Technique for preparing 5í»-inosine acid disodium

A technology of disodium inosinate and disodium inosinate water is applied in the field of production technology of disodium 5'-inosinate, which can solve the problems of unfavorable crystals, long time consumption, and high temperature of solution, and improve yield and purity , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

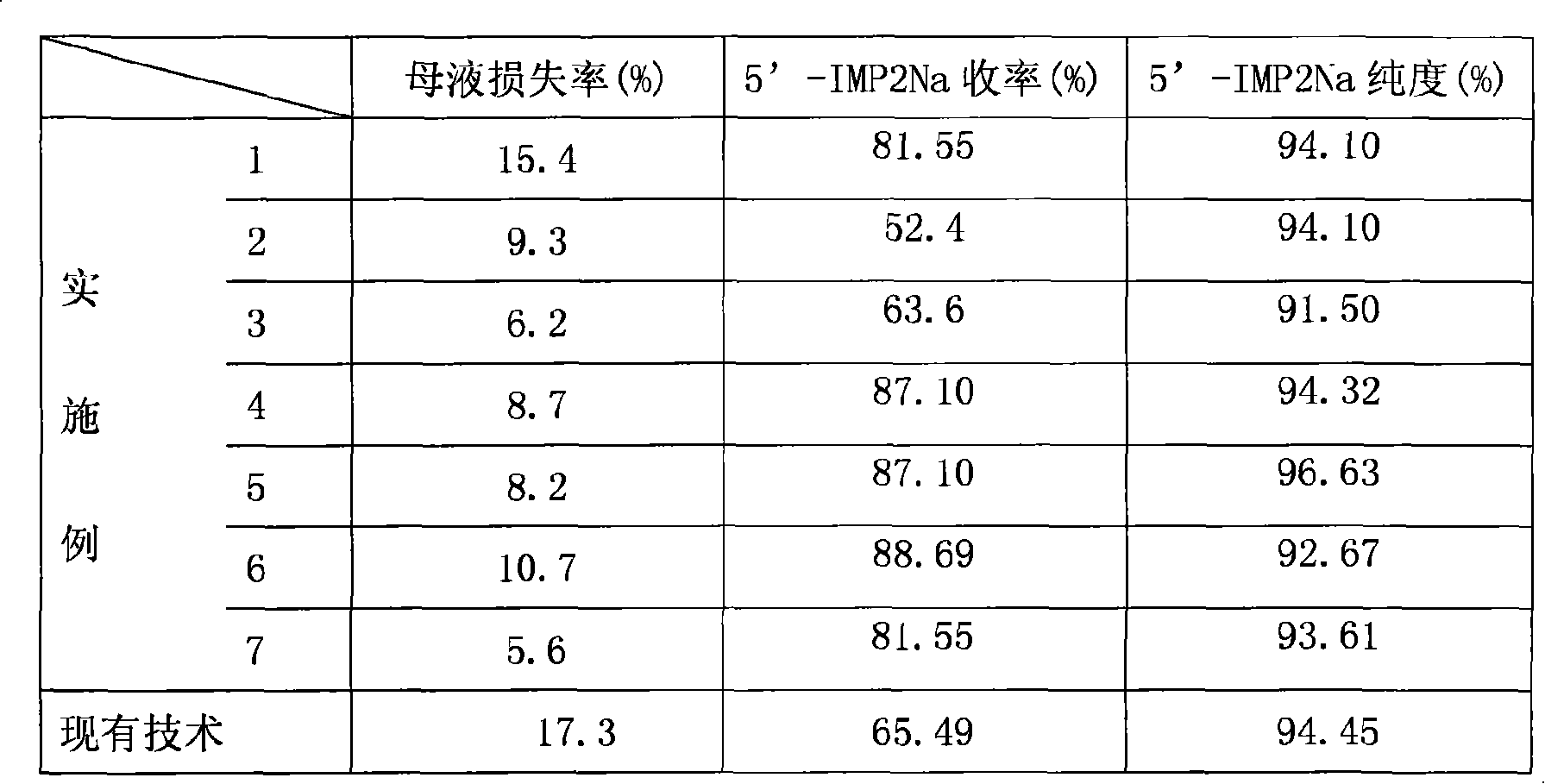

Examples

Embodiment 1

[0008] Take 200ml of the aqueous phase of disodium 5′-inosinate, add BaCl 2 Solution (saturated or nearly saturated) 300ml, while stirring, add membrane alkali to neutralize to PH7.3-7.6, or add alkali to neutralize to PH7.3-7.6, add BaCl 2 Solution (saturated or nearly saturated) 300ml, stirring precipitation, normal temperature, time 5 minutes, vacuum suction filtration with Buchner funnel filter paper, obtain mother liquor and IMPBa salt, calculate mother liquor loss rate, add IMPBa salt to Na 2 SO 4 Solution (saturated or nearly saturated) to 200ml, stirred at 60°C for 3 hours, disodium 5'-inosinate was precipitated, vacuum filtered with Buchner funnel filter paper at 60°C, filtration rate 5L / m 2 h, get BaSO 4 Precipitate and filtrate, calculate the yield of disodium 5'-inosinate in the filtrate and measure the purity.

Embodiment 2

[0010] Take 200ml of the aqueous phase of disodium 5′-inosinate, add BaCl 2 Solution (saturated or nearly saturated) 300ml, while stirring, add membrane alkali to neutralize to PH7.3-7.6, or add alkali to neutralize to PH7.3-7.6, add BaCl 2 Solution (saturated or nearly saturated) 300ml, stirred and precipitated, 0 ℃, time 5 minutes, with Buchner funnel filter paper vacuum filtration, get mother liquor and IMPBa salt, calculate mother liquor loss rate, add IMPBa salt to Na 2 SO 4 Solution (saturated or nearly saturated) to 200ml, stirred at 60°C for 20 minutes, disodium 5'-inosinate was precipitated, vacuum filtered with Buchner funnel filter paper at 60°C, filtration rate 5L / m 2 h, get BaSO 4 Precipitate and filtrate, calculate the yield of disodium 5'-inosinate in the filtrate and measure the purity.

Embodiment 3

[0012] Take 200ml of the aqueous phase of disodium 5′-inosinate, add BaCl 2 Solution (saturated or nearly saturated) 300ml, while stirring, add membrane alkali to neutralize to PH7.3-7.6, or add alkali to neutralize to PH7.3-7.6, add BaCl 2 Solution (saturated or nearly saturated) 300ml, stirred and precipitated, cooled to below 10°C for 40 minutes, vacuum filtered with Buchner funnel filter paper to obtain mother liquor and IMPBa salt, calculate mother liquor loss rate, add IMPBa salt to Na 2 SO 4 Solution (saturated or nearly saturated) to 200ml, stirred at room temperature for 20 minutes, precipitated disodium 5'-inosinate, vacuum filtered with Buchner funnel filter paper, filter speed 5L / m 2 h, get BaSO 4 Precipitate and filtrate, calculate the yield of disodium 5'-inosinate in the filtrate and measure the purity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com