Patents

Literature

120 results about "Disodium inosinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disodium inosinate (E631) is the disodium salt of inosinic acid with the chemical formula C₁₀H₁₁N₄Na₂O₈P. It is used as a food additive and often found in instant noodles, potato chips, and a variety of other snacks. Although it can be obtained from bacterial fermentation of sugars, it is often commercially prepared.

Flavoring with beef flavor and preparation method thereof

The invention provides flavoring with beef flavor and a preparation method thereof. The flavoring is prepared from pure beef powder, refined butter, a yeast extract, hydrolyzed vegetable protein, bovine ossein, disodium 5'-ribonucleotide, salt, white sugar, glucose, dahurian angelica root powder, ginger powder, black pepper powder, white pepper powder, garlic powder, onion powder, tsaoko fruit powder, kaempferia galamga powder, anise powder, groud cinnamon, nutmeg seed powder, disodium 5'-inosinate, monosodium glutamate, maltodextrin and an anticaking agent. The flavoring with beef flavor prepared by mixing, heating, drying and crushing the above mentioned raw materials has rich meat flavor, natural and comfortable taste and a strong cooking property, is convenient to store, carry and utilize, is especially applicable as flavoring in the food industries of instant noodles, bibimbap, food and drink, leisure food and the like, and has the advantages of simple preparation, natural and rich flavor, high quality of a finished product, low production cost, etc.

Owner:天津市春升清真食品有限公司

Salt replacing composition, process for its preparation and food systems containing such composition

A salt replacing composition for replacing sodium chloride in food contains a major amount of potassium chloride, in combination with ammonium chloride, sucrose, one or more of disodium inosinate and disodium guanylate, an organic acid, and a salt of glutamic acid. A reduced sodium chloride composition contains the salt replacing composition and sodium chloride. A food containing the salt replacing composition and a process for making the salt replacing composition.

Owner:MCCORMICK & CO INC

Yeast extract, preparation method and application thereof

InactiveCN101513246AFlavor coordinationTaste balanceFood preparationCaramel FlavorVegetable Proteins

