Patents

Literature

226results about "Granulation using vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrocatalyst powders, methods for producing powders and devices fabricated from same

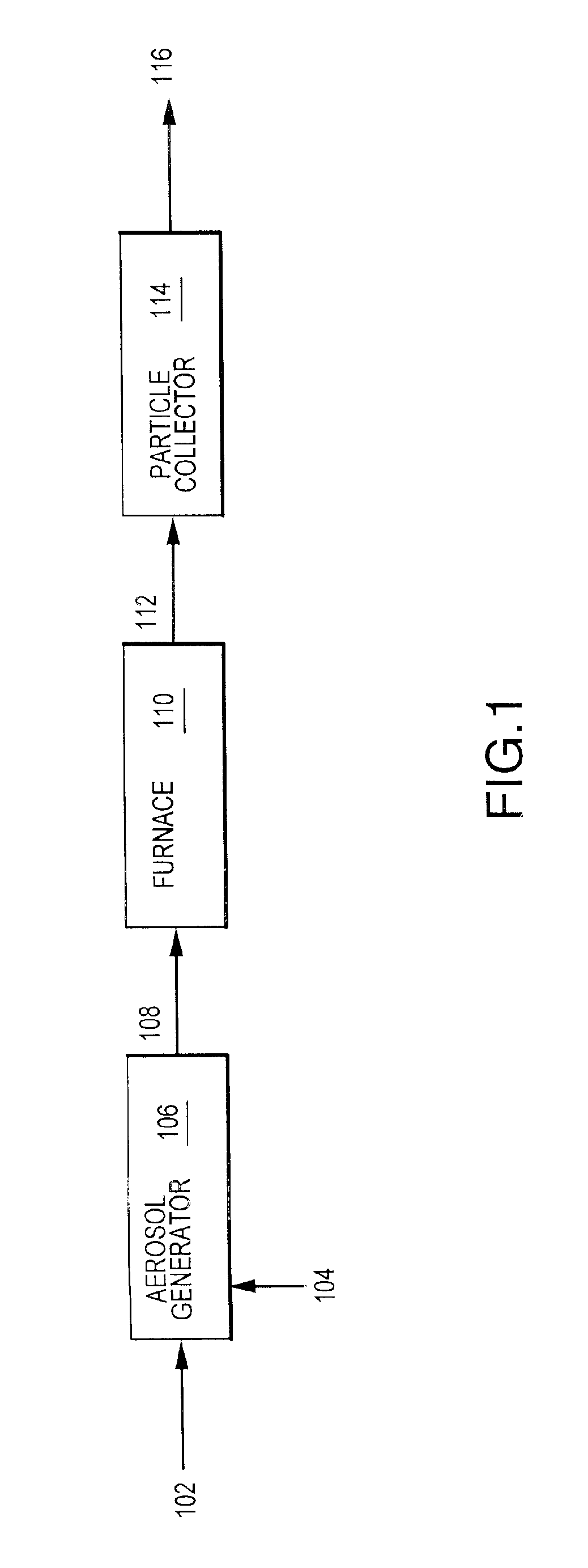

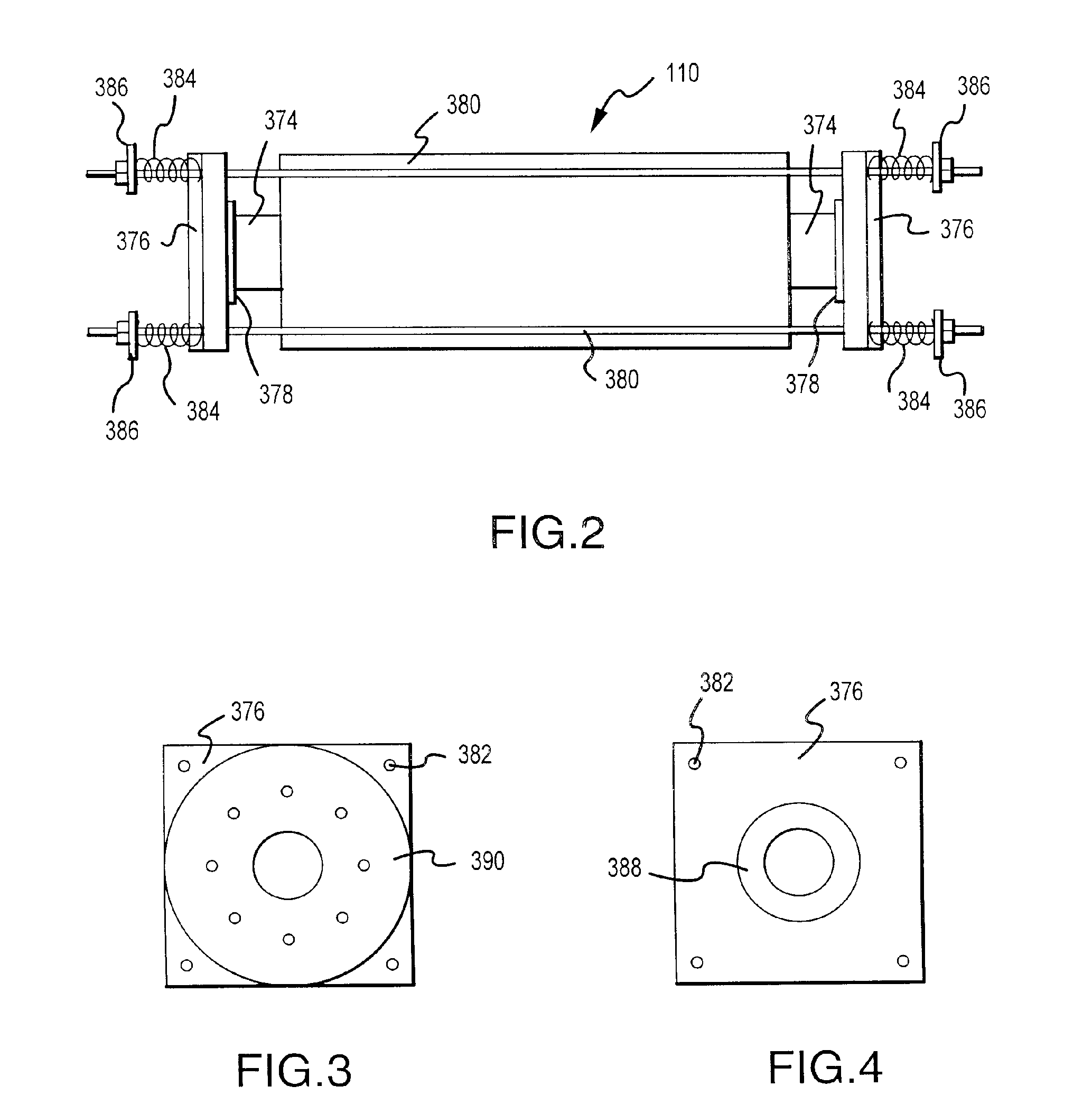

