Patents

Literature

70results about How to "Change the processing technology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for nanocrystals cellulose/white carbon black/rubber composite material

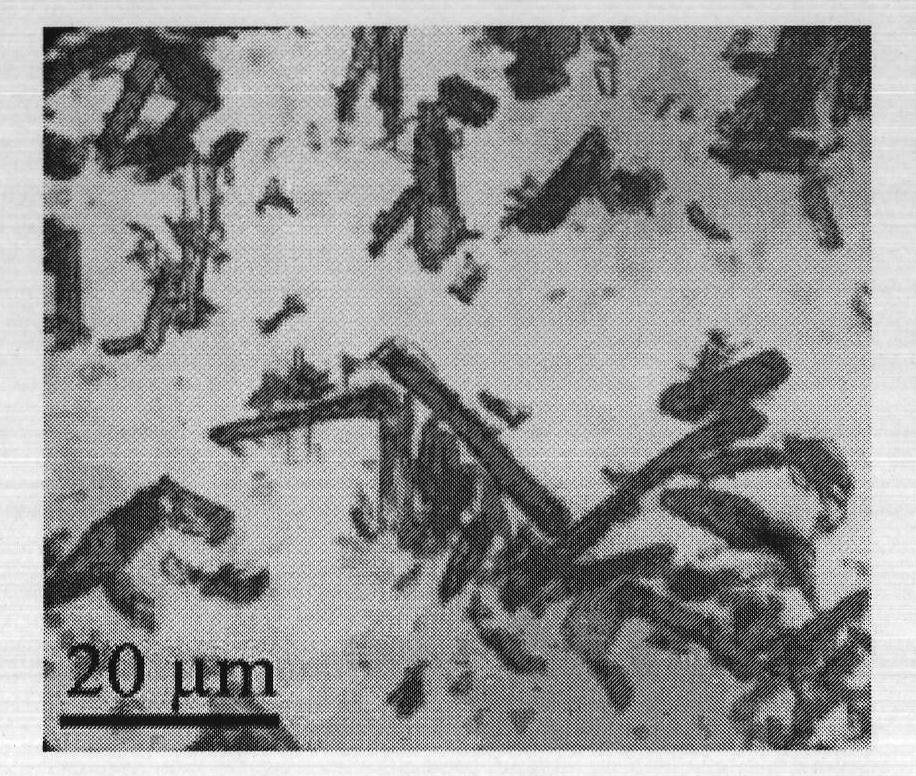

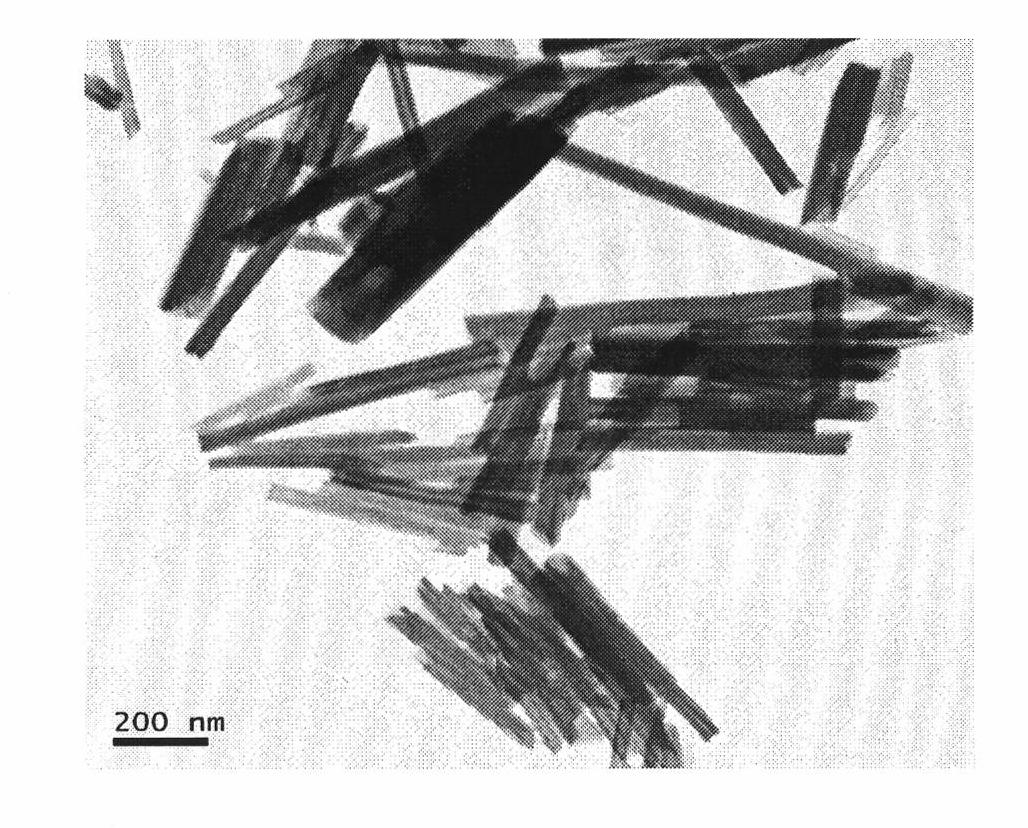

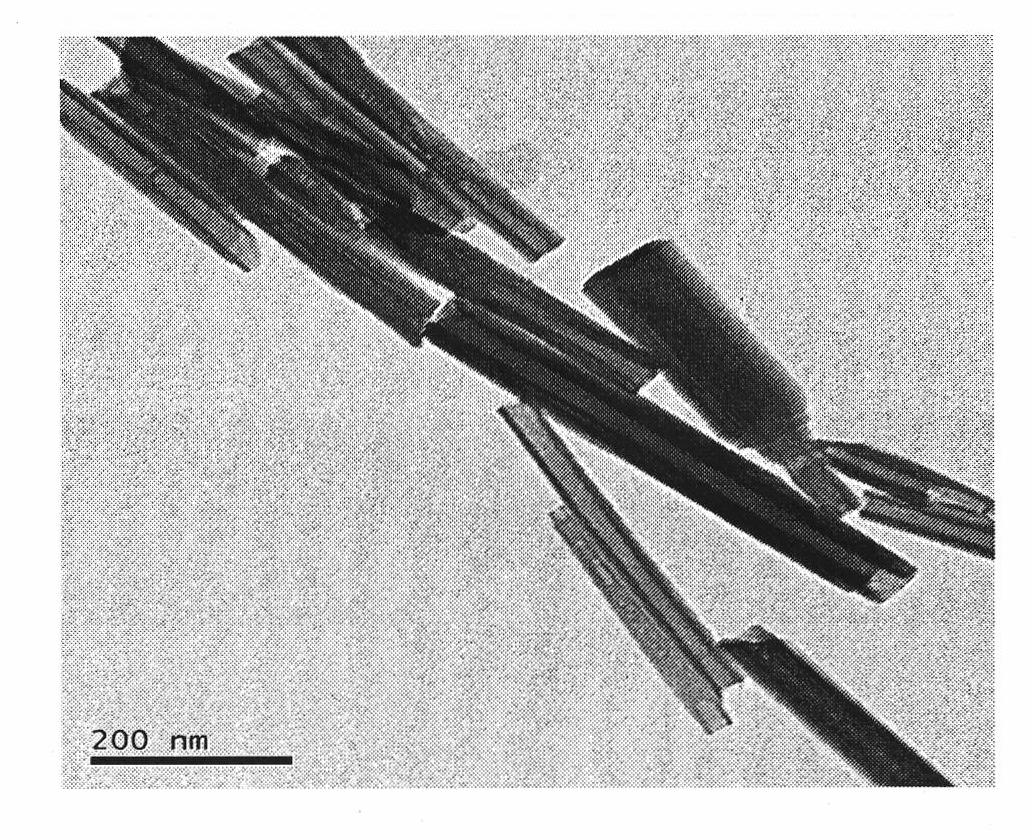

The invention discloses a preparation method for a nanocrystals cellulose / white carbon black / rubber composite material. The nanocrystals cellulose (Nanocrystals Cellulose, called NCC for short) is a rod-shaped crystallized product which is obtained by performing acidolysis on microcrystalline cellulose, has the diameter of between 20 and 60 nm and the average length of 300 nm, can serve as a novel reinforcing material for rubber, and has the characteristics of reproducibility, low density, orientation, high strength and the like; moreover, the preparation method is simple and convenient; the cost is low; and the NCC is easy to obtain. Researches discover that a reinforcing effect of the NCC to natural rubber is superior to that of white carbon black; the thermal-oxidative ageing property of the natural rubber is improved very well; simultaneously the heat generation of the composite material is reduced; and the nanocrystals cellulose / white carbon black / a rubber composite material can be prepared by adopting a conventional rubber processing process. The nanocrystals cellulose / white carbon black / a rubber composite material prepared by the invention can be used for manufacturing various vulcanized rubber products.

Owner:SOUTH CHINA UNIV OF TECH

Preparation of microcapsule humectant and application thereof to cigarette

ActiveCN102217795AImprove sensory qualityReduce drynessTobacco treatmentBiotechnologyEnzymatic hydrolysis

