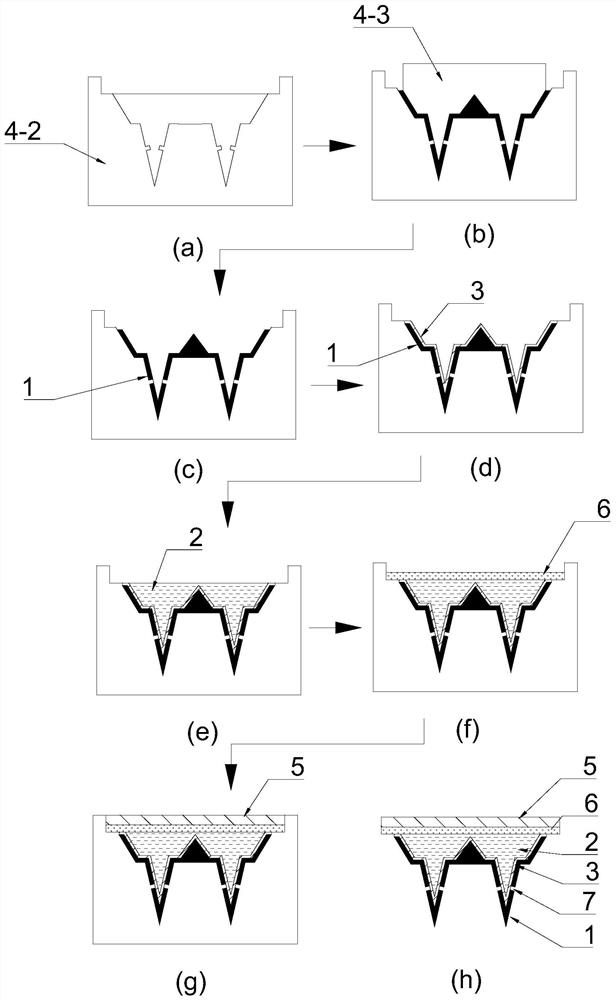

[0053] (1') The dissolvable hollow needle body 1 is prepared through a microneedle mold. The microneedle mold includes a female mold 4-2 and a male mold 4-3, and the side of the female mold 4-2 has a boss for forming the needle port 7 of the soluble hollow needle body 1 .

[0054] This step is more specific as follows: figure 2 As shown in a, 2b and 2c, deionized water and sodium hyaluronate powder are stirred and mixed to obtain a concentration of 5% gelatinous hyaluronic acid. In the mold 4-2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com