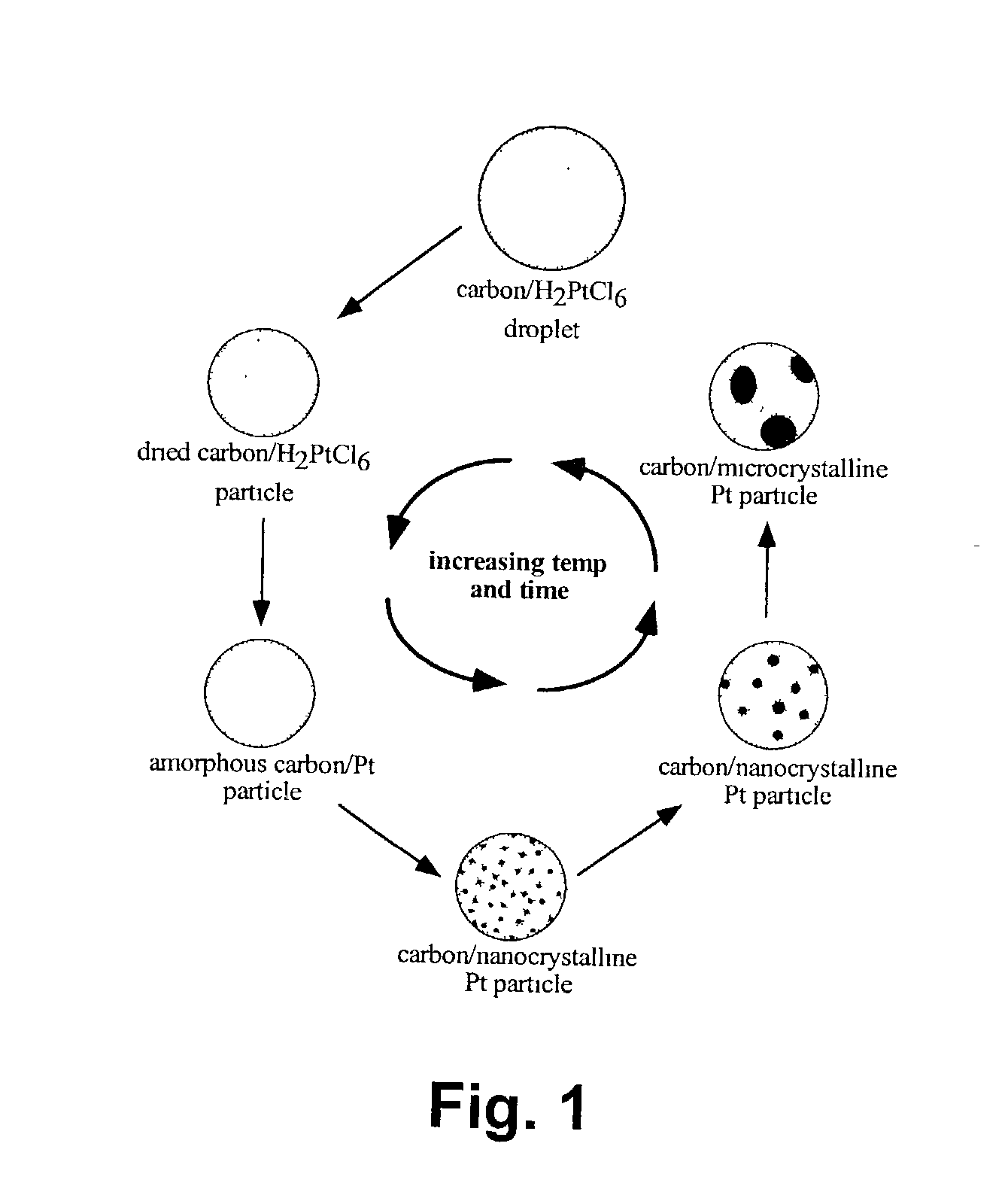

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

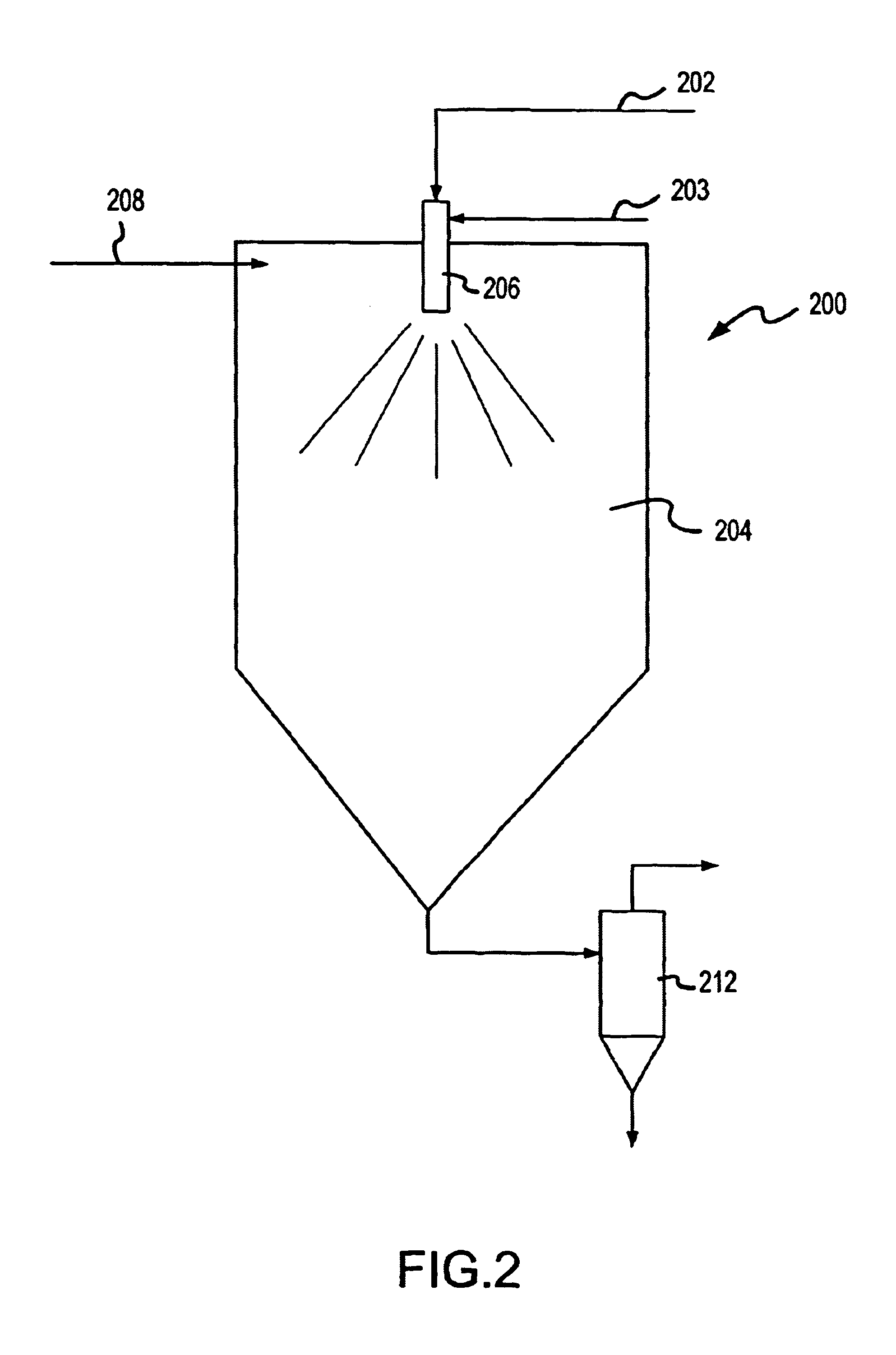

