Patents

Literature

66results about How to "Sensual" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

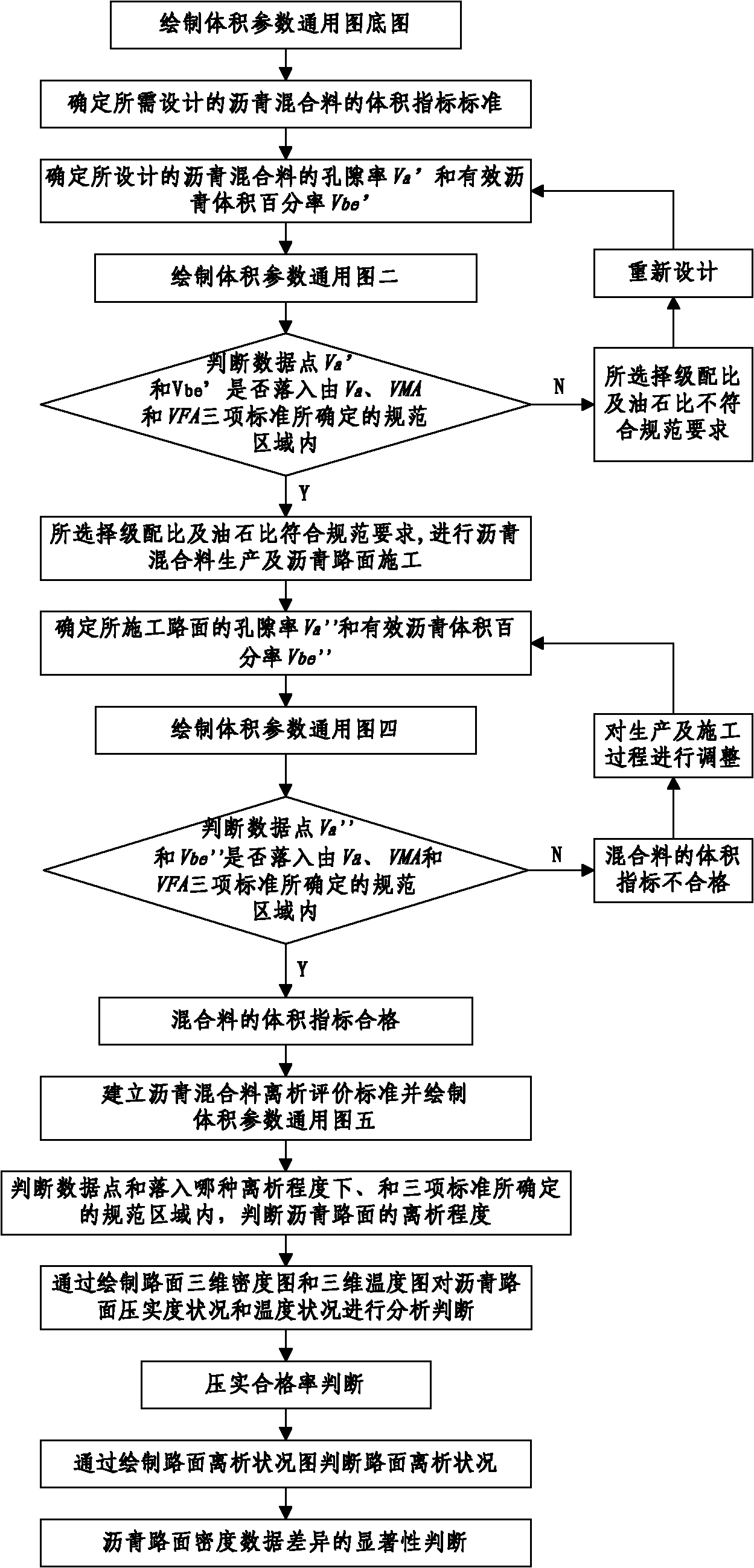

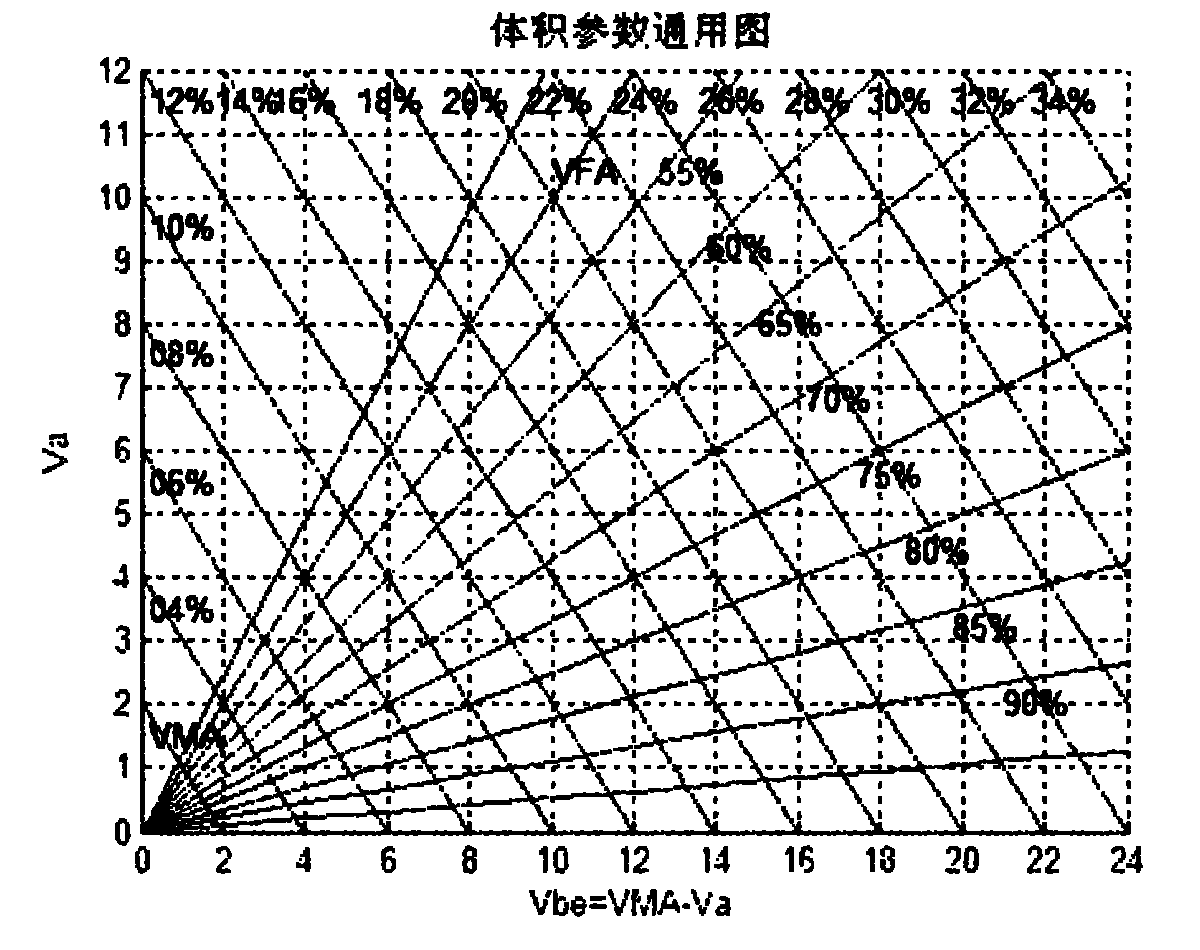

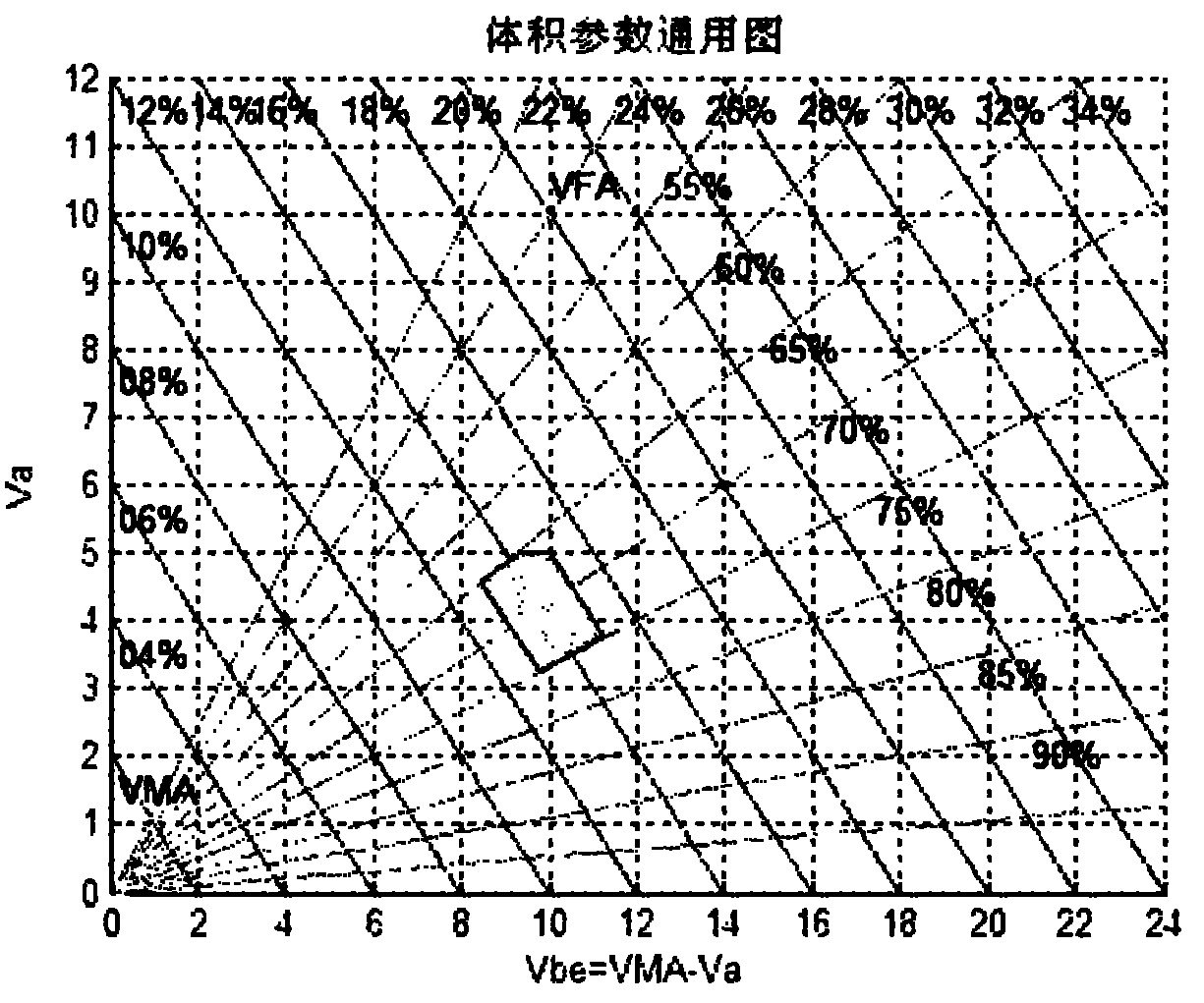

Method for controlling construction quality of asphalt pavement in real time

The invention discloses a method for controlling construction quality of an asphalt pavement in real time, which comprises the following steps of: 1, drawing a universal volumetric chart to evaluate volumetric parameter characteristics of various asphalt mixtures, and selecting a proportion of an asphalt mixture, which is suitable for the local environment and is difficult to segregate; 2, checking that whether volumetric parameter information of the asphalt mixture produced in the day meets requirements of design and construction specifications so as to quickly regulate the production process; 3, evaluating the aggregation condition of the asphalt pavement by using the universal volumetric chart; and 4, analyzing and judging the compaction degree condition and temperature condition of the asphalt pavement, judging the compaction qualified rate, judging the significance of the density data difference of the asphalt pavement, checking the construction quality of the asphalt pavement and providing quantitative basis for later period payment adjustment. The method has the advantages of reasonable design, high reliability, high operability, high real-time property, high efficiency of evaluating the construction quality of the asphalt pavement, and high practicability, and contributes to improving construction quality and saving economic cost.