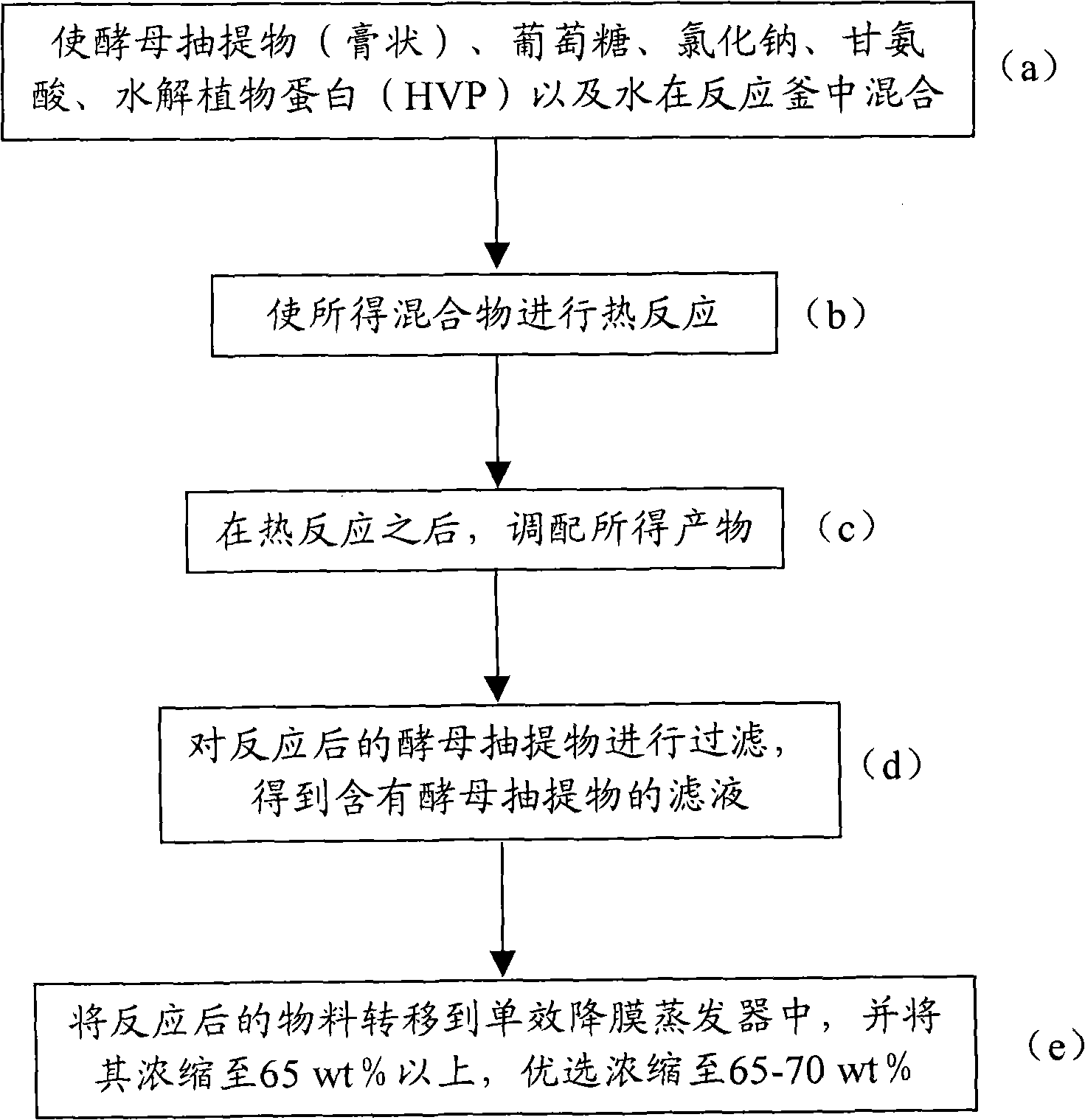

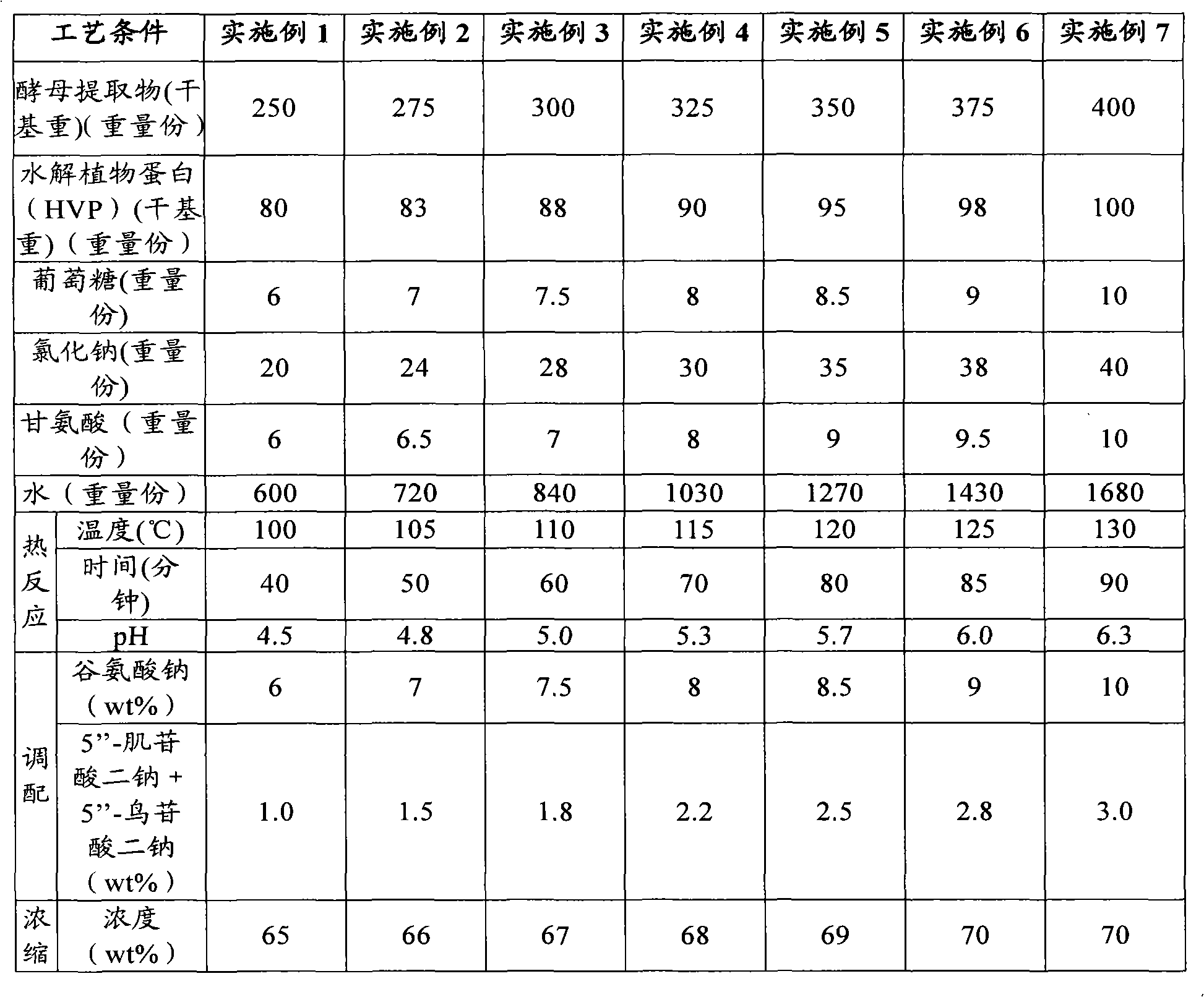

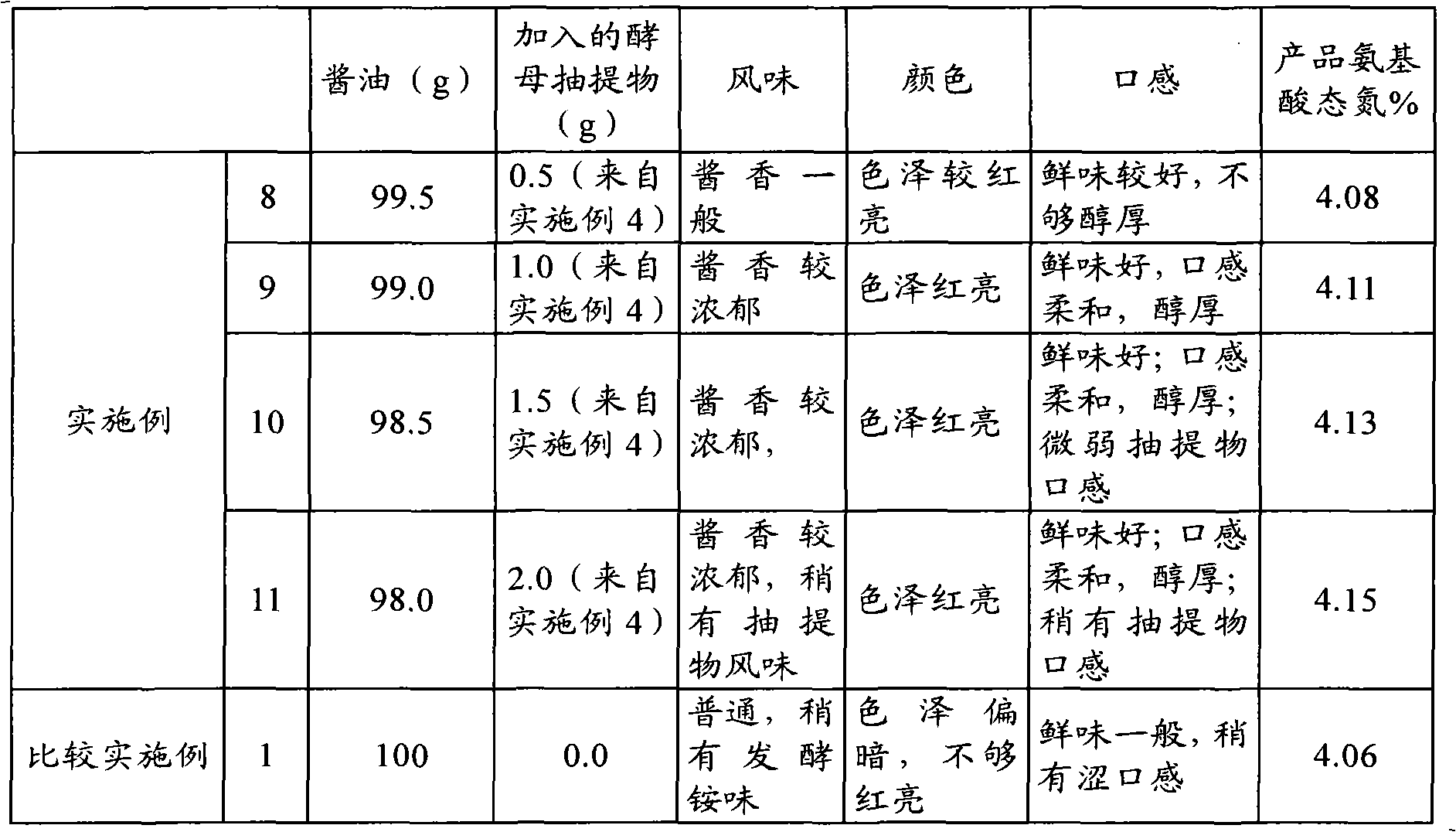

The invention provides a yeast extract, a preparation method and application thereof. The preparation method of the yeast extract comprises the following steps: (a) mixing the yeast extract, glucose, sodium chloride, glycin, hydrolyzed vegetable protein and water in a reaction kettle; (b) performing heat reaction on the mixture in step (a) for 40 to 90 minutes at a temperature of between 100 and 130 DEG C and pH of between 4.5 and 6.3; (c) after the heat reaction, adding 6 to 10 weight percent of sodium glutamate and 1.0 to 3.0 weight percent of disodium inosinate and disodium guanylate into an obtained product for preparation; (d) filtering the yeast extract after the reaction to obtain filtrate containing the yeast extract; and optional (e) transferring materials after the reaction to a single effect falling film evaporator, and concentrating the materials to more than 65 weight percent and preferably concentrating the materials to between 65 and 70 weight percent. The yeast extract prepared by the method has sauce fragrance and caramel like deep bright red color, and a water solution of the yeast extract has transparent bright red color and fresh and salty mouthfeel.

Owner:ANGELYEAST CO LTD

Meaty paste essence and preparation method thereof

InactiveCN102160633AHigh technical contentIncrease added valueFood preparationMaillard reactionDL-methionine

The invention discloses meaty paste essence and a preparation method thereof. The meaty paste essence comprises the following components in part by weight: 10 to 30 parts of L-cysteine, 15 to 20 parts of vitamin B, 20 to 40 parts of glucose, 10 to 20 parts of L-leucine, 5 to 10 parts of DL-methionine, 2 to 8 parts of alanine, 50 to 150 parts of yeast fine paste, 200 to 300 parts of bean pulp zymolyte, 2 to 5 parts of disodium inosinate and disodium guanylate (I+G), 30 to 60 parts of soy sauce, 50 to 80 parts of animal fat, 50 to 80 parts of salt, 50 to 100 parts of white granulated sugar, 1 to 3 parts of xanthan gum, 50 to 100 parts of sodium glutamate, 30 to 60 parts of corn starch and 10 to 30 parts of meaty flavoring base. The meaty paste essence prepared by combining the Maillard reaction technology and the bean pulp proteolysis technology has good mouthfeel, high environment-friendly indexes, stable quality, low cost and high safety performance.

Owner:TIANNING FLAVOR JIANGSU

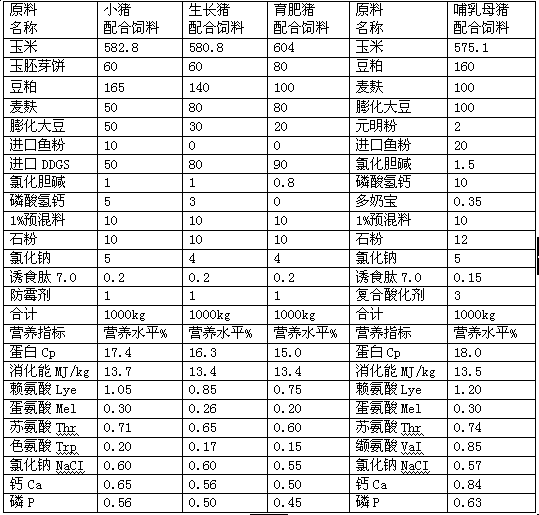

Dorking feed and preparation method thereof

InactiveCN101999559AIncrease contentDoes not affect productivityFood processingAnimal feeding stuffBiotechnologyInosinic acid

The invention discloses dorking feed and a preparation method thereof. The dorking feed can be prepared by crushing and uniformly mixing wheat bran, distillers dried grains with soluble, maize, soybean meal, cotton dregs, rapeseed meal and other raw materials; adding disodium 5'-inosinate, disodium 5'-guanylate, methionine, threonine and other nutrition agents for uniformly mixing and then modulating by steam to cure cornstarch to a certain extent; and granulating to obtain the finished product. By using the invention, the content of the disodium 5'-inosinate in chicken can be improved and the edible flavor of the dorking can be improved. In addition, the method is simple, safe and reliable and cannot influence the growing vigor and the raising effect of the dorking.

Owner:TONGWEI

Beef taste seasoning

The present invention provides a beef taste seasoning, which is prepared through the following method, wherein the method comprises the following steps: uniformly mixing pure beef powder, refined butter, a yeast extract, hydrolyzed vegetable protein, bovine ossein, disodium 5'-ribonucleotide, gravy salt, white granulated sugar, glucose, angelica archang lica powder, ginger powder, black pepper powder, white pepper powder, garlic powder, onion powder, tsao-ko amomum fruit powder, kaempferia galangal powder, illicium verum powder, cassia bark powder, nutmeg powder, disodium 5'-inosinate, sodium glutamate, maltodextrin and a anticaking agent, drying for 50-80 min at a temperature of 55-65 DEG C, cooling to a room temperature, crushing by using a crusher, and screening with a 30 mesh sieve to obtain the beef taste seasoning. The beef taste seasoning has characteristics of rich meat fragrance, natural and comfortable taste, strong cooking feeling, easy storage, easy carrying, and easy use, is especially adopted as a seasoning for instant noodles, mixed rice, food, snack foods and other food industries, and has advantages of simple preparation, natural and rich flavor, high finished product quality, low production cost and the like.

