Low temperature curing beefsteak and processing method

A technology of low-temperature curing and processing method, applied in the field of food processing, can solve problems such as the impact on human health, and achieve the effects of improving the quality of steak, reducing the use of salt, and improving the degree of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

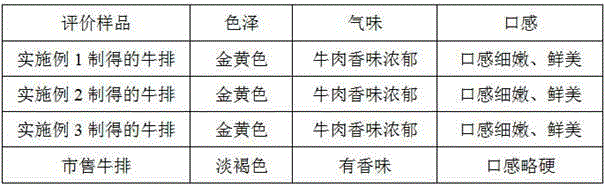

Examples

Embodiment 1

[0021] 1) Thawing: Thaw frozen beef at 6°C and 50% relative humidity;

[0022] 2) Cutting: Rinse the thawed beef, remove the fascia on the surface of the beef, and cut the beef into steaks;

[0023] 3) Preparation of pickling solution: first wash and peel the garlic and mash it into a puree; then wash the onion, remove the skin and cut into cubes, add water to squeeze the juice; then mix the obtained garlic with lemon juice and light soy sauce , pepper powder, cinnamon powder and rosemary are added to the onion juice and mixed, and finally edible starch is added and stirred evenly;

[0024] The raw materials used are calculated by weight: 10 parts of onion, 6 parts of lemon juice, 5 parts of soy sauce, 3 parts of edible starch, 2 parts of pepper, 2 parts of cinnamon powder, 1 part of rosemary, 1 part of garlic, and 10 parts of water ;

[0025] 4) Pickling: Put the cut steak into a vacuum tumbler, add a pickling solution 20% of the weight of the steak, and knead and marinate ...

Embodiment 2

[0030] 1) Thawing: Thaw frozen beef at 8°C and 55% relative humidity;

[0031] 2) Cutting: Rinse the thawed beef, remove the fascia on the surface of the beef, and cut the beef into steaks;

[0032] 3) Preparation of pickling solution: first wash and peel the garlic and mash it into a puree; then wash the onion, remove the skin and cut into cubes, add water to squeeze the juice; then mix the obtained garlic with lemon juice and light soy sauce , pepper powder, cinnamon powder and rosemary are added to the onion juice and mixed, and finally edible starch is added and stirred evenly;

[0033] The raw materials used are calculated by weight: 11 parts of onion, 7 parts of lemon juice, 5 parts of soy sauce, 4 parts of edible starch, 2 parts of pepper, 2 parts of cinnamon powder, 1 part of rosemary, 1 part of garlic, and 12 parts of water ;

[0034] 4) Pickling: Put the cut steak into a vacuum tumbler, add a pickling solution with 25% of the weight of the steak, and knead and mari...

Embodiment 3

[0039] 1) Thawing: Thaw frozen beef at 10°C and 60% relative humidity;

[0040] 2) Cutting: Rinse the thawed beef, remove the fascia on the surface of the beef, and cut the beef into steaks;

[0041] 3) Preparation of pickling solution: first wash and peel the garlic and mash it into a puree; then wash the onion, remove the skin and cut into cubes, add water to squeeze the juice; then mix the obtained garlic with lemon juice and light soy sauce , pepper powder, cinnamon powder and rosemary are added to the onion juice and mixed, and finally edible starch is added and stirred evenly;

[0042] The raw materials used are calculated by weight: 12 parts of onion, 8 parts of lemon juice, 6 parts of soy sauce, 5 parts of edible starch, 3 parts of pepper, 2 parts of cinnamon powder, 2 parts of rosemary, 1 part of garlic, and 15 parts of water ;

[0043] 4) Pickling: Put the cut steak into a vacuum tumbler, add a pickling solution 30% of the weight of the steak, and knead and marinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com