Owner:XINJIANG BEIXIN ROAD & BRIDGE GRP +1

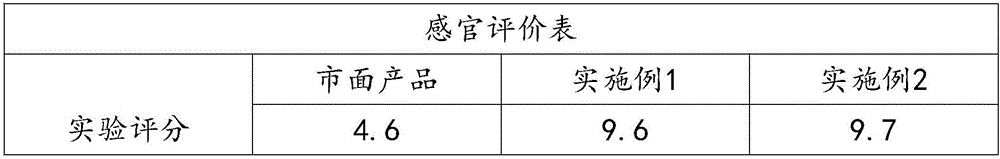

A kind of original beef balls and preparation method thereof

The embodiment of the invention discloses a manufacture method of primary taste beef dumplings, which comprise the following components in percentage by weight: 75 to 85 percent of refined braised beef, 5 to 10 percent of cattle fat, 1 to 1.5 percent of mashed garlic, 1 to 2 percent of table salt, 0.8 to 1.5 percent of monosodium glutamate and the balance of starch. The embodiment of the invention also discloses a method for preparing the primary taste beef dumplings. The method comprises the following steps of: mincing the refined braised beef by using a beef fiber separation device along the direction of beef fibers and controlling the processing temperature to prepare the primary taste beef dumplings which are fresh in flavor, high in elasticity and meat sense and convenient to eat, does not contain harmful chemical additives or preservatives, and can relieve labor intensity and realize batch production.

Owner:汕头市潮庭食品股份有限公司

Dry garment leather base and preparation process thereof

InactiveCN106118034ASensualImprove tensile propertiesGrip property fibresProcess engineeringMaterials science