Owner:天津市春升清真食品有限公司

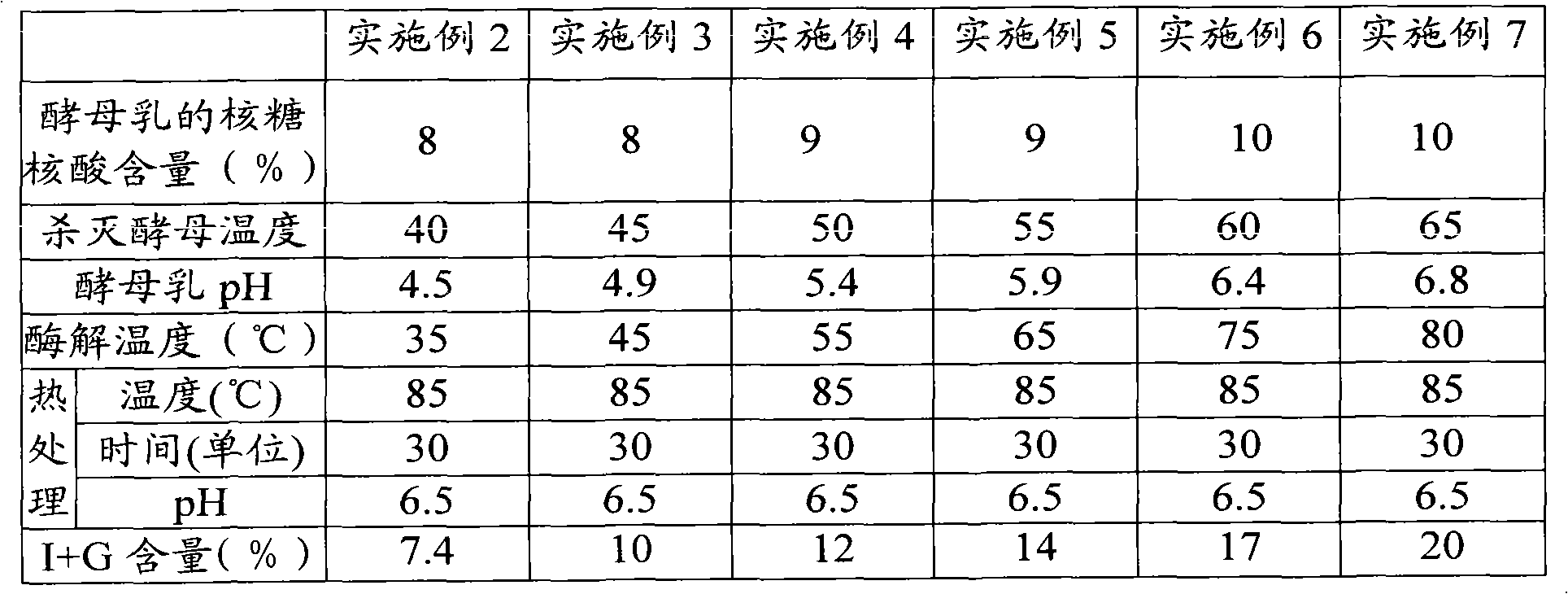

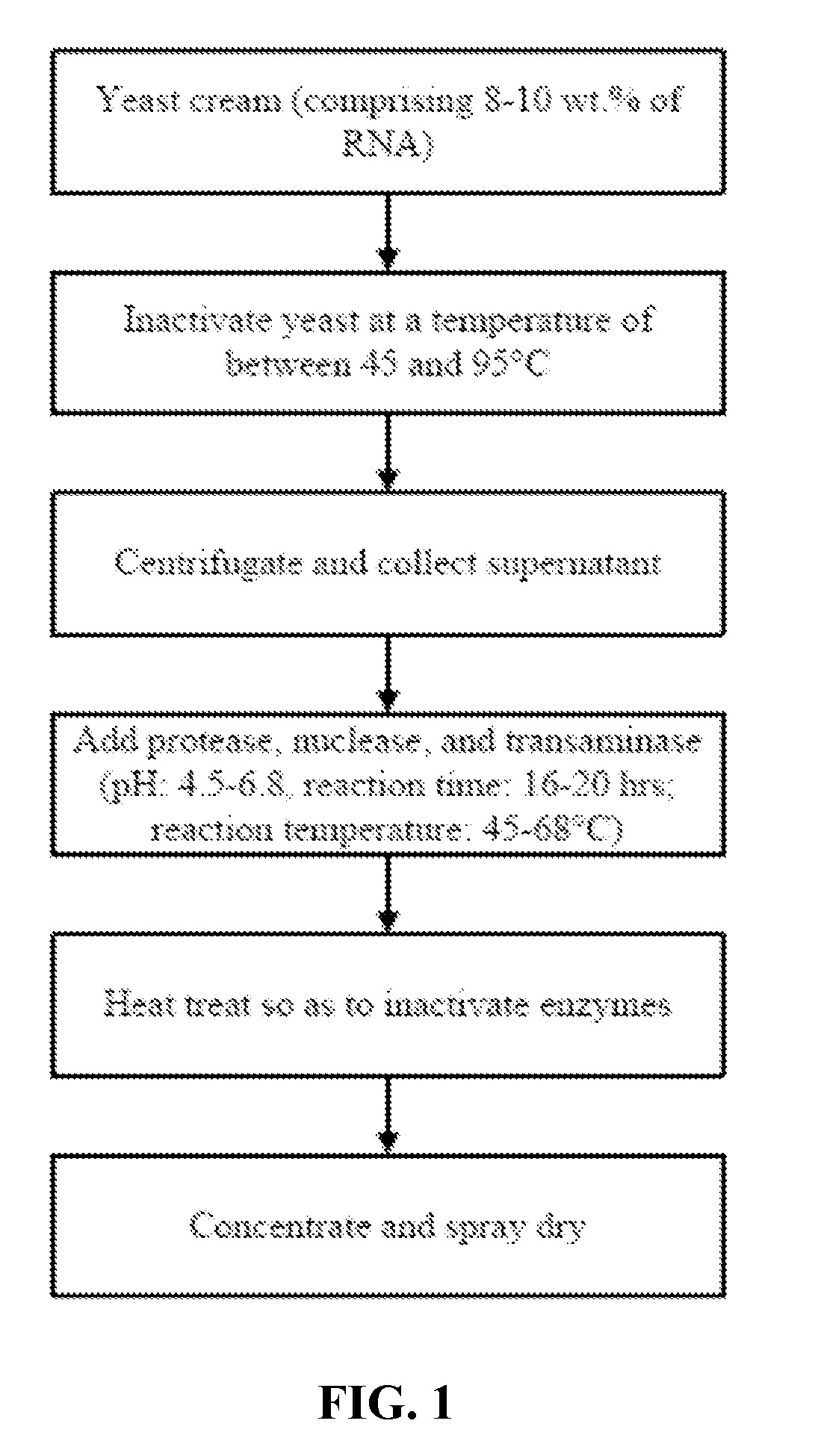

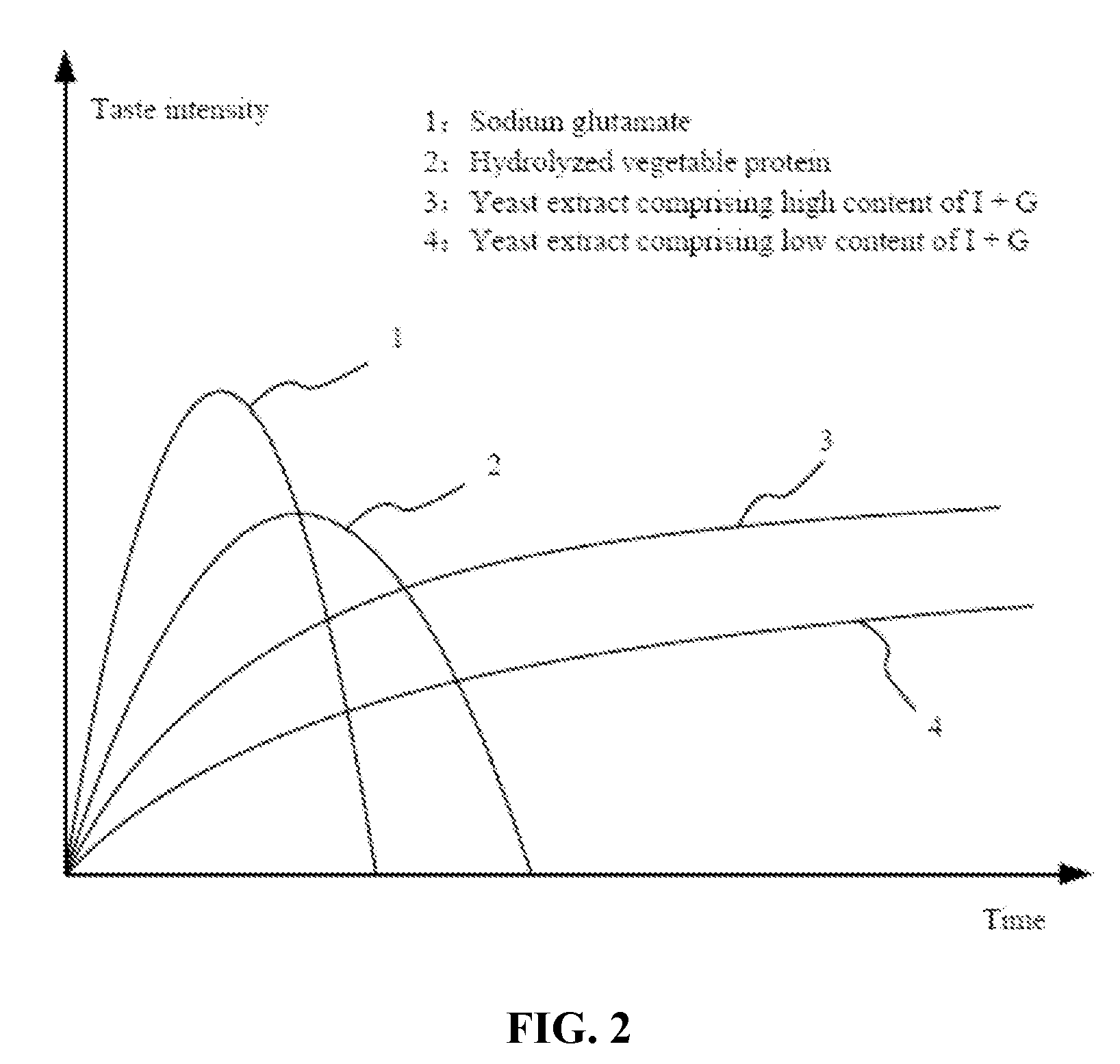

Yeast extract containing inosinic acid disodium salt and guanylic acid disodium and method for preparing same

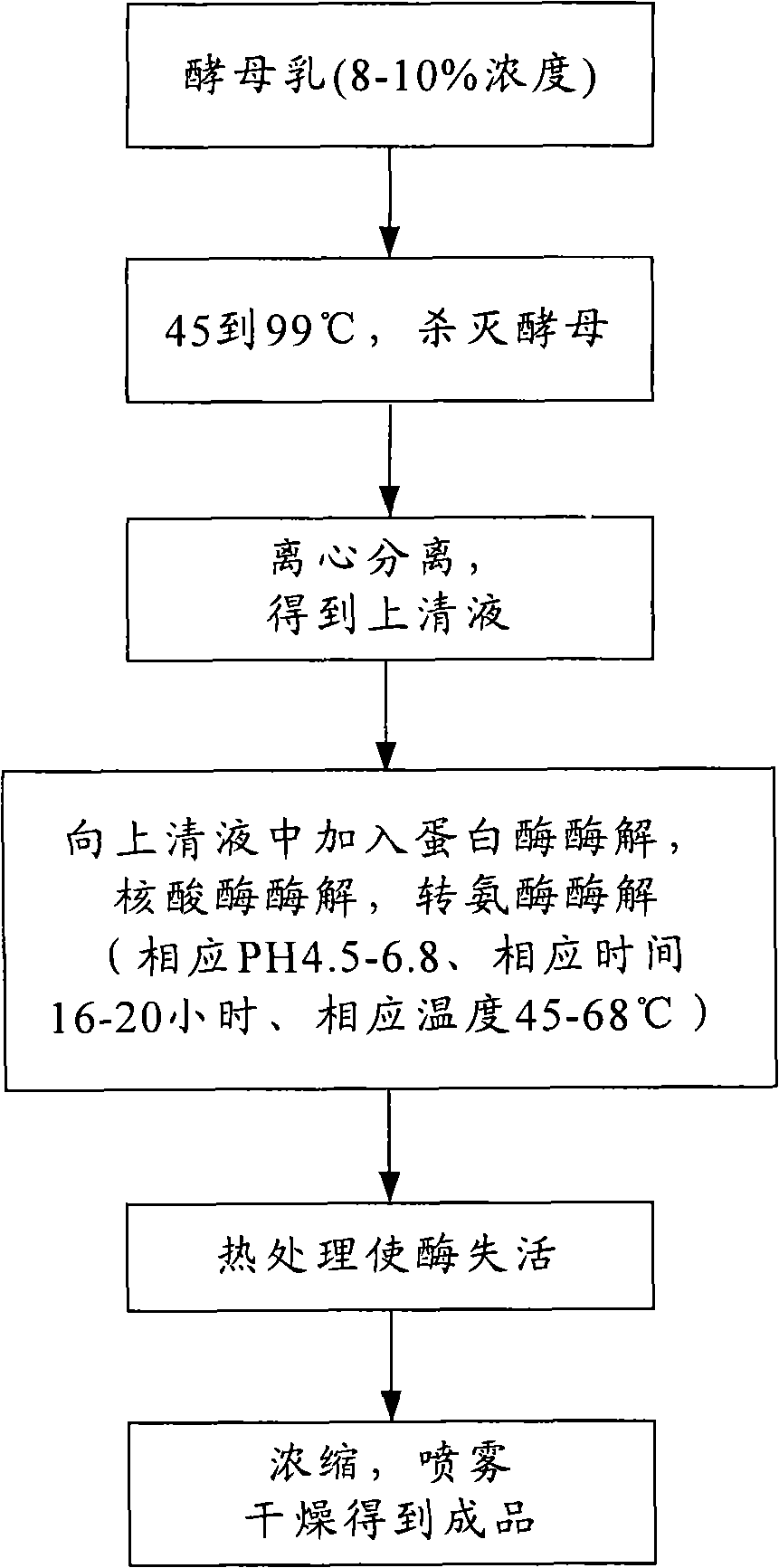

The invention relates to a method for preparing a yeast extract containing 4 to 30 percent of inosinic acid disodium salt and guanylic acid disodium (I+G), which comprises the following steps: a) providing a yeast cream containing 8 weight percent or more of ribonucleic acid; b) killing yeasts in the yeast cream; c) performing centrifugal separation on the yeast cream to obtain a supernatant; d) adding enzyme to the supernatant simultaneously to perform enzymolysis; e) performing heat treatment on the supernatant after the enzymolysis to inactivate the enzyme; and f) concentrating and drying the supernatant with inactivated enzyme to obtain the yeast extract containing 4 to 30 percent of the inosinic acid disodium salt and the guanylic acid disodium. The invention also relates to a yeast extract which is prepared by the method and contains high-content of the I+G. The yeast extract prepared by the method and containing the I+G is rich in disodium nucleotide, integrates the advantages of the yeast extract and disodium 5' ribonucleotide, and has the characteristic of savageness without additives.