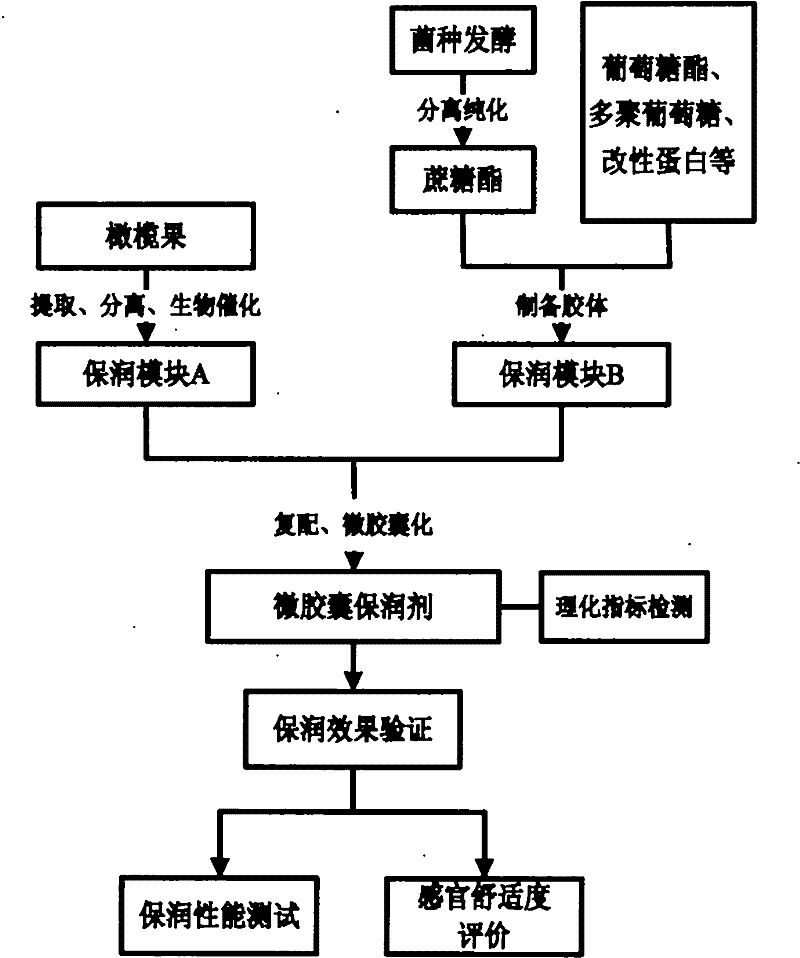

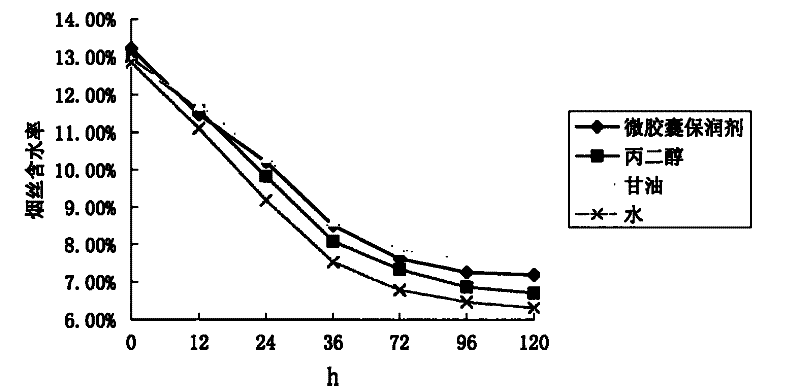

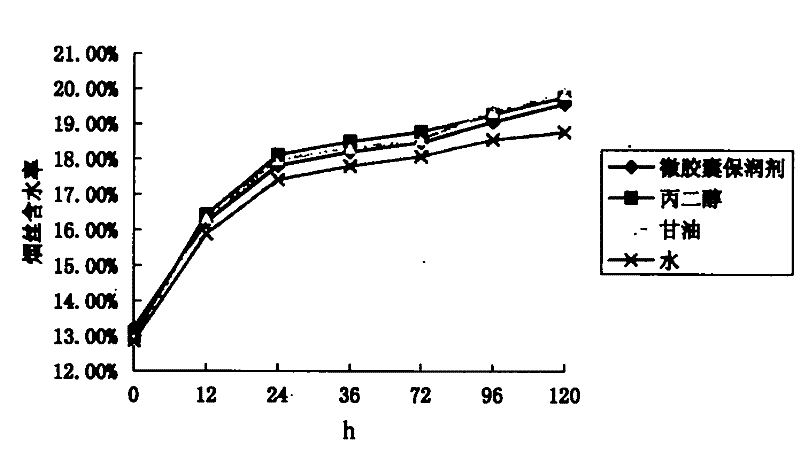

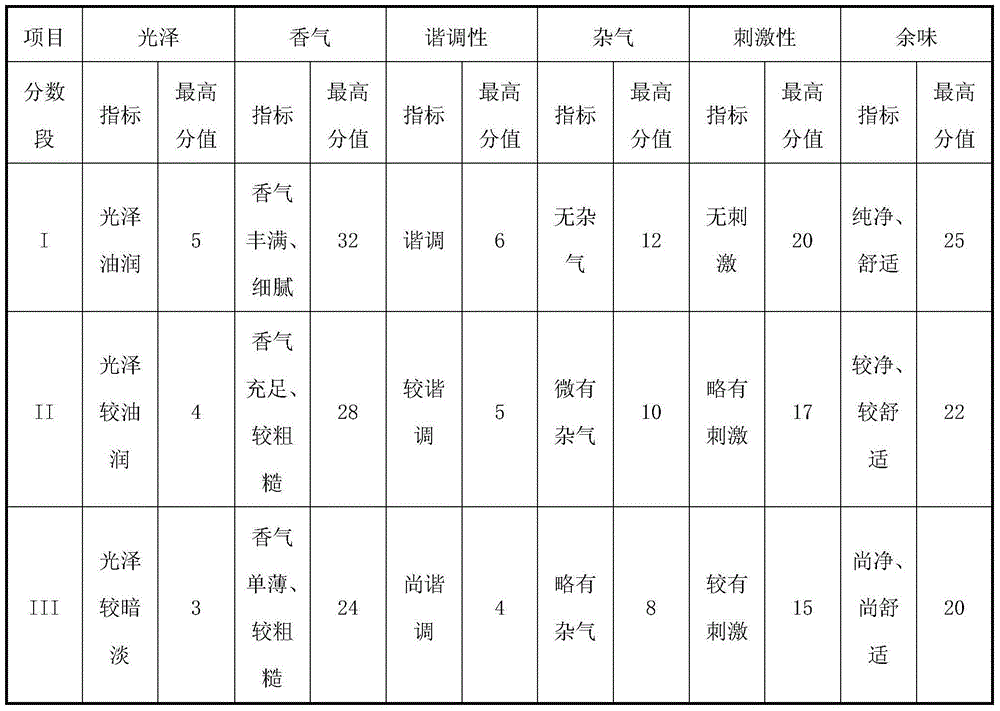

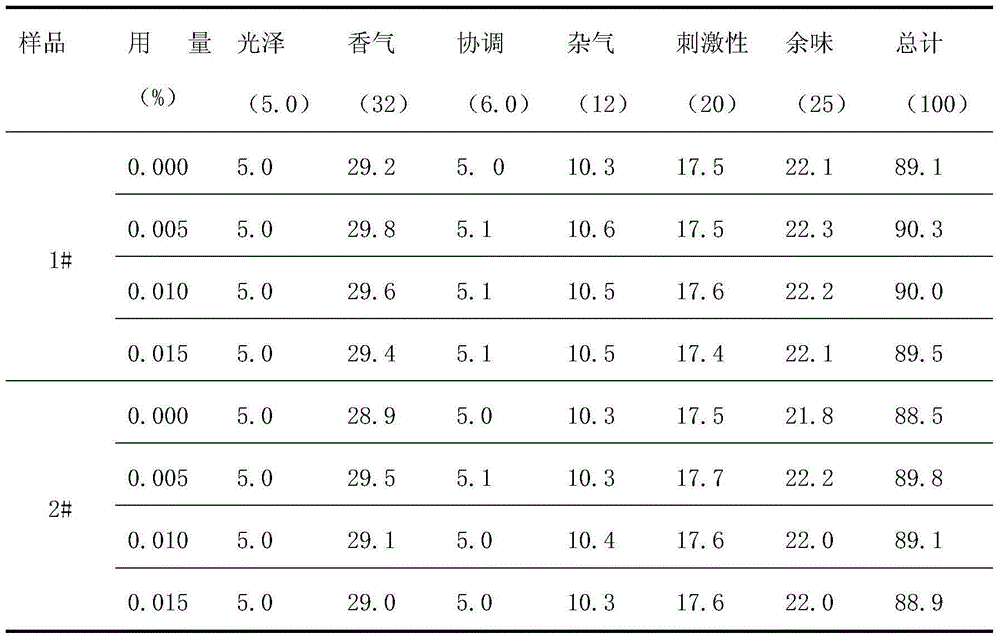

The invention discloses preparation of a microcapsule humectant and application thereof to a cigarette. A preparation method comprises the following steps of: (1) treating oil and fat extracted from an olive fruit by biological enzymatic hydrolysis to obtain a humectation module A; (2) autonomously making sucrose ester by using a fermentation technology, preparing the autonomous made sucrose ester and other raw materials into colloids to obtain a humectation module B; (3) matching the humectation module A and the humectation module B with tobacco molecule distillation, and micro-encapsulating by spray drying ; and (4) dissolving the micro-encapsulated humectant in water and then adding the dissolved humectant to cut tobaccos. By using the microcapsule humectant, a humectation effect of the cigarette is improved obviously; and when the cigarette is smoked, a dry sense of the cigarette is reduced, and sweetness and humectation degree of the cigarette are reinforced. The microcapsule humectant disclosed by the invention has the outstanding advantages that: a sensuous quality of the cigarette can be increased, the dry sense of the cigarette is decreased, the sweetness and humectation degree, and comfort level of the cigarette are improved, and the cigarette has an obvious saliva secretion promotion effect and an obvious humectation effect; besides, application of the microcapsule humectant does not change the traditional processing technology of the cigarette and the microcapsule humectant is valuable in actual production and application.

Owner:HONGTA TOBACCO GRP +1

Method for extracting bolete polysaccharide and application of bolete polysaccharide in tobacco products

ActiveCN104126867AIncrease smoke aromaIncrease sweetnessTobacco preparationTobacco treatmentNicotiana tabacumIrritation

The invention discloses a method for extracting bolete polysaccharide. The method includes the following steps that with the help of microwaves, an extracting solution is extracted from bolete sporocarps through water, the extracting solution is concentrated, alcohol substances are added to the concentrated extracting solution, and crude bolete polysaccharide is obtained through settlement, wherein the bolete polysaccharide is a mixture composed of glucose, galactose, mannose, xylose and fucose and the average molecular weight of the bolete polysaccharide is 1.3*10<4> dalton to 5.2*10<4> dalton. Protein in the crude bolete polysaccharide can further be removed according to a polyamide column adsorption-desorption method. The bolete polysaccharide is dissolved in liquid and added to tobacco products, special fragrance can be given to the tobacco products, tobacco fragrance is obviously improved, irritation of smoke is obviously reduced, and the sensory quality of the tobacco products is obviously improved.