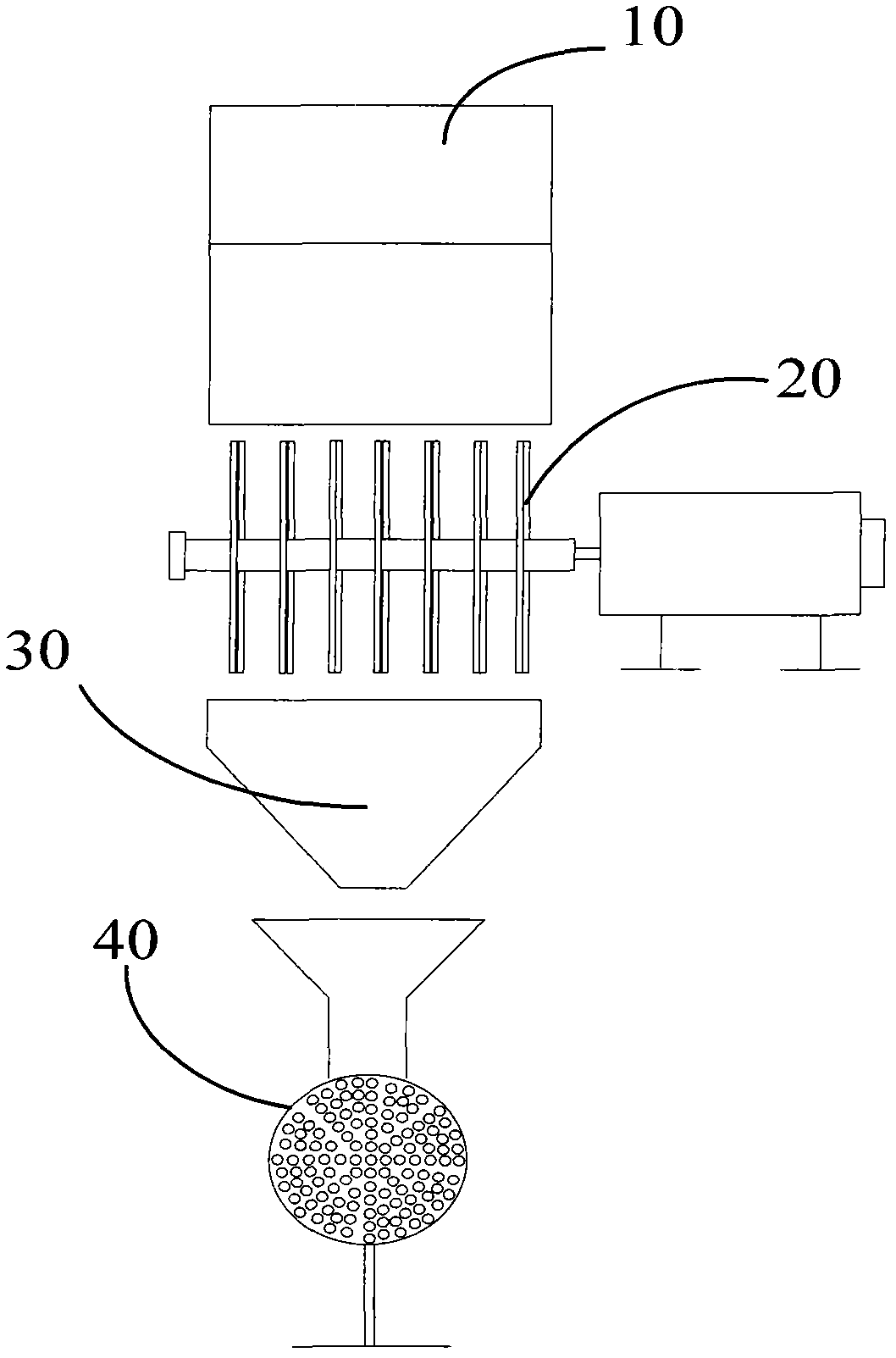

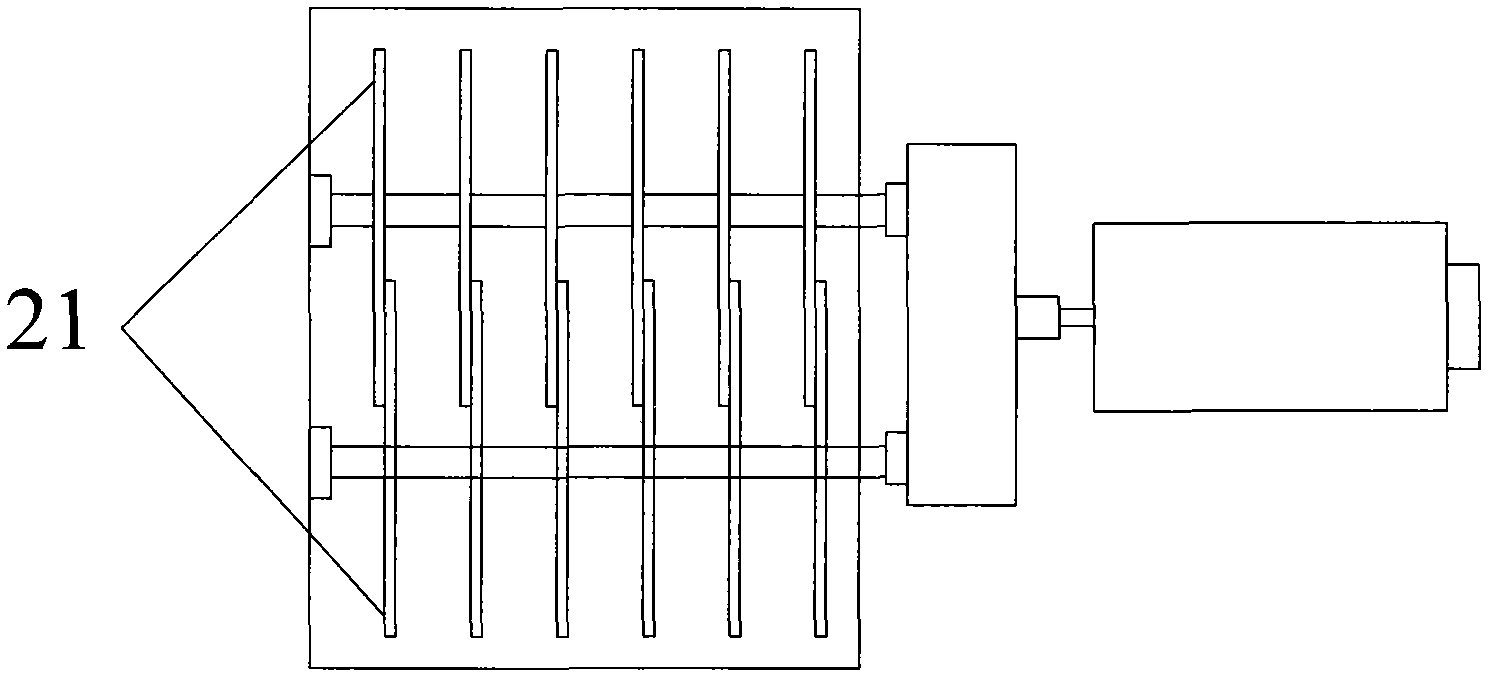

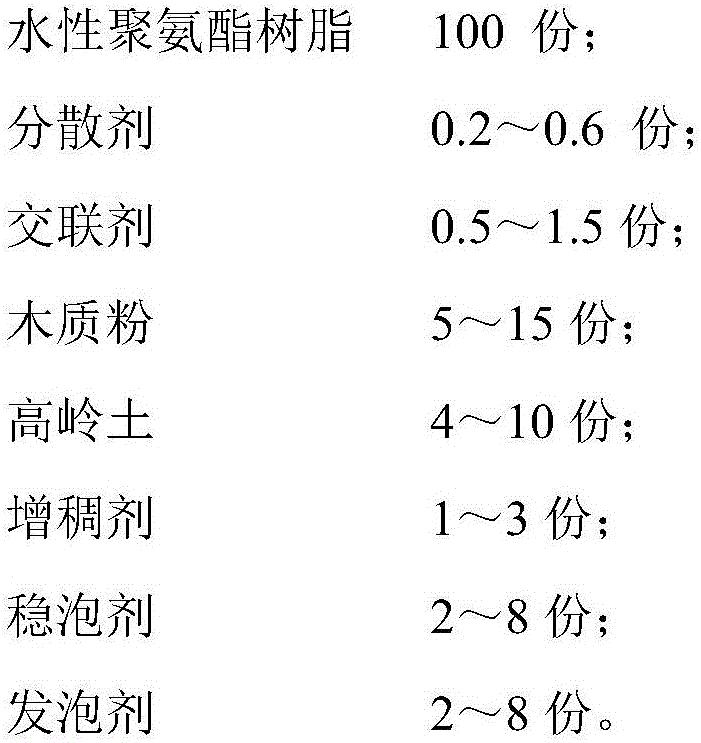

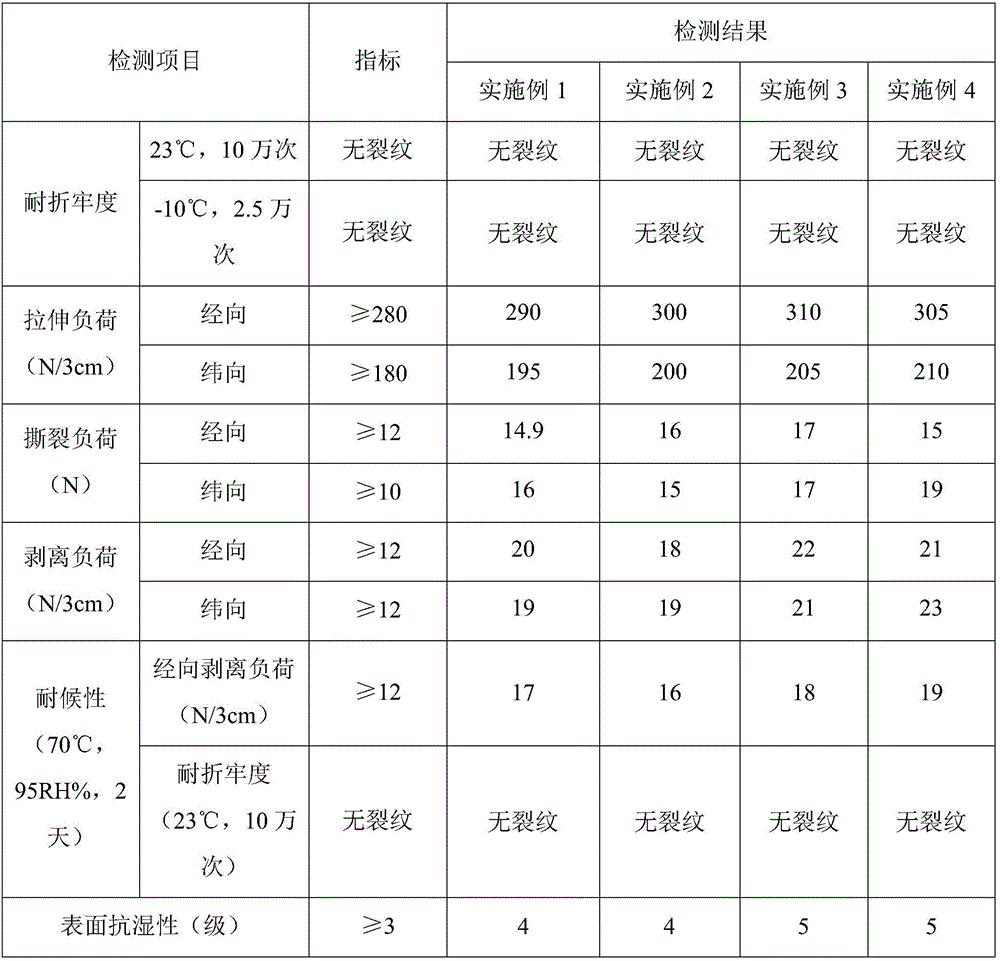

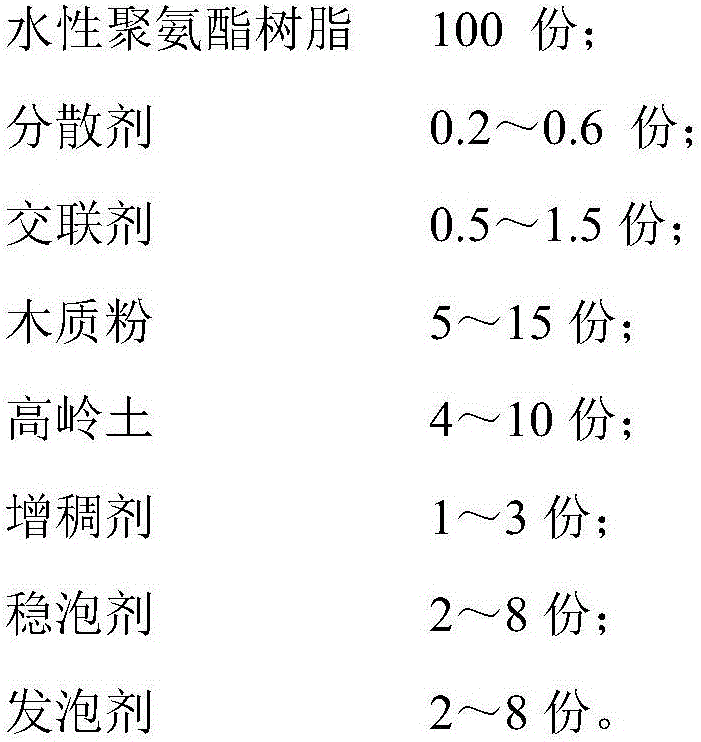

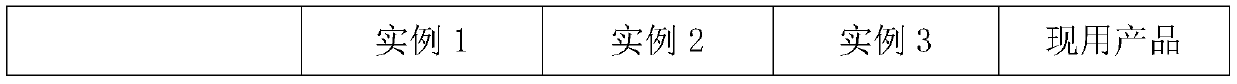

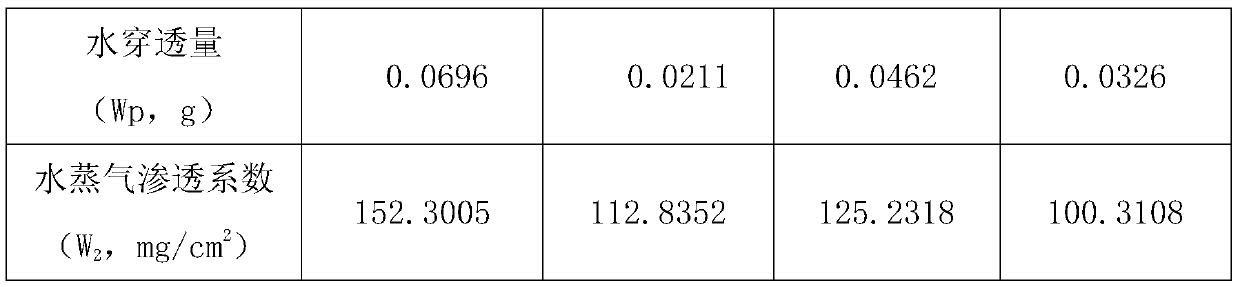

The invention provides a dry garment leather base and a preparation process thereof. The preparation process includes the steps: 1) base cloth treatment: completely soaking base cloth in mixed solution of soluble calcium salt and leather softeners, mangling the base cloth and then ironing and drying the base cloth by an ironing roller; 2) coating the base cloth with 200-500g / m<2> of garment leather base foaming slurry by a scraping method; 3) drying the base cloth in a drying oven; 4) base rolling: cooling and rolling the base cloth by a cooling roller to prepare the dry garment leather base. The prepared dry garment leather base has good moisture and air permeability, is quite soft in hand feeling and good in rebound resilience and wear resistance, and can meet higher performance requirements and environmental protection standards.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD

Environment-friendly breathable TPU (Thermoplastic polyurethanes) synthetic leather and preparation method thereof

InactiveCN105966027AReduce pollutionMethod route shortLamination ancillary operationsSynthetic resin layered productsPolyurethane adhesiveAdditive ingredient

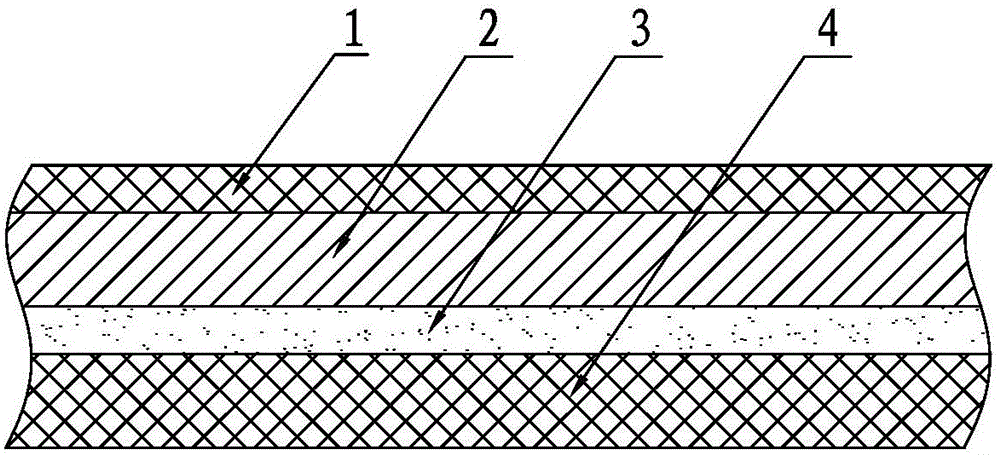

The invention discloses an environment-friendly breathable TPU synthetic leather and a preparation method thereof. The environment-friendly breathable TPU synthetic leather comprises a decorative surface layer, a TPU surface layer, an adhesive layer and a base cloth layer. The decorative surface layer is coated on The treatment agent on the upper surface of the TPU surface