Owner:ANGELYEAST CO LTD

Peptide-rich flavour development based material and preparation method

The invention discloses a seasoning material rich in peptide, the composition and mass percent of which are: water: 20-65; protein sources raw material: 15-50; reducing sugar: 1-10; L-cysteine Hydrochloride: 1-5; Disodium 5'-ribonucleotide: 0.1-2.5; sauce: 2-15; hydrolyzed vegetable protein: 2-15; 5-disodium inosinate: 0.6-3.8; cane sugar: 2-18; salt: 2-20; monosodium glutamate: 2-15; grease: 2-15; excipient: 5-20; spice:0.5-2; and edible spice: 0.2-1.5. The invention also discloses a method for preparing the seasoning material rich in peptide. The method consists of the steps of enzymolysis, filtering, dissolvation, pH adjusting, reaction, preparation, drying, crushing and the like. The seasoning material rich in peptide has long-lasting flavor and heavy aftertaste, is easy to use and can be applied to instant noodles, snack foods, complex condiment, meat products and the like.

Owner:广东汇香源生物科技股份有限公司

Hot pot baozi and preparation method thereof

The invention discloses a hot pot baozi, which comprises baozi wrappers and stuffing, wherein the baozi wrappers are prepared from the following raw materials: wheat starch, modified starch, water, quick-frozen oil, mycose, sodium stearoyl lactylate, sodium caseinate, and modified soybean lecithin. The stuffing is prepared from the following raw materials: meat, pure fat, dark soy sauce, water, spring onion, water chestnut, agar jelly, salt, white sugar, ground pepper, monosodium glutamate, inosine 5'-monophosphate and guanosine 5'-monophosphate. The invention discloses a preparation method of the hot pot baozi, which comprises the following steps: a) preparing starch gravy; b) adding auxiliary material; c) carrying out vacuum dough making; d) stirring the stuffing; e) molding; f) boiling with water; g) cooling; and i) cold preservation. The hot pot baozi provided with the above-mentioned materials and preparation method has rich nutrition, good taste and good chewing quality. The wrapper of the hot pot baozi has strong toughness, high transparency after water boiling and better retention of cooking liquor. Furthermore, the hot pot baozi has good boiling-resistance and good anti-aging effect.

Owner:WUXI HUASHUN MINSHENG FOOD

Chemical fertilizer specially used for rice

The invention relates to a chemical fertilizer specially used for rice. The chemical fertilizer is prepared from the following components in percentage by weight: 18-23 parts of urea, 15-20 parts of ammonium bicarbonate, 10-15 parts of potassium chloride, 15-20 parts of potassium sulphate, 5-8 parts of zinc sulfate, 5-8 parts of sodium borate, 2-4 parts of ammonium chloride, 2-4 parts of nitrohumic acid, 2-4 parts of calcium magnesium phosphate, 1-3 parts of disodium guanylate, 1-3 parts of disodium inosinic acid, 1-3 parts of silicate mineral powder and the balance of glycerinum. The chemical fertilizer specially used for the rice, which adopts the technical features, can be applicable to the growth of all stages of the rice by controlling different ratios of the chemical fertilizer to an additive in the components.