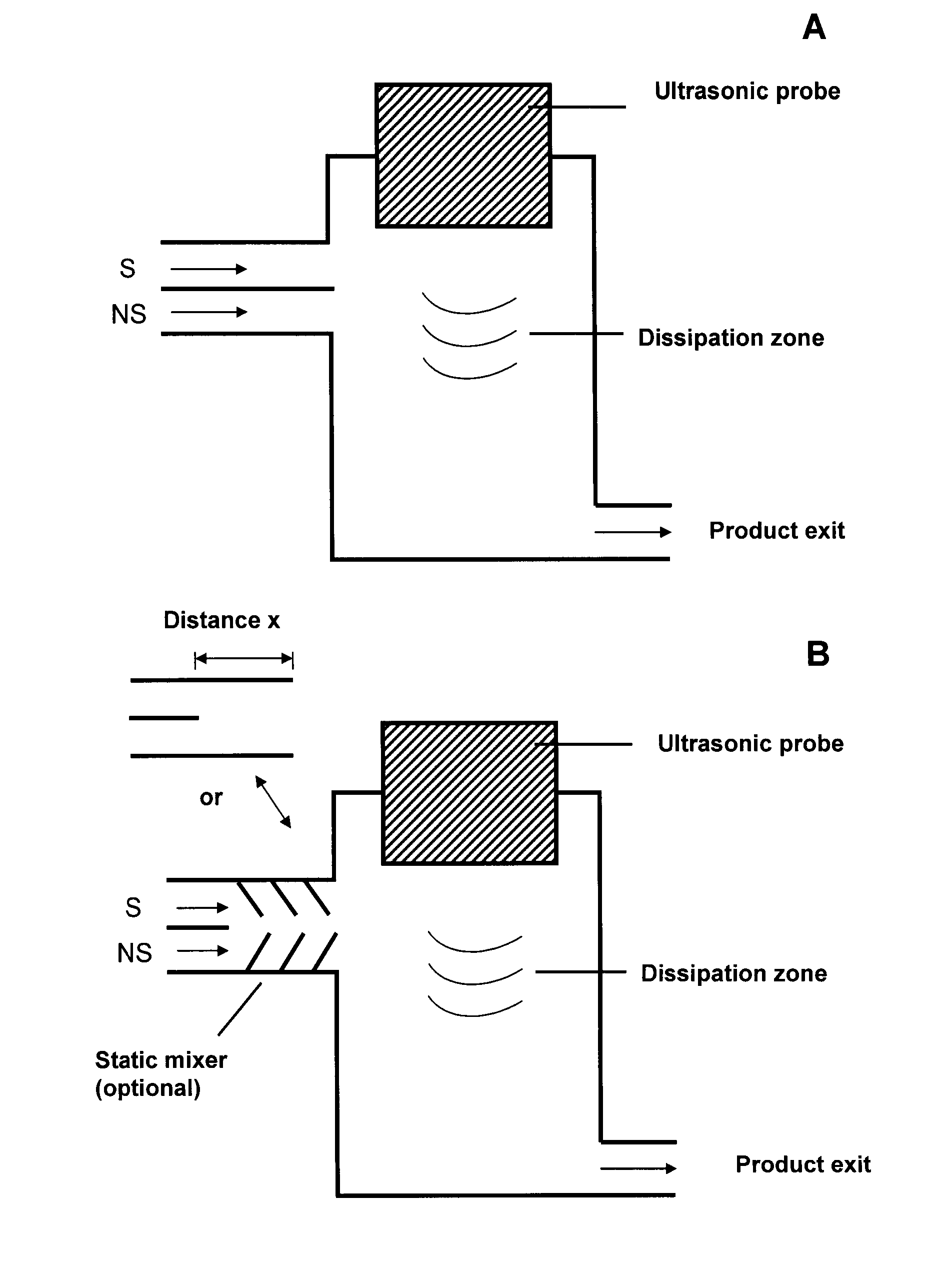

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids with enhanced mass transfer