Owner:CHINA TOBACCO YUNNAN IND

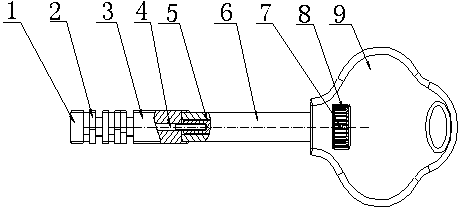

Changeable combined mechanical key

Owner:YANTAI TRI CIRCLE SCI & TECH

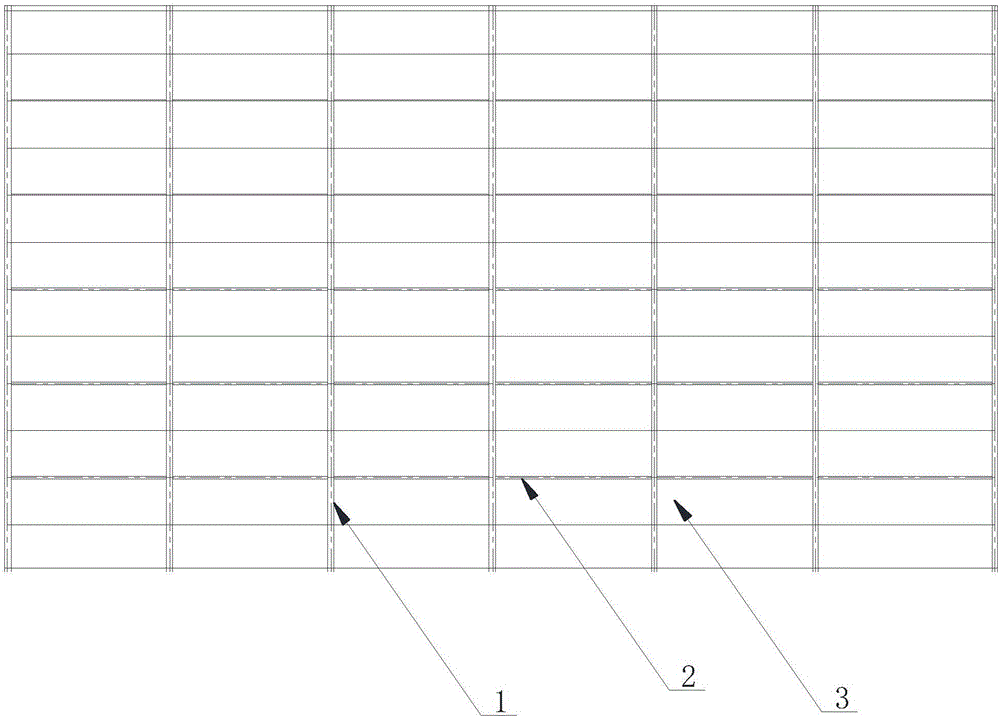

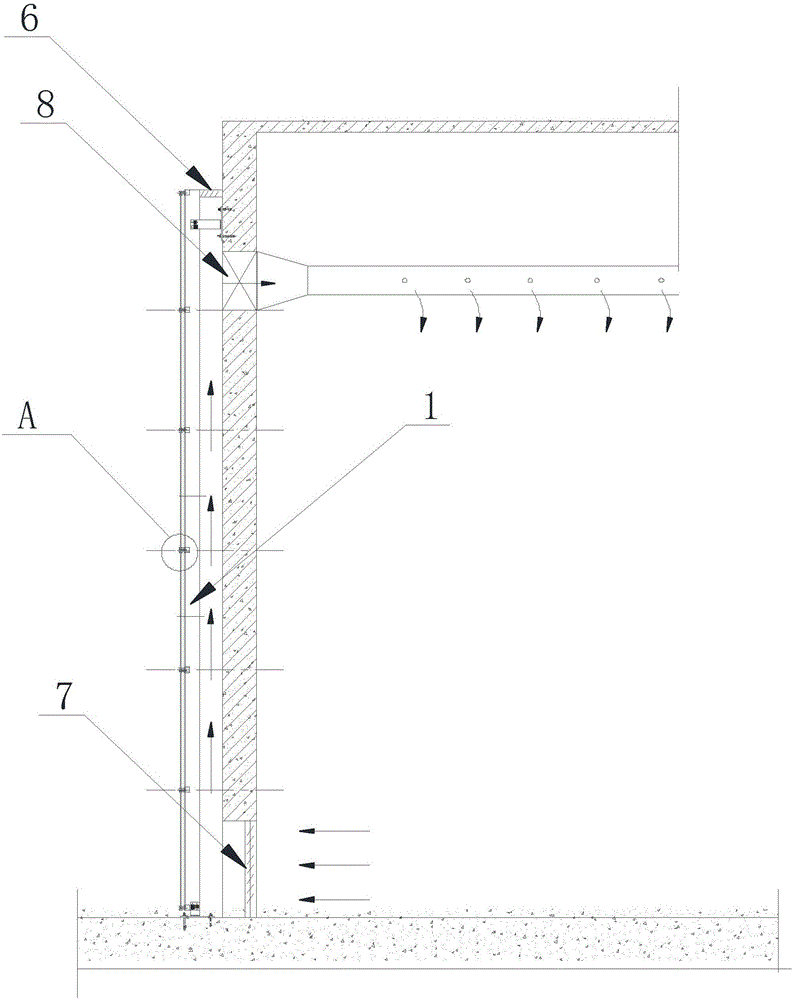

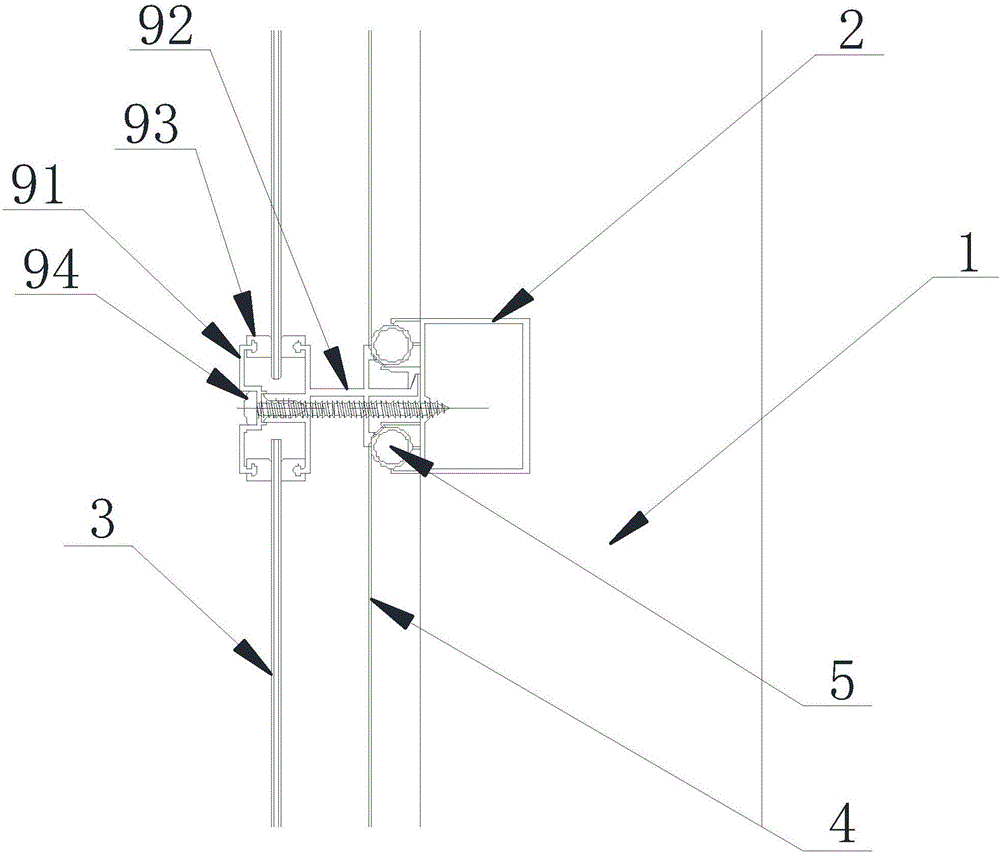

Curtain wall with solar air and hot water heat collector

ActiveCN104975668ASolve the problem of having to process in the factoryAchieve airRoof covering using slabs/sheetsRoof covering using tiles/slatesAir cycleFresh air

The invention discloses a curtain wall with a solar air and hot water heat collector. The curtain wall comprises a solar heat collector and a curtain wall plate which are in sequential arrangement in a direction leaving far away from the outer surface of a wall body of a building, wherein the curtain wall plate is made of light transmission materials; the solar heat collector comprises a heat absorption film and a heat absorption structure; the heat absorption film and the outer surface of the wall body of the building are defined into a sealed air circulation passage; the top of the heat absorption film is provided with a first ventilation device; a ventilation opening is formed in the upper part of the wall body of the building; an air circulation device is arranged at the ventilation opening formed in the upper part of the wall body of the building; the bottom of the wall body of the building is provided with a ventilation opening; and a second ventilation device is arranged at the ventilation opening formed in the bottom of the wall body of the building. The curtain wall has the beneficial effects that the solar air and hot water collector function is integrated in the curtain wall; the problem that the solar heat collector needs to be processed in a factory is solved; the effect of beatifying the building is achieved; the air and hot water function of a conventional solar heat collector is achieved; and the curtain wall can achieve a temperature reduction effect on the building in summer and can provide heating and fresh air preheating for the building in winter.

Owner:李俊

Method for processing hot-stewed airing rabbit

InactiveCN102429250AChange the processing technologySuitable for mass productionFood preparationFermentationChemistry

The invention relates to a method for processing a hot-stewed airing rabbit. The method comprises the following steps of: inoculating auxiliary materials to an integral rabbit which is cooled and subjected to acid discharge, rolling and kneading under vacuum, salting and fermenting at low temperature, hanging, airing and fermenting in the shade, performing halogen cooking, drying, finishing, packaging, sterilizing, keeping temperature and inspecting, wherein the auxiliary materials consist of the following components in part by weight: 3 to 5 parts of fermentation agents, 3 to 4 parts of halogen materials and 4 to 5 parts of flavorings. In the method, the convention salting process is changed by utilizing a vacuum rolling and kneading technology, and the fermentation agents such as a probiotics growth promoter, a proenzyme activator and the like are added by utilizing a microbial fermentation technology; the integral rabbit is fermented twice and is flavored and subjected to the halogen cooking, a modernization processing process and the conventional sauce halogen process are combined, the conventional process for processing airing products is changed, the production period of the products is shortened, the integral production process is finished only for 22 to 26 hours, and the integral processing process can be programmed and standardized; and thus, method is suitable for large-scale batch production of factories.

Owner:青岛康大食品有限公司

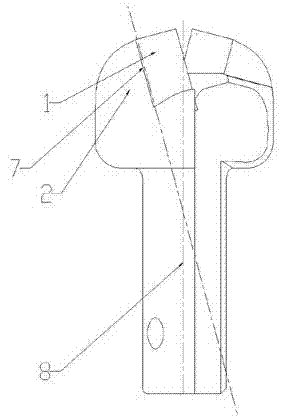

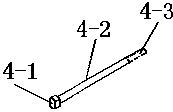

Casting spliced diamond composite sheet anchor rod drill bit and connecting sleeve thereof

InactiveCN102345447ASimplify the production processIncrease productivityDrill bitsDrilling rodsAcute angleEngineering

The invention relates to a casting spliced diamond composite sheet anchor rod drill bit and a connecting sleeve thereof. Although certain effects on improving and perfecting the conventional drill bit are achieved, the problems of difficulty in assembling and disassembling a drill bit and complex processing technic are not solved. In the invention, the lower end of a drill bit body is connected with a connecting rod; the lower end of the outer wall of the connecting rod is provided with a connecting pin hole; two wing end faces of cutting wings are formed oppositely and symmetrically at 180 degrees; the tops of the cutting ends of the cutting wings are circular-arc-shaped, and smoothly extend to the gauge protection ends of wing parts; two circular medium channels are formed between the two cutting wings, are formed outside the drill bit body, and extend to the bottom of the outer wall of the connecting rod; and an acute angle is formed between a welding surface and a drill bit body vertical surface. According to the invention, the early-stage manufacturing flow of the drill bit is simplified, the production efficiency is increased, the drill bit is more convenient to assemble and disassemble, and damage to drill bit cutting teeth in the assembling and disassembling processes is avoided.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