Owner:黄蓉华

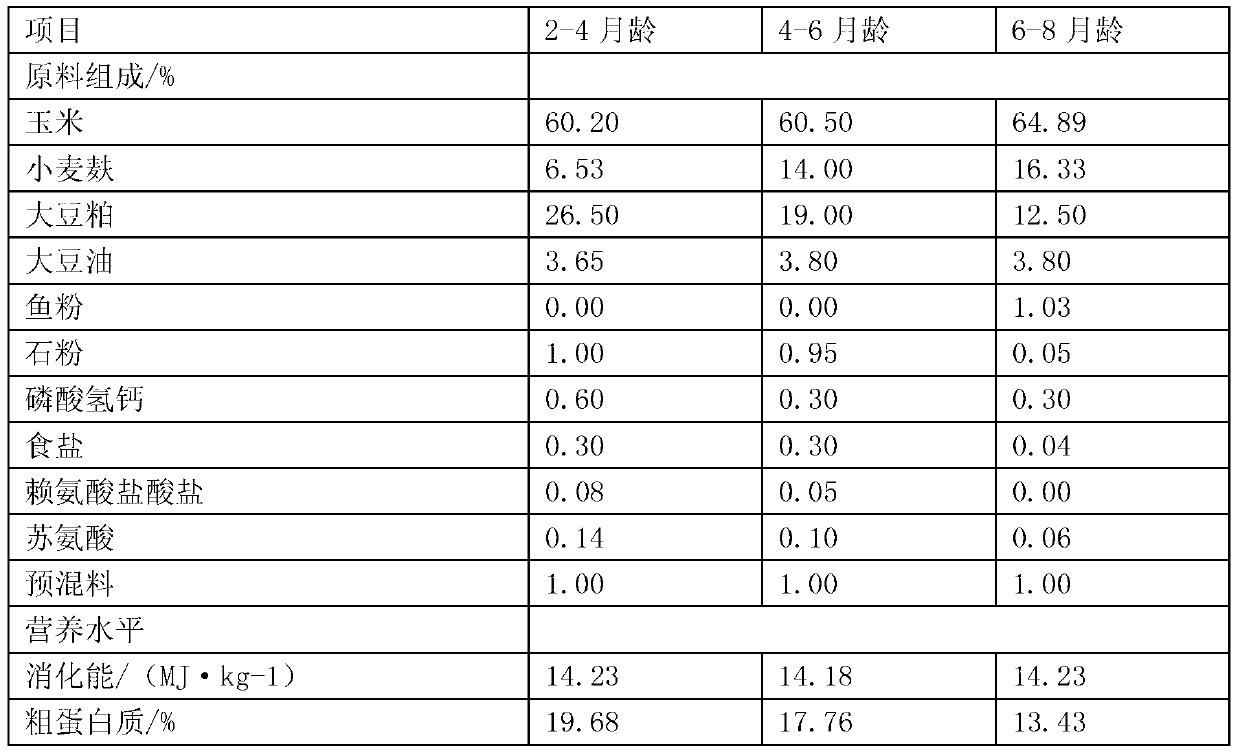

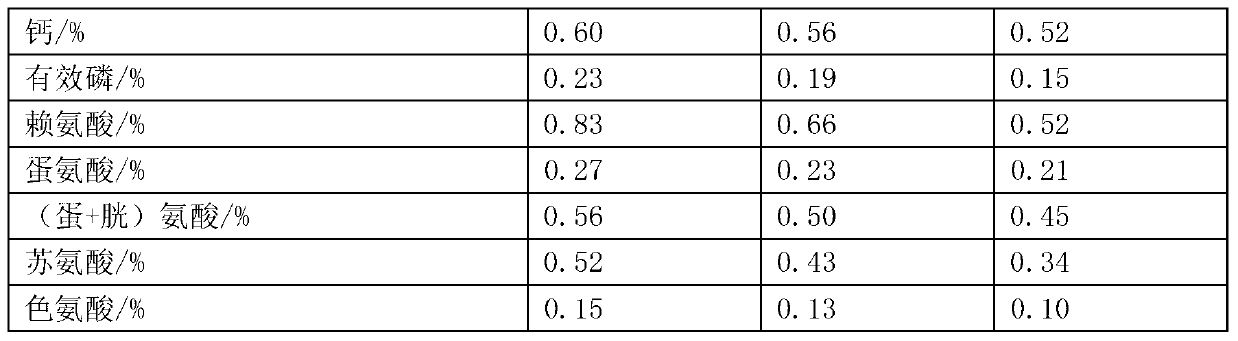

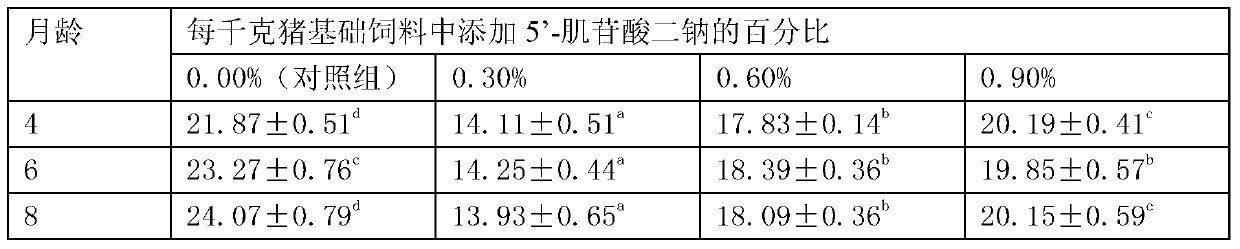

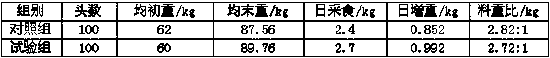

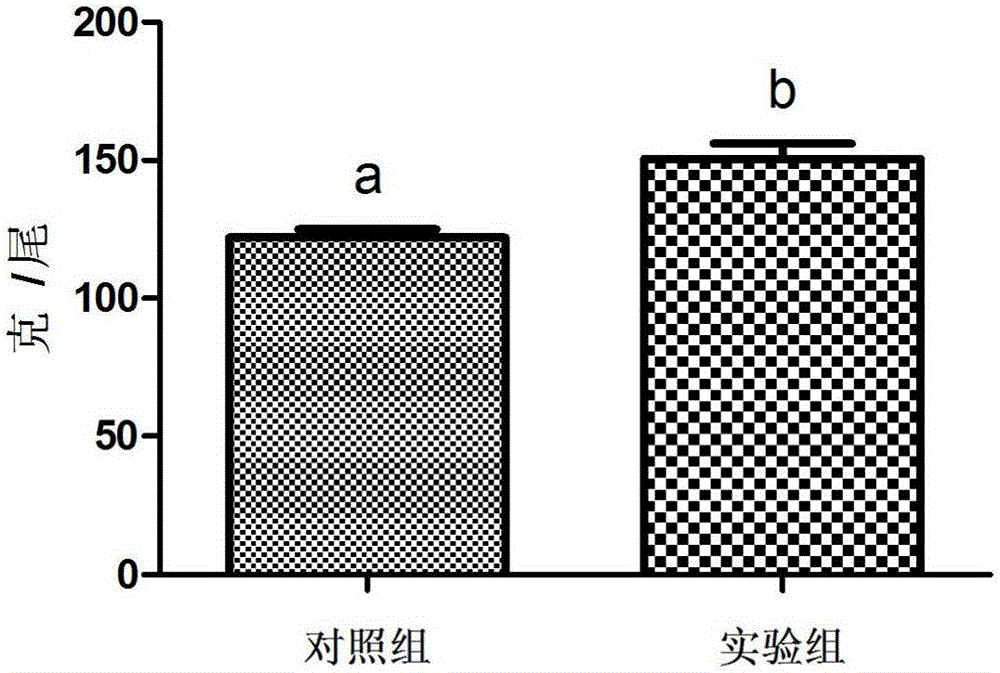

Pig feed capable of improving pork delicate flavor

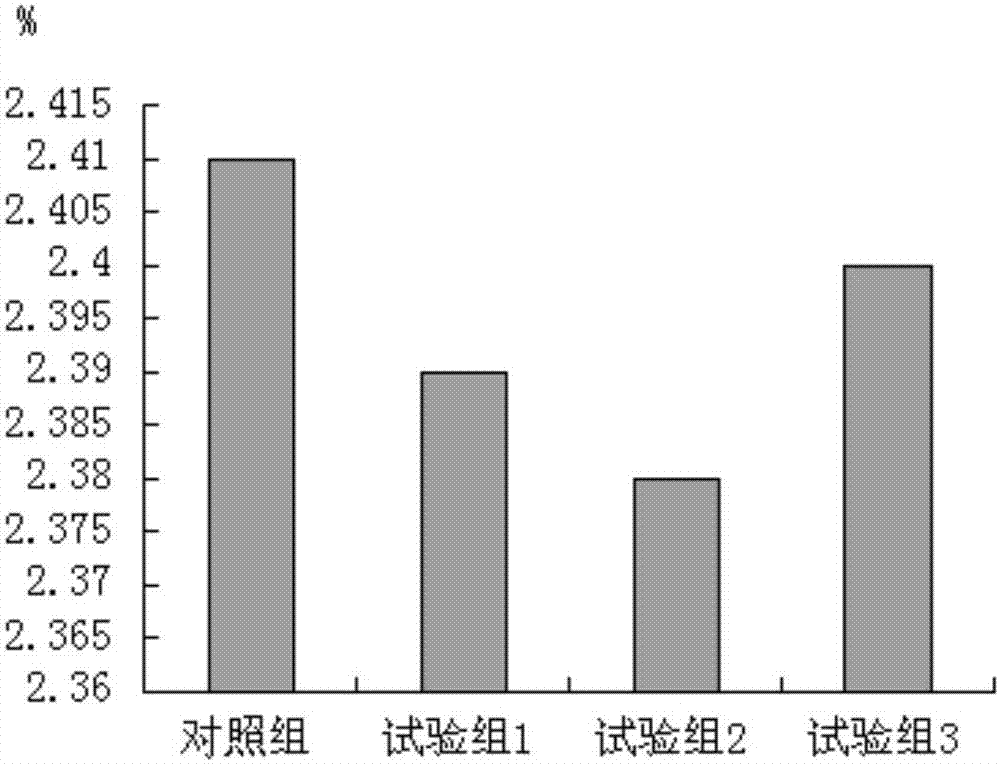

The invention discloses a pig feed capable of improving the pork delicate flavor. The pig feed capable of improving the pork delicate flavor comprises a pig basal feed and 5'-disodium 5-inosinate with the mass ratio of 100:0.3, and a corn-bean pulp-type feed formula is adopted for the basal feed. The pig feed capable of improving the pork delicate flavor provided by the invention is low in cost, is environmentally-friendly and safe, and can be used for enabling the delicate flavor of the pig feed to be multiplied, improving the pig appetite obviously, promoting the growth, meanwhile effectively improving the pork delicate flavor, and improving the pork quality comprehensively.

Owner:播恩集团股份有限公司

Seasoning hot pepper for steaming fish and processing method thereof

InactiveCN101617809AGood colorImprove crispnessFood preparationMonosodium glutamateAdditive ingredient

The invention relates to a seasoning hot pepper for steaming fish and a processing method thereof. The seasoning hot pepper is prepared by the steps: taking the desulfurated pickled capsicum frutescens and the pickled hot green pepper to be matched with other ingredients of ginger, mild water with the temperature of 65 DEG C, citric acid, monosodium glutamate, sodium cyclamate, Acesulfame-K, disodium 5'-Inosine monophosphate, disodium 5'-guanosine monophosphate and ethyl maltol; stirring, standing and sterilizing the substances to obtain the seasoning hot pepper. The seasoning hot pepper has stable quality and low content of sulfur dioxide, better retains the fragility, color and lustre of the hot pepper, as well as the nutrition of the hot pepper, and has longer time and shelf life.

Owner:CHANGSHA TANTANXIANG FLAVORING FOOD +1

Chicken meat powder flavouring and its preparation method

InactiveCN101283770APure natural meat flavorOutstanding meat aromaFood preparationMonosodium glutamateYeast

The invention discloses a chicken powder seasoning, which is mainly prepared from chicken extract, refined edible salt, monosodium glutamate, white sugar, cinnamon, sodium guanylate, disodium inosinate, hydrolyzed vegetable protein and yeast in a certain weight ratio. The chicken powder seasoning has the advantages of fine selection of materials, unique formula and fresh flavor, and can be used for food seasoning fast and conveniently with good effect.

Owner:侯玉华

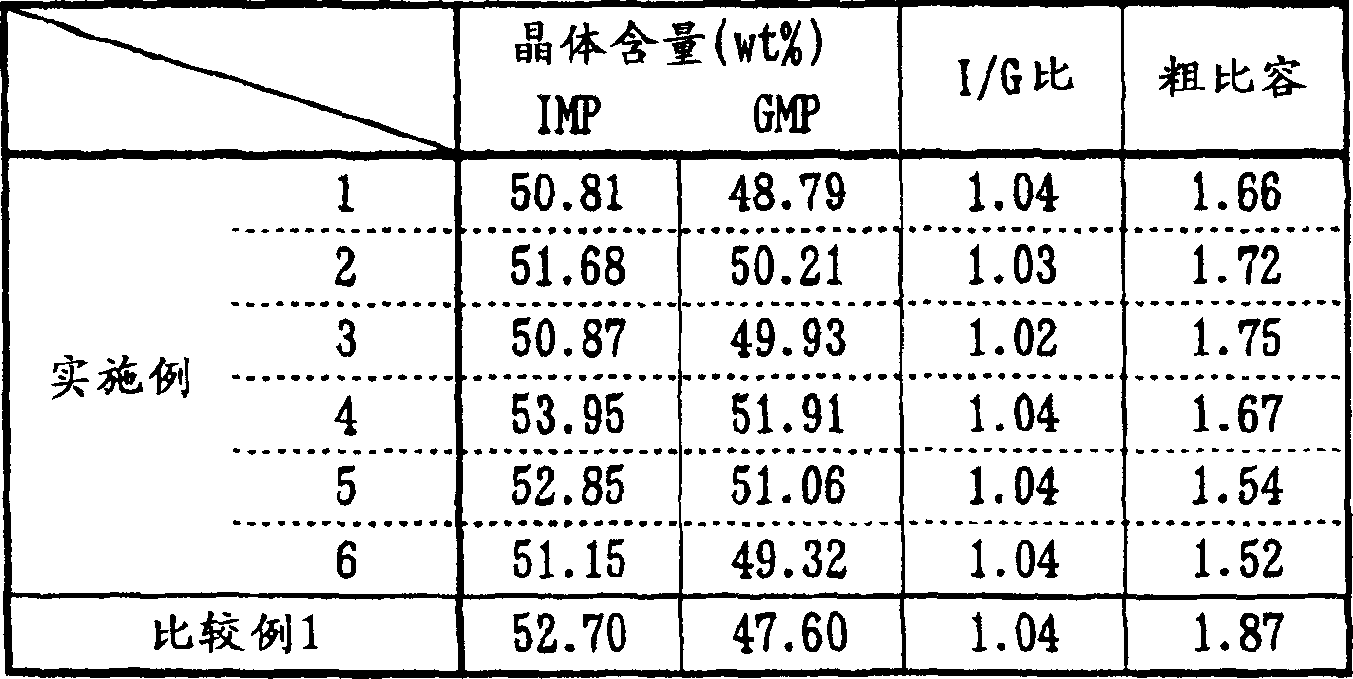

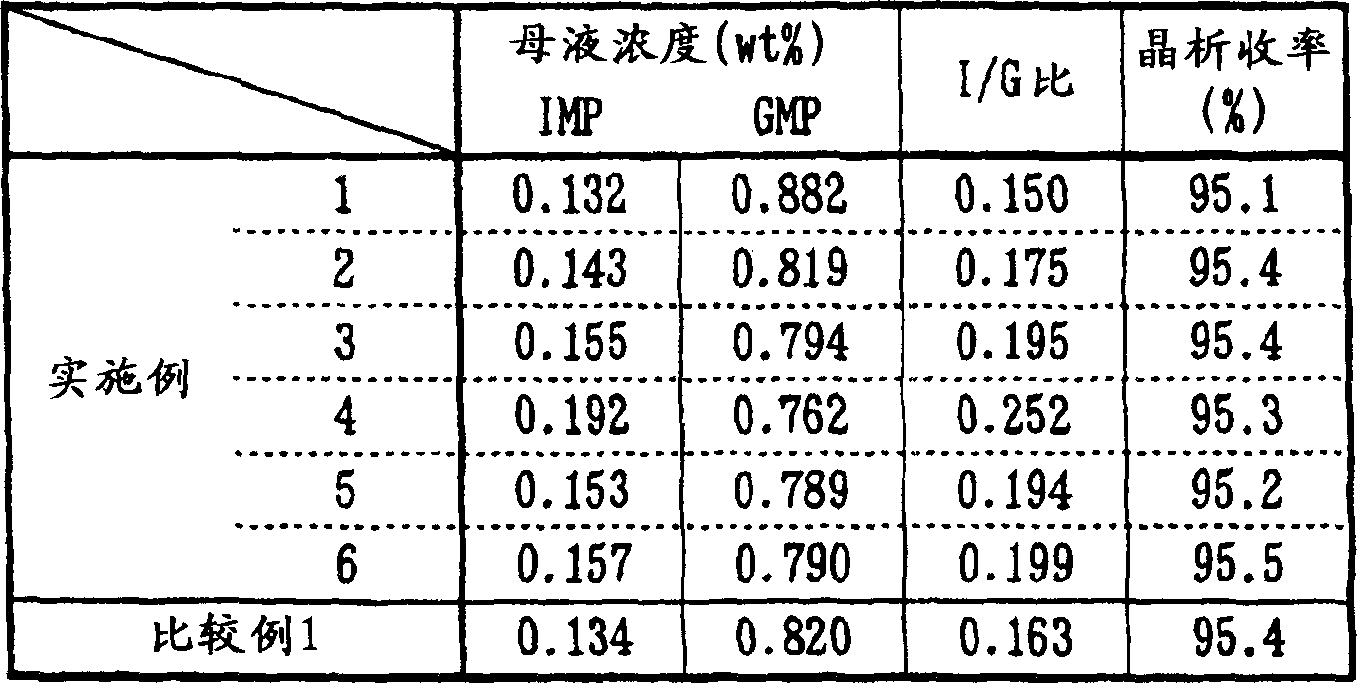

Method for producing mixed crystal of disodium 5'-guanylate and disodium 5'-inosinate

InactiveCN1527837APrevent precipitationCrude specific volume is smallSugar derivativesSugar derivatives preparationProduction rateOrganic solvent

Owner:AJINOMOTO CO INC

Tasty spicy flavouring and its preparation method

InactiveCN101283771ASimple materialUnique formulaFood preparationPericarpium citri reticulataeFood flavor

The invention discloses a seasoning with hot, spicy and fresh flavors, which is mainly prepared from cinnamon, sodium guanylate, disodium inosinate, hydrolyzed vegetable protein, Rhizoma Kaempferiae, Fructus Amomi Rotundus, Pericarpium Citri Reticulatae and Syringa oblate in a certain weight ratio. The seasoning has the advantages of accurate selection of materials, unique formula and fresh flavor, and can be used for food seasoning fast and conveniently with good effect.