layer is generated, and the TPU surface layer is combined with the base cloth layer through the adhesive layer. The components and parts by weight of the TPU surface layer are: 30 to 95 parts by weight of TPU particles; 3 to 95 parts by weight of the flame retardant 25 parts by weight; 2-15 parts by weight of pigment; 0-5 parts by weight of light stabilizer; 0-5 parts by weight of anti-scratch agent; 0-20 parts by weight of filler. The adhesive is a water-based polyurethane adhesive; the surface treatment agent is a water-based polyurethane surface treatment agent. Adopting the preparation method of extrusion casting, shaping first, then compounding, and negative pressure embossing, the products are environmentally friendly, non-toxic, low-odor, low-VOC, clear in structure, soft in hand, scratch-resistant, wear-resistant, hydrolysis-resistant, genuine leather Strong features.

Owner:常州三聚塑胶科技有限公司

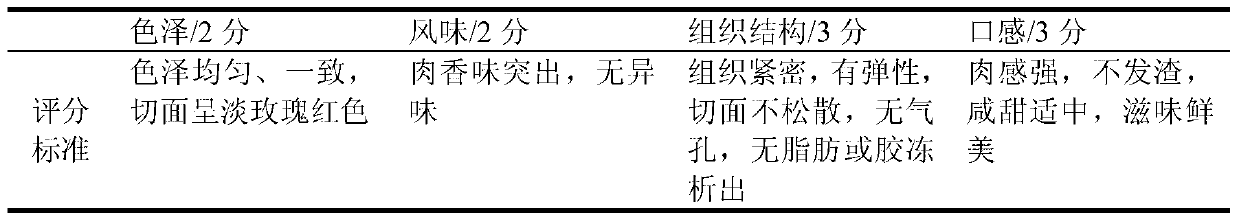

Crystal pork sausage and preparation method thereof

InactiveCN103340439ARuddy colorOutstanding fragranceFood preparationMonosodium glutamateRed yeast rice

The invention discloses crystal pork sausage and a preparation method of the crystal pork sausage. The crystal pork sausage takes pork and pig skin as raw materials and ice water, protein powder, carrageenan, edible salt, sodium nitrite, red yeast rice, white pepper powder, glucose, ginger powder, sodium tripolyphosphate and monosodium glutamate as auxiliary materials, and is prepared by the following steps of tumbling, salting, filling, smoking, cooking, radiating, packaging and sterilizing. The production process is simple, short in cycle and high in efficiency; the processed crystal pork sausage has the characteristics of ruddy color and luster, outstanding fragrance, compact tissues, good elasticity, semi-transparent tangent plane, rich nutrition and the like.