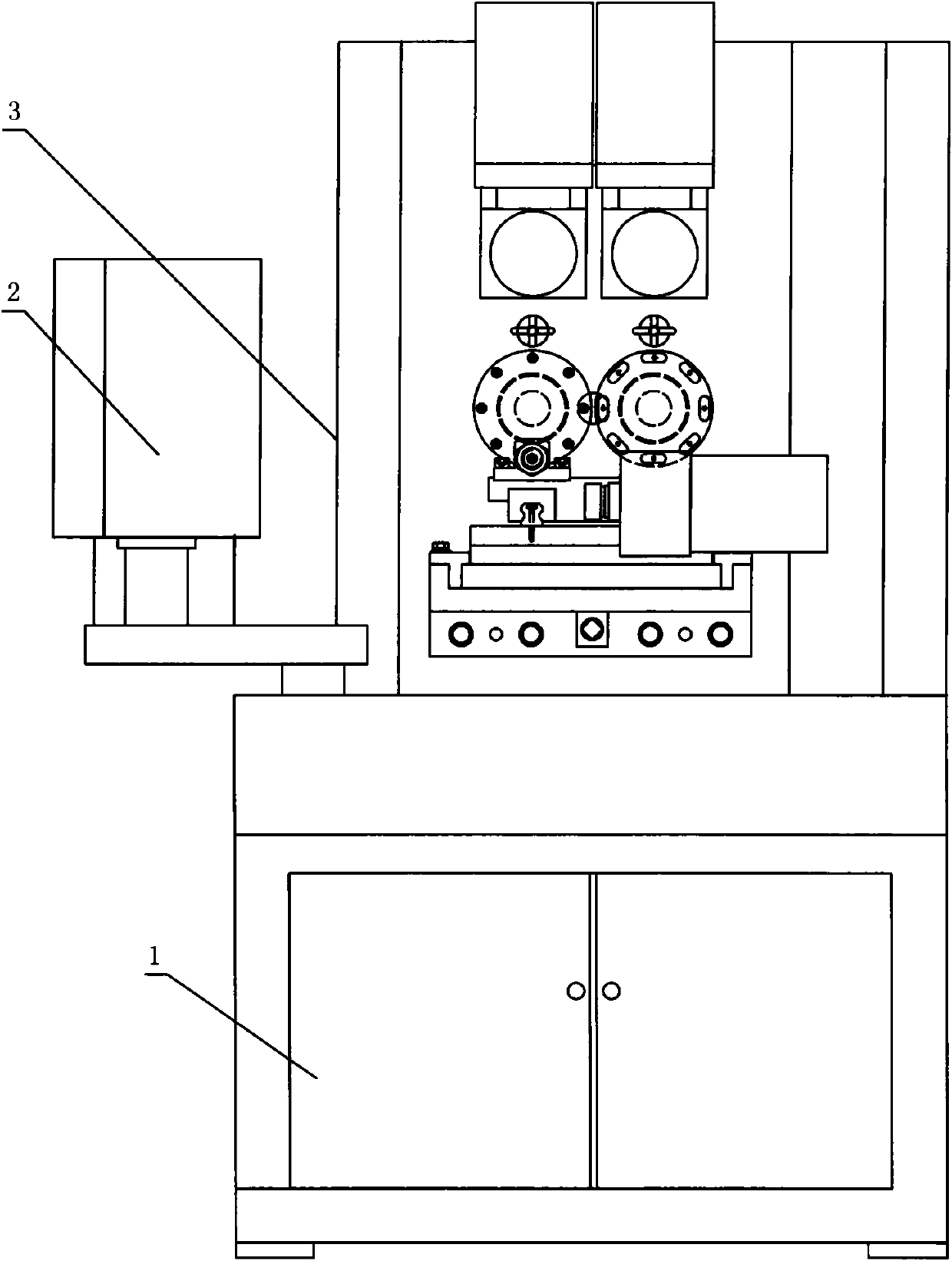

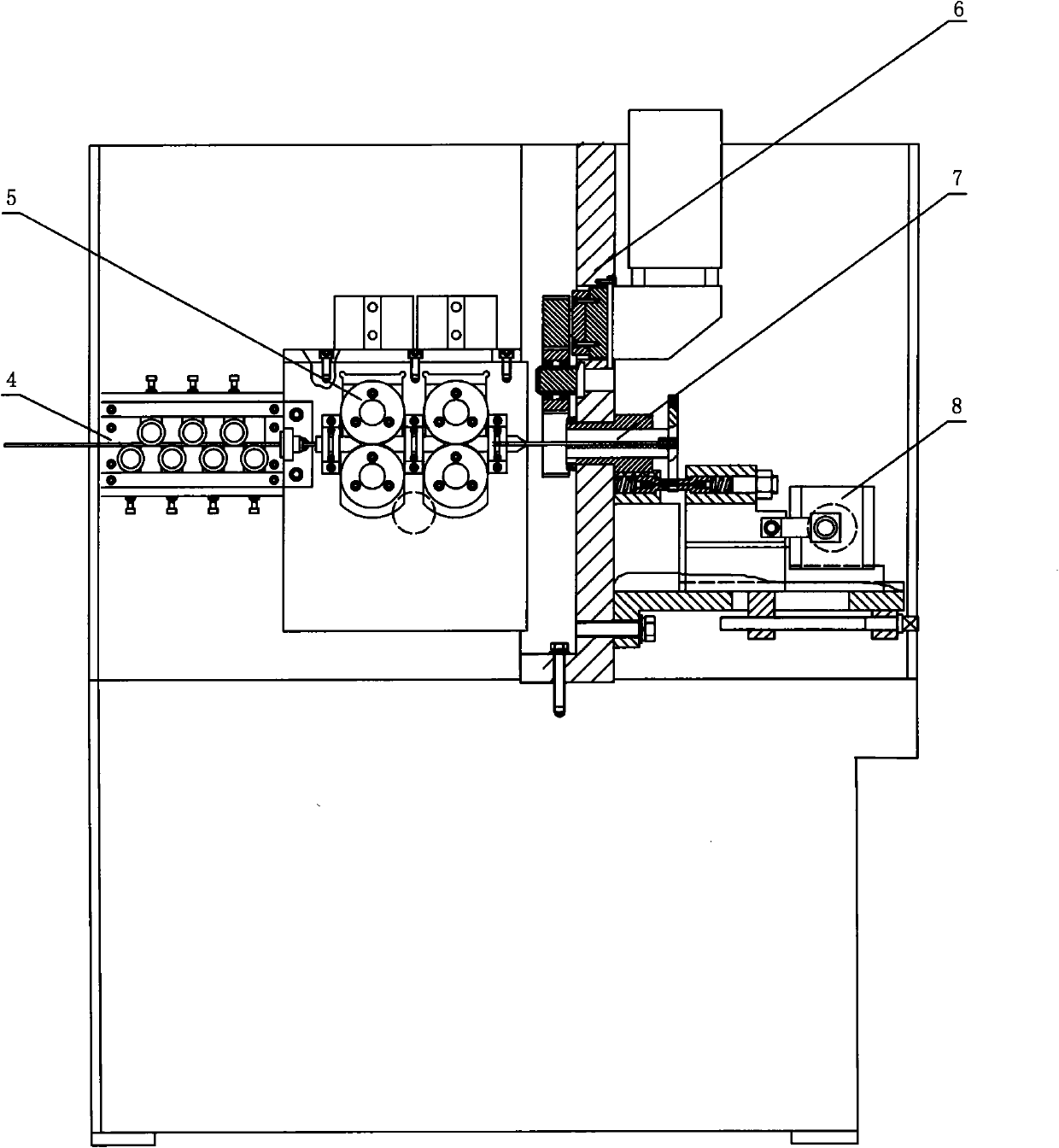

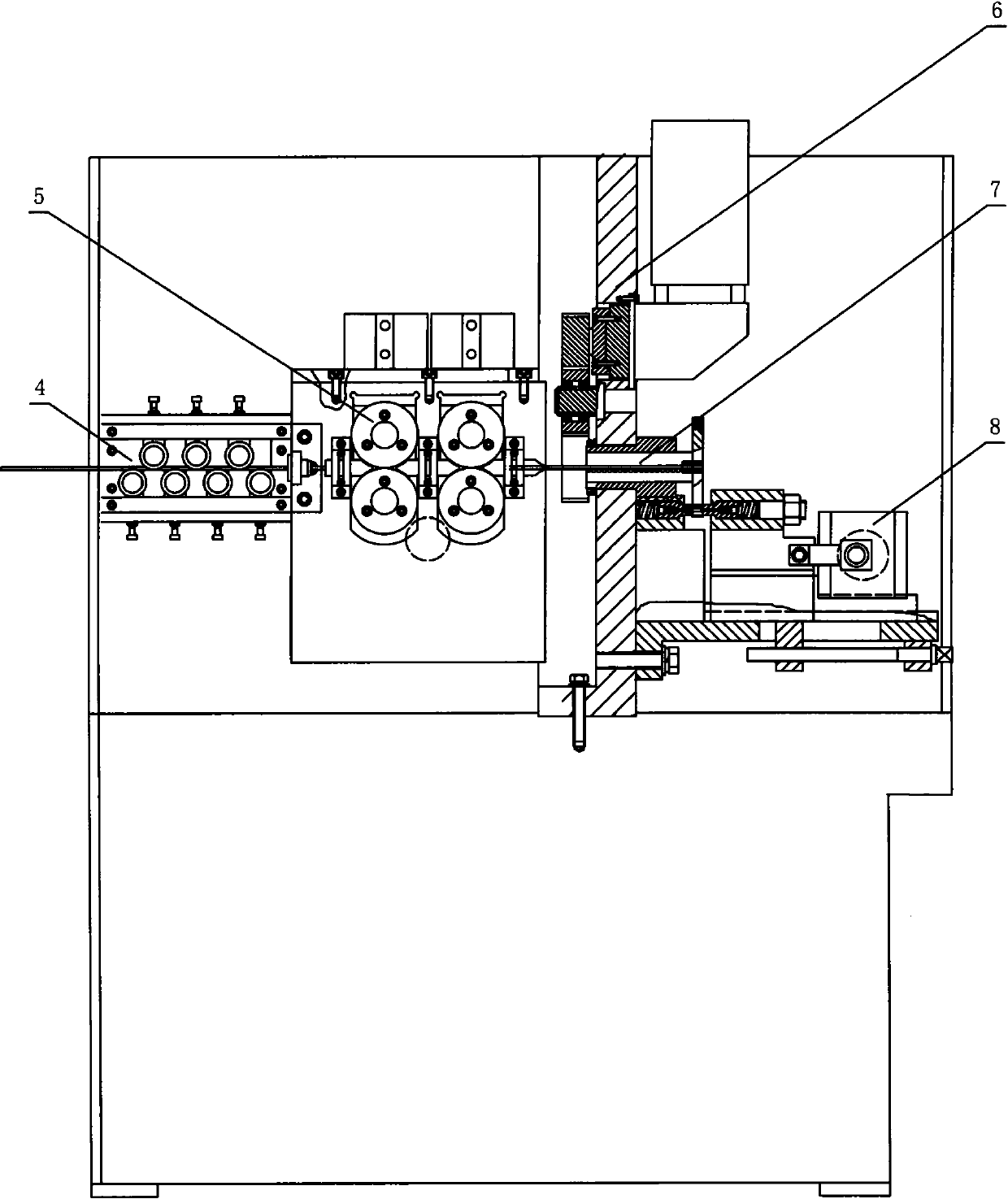

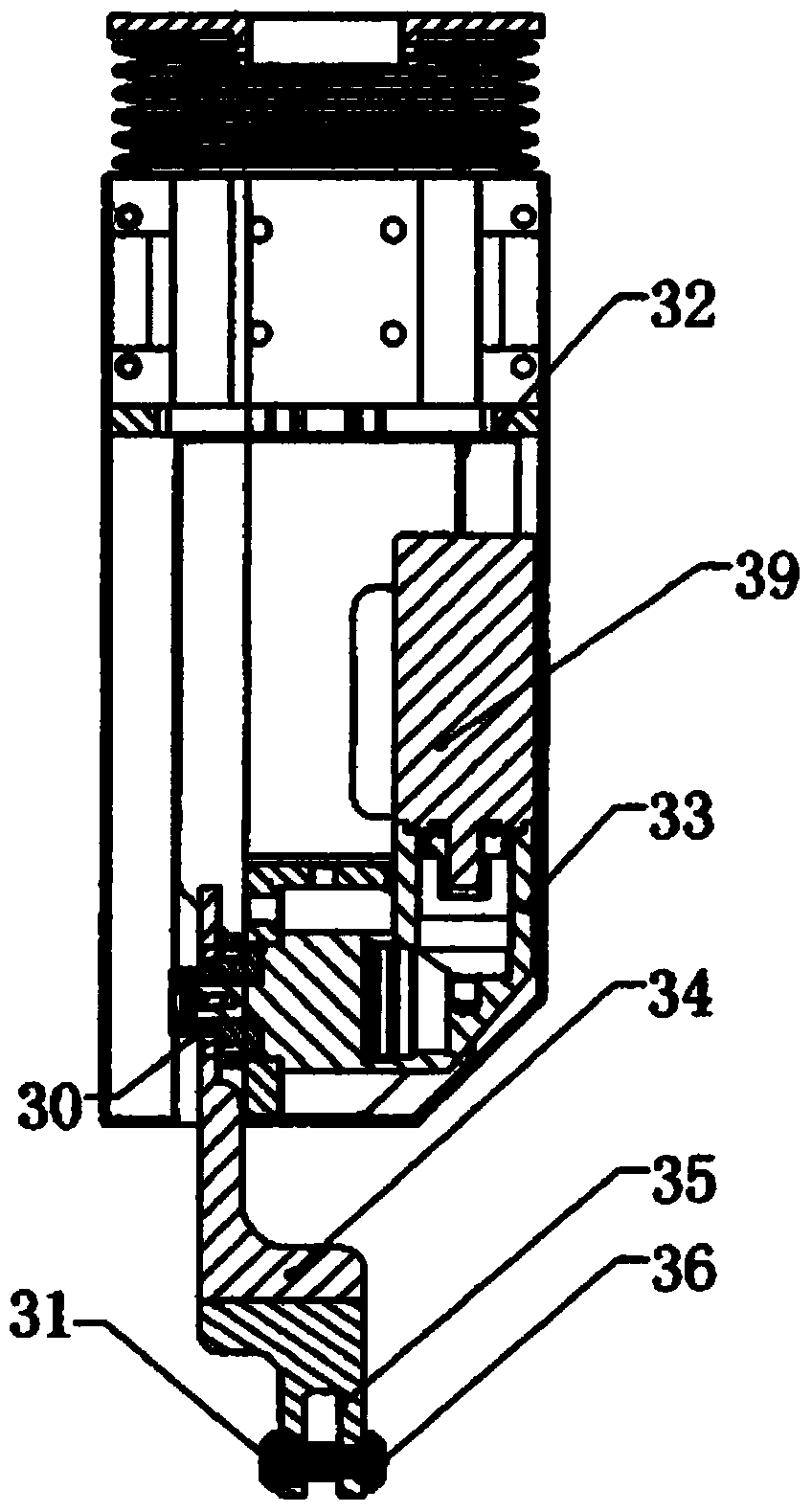

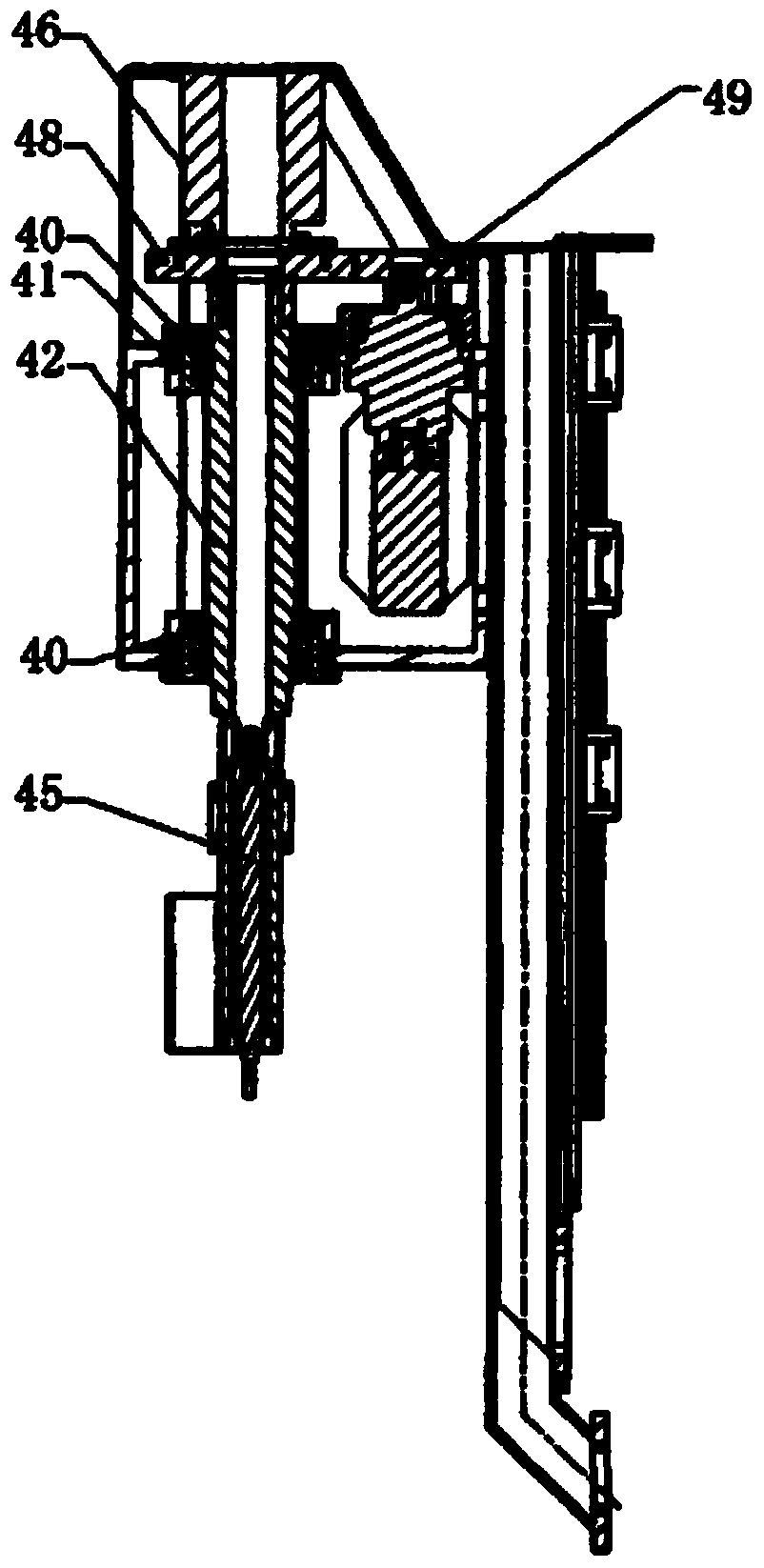

High-precision numerical control pin machine

InactiveCN102554625AAvoid pollutionOperational intelligenceOther manufacturing equipments/toolsNumerical controlControl system