Owner:侯玉华

Food flavoring agent and preparing method thereof

The invention discloses a food flavoring agent and a preparing method thereof. The food flavoring agent can be obtained by stirring and then drying L-aspartic acid, 5'-disodium inosinate, guanosine-5'-monophosphate disodium salt, starch sugar, gluten, aspergillus niger, soybean meal, a neutralizer, sodium chloride, disodium ribonucleotide, monosodium glutamate, sodium selenite, zinc lactate and auxiliaries. The melting point of the product is 200-300 DEG C, the pH value is 7-9, and the weight loss on drying is 0.1-0.3%. The product comprises 0.001-0.002% of heavy metal, 0.0001-0.0003% of arsenic and 0.0001-0.001% of lead.

Owner:NANTONG SHUANGHE FOOD

Functional food-calling peptide feed additive

InactiveCN108201005AIncrease feed intakeIncrease production capacityFood processingAnimal feeding stuffBiotechnologyFeed conversion ratio

The invention relates to an additive premixing feed, a mixed feed additive and a functional feed additive suitable for livestock and poultry, and discloses a functional food-calling peptide feed additive which is obtained by compatibility of sodium glutamate, disodium 5'-guanylate and guanosine-5'-monophosphate disodium salt, and the palatability is improved. Exogenous food calling is combined with endogenous adjustment, control and food calling, compatibility is mainly used for synergism, aspartic acid (aspartic acid) is in synergism, and particularly, the pharmacological action of vitamin B6is adopted; glutamic acid is transformed into aminobutyric acid, the activity of aminobutyric acid is activated, amino acid derivatives and the like exert the functional effects, and various stress is relieved and controlled. Plant extract essence components are in compatibility, based on increment of food consumption of livestock and poultry animals, the effects of promoting digestion and transformation utilization are achieved, the best growth potential and production performance can be exerted, and the purpose of calling foods to increase the food consumption, increasing the feed conversion rate and promoting growth can be realized.

Owner:张自力

Pork chop powdered stock soup composite seasoner and preparation method thereof

InactiveCN101356965ASimple materialComplete ingredientsFood preparationMonosodium glutamateFlavoring essences

The invention discloses a complex seasoning of stock of spareribs, which is mainly prepared by edible salt, monosodium glutamate, crystal sugar, flavoring essence of spareribs, sodium guanylate, disodium inosinate, star anise and hydrolyzed vegetable protein according to a certain weight proportion; the invention has superior sorting, unique formulation and fresh taste and can be used for seasoning of foods with convenience, fastness and good effect.

Owner:侯玉华

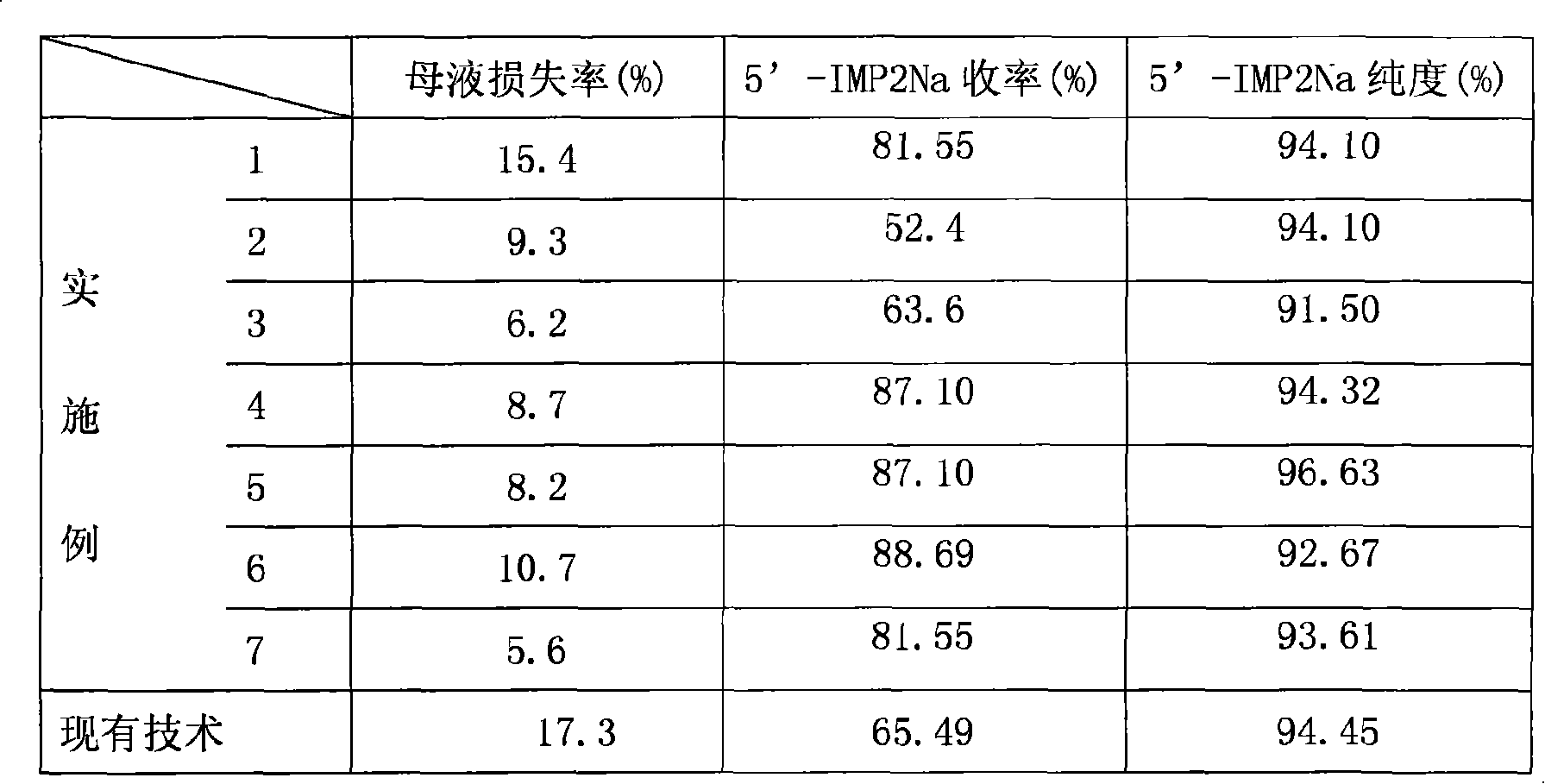

Method for purifying 5-inosinic acid zymotic fluid by crystallization

The invention relates to a method for purifying the 5'-IMP2Na from a 5'-IMP fermenting liquor generated by the microbial fermentation. The invention improves the prior purification procedure, substitutes the prior procedure of an anion exchange resin vessel so as to reduce the yield of the waste water / waste liquid and the usage of the chemical medicine of the acid and alkali and the like in a large scale.

Owner:CJ CHEILJEDANG CORP

Cream flavoring agent and making process thereof

A flavouring cream is prepared from edible salt, flavouring (gourmet powder, 5'-disodium inosinate, 5'-disodium guanylate, etc), edible liquid (water or edible oil), thickening agent (carboxy methyl starch sodium carboxymethyl cellulose sodium, etc), and emulsifier (cane sugar ester of fatty acid) through diluting, proportioning and stirring. Its advantages are high flavouring effect and health-care action.

Owner:陈宝华

Seasoning for spicy beef and preparation method of seasoning

The invention discloses seasoning for spicy beef. The seasoning is mainly prepared from the following components according to a certain ratio by weight: pure beef powder, cloves, fennel, cinnamon, dried orange peel, pepper fruits, hot peppers, Chinese prickly ash, fresh ginger, edible refined salt, gourmet powder, puffing rice flour, white granulated sugar, garlic powder, GMP, disodium 5'-inosinate, yeast, fructus tsaoko, angelica dahurica and hydrolyzed vegetable protein. The seasoning for cooking foods, disclosed by the invention is excellent in material selection, unique in formula, delicious in taste, convenient, rapid, and good in effects.

Owner:ANHUI SHENRAN FOOD CO LTD

Instant noodles seasoning powder material

InactiveCN101258919AHigh nutritional valueRich taste seriesFood preparationNutritive valuesMonosodium glutamate

The invention relates to an instant noodle seasoning powder which contains the component of tea and is packaged in a seasoning powder package of the instant noodle. The instant noodle seasoning powder comprises the following components by weight portion: 0.8-21.5 percent of tea powder, 48.3-69 portions of salt, 16 portions of gourmet powder, 6 portions of white sugar, 1.5 portions of yeast extract, 1.5 portions of protein hydrolysate, 1 portion of maltodextrin, 0.6 portion of inosine 5' -monophosphate (IMP), 0.6 portion of guanosine 5'-monophosphate (GMP) and 3 portions of pig bone refined powder. The instant noodle adopts tea in the seasoning and has the following advantages: the nutritive value of the instant noodle is promoted, the flavor series of the instant noodle can be enriched and the shelf life of the seasoning powder package of the instant noodle can be prolonged.

Owner:HENAN ZHENGLONG FOOD

Flavoring agent for livestock and poultry

The invention relates to a flavoring agent for livestock and poultry. The flavoring agent comprises sodium glutamate, disodium 5'-guanylate and disodium 5'-inosinate, wherein the mass of the sodium glutamate is 6-8% of the total mass of the flavoring agent, the mass of the disodium 5'-guanylate is 0.16-0.2% of the total mass of the flavoring agent, and the mass of the disodium 5'-inosinate is 0.16-0.2% of the total mass of the flavoring agent. The preparation method for the flavoring agent for the livestock and the poultry comprises the following concrete steps: adding various raw material components to a mixer to carry out mixing for 8-10 minutes according to the required mass percentage, such that the uniformity is 5%; then screening the mixed powder material by a sieve to obtain the flavoring agent. With the flavoring agent of the present invention, the palatability of the feedstuff can be enhanced, the feed intake of the livestock and the poultry can be improved, the diet resources can be saved, and the production cost can be reduced.