Owner:江苏迈斯克食品有限公司

Making method of foaming PU (polyurethane) leather

ActiveCN103507378AElasticFeel plumpLamination ancillary operationsSynthetic resin layered productsSurface layerFoaming agent

The invention discloses a making method of foaming PU (polyurethane) leather, the method is as follows: 100 kg of polyurethane dry-method surface layer resin, 15-20 kg of dimethyl formamide, 15-20 kg of butanone, 15-20 kg of toluene, 0.5-1.0 kg of an additive and 3-5 kg of color powder are evenly mixed to obtain a polyurethane dry-method surface layer resin ingredient, 100 kg of foaming PU (polyurethane) resin; 15-20 kg of heavy calcium carbonate, 1.5-2 kg of a foaming agent, 10-15 kg of the dimethyl formamide and 5-8 kg of color paste are evenly mixed to obtain a foaming PU (polyurethane) resin mixed ingredient; 100 kg of bonding layer resin, 10-15 kg of the dimethyl formamide, 10-15 kg of the butanone and 10-15 kg of the toluene are evenly mixed to obtain a polyurethane bonding layer resin mixed ingredient; release paper is successively scraped and coated with the above three mixed ingredients, then a knitted fabric substrate is bonded for drying, and the artificial leather obtained by the making method is high in resilience, full in hand feeling and pattern, strong in sensual appeal and is hydrolysis resistant.

Owner:KUNSHAN XIEFU NEW MATERIALS LTD BY SHARE LTD

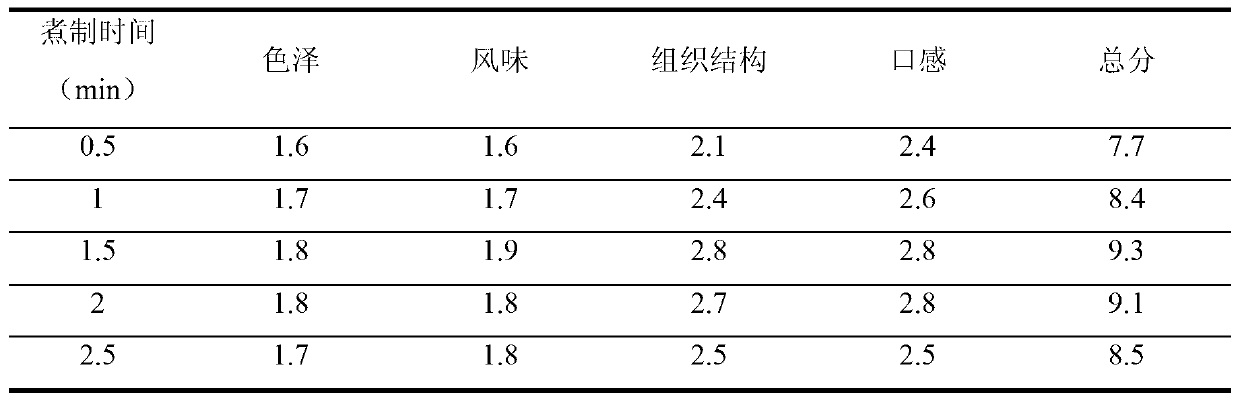

Self-heating instant steak and processing method thereof

The invention relates to the field of food processing, in particular to self-heating instant steak and a processing method thereof. The processing method of the self-heating instant steak comprises the following steps of frying the tenderized and pickled steak with the thickness of 1.0-2.0cm for 30-50 seconds at the temperature of 150-200 DEG C; baking the fried steak for 15-20 minutes at the temperature of 200-210 DEG C; cooling down the baked steak to the temperature of 10-20 DEG C; packaging the steak in a vacuum state; and quickly freezing the packed steak to the temperature of minus 18 DEG C to minus 15 DEG C in an environment with the temperature of minus 40 DEG C to minus 36 DEG C. By the method, the steak is tenderized and pickled at first and then is fried and baked, the baked steam is cooked eighty to ninety percent and is frozen quickly, and the processed steak can be eaten instantly after being placed in boiling water, tastes good, tender and crisp, is delicious and has developmental nutrition; and moreover, the steak is convenient to carry and eat and is convenient and instant, and people can eat the steak in any outdoor places such as fields and trains except for airplanes.

Owner:GUIZHOU FENGGANG CHANGBO FOOD CO LTD

Method for processing hot-stewed airing rabbit

InactiveCN102429250AChange the processing technologySuitable for mass productionFood preparationFermentationChemistry

The invention relates to a method for processing a hot-stewed airing rabbit. The method comprises the following steps of: inoculating auxiliary materials to an integral rabbit which is cooled and subjected to acid discharge, rolling and kneading under vacuum, salting and fermenting at low temperature, hanging, airing and fermenting in the shade, performing halogen cooking, drying, finishing, packaging, sterilizing, keeping temperature and inspecting, wherein the auxiliary materials consist of the following components in part by weight: 3 to 5 parts of fermentation agents, 3 to 4 parts of halogen materials and 4 to 5 parts of flavorings. In the method, the convention salting process is changed by utilizing a vacuum rolling and kneading technology, and the fermentation agents such as a probiotics growth promoter, a proenzyme activator and the like are added by utilizing a microbial fermentation technology; the integral rabbit is fermented twice and is flavored and subjected to the halogen cooking, a modernization processing process and the conventional sauce halogen process are combined, the conventional process for processing airing products is changed, the production period of the products is shortened, the integral production process is finished only for 22 to 26 hours, and the integral processing process can be programmed and standardized; and thus, method is suitable for large-scale batch production of factories.

Owner:青岛康大食品有限公司

Intelligence promoting health care fish ball and making method thereof

InactiveCN104323334AEnhance immune functionAttractive colorNatural extract food ingredientsFood ingredient functionsMedicinal herbsSide effect

The invention discloses an intelligence promoting health care fish ball and a making method thereof. According to a formula, the fish ball is composed of the following raw materials: 45-50 of fresh fish, 20-25 of glutinous rice pulp, 3-4 of rhizoma gastrodiae, 10-12 of black sesame, 3-5 of walnut kernel, 2-4 of sharpleaf galangal fruit, 1-3 of arborvitae seed, 4-5 of Codonopsis pilosula, 1-3 of acorus gramineus, 3-4 of Rhizoma Wenyujin Concisum, 5-6 of milk, 2-4 of deep sea fish oil, 2-4 of Fistular Onion Stalk, 1-2 of aromatic vinegar, 3-4 of soy sauce, 2-4 of ground pepper and a proper amount of refined salt. According to the invention, the fresh fish is combined with the glutinous rice pulp, the color is attractive, and a lot of protein and unsaturated fatty acid are contained. The prepared product has the characteristics of novel color, full meat sense and delicious taste, and is smooth, tender and juicy. The raw materials are added with a variety of intelligence promoting medicinal herbs, the fish ball has slight aroma of traditional Chinese medicines and is free of side effect, can enhance the body immunity function of children and has obvious intelligence promoting, brain invigorating and health care effects, and can be used for intelligence promoting, brain invigorating and health care.

Owner:HEFEI YUEJIE ECOLOGICAL AGRI TECH

Method for preparing sea sedge chicken cutlets

The invention discloses a method for preparing sea sedge chicken cutlets. The method comprises the following steps: preparing minced chicken to an integral piece of meat, grinding the minced chicken in a meat grinder without winch, vacuum stirring the minced chicken by using a vacuum stuffing mixer, molding the minced chicken into chicken cutlets with different specifications, different flavors and different shapes in a molding machine after being pickled, then milling, starching, coating powder, frying and quick-frozen packaging to obtain the sea sedge chicken cutlets. The sea sedge chicken cutlets have the relatively strong meat quality, the cost can be reduced, and sea sedge is innovatively and smartly matched with the chicken cutlets made of minced chicken in the invention to enrich the nutrition and the taste of the sea sedge chicken cutlets, and the market prospect is broad.

Owner:河南永达清真食品有限公司

Pork kiss sausage and preparation method thereof

InactiveCN104013026ASensory noveltyAttractive colorSausage makingFood preparationBiotechnologyMonosodium glutamate

The invention discloses a pork kiss sausage and a preparation method thereof. The pork kiss sausage is prepared from the following raw materials in parts by weight: 40-50 parts of pig lean meat, 25-35 parts of water, 2-3 parts of soy isolate protein, 6-10 parts of pig prime condition, 5-15 parts of starch, 1-1.4 parts of salt, 1.5-2.5 parts of glucose, 0.5-0.7 part of monosodium glutamate, 0.2-0.4 part of spice, 0.05-0.07 part of monascus color and 0.32-0.36 part of essence. The pork kiss sausage disclosed by the invention has the beneficial effects that a sausage body is novel in feeling and attractive in color and luster, and the sausage is rich in abundant proteins, essential amino-acids required by a human body as well as various nutritional elements, such as potassium, ferrum and magnesium, required by the human body; the sausage is full in integral structure, quite in flesh appeal and delicious in taste.