A high-precision numerical control pin machine belongs to pin machining mechanical equipment and comprises a base, a computer control box, a machine tool body, a straightening mechanism, a wire feeding mechanism, a main wallboard, a cutting-off mechanism and an extrusion mechanism. The pin machine is designed by combining advanced driving technology, four-axis linkage numerical control technology and pneumatic technology, and is formed once by means of 'cutting off and chamfering'. Under the instruction of a control system, a steel wire on a rack enters a feeding wheel groove after passing through the straightening mechanism, the wire feeding mechanism drags the steel wire to the cutting-off mechanism and is cut off by a cutting-off die, the steel wire cut off according to a specified length enters the extrusion mechanism by means of moving along with the cutting-off die and is extruded by the extrusion mechanism, and a formed pin returns an original cutting-off position along with the cutting-off die and is pushed out by the steel wire entering the cutting-off die again. The procedures and actions are repeated, so that pins can be continuously machined. The pin machine is high in automation degree, low in production noise and safe and convenient in operation, production cost is reduced, energy conservation and emission reduction are realized, and product quality and production efficiency are improved.

Owner:盐城海旭数控装备有限公司 +1

Preparation method of enteromorpha ethanol extract and application thereof in cigarette

ActiveCN102100398AChange performanceChange the processing technologyTobacco treatmentBiotechnologyBurn cigarette

The invention provides a preparation method of an enteromorpha ethanol extract and an application thereof in a cigarette. The invention is characterized in that the preparation method comprises the following steps: carrying out high-temperature enzyme destroying on enteromorpha, cleaning and removing impurities, drying and smashing, carrying out ethanol extracting, solid-liquid separating, concentrating to obtain enteromorpha ethanol extract. The enteromorpha ethanol extract is prepared into liquid with different concentrations, and is uniformly sprayed on tobacco shreds, wherein the enteromorpha ethanol extract accounts for 0.05-1% of the tobacco shred in mass. The smoke panel test result shows that the smoke of the burnt cigarette is free from peculiar smell and has fine aroma after the enteromorpha ethanol extract is added, the irritancy and miscellaneous gases are obviously reduced, the return sweet feeling is increased, and the aftertaste is improved. In the invention, the smoking quality of the cigarette is improved without changing the original property of the cigarette, thereby having practical significance and value.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

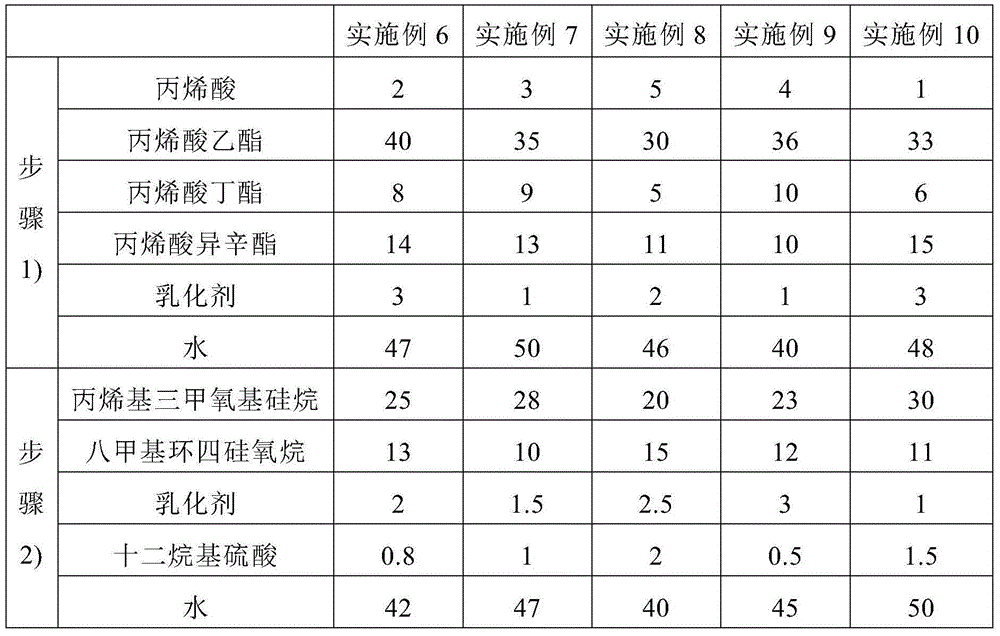

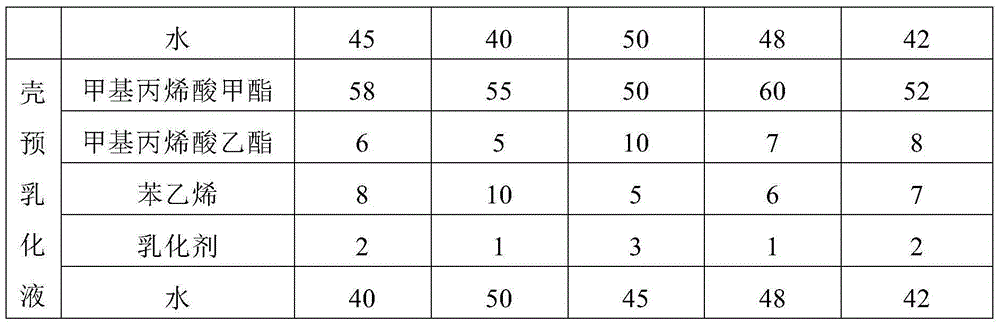

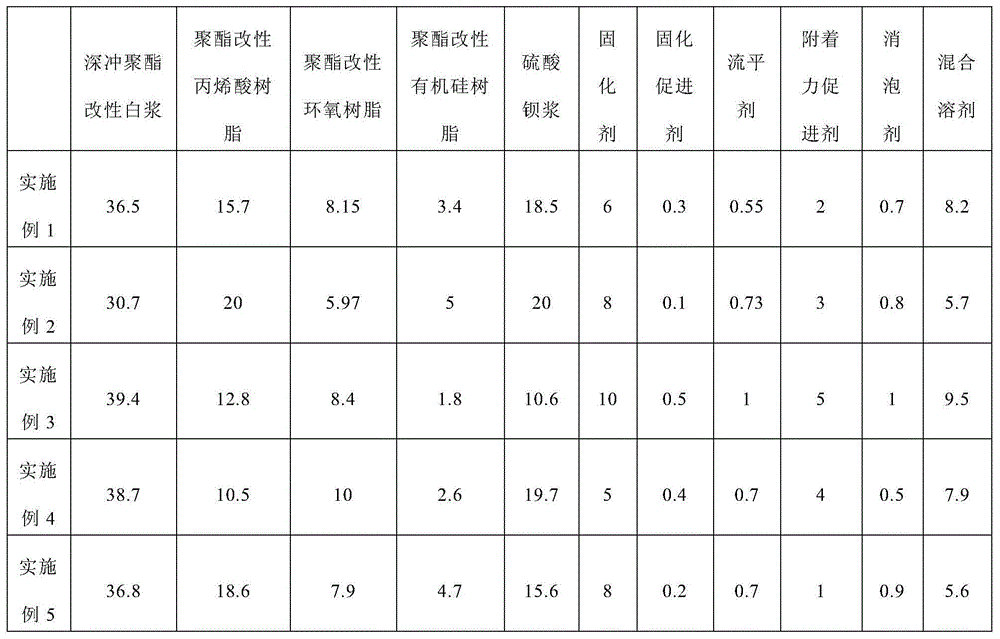

Modified acrylic resin energy conservation and environment protection coating for suspended ceiling print-coating plate

InactiveCN105038474AQuality assuranceImprove environmental performanceFireproof paintsAnti-corrosive paintsAcrylic resinAging resistance

The invention provides a modified acrylic resin energy conservation and environment protection coating for a suspended ceiling print-coating plate. The coating adopts organic fluorine-silicon modified acrylic resin, and therefore the coating has the advantages that the excellent flame retardance and wear resistance property are achieved, the curing speed is high, the better mechanical property, aging resistance property and chemical corrosion resistance property are achieved, the adhesive force is high, the ductility is good, the high temperature resistance property is achieved, the service life is long, the processing technology is changed, roller coating processing is concentratedly completed on a plate blank of the suspended ceiling print-coating plate, the processing procedure is simplified, and a painting workshop does not need to be separately arranged.

Owner:TAICANG JINXIN PAINT

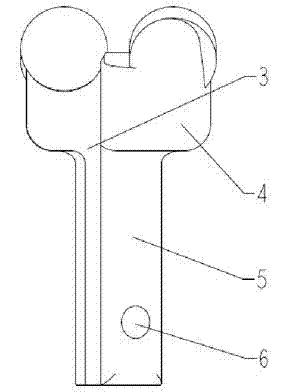

Key shape structure

The invention relates to a key shape structure, in particular to the key shape structure applied to mechanical keys, and belongs to the technical field of key shape structures. The key shape structure is characterized in that the a plurality of independent key shape parts where a screw penetrates through are detachably combined to form the key shape structure, and a key thread form which can be inserted into a lock cylinder and matched with the lock cylinder to conduct unlocking is formed after the key shape parts are arrayed and combined. According to the key shape structure, thievery prevention and duplication prevention of a key are achieved, and the unique advantages are achieved in the various important fields such as the safe case field, the military area field, the bank field, the domestic intelligent anti-theft lock field and other fields where security protection is needed. The problems which are caused by electronic circuit device software to electronic keys can not occur, the key shape structure has the advantage of being unique, a traditional mechanical key machining process is changed, energy is saved, consumption is lowered, and the application prospects are wide.