Owner:WUXI ZHENGDA POULTRY

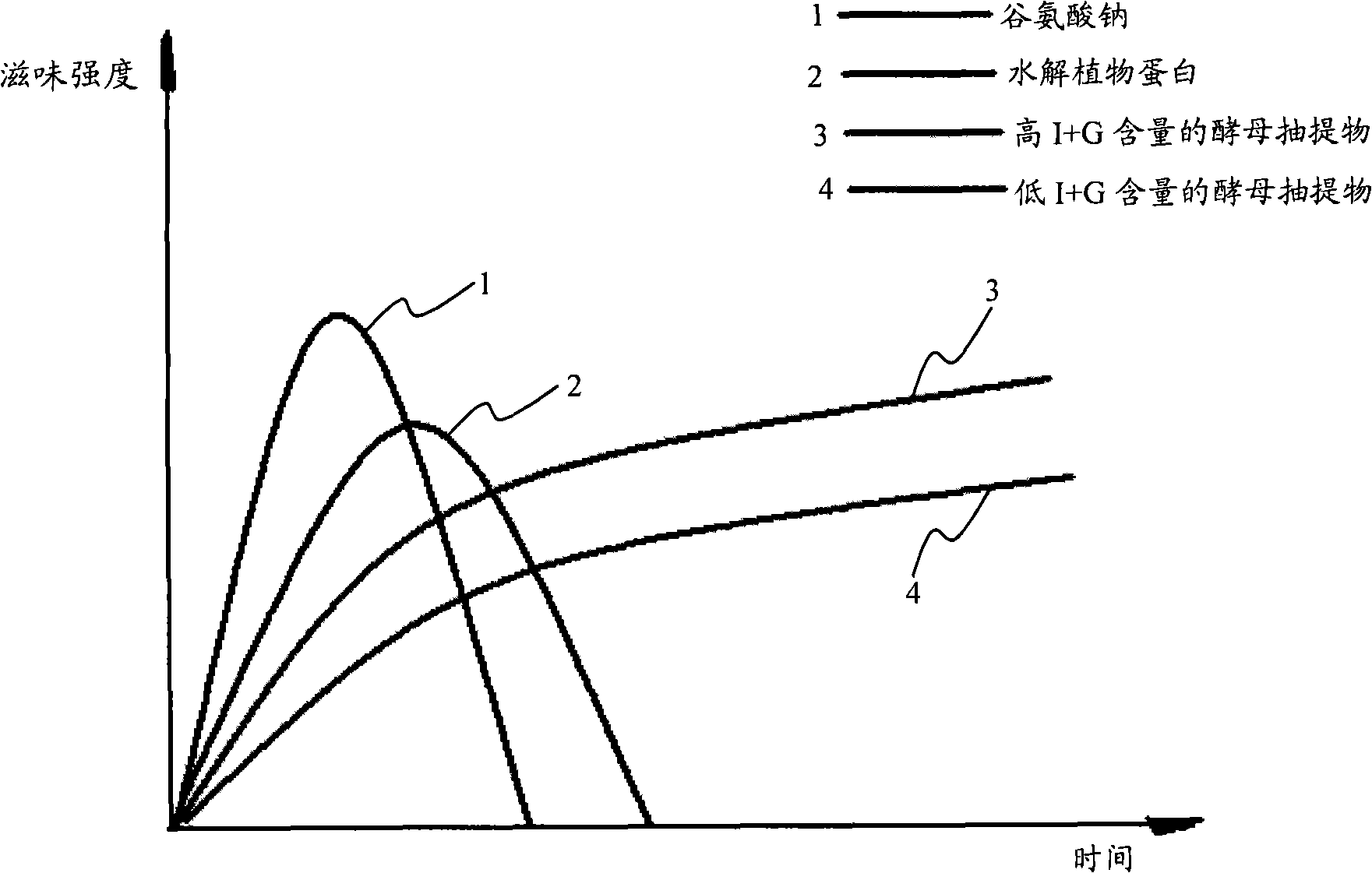

Yeast extract and method of producng the same

InactiveUS20100303960A1Increase contentDelicious tasteSolid waste disposalFermentationBiotechnologyFlavor

A method for producing yeast extract including 4-30% disodium inosinate and disodium guanylate (I+G), comprising a) providing a yeast cream including 8 wt. % or more of RNA, b) inactivating the yeast in the yeast cream, c) centrifugating the yeast cream and collecting a supernatant, d) degrading the supernatant with enzymes, e) heat-treating, and f) concentrating and drying the supernatant. The resultant yeast extract is natural, involves no additive, and has better flavor. The invention further provides yeast extract is produced by the method.

Owner:YU XUEFENG +6

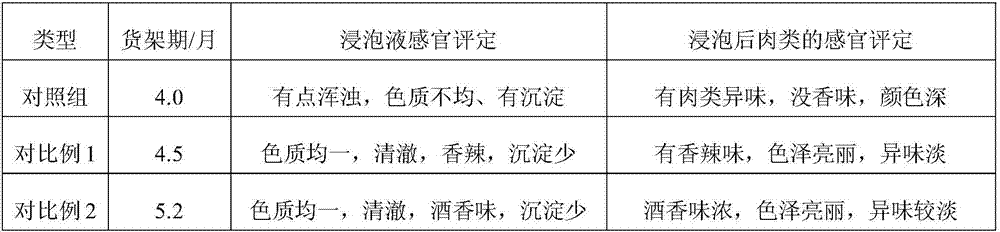

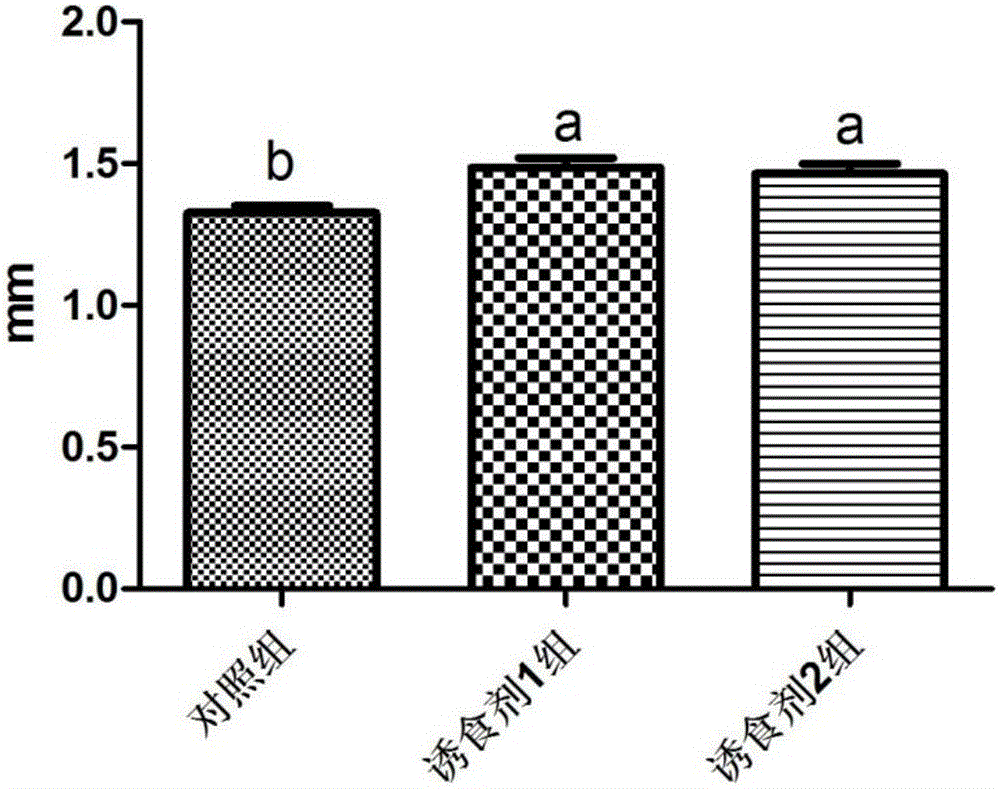

Meat soak solution and preparation method thereof

InactiveCN106982917AExtended shelf lifeEliminate odorFood ingredient as antioxidantFood ingredient as taste affecting agentFiltrationAdditive ingredient

The invention relates to the technical field of food processing and particularly relates to a meat soak solution and a preparation method thereof. The meat soak solution is mainly prepared through the steps of raw material treatment, filtration, decoloration and sterilization of the following raw materials in parts by weight: 15-20 parts of amomum tsao-ko, 15-20 parts of alpinia katsumadai, 15-17 parts of piperis longi, 10-15 parts of carum carvi, 17-20 parts of vanilla planifolia, 10-15 parts of herba artemisiae scopariae, 20-25 parts of radix angelicae, 10-12 parts of galangal, 7-10 parts of horseradish, 7-10 parts of clove, 5-7 parts of pericarpium citri reticulatae, 10-15 parts of fructus amomi, 13-15 parts of nutmeg, 1-2 parts of calcium glutamate, 1-2 parts of 5-disodium inosinate, 0.5-1 part of a preservative and 1-2 parts of an adsorbent. The shelf life of the meat soak solution is significantly prolonged, the fishy smell and the peculiar smell are effectively removed, the freshness and the aroma are improved, the flavor is unique, the appetite is promoted, the nutrients of meat are increased, and the meat has the health effects of clearing heat, promoting diuresis, protecting the liver, increasing choleresis, invigorating the stomach and tonifying the kidneys.

