Environment-friendly breathable TPU (Thermoplastic polyurethanes) synthetic leather and preparation method thereof

A breathable, synthetic leather technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of hard hand feeling, strong plastic feeling, low market recognition, etc. Clear skin texture and full-feeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

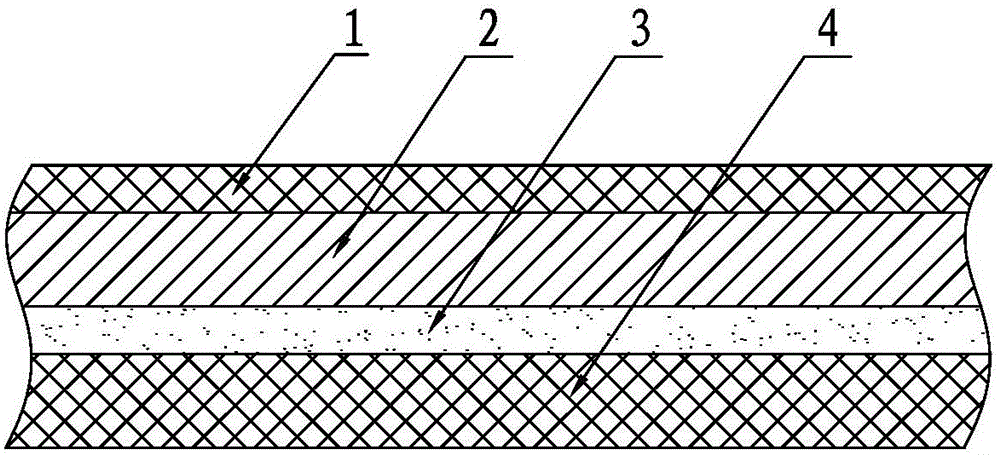

[0020] An environmentally friendly breathable TPU synthetic leather, such as figure 1 As shown, it includes a decorative surface layer 1, a TPU surface layer 2, an adhesive layer 3 and a base cloth layer 4. The decorative surface layer 1 is generated by a treatment agent coated on the upper surface of the TPU surface layer 2, and the TPU surface layer passes through the adhesive layer 3. Combined with the base cloth layer 4, the components and parts by weight of the TPU surface layer 2 are: 30-95 parts by weight of TPU particles; 3-25 parts by weight of flame retardant; 2-15 parts by weight of pigment; light stabilizer 0 to 5 parts by weight; 0 to 5 parts by weight of anti-scratch agent; 0 to 20 parts by weight of filler, wherein, TPU particles are polyester type, polyether type and aliphatic heat-shrinkable polyurethane elastomer particles; flame retardant is no Halogen nitrogen phosphorus flame retardants such as: polyphosphate amine, melamine phosphate; scratch resistance a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com