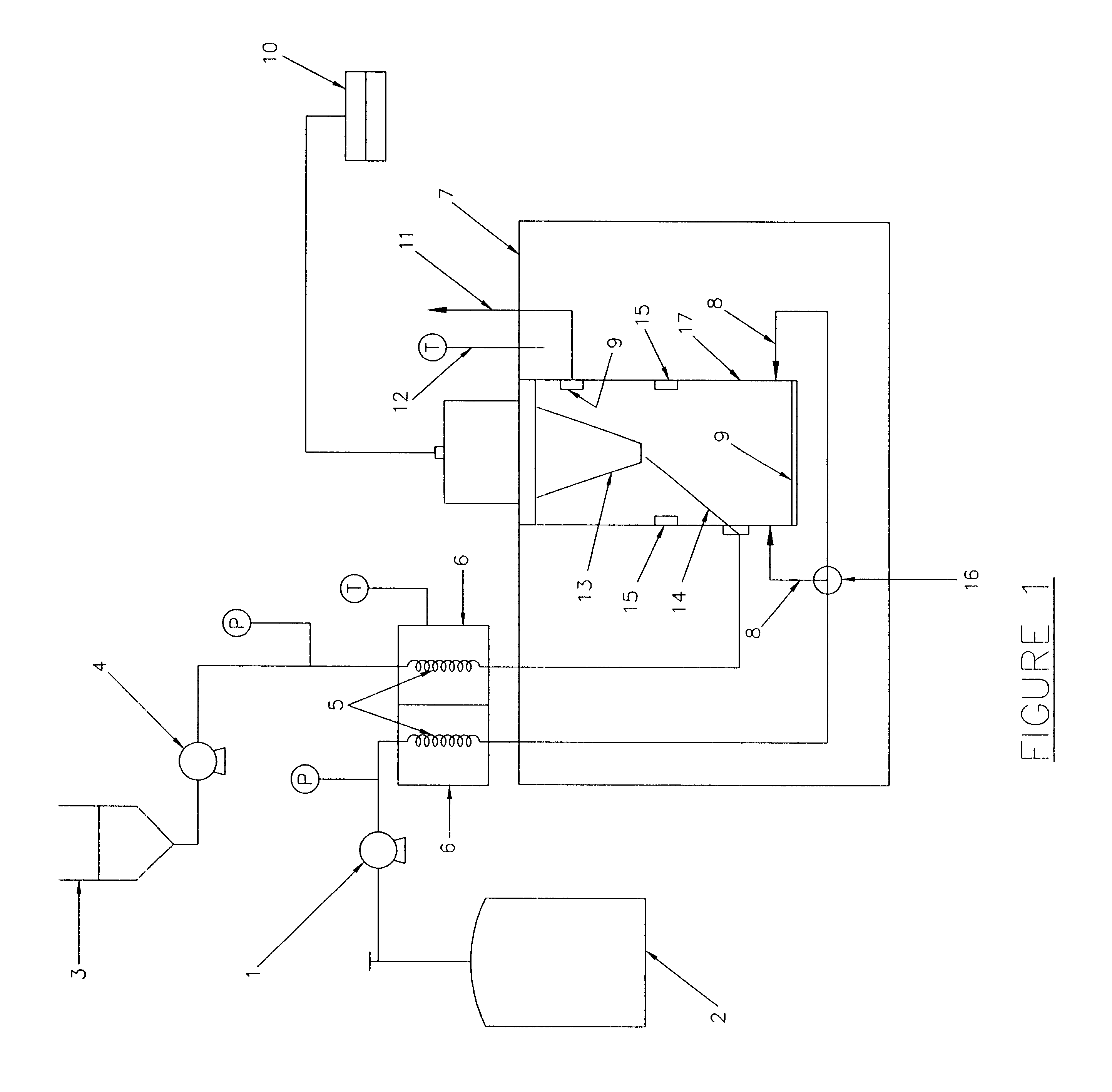

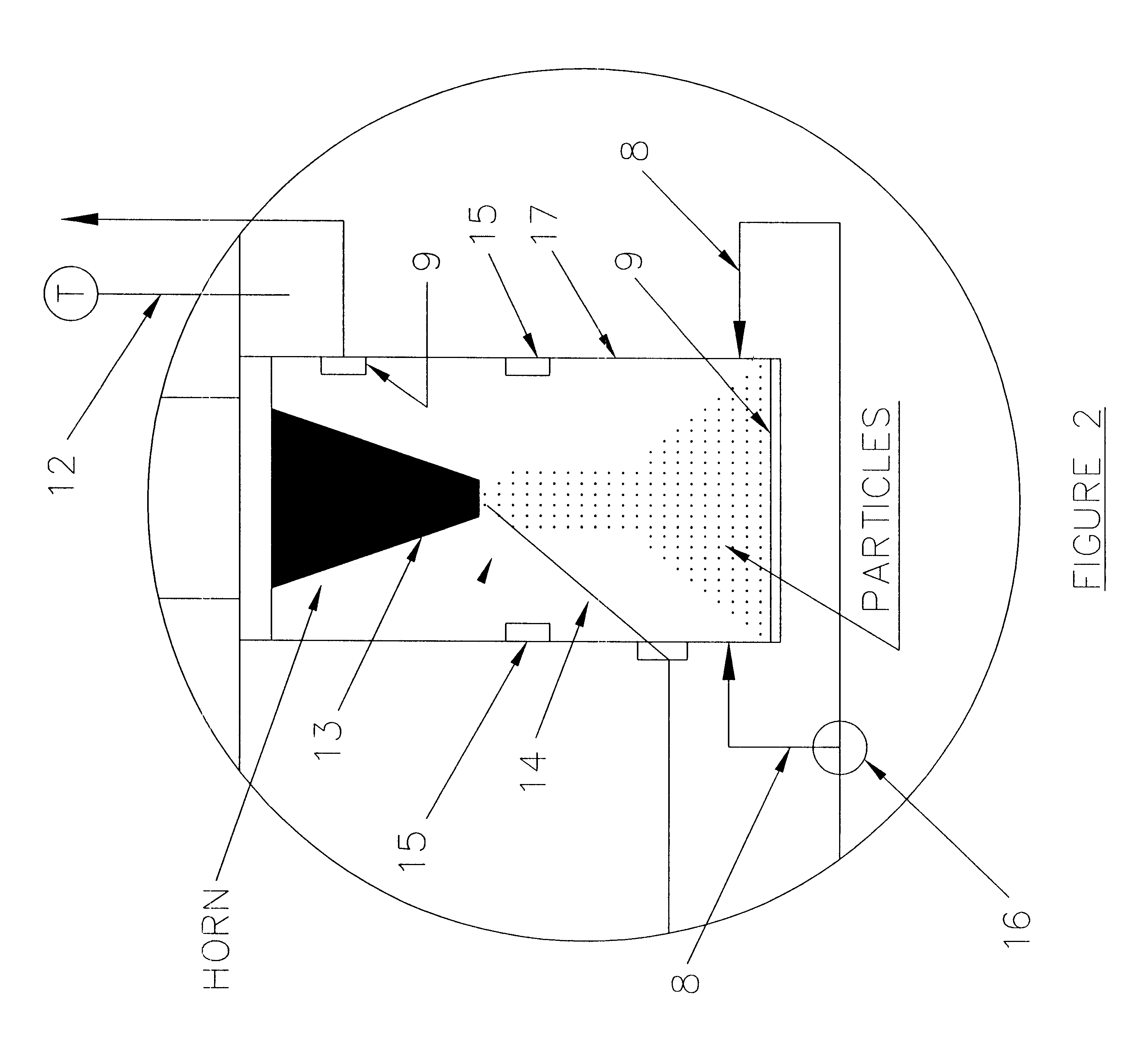