Owner:岑健

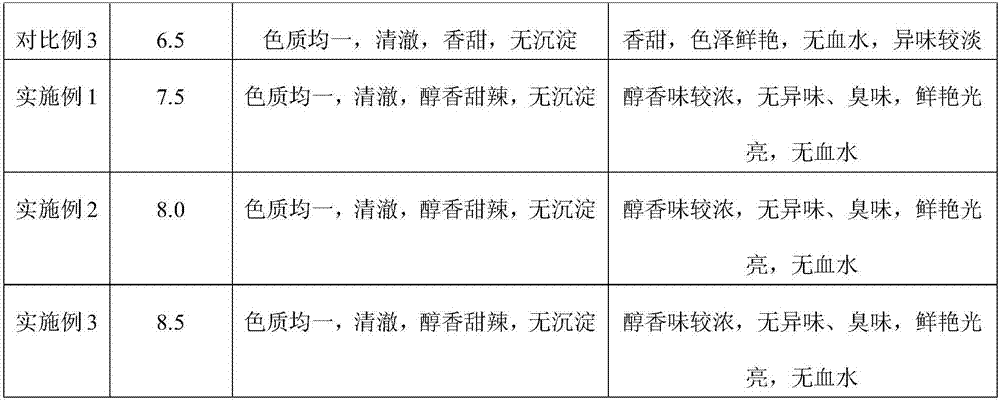

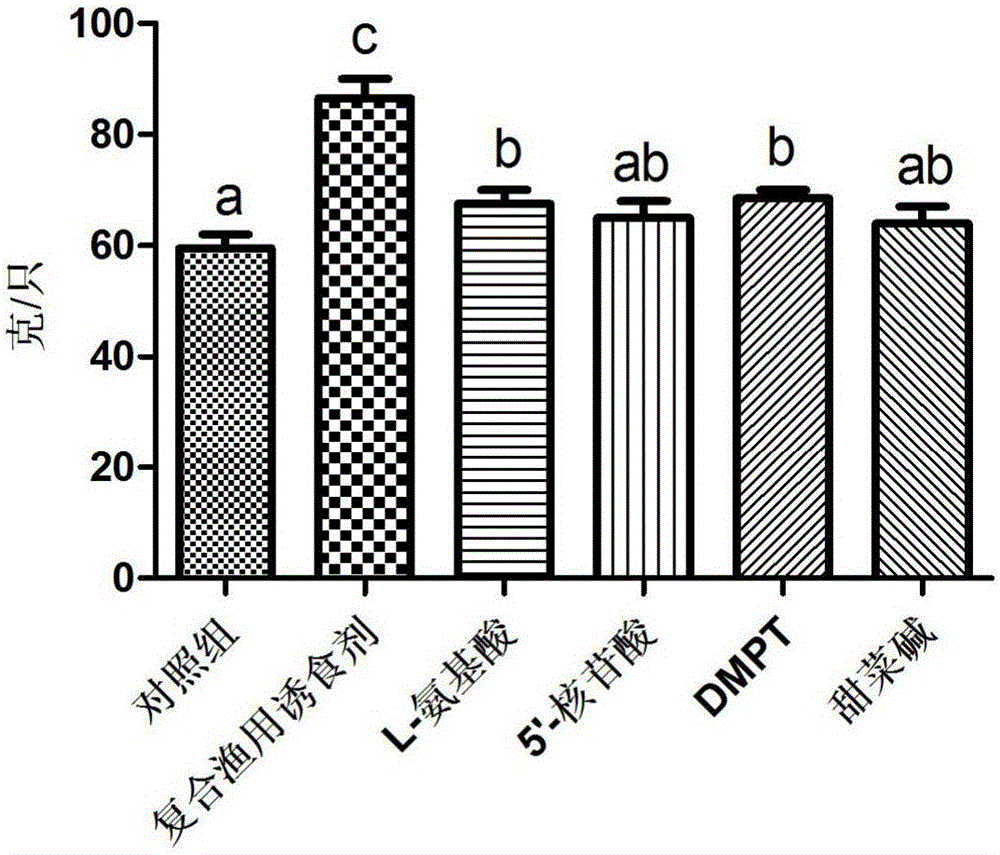

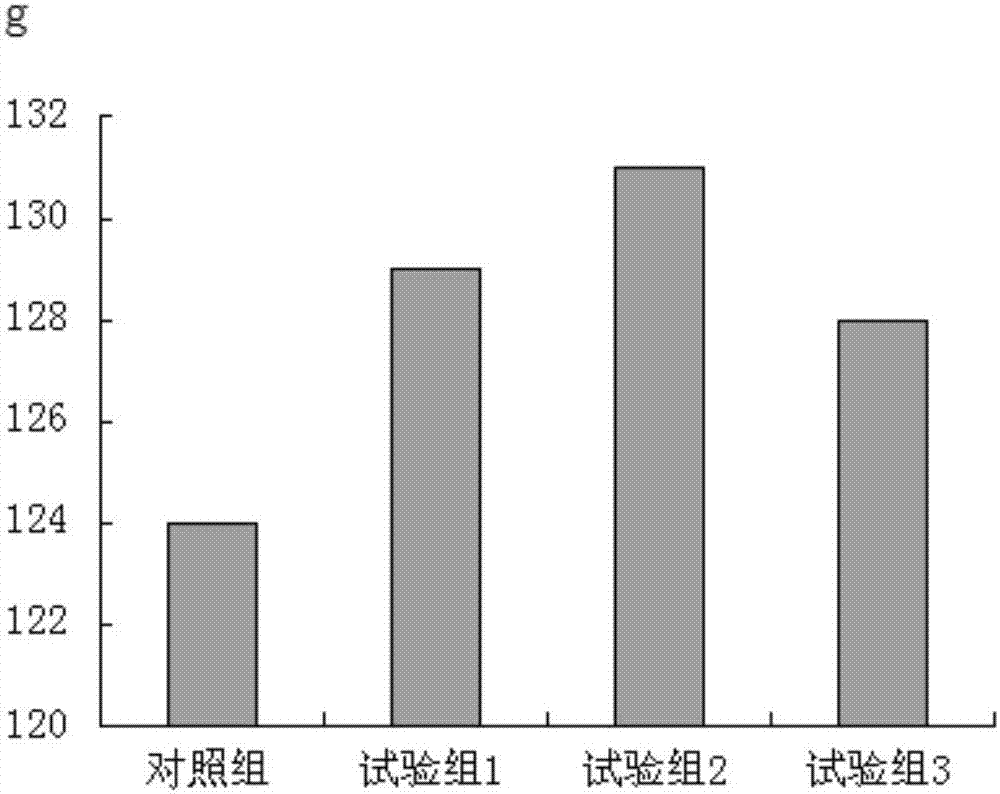

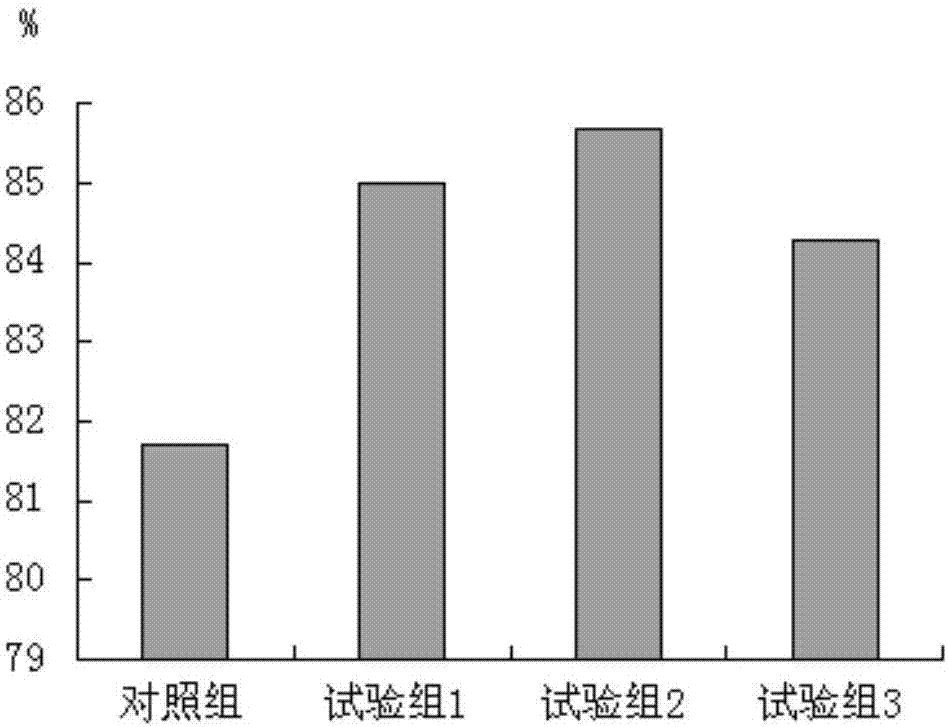

Composite feed attractant for fishing and preparation method and application thereof

ActiveCN105724830AReduce usageGood effectAnimal feeding stuffAccessory food factorsWeight gainingAnimal science

The invention discloses a composite feed attractant for fishing. The composite feed attractant is prepared from, by weight, 15-30 parts of glycine betaine, 2-6 parts of dimethyl betaine-beta-dimethylpropiothetin, 2-6 parts of disodium 5-inosinate, 20-30 parts of taurine, 30-50 parts of sleeve-fish ointment and fruit sugars and 10-20 parts of a fructooligosaccharide and bacillus licheniformis compound. The invention further discloses a preparation method and application of the composite feed attractant for fishing. Compared with the prior art, the composite feed attractant can obviously improve the ingestion amount, the weight gain rate and feed conversion ratio of fishes, crustaceans and terrapins and can remarkably strengthen the immune function and digestive enzyme activity of the intestinal tract and promote absorption and utilization of nutrient substances. In addition, the utilized raw materials are stable in source, low in price and simple in preparation process, and reduction of the production cost, decrease of feed waste and environmental protection are promoted.

Owner:NANJING AGRICULTURAL UNIVERSITY

Delicate flavor condiment similar to delicate flavor of steamed crab and method of processing the same

The invention discloses a fresh taste seasoning with fresh taste similar to steamed crab and a preparation method thereof. The fresh taste seasoning is prepared from high hydrolyzing degree fish albumen powder, gourmet powder, salt, glucose, sucrose, glycine, alanine, arginine, 5'-disodium inosinate, 5'-disodium guanylate, 5'-disodium cytidylate, lactic acid, sodium succinate and sodium citrate, which are mixed evenly. The preparation method comprises the following steps: 1) pretreatment of fish; 2) deep hydrolysis of the fish; 3) drying of the high hydrolyzing degree fish albumen powder and 4) compound of the fresh taste seasoning. The fresh taste seasoning with fresh taste similar to steamed crab not only has intense fresh taste, but also has rich taste, does not cause thirst after the fresh taste seasoning is eaten, and can replace the seasonings such as chicken essence and the like on many occasions.

Owner:GUANGXI UNIV

Pickled vegetable and beef flavored paste flavoring and preparation method thereof

InactiveCN105166832AAroma harmonyNatural characteristic aroma is obviousSugar food ingredientsYeast food ingredientsBiotechnologyLactylate

The invention discloses a pickled vegetable and beef flavored paste flavoring comprising the following components, by weight: 8-12 parts of fried butter, 15-25 parts of enzymatic-hydrolysis beef paste, 6-10 parts of Haitian light soy sauce, 15-25 parts of crushed Sichuan pickled vegetable, 8-12 parts of crushed Sichuan pickled pepper, 0.3-0.8 parts of alanine, 0.3-0.8 parts of glycine, 0.3-0.8 parts of taurine, 1-5 parts of glucose, 3-7 parts of salt, 8-12 parts of sodium glutamate, 0.3-0.7 parts of a mixture of disodium 5'-inosinate and disodium 5'-guanylate, 3-7 parts of white granulated sugar, 2-6 parts of yeast powder, 0.4-0.8 parts of prickly ash seed powder, 0.1-0.5 parts of white pepper powder, 0.4-0.8 parts of ginger powder, 0.1-0.7 parts of xanthan gum, 3-7 parts of water, 0.3-0.8 parts of citric acid, 0.3-0.8 parts of lactic acid and 0.3-0.8 parts of acetic acid.

Owner:湖南汇湘轩生物科技股份有限公司

Technique for preparing 5í»-inosine acid disodium

Owner:肇东星湖生物科技有限公司

Functional attractant for feeds and preparation method thereof

InactiveCN107467370AImprove palatabilityIncrease feed intakeAnimal feeding stuffAccessory food factorsBiotechnologyGamma-Aminobutyric acid

The present invention discloses a functional attractant for feeds. The functional attractant comprises the following raw materials in percentages by mass: 5-10% of glutamine, 5-10% of 5'-disodium guanylate, 5-10% disodium 5'-inosinate, 5-8% gamma-aminobutyric acid, 5-8% of a fructus momordicae extract and the balance corn starch. The attractant comprises the natural fructus momordicae extract and amino acids. By using a delicate taste of amino acids and a special sweet taste of the fructus momordicae extract, the functional attractant improves a palatability of feeds, can also improve a meat quality flavor, at the same time improves intestinal functions, reduces productions of skatole, improves meat quality and animal internal organ flavor, promotes cardiovascular system functions, increases hemoglobin and myoglobin synthesis, and enables meat quality to be ruddy and nutritious.

Owner:WUXI ZHENGDA POULTRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com