Method for producing mixed crystal of disodium 5'-guanylate and disodium 5'-inosinate

A technology of disodium inosinate and disodium guanylate, which is applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve the problems of difficult operation of mixtures, difficult control of crystallization conditions, difficult mixtures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

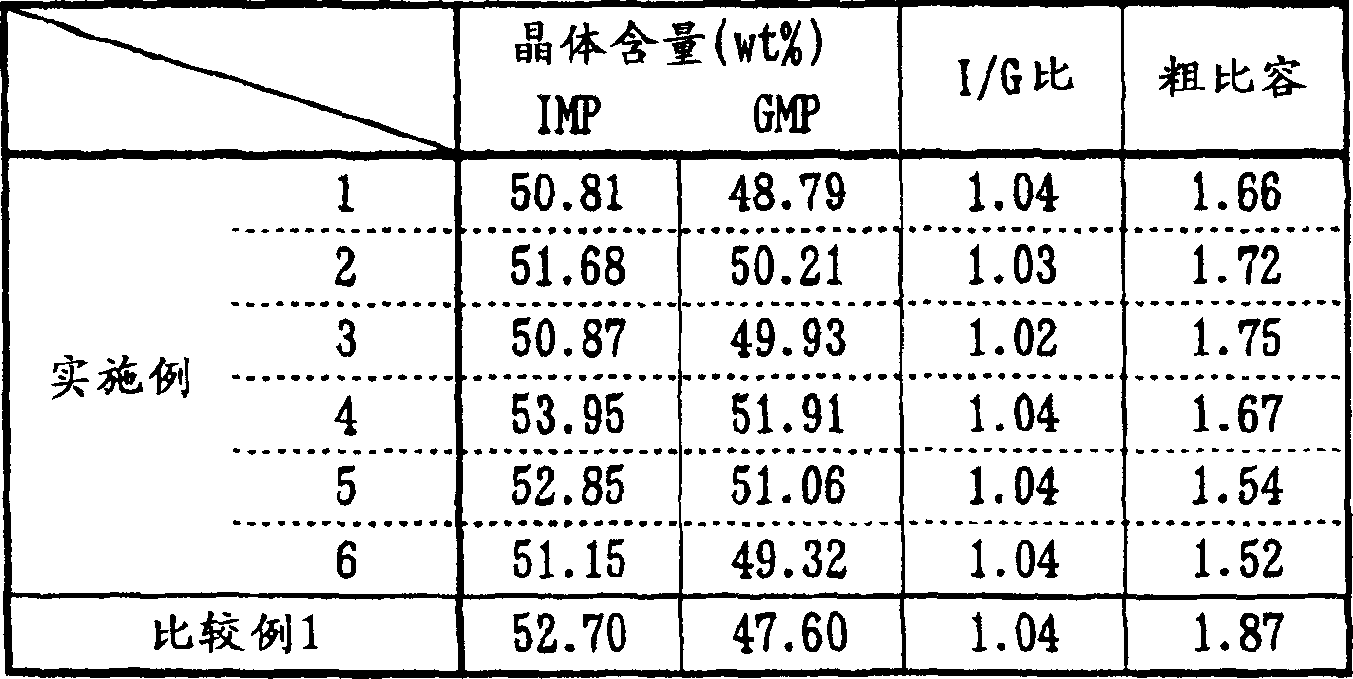

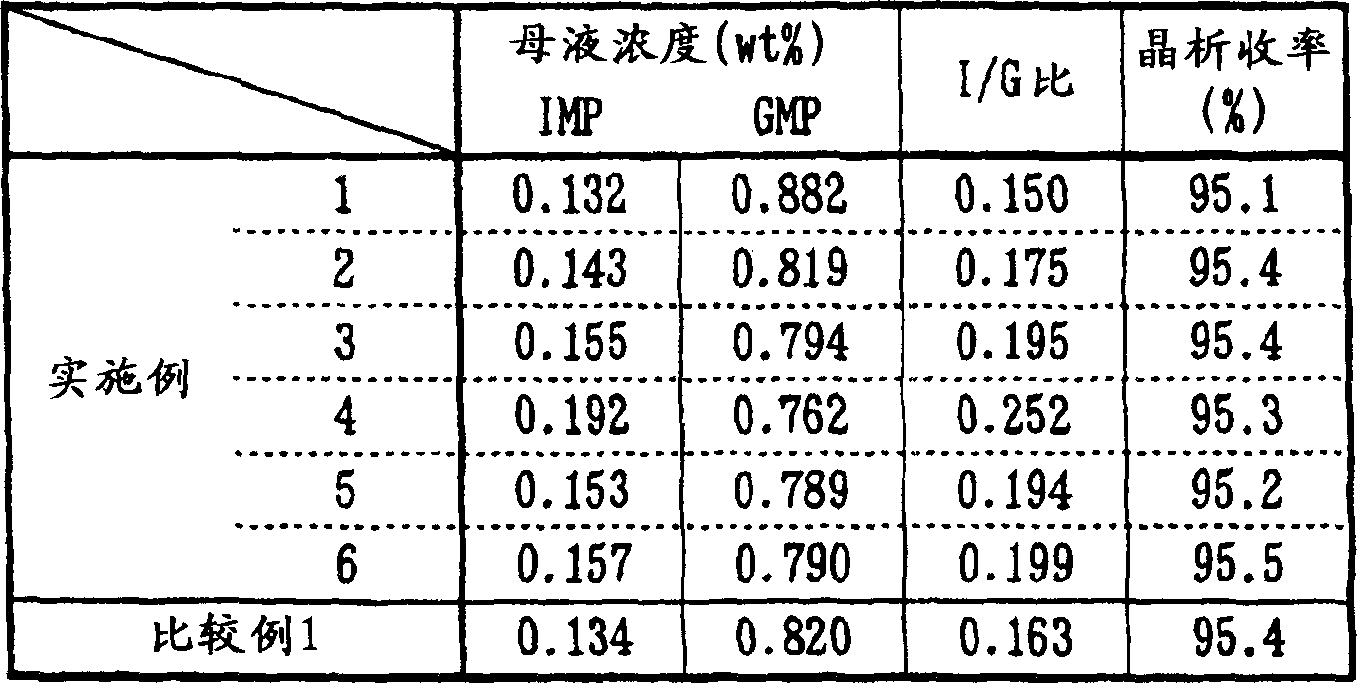

Embodiment 1

[0022] 200ml of aqueous methanol solution with a concentration of 30% by volume was put into a crystallization tank, kept at 40°C, and 872.0g of aqueous solution containing 5'-IMP2Na89.5g and 5'-GMP2Na91.1g and 5'-GMP2Na91.1g were injected simultaneously therein with 95% by volume methanol in water. At the same time, in the process of filling, it is carried out by making the concentration of methanol in the crystallization tank during filling reach 30% by volume.

[0023] After the injection was completed, it was cooled to 10°C, but the precipitation of an amorphous solid of 5'-GMP2Na was not confirmed.

Embodiment 2

[0025] Put 200ml of methanol aqueous solution with a concentration of 35% by volume into a crystallization tank, keep it warm at 40°C, and add 872.0g of aqueous solution containing 5'-IMP2Na89.5g and 5'-GMP2Na91.1g and 95 volume % methanol in water. At the same time, during the filling process, control is carried out so that the concentration of methanol in the liquid phase in the crystallization tank reaches 30% by volume.

[0026] After the injection was completed, it was cooled to 10°C, but the precipitation of an amorphous solid of 5'-GMP2Na was not confirmed.

Embodiment 3

[0028] Put 175ml of methanol aqueous solution with a concentration of 45% by volume into the crystallization tank, keep it warm at 40°C, and add 763.0g and 95 volumes of aqueous solution containing 5'-IMP2Na78.3g and 5'-GMP2Na79.2g to it at the same time in 3 hours % Methanol is not in solution. At the same time, during the filling process, the methanol concentration in the liquid phase in the crystallization tank was controlled to reach 45% by volume.

[0029] After the injection was completed, it was cooled to 10°C, but the precipitation of an amorphous solid of 5'-GMP2Na was not confirmed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com