Owner:YANTAI TRI CIRCLE SCI & TECH

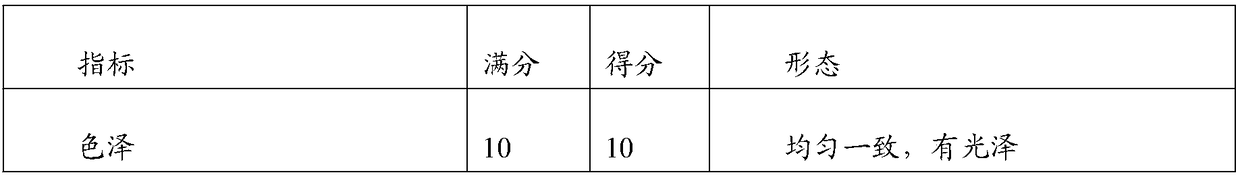

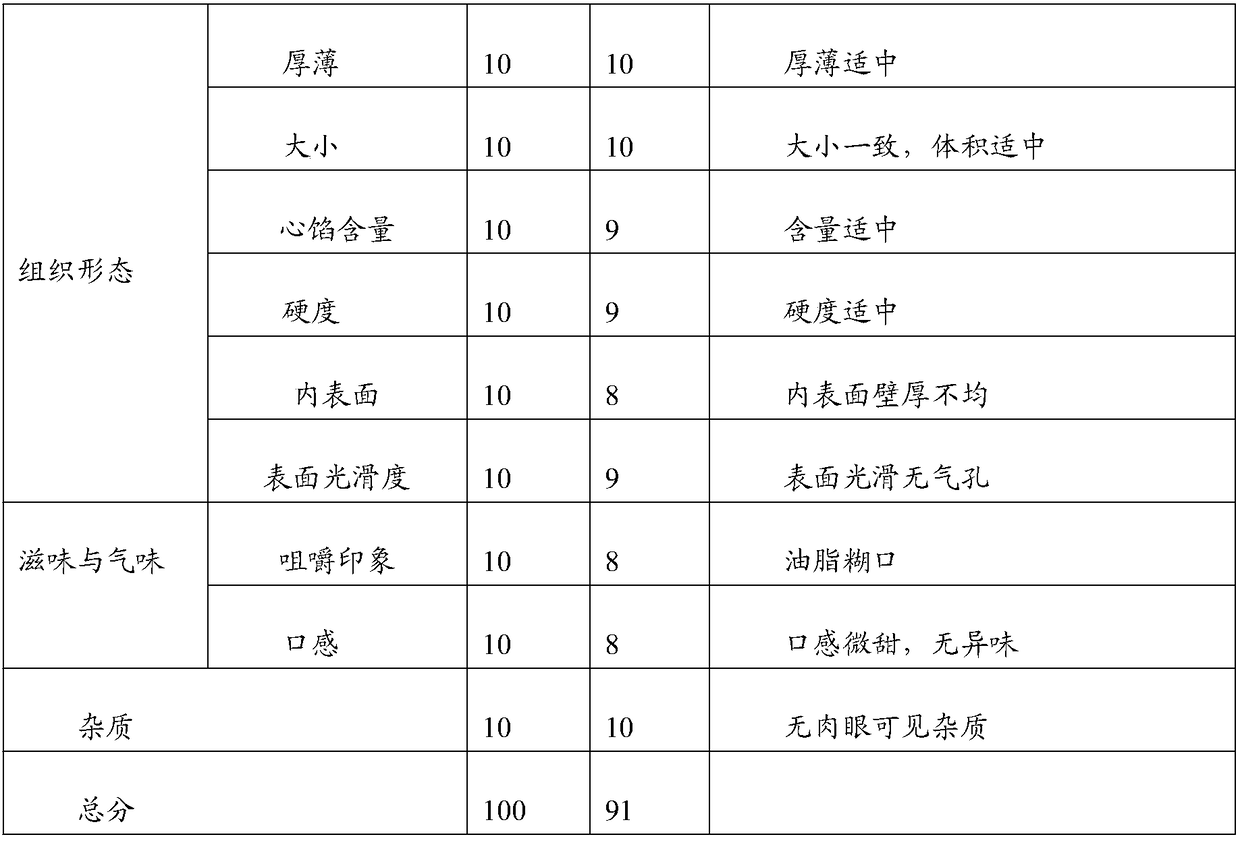

Stuffed potato meat ball and processing technology thereof

The present invention relates to a stuffed potato meat ball and a processing technology thereof. The stuffed potato meat ball includes outer layer skin material and filling material wrapped by the outer layer skin material. The stuffed potato meat ball is characterized in that the outer layer skin material and the filling material are chosen from the following two ingredients: the raw materials of ingredient A include lean meat, tilapia skin, water, phosphate, edible salt, tapioca starch and seasonings and the mass ratio of the lean meat and tilapia skin is 60-75 : 25-40; the raw materials of ingredient B include potatoes, potato starch and edible salt, and the mass ratio of the potato starch and potatoes are 0-15%; when one of the ingredients is selected to be used as the outer layer skin material, the other ingredient is thus used as the filling material. Compared with the traditional meat balls, the provided stuffed potato meat balls have a traditional meat ball flavor and a fresh potato flavor, and are reasonable in nutrition ratio, better in mouthfeel, moderate in hardness, relative good in chewiness, and richer in flavor.

Owner:FARM PROD PROCESSING & NUCLEAR AGRI TECH INST HUBEI ACAD OF AGRI SCI

Application of ulva polysaccharide in cigar

ActiveCN103070476AChange the processing technologyImprove aroma qualityTobacco treatmentBiotechnologyFreeze-drying

An application of ulva polysaccharide in a cigar is characterized in that ulva polysaccharide is added into tobacco shreds, cigar smoke does not have foreign taste, the aroma is coordinated, offensive odor and stimulus are reduced, no residual taste is left, a feeling of saliva or body fluid secretion promotion due to soft taste is increased, and the whole smoking quality is improved. The ulva polysaccharide is prepared through the following methods of ulva cleaning and impurity removing-drying and grinding-soaking with water-enzyme treatment-heating and extracting-solid-liquid separating-vacuum concentrating-ethanol precipitating-freeze drying-ulva polysaccharide. The application has the beneficial effects that an ulva polysaccharide cigar additive which is extracted from an ulva raw material is provided, the application of the ulva polysaccharide cigar additive does not change the original performance of cigars, an original cigar processing technology is not changed, the cigar aroma quality is improved, the cigar sensitive comfortability is improved, so that practical production meaning and value are obtained.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Combined machining tool for molded surfaces of deep cavities among drum webs and machining method of combined machining tool

InactiveCN103586494AImprove reliabilityMeet the design size requirementsTurning toolsMachine toolMachining

The invention belongs to the technical field of machining, particularly relates to a combined machining tool for molded surfaces of deep cavities among drum webs and a machining method of the combined machining tool. By the combined machining tool, the technical problems of vibration, tool collision and poor surface quality during machining of the molded surfaces of the deep cavities among the drum webs of aero-engines are solved. The combined machining tool comprises a middle plate-shaped tool, an upper plate-shaped tool and a lower plate-shaped tool. The machining method includes the following steps: step 1, fixedly connecting a transfer tool with a numerically-controlled vertical turning tool clamp; step 2, machining middle molded surfaces of the deep cavities among the drum webs; step 3, machining upper molded surfaces and upper arc-shaped molded surfaces of the deep cavities among the drum webs; step 4, machining lower molded surfaces and lower arc-shaped molded surfaces of the deep cavities among the drum webs to complete machining of primary inner cavities; step 5, circularly performing the step 2 to the step 4 to sequentially complete machining of each-level inner cavities.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

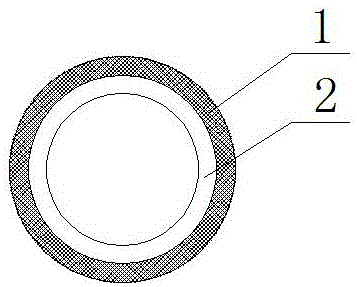

Nano-antibacterial composite plastic masterbatch

The invention discloses nano-antibacterial composite plastic masterbatch which is prepared from the following ingredients in parts by weight: 50 to 65 parts of nano-silver, 8 to 15 parts of polyethylene, 1 to 5 parts of polymethyl phenolic aldehyde, 0.1 to 5 parts of coupling agent, 0.1 to 5 parts of dispersing agent, 2 to 8 parts of polyethylene wax, 50 to 65 parts of nanometer titania antibacterial agent, 20 to 40 parts of plastic resin, 20 to 70 parts of carrier resin, 15 to 40 parts of pigment, 15 to 40 parts of filler, 0.5 to 2 parts of antioxidant and 0.5 to 5 parts of dispersing agent. The plastic masterbatch is wide in antibacterial bacterial spectrum, lasting in antibacterial action, good in antibacterial performance, good in thermal stability, good in high temperature resistance, not prone to color change, good in compatibility and dispersibility and free of changing an original plastic processing technology.

Owner:WUHU TIANXIONG NEW MATERIAL TECH

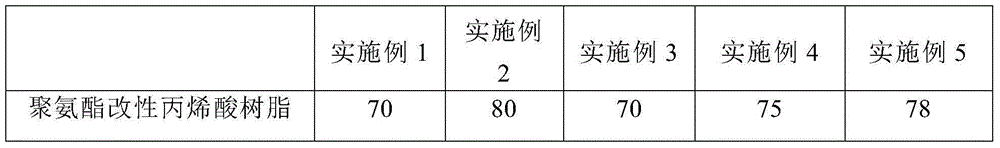

Modified acrylic resin energy-conservation and environmental-friendly coating for product packing metal box

ActiveCN105038489AQuality assuranceImprove environmental performanceFireproof paintsAnti-corrosive paintsAcrylic resinEnergy conservation

The invention provides a modified acrylic resin energy-conservation and environmental-friendly coating for a product packing metal box. Polyurethane modified acrylic resin is adopted in the coating, so that the obtained coating has good inflaming retarding performance and wear resisting performance, the curing speed is high, good mechanical performance, aging-resisting performance and chemical erosion resisting performance are achieved, adhesive force is high, ductility is good, high temperature resistance is achieved, the service life is long, the processing technology is changed, roller painting processing is completed on a product packing metal box slab in a concentrated mode, the processing procedure is simplified, and a painting workshop does not need to be arranged independently.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