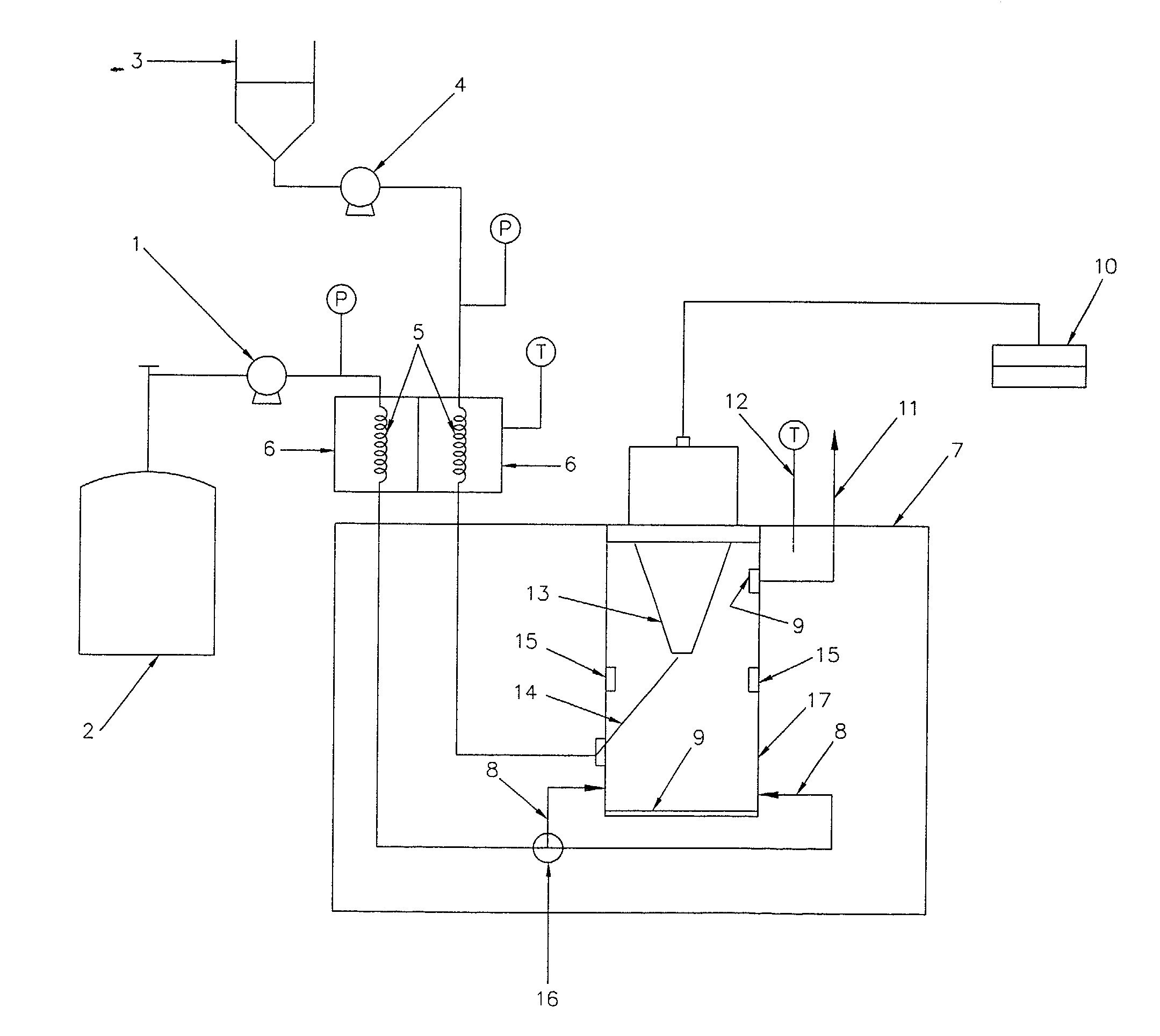