Owner:SHANDONG JIASHIBO FOOD

Low-temperature meat sausage containing shredded meat

The invention belongs to the technical field of low-temperature meat sausage, and particularly relates to a low-temperature meat sausage containing shredded meat. The invention aims to provide a low-temperature meat sausage containing shredded meat, which has good mouthfeel and contains visible shredded meat so as to satisfy the consumer demands for high-grade sausage. The low-temperature meat sausage containing shredded meat is prepared by filling main materials and auxiliary materials and sterilizing at low temperature, wherein the main materials are composed of 35-50 parts of minced meat and 25-35 parts of shredded meat, and the shredded meat is cooked. The meat is shredded and added into the meat sausage, so that the product has strong meat sensation; and by making the shredded meat in a drying mode, the meat sausage has unique flavor, and the shredded meat and minced meat are well distinct, thereby satisfying the special requirements of consumers for high-quality sausage.

Owner:CHENGDU XIWANG FOOD

Vegetable fish balls and preparation method thereof

The invention discloses vegetable fish balls. The vegetable fish balls comprise the following components: fresh fish flesh, fresh caraways, water, starch, salt, sugar, sodium glutamate and garlic powder. The invention also discloses a preparation method of the vegetable fish balls. The vegetable fish balls and the preparation method have the beneficial effects that combining the fresh fish flesh with the fresh caraways, the vegetable fish balls have attractive colors and contain proteins, unsaturated fatty acids and vitamins; the caraways also contain rich minerals, such as iron, phosphorus, calcium and the like; the products have novel colors and are fully fleshy, tasty, smooth, tender and juicy; two-stage water temperature forming is adopted during cooking, and the vegetable fish balls are quickly frozen and packaged directly after quick cooling, thus ensuring that the nutritional ingredients of the fish flesh and vegetables are not easy to lose, and furthest ensuring the original colors, aromas and tastes of the food materials.

Owner:SHANDONG JIASHIBO FOOD

Process for producing sausages through strip cutting

The invention discloses a process for producing sausages through strip cutting. The process comprises the following steps of meat cutting, salting, filling, drying, smoking, cooling, packaging and warehousing, wherein in the meat cutting step, selected fresh meat is put in a strip cutting machine to carry out mechanical strip cutting, the width of the cut meat strips is unified to 1.5cm and the length of the strips is unified to 1-2cm.The sausages include Cantonese sausages, Sichuan sausages, Rugao sausages, shrimp meat sausages, garlic cumin sausages and the like; the dried sausages are further needed to be smoked in a smoking oven by using smoke flavorings. The process disclosed by the invention has the advantages that the selected fresh meat is cut into strips through the strip cutting machine, uniform meat strips are obtained through controlling the width and the length between blades of the strip cutting machine, the sausages produced from the meat strips have outstanding fleshy feeling and taste more delicious, various sausages can be produced according to the requirements of different consumer groups and the produced sausages are wide in applicability; liquid flavorings are obtained through rectifying and purifying natural plants and the smoked sausages are bright in luster, free of cancerogenic substances such as 3, 4-benzopyrene, safe, reliable and beneficial to the physical health of eaters.

Owner:SICHUAN SIHAI FOOD

Purple steamed crystal dumpling and making method thereof

ActiveCN104026459AAttractive colorNew colorFood freezingFood thermal treatmentMonosodium glutamateAdditive ingredient

The invention discloses a purple steamed crystal dumpling which is characterized by comprising a wrapper consisting of modified starch, wheat starch, boiled water, edible salt, salad oil and mashed purple sweet potatoes, and stuffing consisting of minced fillet, water, shrimp meat, fat, starch, green onion leaves, carrots, edible salt, white granulated sugar and monosodium glutamate. The invention also discloses a making method of the purple steamed crystal dumpling. By the combination of fresh fish meat and fresh caraway, the purple steamed crystal dumpling has an attractive color and contains proteins, unsaturated fatty acid and vitamins, and caraway also contains rich mineral substances such as iron, phosphorus and calcium. The purple steamed crystal dumpling prepared by the making method disclosed by the invention has a novel color, is fleshy enough, has a delicious taste and is tender and juicy; during steaming, the purple steamed crystal dumpling is formed through two-section water temperature and is directly quickly frozen and packaged after being quickly cooled, so that nutritional components of fish meat and vegetables are unlikely to lose, and the original color, fragrance and taste of food materials are guaranteed to the maximum extent.

Owner:SHANDONG JIASHIBO FOOD

Roasted beef sausage and preparation method thereof

The invention discloses a roasted beef sausage and a preparation method thereof. The roasted beef sausage comprises the following raw materials, by mass: 20-30 parts of beef, 5-6 parts of chicken, 5-8 parts of starch, 4-6 parts of isolated soybean protein, 8-10 parts of water, 0.5-2 parts of salt, 1-2.5 parts of sugar, 0.2-0.6 part of monosodium glutamate, 0.05-0.1 part of spice, 0.3 part of carrageenan, 0.1-0.2 part of beef essential oil and 0.005 part of monascus red pigment. The sausage has the following beneficial effects: the product is rich in protein, essential amino acids, unsaturated fatty acid and taurine, and is also rich in calcium, iron, copper, zinc and other nutritional elements required by human body; the sausage also has characteristics of full structure, complete meat taste, delicious taste, complementation of nutrients contained in chicken and beef, better taste compared with roasted sausage of pure chicken and better process and edible convenience.

Owner:SHANDONG HUACHANG FOOD TECH

Seaweed fish ball and processing method thereof

InactiveCN104041855ADeliciousSensualFood ingredient functionsFood preparationTrace elementFresh fish

The invention discloses a seaweed fish ball which is processed from the following components in parts by weight: 72-75 parts by weight of fresh fish flesh, 9-11 parts by weight of seaweed, 5-8 parts by weight of water, 3-5 parts by weight of starch, 2-3 parts by weight of fresh egg white, 1.2-1.6 parts by weight of salt, 3-4 parts by weight of sugar, 0.4-0.6 part by weight of sodium glutamate, 0.3-0.5 part by weight of garlic powder and 0.3-0.5 part by weight of white pepper powder. The seaweed fish ball is delicious in taste, sufficient in meat, novel in color and rich in various mineral substances and trace elements necessary for a human body.

Owner:SHANDONG JIASHIBO FOOD

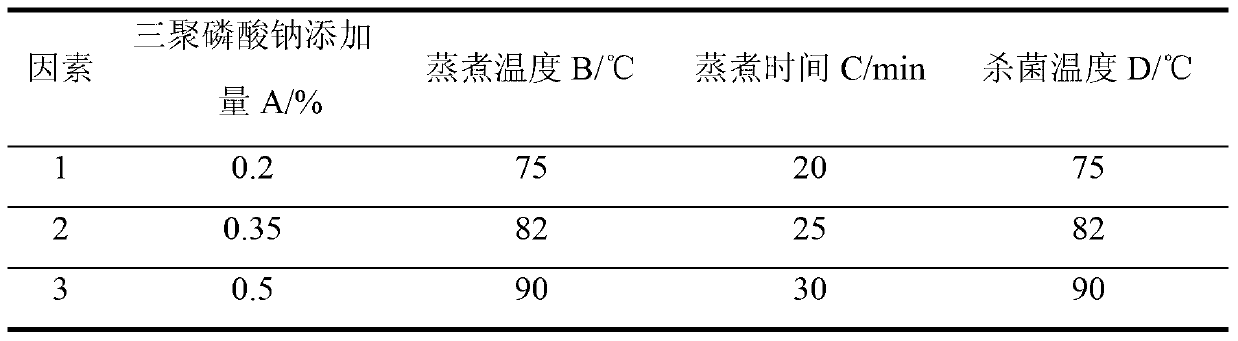

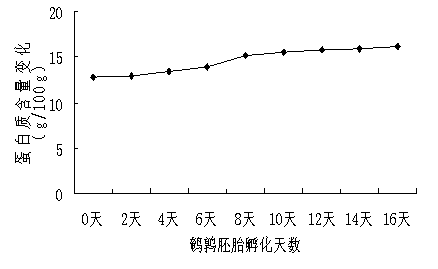

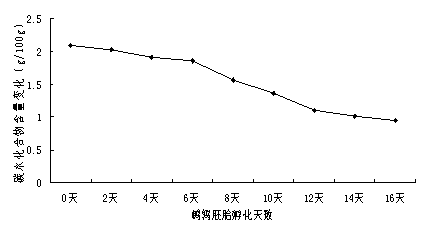

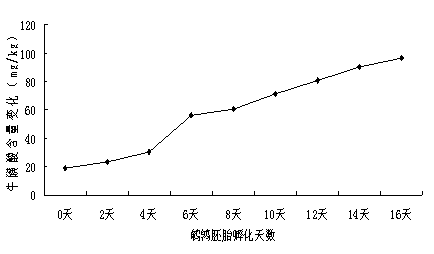

Quail embryo egg ham sausage and preparation method thereof

The invention discloses a quail embryo egg ham sausage which is prepared by mainly using the raw materials of quail embryo egg with the embryonic age of 10-16 days and starch and adding seasonings and an additive, wherein the weight ratio of the quail embryo egg to the starch is 3.5 to1, the adding amount of the seasonings is 8.84 percent of the weight of the quail embryo egg, and the adding amount of the additive is 11.43 percent of the weight of the quail embryo egg. The preparation method of the quail embryo egg ham sausage comprises the steps of: selecting and pretreating the raw materials, preserving the raw materials, chopping and mixing, subpackaging, and curing and sterilizing. The quail embryo egg ham sausage provided by the invention is low in cost and convenient to prepare, contains high-level protein, vitamins, minerals and taurine, is less in contents of fat and cholesterol, high in nutritive value, rich in calcium, special in taste, and good in market prospect.