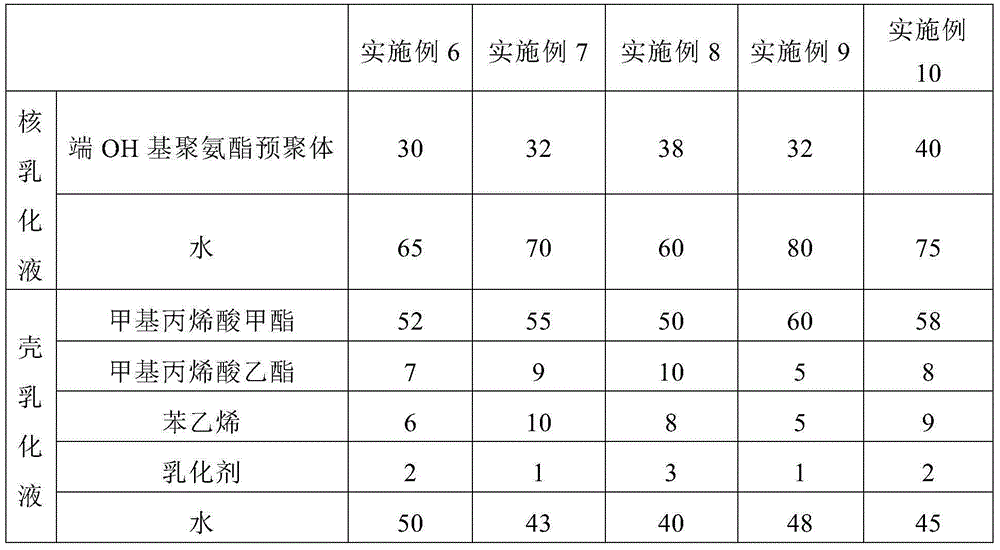

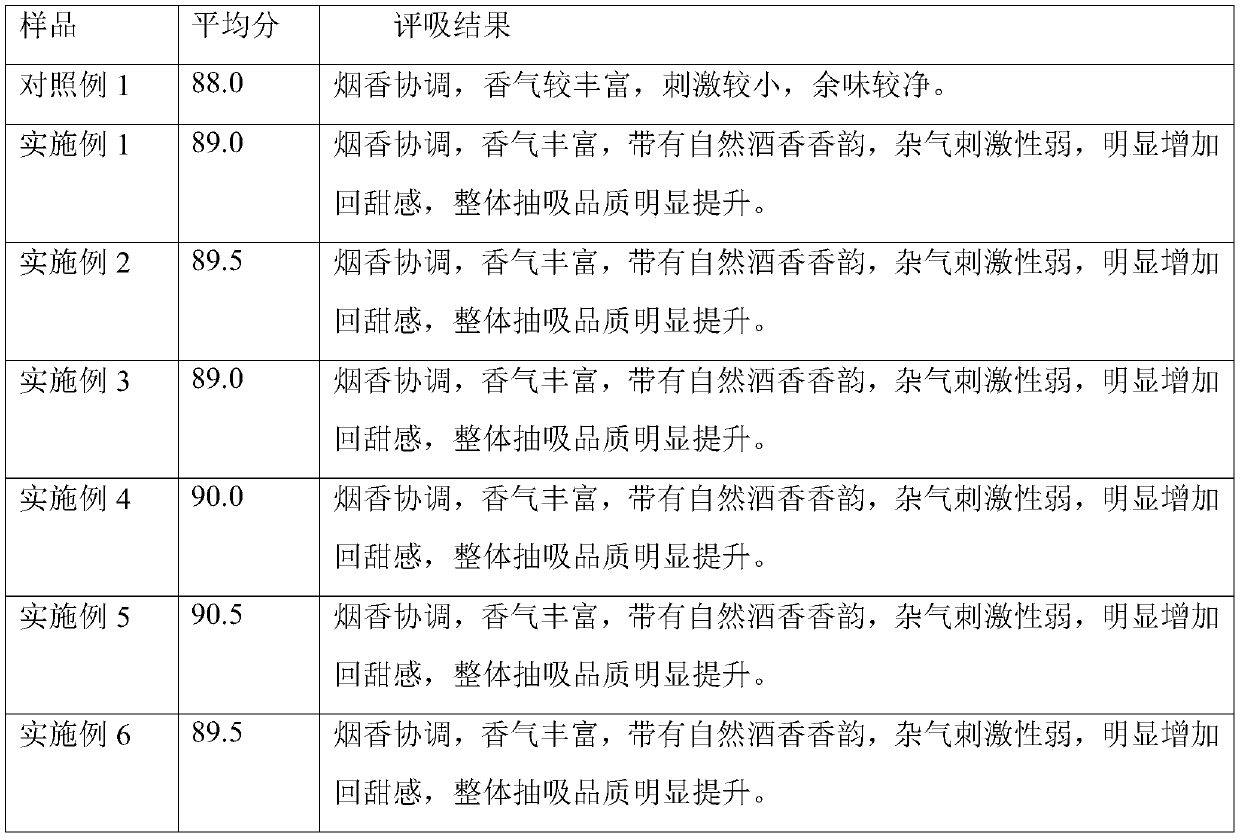

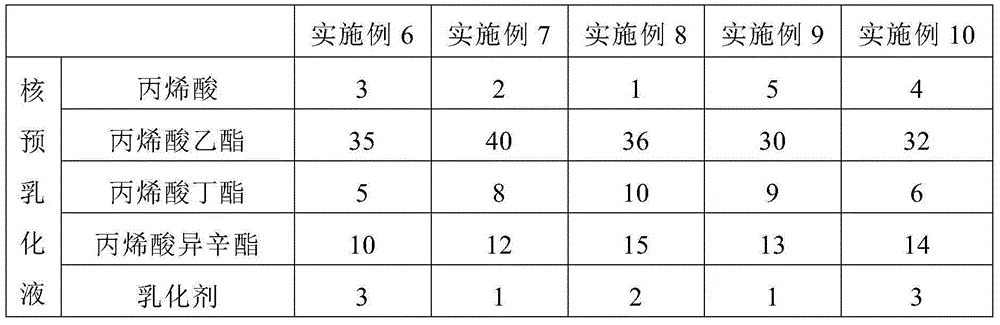

Baijiu distiller's grain oil and preparation method and application thereof

ActiveCN109793260AReduce hardnessReduce brittlenessTobacco treatmentTobacco smoke filtersMechanical crushingSolvent

The invention discloses Baijiu distiller's grain oil and a preparation method and application thereof. The preparation method includes the steps of firstly, sequentially subjecting fresh Baijiu distiller's grains to low-temperature freezing and mechanical crushing to obtain crushed fresh distiller's grains; secondly, using an extraction solvent to extract the crushed fresh distiller's grains through an ultrasonic-assisted heating method, and performing solid-liquid separation to obtain extract, namely the Baijiu distiller's grain oil. By adding the Baijiu distiller's grain oil into capsules for cigarettes, the cigarettes can be endowed with natural wine fragrance, cigarette fragrance can be enriched, soft and mellow smoke can be achieved, and smoking comfortableness can be improved.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

Modified acrylic resin energy-saving and environment-friendly coating for microwave oven shell

InactiveCN105038479AQuality assuranceImprove environmental performanceChemical industryAnti-corrosive paintsMicrowave ovenAcrylic resin

The invention provides a modified acrylic resin energy-saving and environment-friendly coating for a microwave oven shell. Nano SiO2 modified acrylic resin is adopted as the coating. The coating has the good glossiness, anti-static electricity capacity, mechanical property, ageing-resistant performance and chemical corrosion resisting performance, can be used as the anti-static electricity coating, has the advantages of low cost and environmental protection, and is high in adhesive force, good in malleability, resistant to high temperature and long in service life. The processing technology is changed, roller coating treatment is completed on a microwave shell slab in a concentrated mode, the processing steps are simplified, and no coating workshop needs to be independently arranged.

Owner:TAICANG JINXIN PAINT

Application of ulva water extract in cigarette

ActiveCN103054155AChange the processing technologyImprove aroma qualityTobacco preparationBiotechnologyMicrobiology

The invention relates to an application of an ulva water extract in a cigarette. The application is characterized in that the ulva water extract is added to tobacco shreds, the cigarette is free of abnormal-taste smoke gas and residual remaining taste, the fragrance is increased and is harmonious, the offensive odor and the pungency are reduced, the sweetening and secretion promoting feels are increased, and the overall smoking quality is improved. The ulva water extract is prepared by the following method which comprises the steps of cleaning and removing impurities of ulva; drying and crushing; adding water for soaking; carrying out enzymolysis solubilization; heating for leaching; centrifuging for separating; and concentrating under reduced pressure to obtain the ulva water extract. The application is characterized in that an ulva water extract cigarette additive extracted by using ulva as a raw material is provided; by adopting the ulva water extract cigarette additive, the original property of the cigarette is not changed, the original processing technique of the cigarette is not changed, the fragrance quality of the cigarette is improved, the sensory comfort of the cigarette is enhanced, and therefore, the application of the ulva water extract in the cigarette has practical production significance and value.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

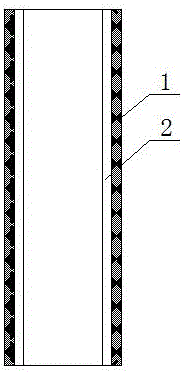

PE composite antibacterial water feed pipe

InactiveCN106247029ABroad inhibitory effectFree from harmRigid pipesManufacturing technologyPollution

The invention relates to a PE composite antibacterial water supply pipe, which belongs to the technical field of PE pipe manufacture. It is composed of an outer layer and an inner layer. The outer layer is a black protective layer, and the inner layer is a white antibacterial layer. Antimicrobial plastic layer made after mixing. The white antibacterial layer of the present invention contains 0.4 to 2.0% of inorganic antibacterial agents and a very small amount of silver ions and zinc ions, and has a wide range of inhibitory effects on gram-negative bacteria, gram-positive bacteria, fungi, molds and algae, It is safe and non-toxic, meets the requirements of various hygienic standards for plastic pipes, and does not need to make many changes to the pipe processing technology. During the use of the PE composite antibacterial water supply pipe, bacteria and other microorganisms cannot grow and survive on the surface of the white antibacterial layer in the inner layer of the water supply pipe, so the self-cleaning performance of the pipe can be realized once and for all, and the secondary pollution problem of drinking water can be completely solved.

Owner:HUBEI XINHUA PLASTIC

Premixed coarse grain powder and preparation method thereof

InactiveCN106578870APromote digestion and absorptionImprove qualityYeast food ingredientsFood ingredient functionsDispersion stabilityRhizopus

The invention belongs to the field of foods, and particularly relates to premixed coarse grain powder and a preparation method thereof. The premixed coarse grain powder is prepared by mixing the raw materials of mixed powder of cereals, Chinese wolfberry fruits, walnuts and sesame seeds, fermented bean powder, Chinese yam powder and the like, wherein the mixed powder of cereals, Chinese wolfberry fruits, walnuts and sesame seeds is obtained through the following steps of mixing black rice with oat and buckwheat, performing soaking, performing inoculation with saccharomyces cerevisiae, aspergillus oryzae and cordyceps sinensis in the fungus count ratio of the saccharomyces cerevisiae to the aspergillus oryzae and to the cordyceps sinensis being (0.5-1.5) to (0.5-1) to (1-3), performing mixed fermentation to obtain cereal type coarse cereal powder, then mixing the cereal type coarse cereal powder with the Chinese wolfberry fruits, the walnuts and the sesame seeds, and performing low-temperature crushing; and the fermented bean powder is obtained through the following steps of soaking red beans, black beans and peas, performing sterilization, performing inoculation with rhizopus, mucor and bacillus subtilis in the fungus count ratio of the rhizopus to the mucor and to the bacillus subtilis being (1-5) to (1-3 ) to (1-3), performing mixed fermentation, and performing crushing. The premixed coarse grain powder provided by the invention is easy to digest, good in dispersion stability and simple in preparation process.

Owner:湖北馥雅食品科技有限公司

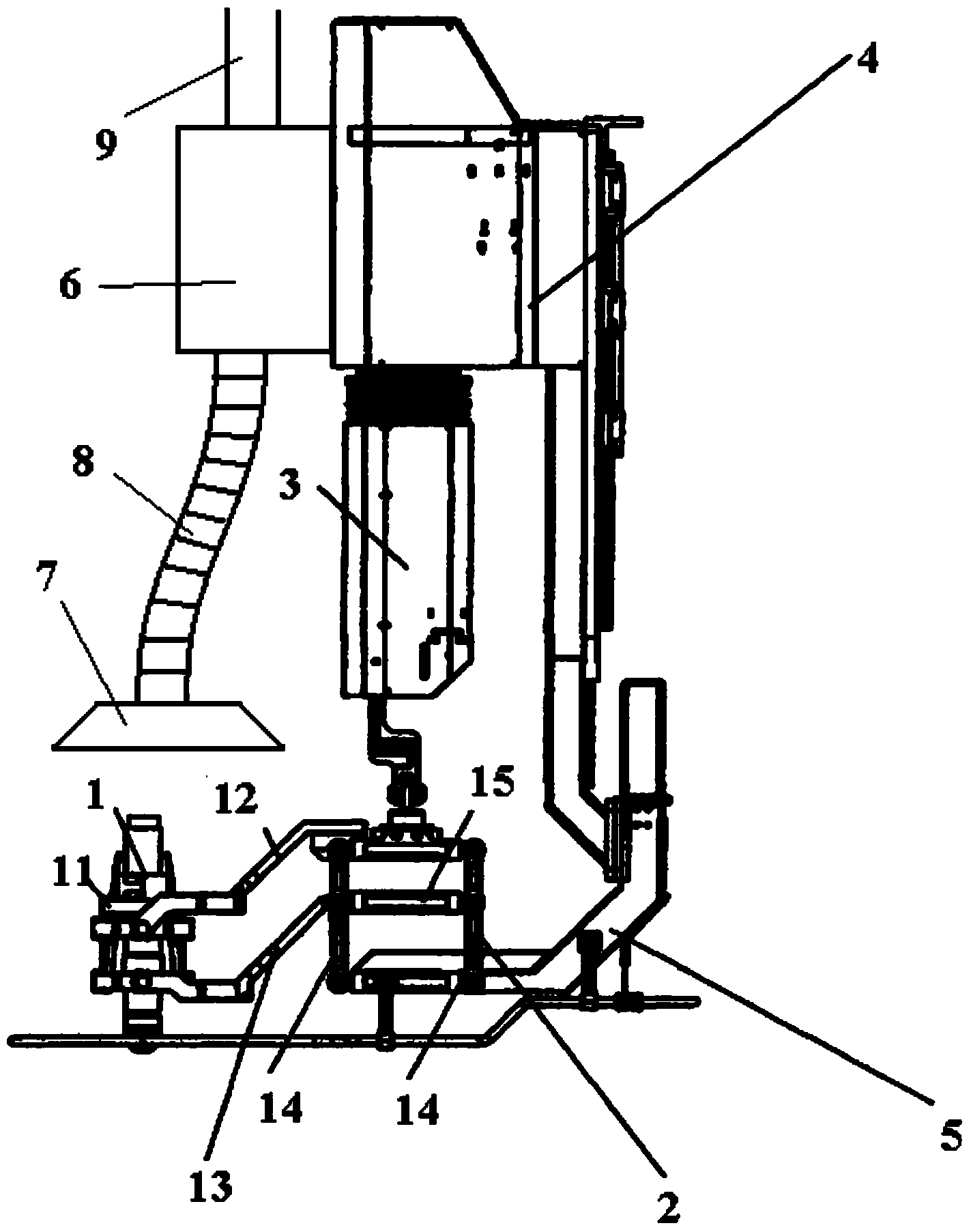

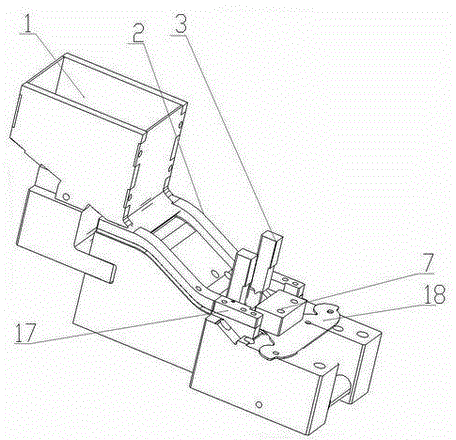

Groove cutting device of sliding adjustment cutting head with smoke sucking device

InactiveCN103521903AChange the processing technologyFully automatedWelding/cutting auxillary devicesDirt cleaningNumerical controlPulp and paper industry

The invention relates to a groove cutting device of a sliding adjustment cutting head with a smoke sucking device. The groove cutting device comprises the cutting head, the cutting head is installed on a fixed base, the upper end of the fixed base and the lower end of the fixed base are in hinge connection with a fixed connecting rod and a sliding connecting rod respectively, the fixed connecting rod is fixedly connected with a push mechanism, the push mechanism is provided with two vertical guide rails, a sliding block is installed between the two guide rails, the other end of the sliding connecting rod is in hinge connection with the sliding block, the upper portion of the push mechanism is connected with a deflection driving device, the deflection driving device is installed below a rotating mechanism, an exhaust fan is installed on the rotating mechanism, an air inlet of the exhaust fan is connected with a draught hood through a stainless steel hose, and an air outlet of the exhaust fan enables smoke to be discharged through a pipeline. The groove cutting device is applied to a numerical control plasma groove device, changes the traditional processing technology, and achieves full automation. The exhaust fan is arranged above the cutting head to suck the smoke generated during high-temperature cutting, and the production environment is protected.