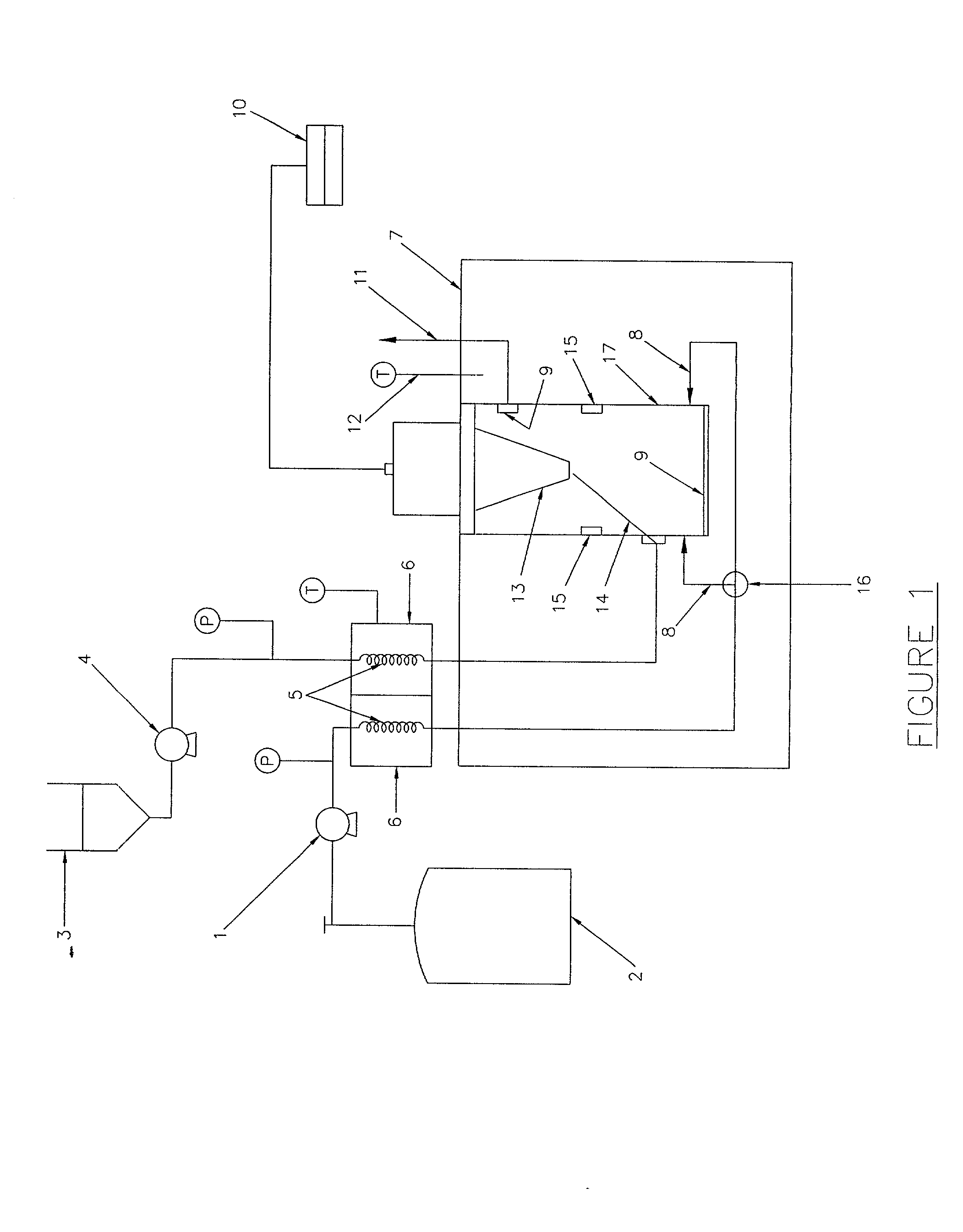

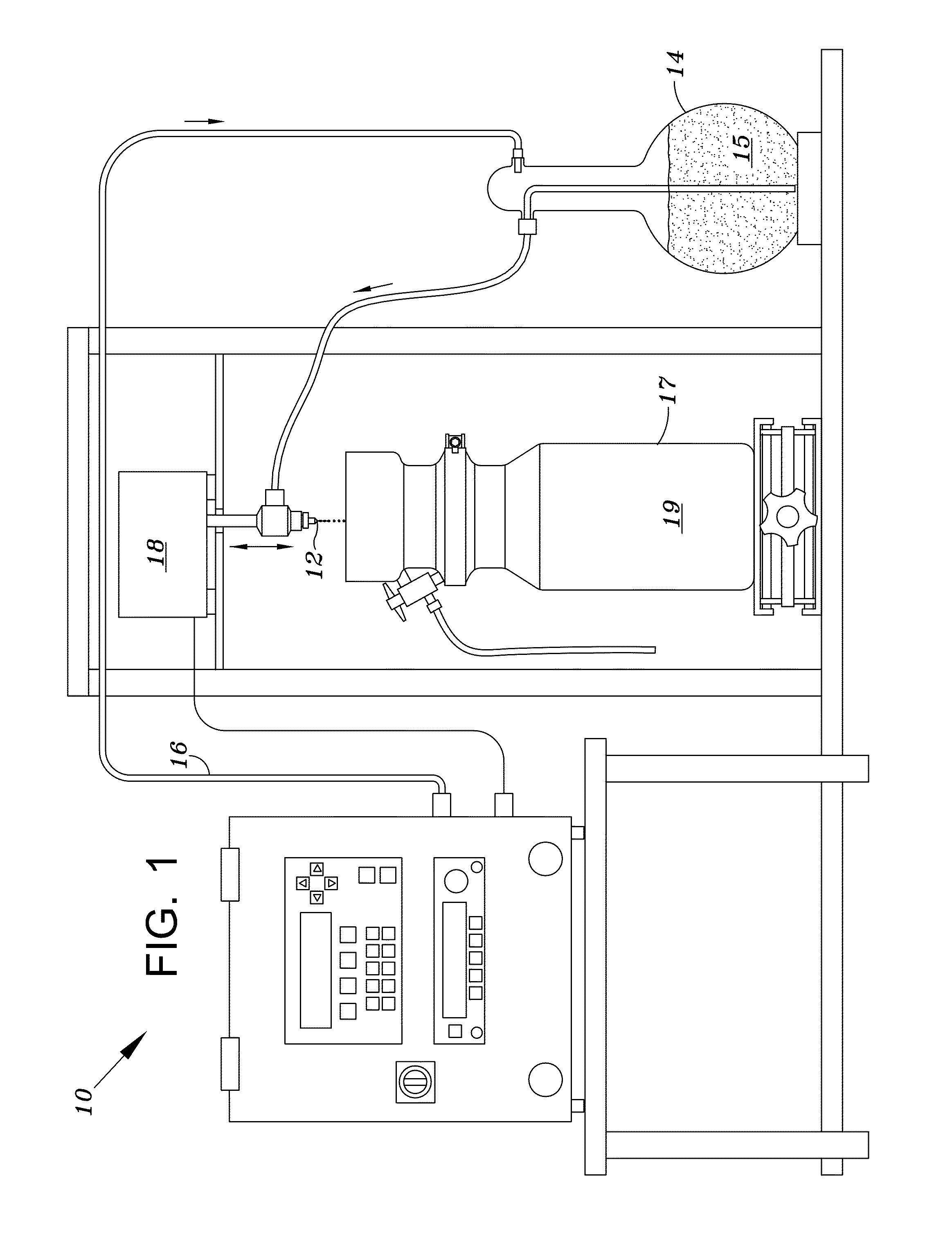

