Flowering sausages and preparation method thereof

A technology of fish paste and miscellaneous fish, which is applied in the field of flowering sausage and its preparation, can solve the problems of poor taste and limited nutritional value, and achieve the effect of good taste, easy nutrition and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

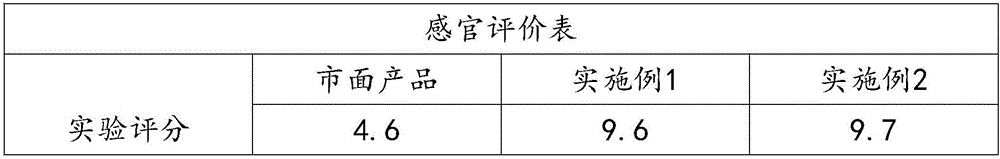

Embodiment 1

[0028] A blooming sausage made from the following components: 19.75kg of chicken, 7.5kg of AA grade fish paste, 5Kg of miscellaneous fish paste, 23kg of soybean protein emulsified paste, 19.8kg of ice water, 6.25kg of tapioca flour, and 7.5kg of tapioca modified starch kg, salt 1.5kg, compound phosphate 0.3kg, white sugar 2.5Kg, sodium nitrite 4g, monosodium glutamate 0.135kg, alanine 0.18kg, meat powder 0.09kg, white pepper 0.09Kg, carrageenan 0.35kg, ethyl Maltol 37.5g, TG enzyme 25g, sesame oil 225g, meat paste 200g, chicken essential oil 112.5g, shallot essence 75g, allura red 1.3g, bioactive peptide 8g, monascus red 5g, fried green bean powder 2.5kg;

[0029] The processing method of above-mentioned fried green bean flour is as follows:

[0030] (1) Select green beans with uniform size, no pests, and no mildew, soak them in drinking water, soak them for 10 hours in summer and autumn, and soak them for 18 hours in spring and winter, then put them in the marinade and mix th...

Embodiment 2

[0047] A blooming sausage made from the following components: 19.75kg of chicken, 7.5kg of AA grade fish paste, 5Kg of miscellaneous fish paste, 23kg of soybean protein emulsified paste, 19.8kg of ice water, 6.25kg of tapioca flour, and 7.5kg of tapioca modified starch kg, salt 1.5kg, compound phosphate 0.3kg, white sugar 2.5Kg, sodium nitrite 4g, monosodium glutamate 0.135kg, alanine 0.18kg, meat powder 0.09kg, white pepper 0.09Kg, carrageenan 0.35kg, ethyl Maltol 37.5g, TG enzyme 25g, sesame oil 225g, meat paste 200g, chicken essential oil 112.5g, shallot essence 75g, allura red 1.3g, bioactive peptide 8g, monascus red 5g, fried green bean powder 2.5kg;

[0048] The processing method of above-mentioned fried green bean flour is as follows:

[0049] (1) Select green beans with uniform size, no pests, and no mildew, soak them in drinking water, soak them for 10 hours in summer and autumn, and soak them for 18 hours in spring and winter, then put them in the marinade and mix th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com