Owner:昆山乾坤机器制造有限公司

Modified acrylic resin energy conservation and environment protection coating for back plate of refrigerator

InactiveCN105038344AQuality assuranceImprove environmental performanceFireproof paintsAnti-corrosive paintsAcrylic resinAging resistance

The invention provides a modified acrylic resin energy conservation and environment protection coating for a back plate of a refrigerator. The coating adopts bisphenol A epoxy resin modified acrylic resin, and therefore the coating has the advantages that the excellent flame retardance and wear resistance property are achieved, the curing speed is high, the better mechanical property, aging resistance property and chemical corrosion resistance property are achieved, the adhesive force is high, the ductility is good, the high temperature resistance property is achieved, the service life is long, the processing technology is changed, roller coating processing is concentratedly completed on a plate blank of the black plate of the refrigerator, the processing procedure is simplified, and a painting workshop does not need to be separately arranged.

Owner:TAICANG JINXIN PAINT

Energy-saving environment-friendly coating adopting modified acrylic resin and used for knurled decoration plate

InactiveCN105038352AQuality assuranceImprove environmental performanceFireproof paintsAnti-corrosive paintsAcrylic resinMachining

The invention provides an energy-saving environment-friendly coating adopting modified acrylic resin and used for a knurled decoration plate. According to the coating, as organic silicon fluoride is adopted for modifying acrylic resin, the coating can have excellent flame-retardant and abrasion-resistant properties, and a good anti-static ability, and can serve as an anti-static coating; moreover, the curing speed is high, the coating also has good mechanical performance, ageing-resistant performance and chemical corrosion resistant performance, and is high in adhesive force, good in ductility, resistant to high temperature and long in service life, the machining technology is changed, roll coating treatment is completed on a plate blank of the knurled decoration plate in a centralized mode, the machining procedures are simplified, and it is unnecessary to arrange a spray painting workshop individually.

Owner:TAICANG JINXIN PAINT

Modified acrylic resin energy-saving environment-friendly paint for suspended ceiling metal sheets

InactiveCN105111871AImprove flame retardant performanceImprove wear resistanceFireproof paintsAnti-corrosive paintsAcrylic resinAging resistance

The invention provides a modified acrylic resin energy-saving environment-friendly paint for suspended ceiling metal sheets. By adopting an organic-fluorine-modified acrylic resin, the paint has the advantages of excellent flame retardancy, excellent wear resistance, high curing speed, favorable mechanical properties, favorable aging resistance, favorable chemical corrosion resistance, high strong, favorable ductility, high temperature resistance and long service life. The processing technique is changed by centrally completing the roller coating treatment on the suspended ceiling metal sheet blank, thereby simplifying the processing procedure and avoiding the independent arrangement of the spray workshop.

Owner:TAICANG JINXIN PAINT

Acrylic modified energy-saving environment-friendly roller-coating paint for metal deep drawing sheets and application method thereof

ActiveCN104817936AStrong adhesionImprove ductilityPretreated surfacesEpoxy resin coatingsMetal sheetDeep drawing

The invention provides an acrylic modified energy-saving environment-friendly roller-coating paint for metal deep drawing sheets and an application method thereof. The paint comprises a white primer and a finish paint. The paint has the advantages of high adhesive force, favorable ductility, high temperature resistance and long service life, changes the processing technique of the metal sheet products, simplifies the processing procedure, centrally completes the roller coating treatment on the metal deep drawing sheet, and does not need to independently arrange any spray workshop.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Energy-saving and environment-friendly roller coating paint for printing plate and application method of energy-saving and environment-friendly roller coating paint

ActiveCN104817950AStrong adhesionImprove ductilityPolyurea/polyurethane coatingsEpoxy resin coatingsEngineeringMechanical engineering

The invention provides an energy-saving and environment-friendly roller coating paint for a printing plate and an application method of the energy-saving and environment-friendly roller coating paint. The paint comprises a priming paint and a finish paint. The paint is high in adhesive force, good in ductility, heat-resistant and long in service life; the processing technology for printing plate products is changed; the processing procedures are simplified; roller coating treatment is intensively finished on a panel of the printing plate; and a painting workshop does not need to be independently arranged.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

Pomegranate liqueur chocolate and preparation method thereof

InactiveCN108497143ABoosts Fresh SmellRelieve discomfortAlcoholic beverage preparationMicroorganism based processesAlcoholMilk Chocolate

The invention provides pomegranate liqueur chocolate and a preparation method thereof. The raw materials of the pomegranate liqueur chocolate comprise main materials and auxiliary materials, wherein the main materials comprise liqueur prepared by inoculating pomegranates as a basic raw material with plant lactobacillus and saccharomycetes or lactobacillus acidophilus and saccharomycetes and then performing sealing and fermenting, edible grade alcohol and block chocolate. The pomegranate liqueur chocolate produced by the preparation method is changed on the basis of a traditional liqueur chocolate processing technology, whole pomegranates are used as a fermentation raw material, the lactobacillus plantarum and multiple starter cultures are used together for performing fermenting to producethe pomegranate liqueur to be used for preparing the liqueur chocolate, and compared with the liqueur chocolate using strong wine on the market, the pomegranate liqueur chocolate is suitable for morepeople.

Owner:XIHUA UNIV

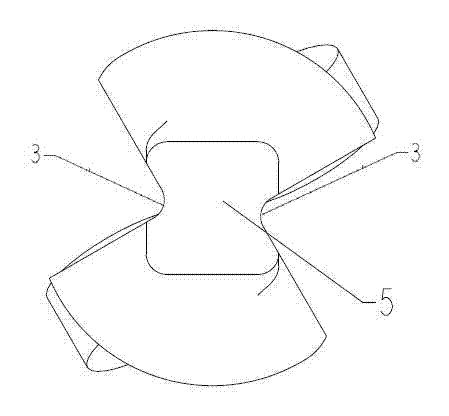

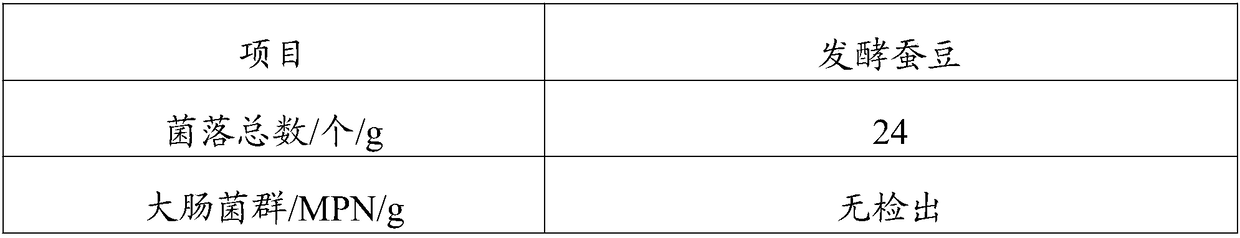

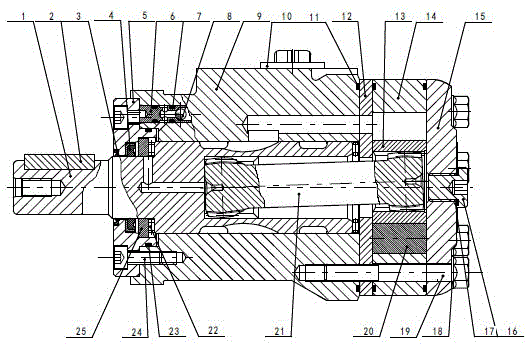

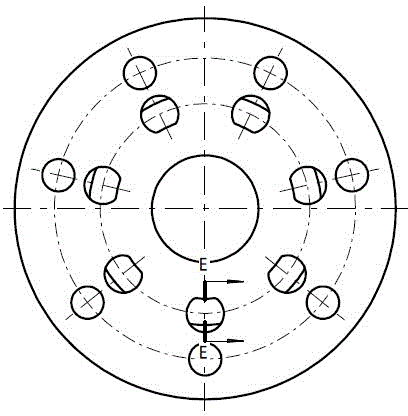

Composite oil passing hole of axis flow distribution cycloid hydraulic motor

ActiveCN105604780AIncrease oil flow areaReduce leakageRotary piston enginesHydraulic motorManufacturing technology

The invention relates to a composite oil passing hole of an axis flow distribution cycloid hydraulic motor, and belongs to the technical field of hydraulic transmission. Oil passing holes in the two end faces of a separating disc of the axis flow distribution cycloid hydraulic motor are different in shape, one end of an oil liquid channel is composed of two segments of circular arcs, the other end of the oil liquid channel is composed of four segments of circular arcs, and the two ends are in smooth transition. Compared with a separating disc structure of an axis flow distribution cycloid hydraulic motor and a manufacturing technology in the prior art, due to the improved structure, the oil passing area of the separating disc is increased, resistance in the liquid flow passing process is reduced, a gap of meshing shaft holes of a flow distribution valve of a coaxial flow distribution structure is increased, possible leakage is reduced, pressure losses are reduced, and the product efficiency is improved.

Owner:ZHENJIANG DALI HYDRAULIC MOTOR

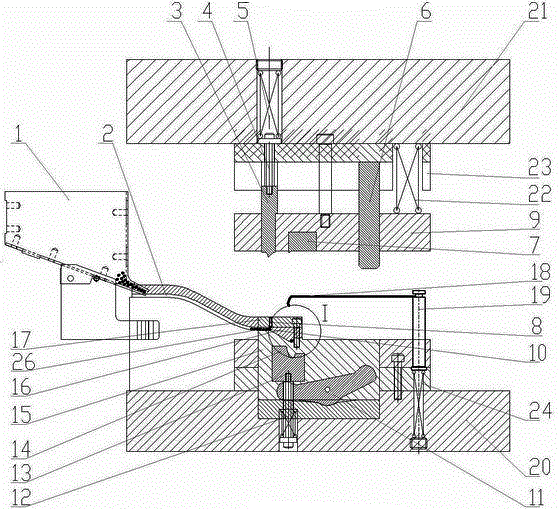

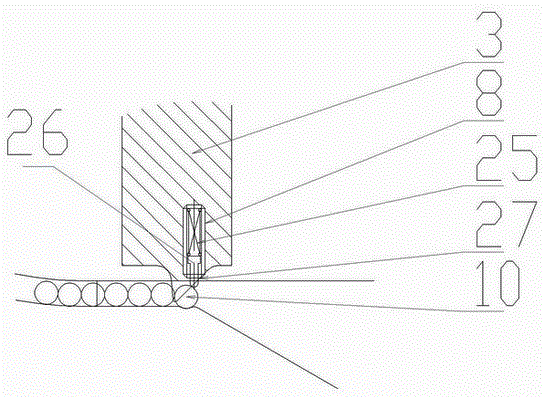

Automatic shaft feeding and rolling structure in continuous die

ActiveCN105983618AChange the processing technologyAvoid manual shaft settingShaping toolsMetal-working feeding devicesPunchingEngineering

The invention discloses an automatic shaft feeding and rolling structure in a continuous die and relates to the technical field of machining. A storage box provided with a shaft is put on a worktable, the storage box is connected with a sliding rail, and the shaft is pushed into a shaft containing groove in a lower die through a push rod on an upper die via the sliding rail. A shaft rolling insert is connected to the lower die through a fourth spring and a second equal-height screw. A swing block is hinged to the shaft containing groove. The upper die descends, an upper die stripper plate is used for pressing a floating material pin to descend so as to drive a sheet metal part to descend. The swing block push rod on the upper die is pressed on the swing block, the swing block drives the shaft rolling insert to upwards move, and the sheet metal part and the shaft are rolled and pressed to be formed in the shaft rolling insert. By means of the automatic shaft feeding and rolling structure in the continuous die, traditional single-time punching and automatic shaft feeding and rolling are integrated, the shaft can be automatically conveyed and rolled and pressed in the continuous die, manual shaft putting is effectively avoided, the working efficiency is improved, the machining technology of a hardware punched part is changed, the structure is simple, operation is convenient, the production cost is low, and the automatic shaft feeding and rolling structure can be applied to various sheet metal shaft rolling parts.

Owner:XIANGYANG SUNRISE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com