Owner:HENAN UNIV OF SCI & TECH

Pork sausage and its processing method

Owner:SHANDONG HUIFA FOODS

Polyurethane resin for waterproof vapor permeable leather and preparation method of polyurethane resin

The invention discloses polyurethane resin for waterproof vapor permeable leather and a preparation method of the polyurethane resin. The polyurethane resin for the waterproof vapor permeable leatheris prepared from the following raw materials in ratio: polyol A, polyol B, a chain extender, a terminator, diisocyanate and a solvent, wherein the molar ratio of the polyol A to the polyol B is 1: 1-50: 1, the molar ratio of the chain extender, the polyol A and the polyol B is 1.5: 1-5: 1, the mole number of the terminator is two times the difference between the mole number of the diisocyanate andthe mole numbers of the polyol A, the polyol B and the chain extender, and the use amount of the solvent is 65%-80% of the total weights of the polyol A, the polyol B, the diisocyanate, the chain extender, the terminator and the solvent. The polyurethane resin for the waterproof vapor permeable leather has excellent hydrophobicity, it ensures that a three-dimensional interpenetrating hole structure is formed in a resin portion in a wet-process solidification process, diameters of holes are small, and water vapor can easily pass through the holes; when used for an ultra-fine fiber suede leather, the polyurethane resin has excellent suede feeling and flesh feeling; and the polyurethane resin for the waterproof vapor permeable leather has the characteristics of simplicity and convenience inoperation and easiness during production.

Owner:HUAFON MICROFIBER SHANGHAI

Flowering sausages and preparation method thereof

The invention relates to flowering sausages. The flowering sausages are made from the following components by weight: 19.75kg of chicken meat, 7.5kg of AA-level fish paste, 5Kg of trash fish paste, 23kg of soybean protein emulsion paste, 19.8kg of ice water, 6.25kg of tapioca flour, 7.5kg of cassava modified starch, 1.5kg of table salt, 0.3kg of composite phosphate, 2.5Kg of white granulated sugar, 4g of sodium nitrite, 0.135kg of gourmet powder, 0.18kg of alanine, 0.09kg of meat essence powder, 0.09Kg of white peppers, 0.35kg of carrageenin, 37.5g of ethyl maltol, 25g of TG enzymes, 225g of sesame oil, 200g of meat essence paste, 112.5g of chicken essence oil, 75g of fried minced shallot essence, 1.3g of allura red, 8g of bioactive peptides, 5g of red rice starters and 2.5kg of deep-fried green bean powder, wherein the bioactive peptide is protein polypeptide obtained through linkage of active factors extracted and separated from plants through two or more amino acids. Peptide elements are added, so that the absorption of beneficial elements can be promoted.

Owner:ANHUI FUHUANG SUNGEM FOODSTUFF GRP

Hotdog sausage and processing method thereof

InactiveCN103734779AHas a Western-style smoky flavorRealize the structureFood preparationBiotechnologyMonosodium glutamate

The invention discloses a hotdog sausage and a processing method thereof. The hotdog sausage is composed of the following raw materials in parts by weight: 90 to 100 parts of pig lean meat, 25 to 30 parts of fat meat, 30 to 32 parts of water, 3.5 to 4.5 parts of starch, 1.4 to 1.6 parts of salt, 0.2 to 0.3 part of sugar, 0.3 to 0.4 part of phosphate, 0.4 to 0.5 part of monosodium glutamate, 2.5 to 3 parts of milk powder, 0.1 to 0.15 part of western spices, and 0.3 to 0.35 part of smoking liquid. The hotdog sausage and the processing method have the advantages that: conventional technologies and formula are optimized, modern food processing technologies are combined at the same time; high-quality fresh pig lean meat is taken as the raw material and then is reasonably matched with fat meat and western spices, and thus the produced sausage has the advantages of full structure, high meat content, fresh and chewy taste, rich nutrients, western smoked flavor, and vast market prospect.

Owner:SHANDONG HUIFA FOODS

Pork sausage and processing method thereof

The invention discloses a pork sausage and a processing method thereof. The pork sausage is prepared from the following raw materials in parts by weight: 90-100 parts of pork, 0.1-0.3 part of starch, 0.05-0.2 part of salt, 0.5-1.5 parts of ice water, 0.05-0.25 part of monosodium glutamate, 0.05-0.2 part of natural spice and 0.05-0.2 part of natural essence. The pork sausage has the beneficial effects that the product is full in appearance, bright and tempting in color and luster, elastic and crisp in taste and strong in sense of flesh, and applicable to a plurality of different edible methods such as charcoal grilling, frying, micro-wave, stewing, matching with vegetables and the like. The edible method of charcoal grilling has the characteristics of local foods, the pork sausage can be directly scattered on a charcoal grill or charcoal-grilled together with a pork shashlik, the charcoal-grilled product is fresh and tender in meat, strong in sense of flesh, chewy, and pure and simple in flavor, and the product accords with natural, healthy, nutrient and safe diet concepts pursued by modern consumers, and can meet the requirements of kinds of consumer groups and consumption channels.

Owner:SHANDONG HUIFA FOODS

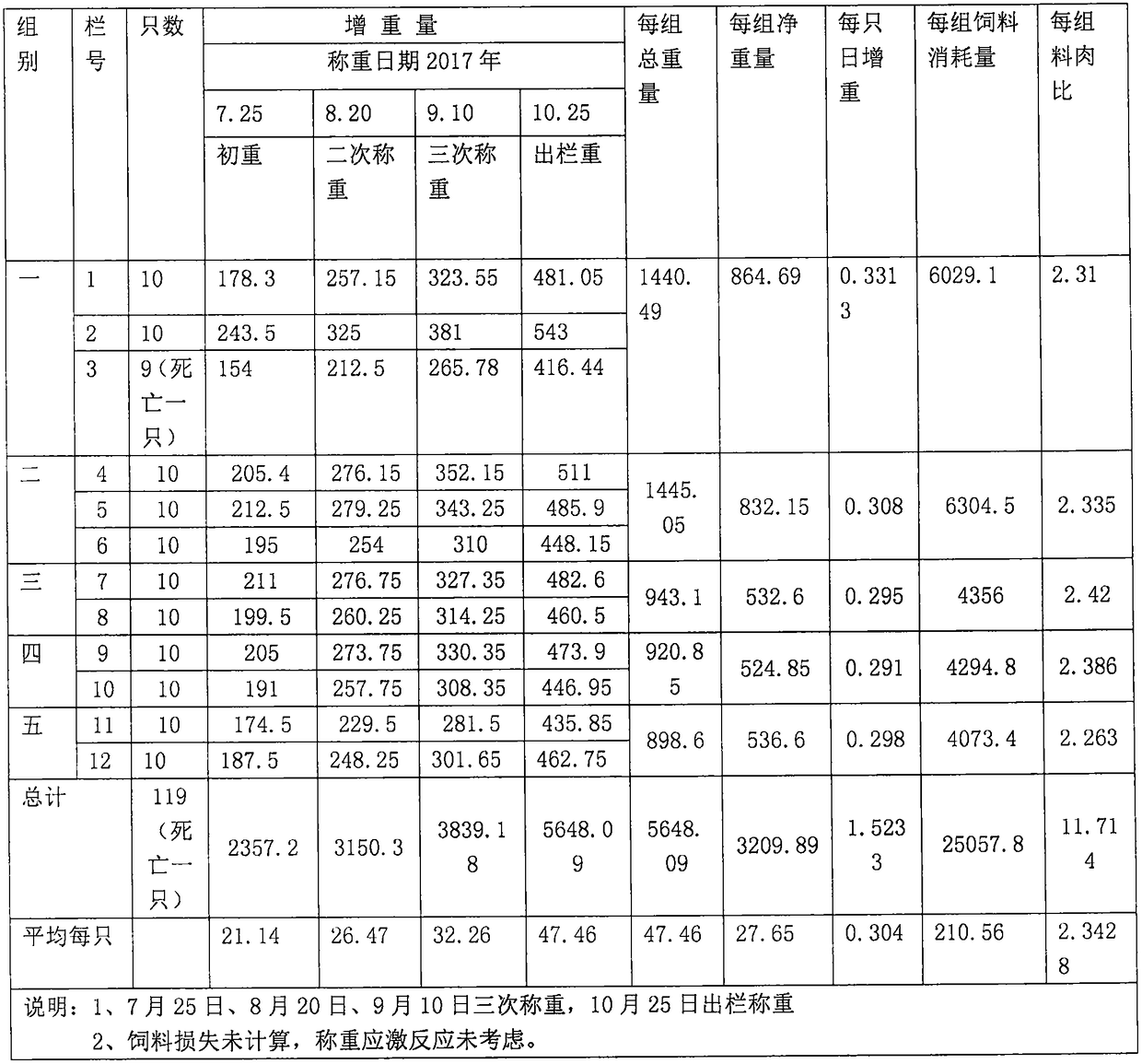

Breeding method of cairina moschata fed with horseradish trees

InactiveCN107279038ASensualDelicious meatFood processingAnimal feeding stuffCairina moschataNutrient

