Method for extracting bolete polysaccharide and application of bolete polysaccharide in tobacco products

An extraction method, boletus technology, applied in tobacco, tobacco preparation, tobacco treatment, etc., can solve the problem of unsatisfactory improvement of smoking comfort, achieve elegant and special aroma, avoid the use of organic solvents, increase recovery The effect of sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

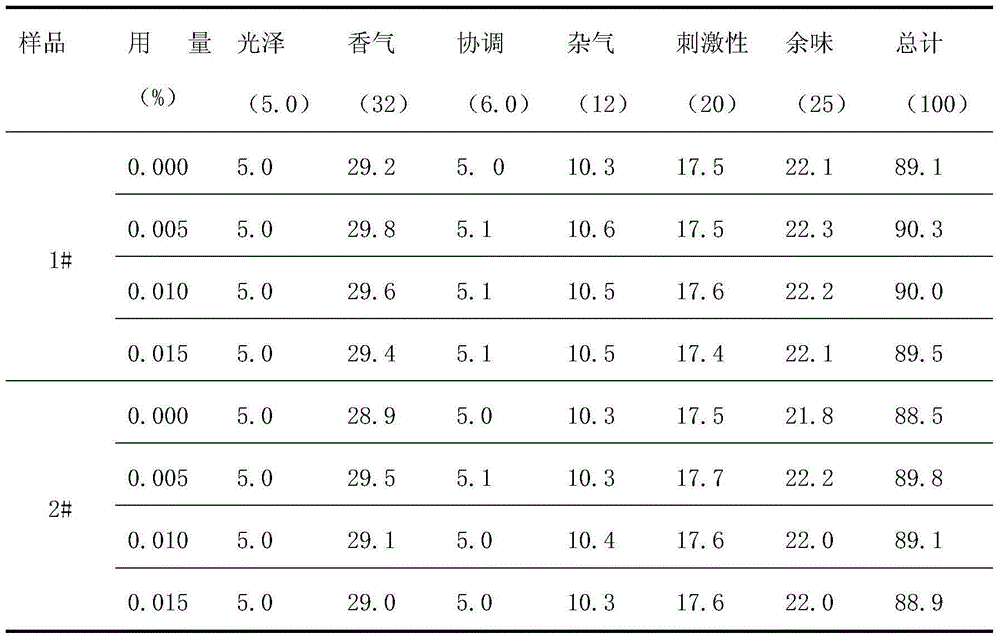

Embodiment 1

[0021] Boletus edulis (Boletus edulis) fruiting body 200g was dried at low temperature, pulverized, powder added with water, the weight ratio of solid to liquid was 1:3, the water temperature was 70°C, the microwave power was fixed at 1kw, and treated for 60s, and the water temperature was kept at 70°C for 5 hours. , concentrate the extract, add ethanol to make the concentration of ethanol in the concentrate reach 70%, then there will be precipitated out, after filtering and washing, the crude boletus polysaccharide is obtained; the crude polysaccharide is dissolved in water, and is adsorbed and eluted through a polyamide column For treatment, first adsorb for 6 hours, then elute the boletus polysaccharide with water, and then concentrate to obtain relatively pure boletus polysaccharide. Boletus polysaccharides were dissolved in water or alcohol solvents, added in different proportions to the cigarette feed liquid and sprayed onto shredded tobacco, and its application effect in...

Embodiment 2

[0026] Boletus Luridus (Boletus Luridus) fruiting body 1000g was dried at low temperature, pulverized, powdered with water, the ratio of solid to liquid was 1:15-1:30, the water temperature was 70-90°C, the microwave power was fixed at 2kw, and treated for 80s, and the water temperature was kept at 80 Extract at ℃ for 12 hours, concentrate the extract, add 95% ethanol to make the ethanol concentration reach 65%, precipitate the crude boletus polysaccharide, dissolve the crude boletus polysaccharide in water, and carry out adsorption-elution treatment through a polyamide column, Adsorb for 2 hours first, then elute the boletus polysaccharide with water, concentrate to obtain the boletus polysaccharide; dissolve the boletus polysaccharide, add it to the tobacco sheet coating liquid as a feed liquid, and the boletus polysaccharide is 0.01% to 0.3% of its weight %.

[0027] The results show that the smoking quality of the tobacco sheet has been improved to a certain extent, which ...

Embodiment 3

[0029] Boletus aereus (Boletus aereus) fruit body 500g, dry at low temperature, pulverize, add water to the powder, the ratio of solid to liquid is 1:15-1:30, the water temperature is 70-90°C, fix the microwave power at 1kw and treat for 80s, continue to maintain the water temperature Extract at 80°C for 12 hours, concentrate the extract, add 95% ethanol to make the ethanol concentration reach 65%, precipitate the crude boletus polysaccharide, dissolve the crude boletus polysaccharide in water, and carry out adsorption-elution treatment through a polyamide column , first adsorb for 2h, then wash out the boletus polysaccharide with water, and concentrate to obtain the boletus polysaccharide; the boletus polysaccharide is dissolved and added to the tobacco sheet coating liquid as a feed liquid, and the bolete polysaccharide is 0.01% to 0.01% of its weight 0.3%.

[0030] The results show that the smoking quality of the tobacco sheet has been improved to a certain extent, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com