The invention discloses a breeding method of cairina moschata fed with horseradish trees, and relates to the field of fowl breeding. The method includes the steps of (1) selection of ducklings, (2) duckling breeding, and (3) ecological stocking. According to the breeding method of cairina moschata fed with the horseradish trees, nutrient feed containing the horseradish trees is adopted to feed cairina moschata, ecological stocking is combined in the method, and therefore the breeding method of cairina moschata fed with the horseradish trees has the advantages of being simple to implement and in great affection of the public, and occupying a large share in the market, and cairina moschata bred according to the method is sufficient in nutrition, robust in muscle, good in meat taste and delicious in meat flavor.

Owner:梁记

Antibiotic-free green ruminant feed

PendingCN108606159ALow costIncrease profitFood processingAnimal feeding stuffFiberIntestinal microorganisms

Relating to the technical field of animal feed, the invention discloses an antibiotic-free green ruminant feed. The antibiotic-free green ruminant feed selects vitamins, trace elements, Chinese herbalmedicines and biological feed needed by ruminants, can supplement and regulate microorganisms in ruminants in quantity and species, and maintain intestinal microorganism balance in ruminants, also can decompose crude fiber in feed, and produce antibiotic, antibacterial peptide, interferon, organic acid, multienzyme, polyphenol like substances, uses Chinese herbal medicines to replace antibiotics,can well improve the animal immunity and antibacterial ability, and obviously reduces illnesses and deaths.

Owner:张骞

Assorted meat ball and manufacturing technique thereof

InactiveCN105029482ASoft colorHigh protein contentFood ingredientsFood preparationBiotechnologyMonosodium glutamate

The invention relates to an assorted meat ball and a manufacturing technique thereof, and relates to the field of food making. The invention solves the problem that a meat ball made through home cooking is low in nutritive value and poor in taste. The assorted meat ball comprises the following components (by weight): 30-50 parts of chicken neck skin, 20-30 parts of minced chicken breast, 2-4 parts of corn starch, 13-17 parts of drawing protein, 3-7 parts of modified cassava starch, 3-5 parts of onion, 3-5 parts of long scallion, 2-4 parts of egg, 1-3 parts of soy protein concentrate, 1-2 parts of soy sauce, 0.5-2 parts of white granulated sugar, 0.1-0.5 part of ginger powder, 0.3-0.7 part of chicken paste, 0.5-1.2 parts of salt, 0.1-0.5 part of a water-retaining agent, 0.2-0.6 part of monosodium glutamate, 0.05-0.2 part of D-sodium erythorbate, 0.05-0.2 part of I+G, 0.05-0.15 part of shisanxiang, 0.1-0.9 part of beef essence paste, 0.01-0.1 part of water-soluble five spice powder, 8 parts of assorted vegetable, 450-550 parts of water, 5-10 parts of dark soy sauce, 0.05-0.08 part of sorghum red pigment, and 2-3 parts of granulated sugar. The assorted meat ball is delicate in taste, and can be open through slight nip with chopsticks after steamed and boiled.

Owner:吉林卓越实业股份有限公司

Making method of hand-torn bamboo fragrance duck

PendingCN110710644AGuaranteed finenessGuaranteed tasteClimate change adaptationFood ingredient functionsBiotechnologyMonosodium glutamate

The invention discloses a making method of a hand-torn bamboo fragrance duck. The making method includes the following steps of: S1, following raw materials are prepared in parts by weight: 250-350 parts of local duck meat, 500-700 parts of purified water, 80-100 parts of rapeseed oil, 10-18 parts of salt, 2-8 parts of monosodium glutamate, 5-15 parts of cooking wine, 3-10 parts of dark soy sauce,2-6 parts of sesame oil, 2-8 parts of rock sugar, 2-10 parts of Chinese prickly ash, 2-8 parts of dried chili, 2-8 parts of light soy sauce, 4-10 parts of fresh ginger, 30-50 parts of thick broad-bean sauce, 4-10 parts of tangerine peel, 2-6 parts of cinnamon bark, 5-10 parts of myrcia, 5-10 parts of garlic cloves, 8-13 parts of spring onion ties, 1-5 parts of fennel, 10-20 parts of yam, 5-10 parts of radix astragali, 2-7 parts of szechuan lovage rhizomes, 2-6 parts of angelica sinensis, 2-7 parts of radix paeoniae alba and 20-30 parts of bamboo leaves; and S2, the purified water is divided in half, the first half of the purified water is poured into a wok for heating and is heated to 80-100 DEG C, and the local duck meat is placed into the wok for blanching. According to the making method of the hand-torn bamboo fragrance duck, the structure design is reasonable, the duck meat can be enabled to be full of meat taste and crispy in skin and tender in meat, and the method further ensures that the duck meat has a fragrance to the marrow and a lasting aftertaste.

Owner:四川省唐鸭儿食品有限公司

Nutrition-rich meat and jujube string and preparation method thereof

The invention discloses a nutrition-rich meat and jujube string and a preparation method thereof. The nutrition-rich meat and jujube string comprises the following raw materials in parts by weight: 25-35 parts of chicken breast, 35-45 parts of water, 5-6 parts of soybean isolated protein, 5-15 parts of chicken skin, 5-15 parts of starch, 1.3-1.5 parts of salt, 2-3 parts of glucose, 0.5-0.7 part of monosodium glutamate, 0.05-0.15 part of a fumigant, 0.04-0.06 part of monascus red and 0.4-0.6 part of essence. The product is prepared from the raw materials through a beating process, a stuffing adding, filling and forming process, a drying and stewing process, and a stringing process. The meat and jujube string disclosed by the invention has the beneficial effects that the finished meat and jujube string is attractive in color, and rich in protein and amino acid essential to human body, as well as nutrient elements required by human bodies such as potassium, iron and magnesium; the meat and jujube string, as sausage food, is full in overall structure, sufficient in meat feeling and delicious in taste. The preparation method is high in working efficiency, and suitable for popularization and application in the field of food.

Owner:SHANDONG JIASHIBO FOOD

Beef balls for barbecue and manufacturing method of beef balls

InactiveCN106343388AOvercome obesityGreat tasteFood freezingFood ingredient as mouthfeel improving agentChemistryMonosodium glutamate

The invention relates to beef balls for barbecue. The beef balls are prepared from the following components in parts by weight: 40 to 70 parts of lean beef, 20 to 40 parts of fat beef, 3 to 6 parts of potato starch, 0.5 to 1.5 parts of table salt, 0.5 to 1.5 parts of white granulated sugar, 0.5 to 1.5 parts of monosodium glutamate, 10 to 20 parts of ice water, 0.1 to 0.5 part of compound phosphate and 0.1 to 0.5 part of a condiment. The beef balls for barbecue, provided by the invention, are processed through mainly taking the lean beef and the fat beef as main raw materials and adding other raw auxiliary materials, and are obtained through processing small lean beef pieces and small fat beef pieces (the fat beef pieces are slightly smaller than the lean beef pieces); the beef balls for barbecue, provided by the invention, have a meat feeling of traditional beef balls for barbecue, and the problems that fat and lean beef of beef skewers is not uniform and safety and sanitation are difficult to control and the like are solved; the beef balls have good quality and delicious taste, can be used for replacing traditional beef skewers for barbecue, are suitable for being roasted and have a good taste.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Chine kebab and making method thereof

The invention discloses a chine kebab and a making method thereof. The chine kebab is prepared from the following raw materials in parts by weight: 90-100 parts of pork #2, 50-57 parts of water, 1-1.2 parts of a water retaining agent and 8.5-9.5 parts of spicy marinade. The chine kebab has the beneficial effects that by the adoption of an oil frying technology, the appearance color of the chine kebab is bright; the chine kebab contains rich proteins and amino acids, vitamins and taurine which are necessary to a human body, and is rich in multiple nutritional elements, such as potassium, iron, magnesium and zinc, which are necessary to a human body; after being fried in oil, the chine kebab is baked outside and tender inside, has an enough meat flavor, tastes delicious, and is chewy and juicy.

Owner:SHANDONG JIASHIBO FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com