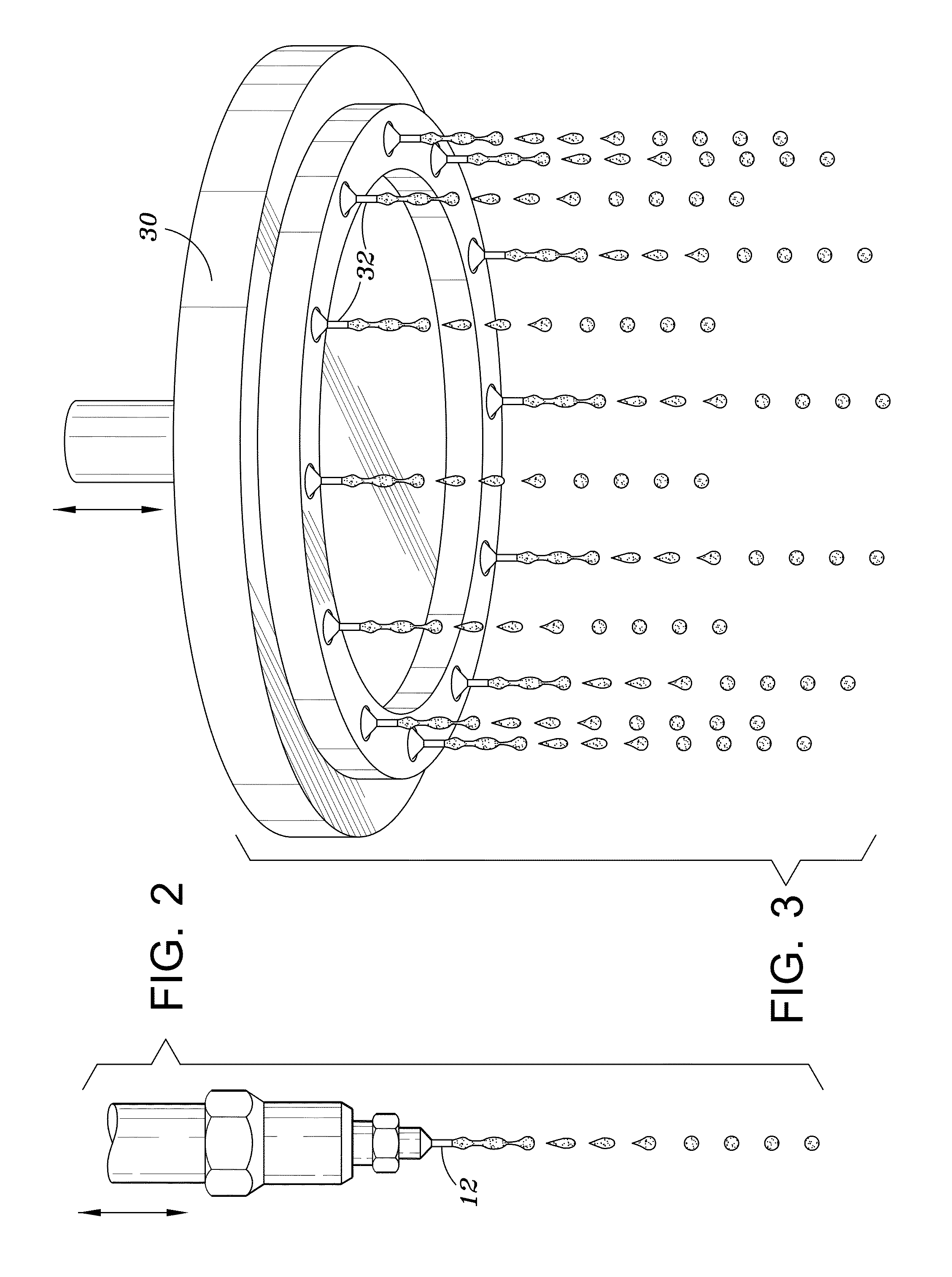

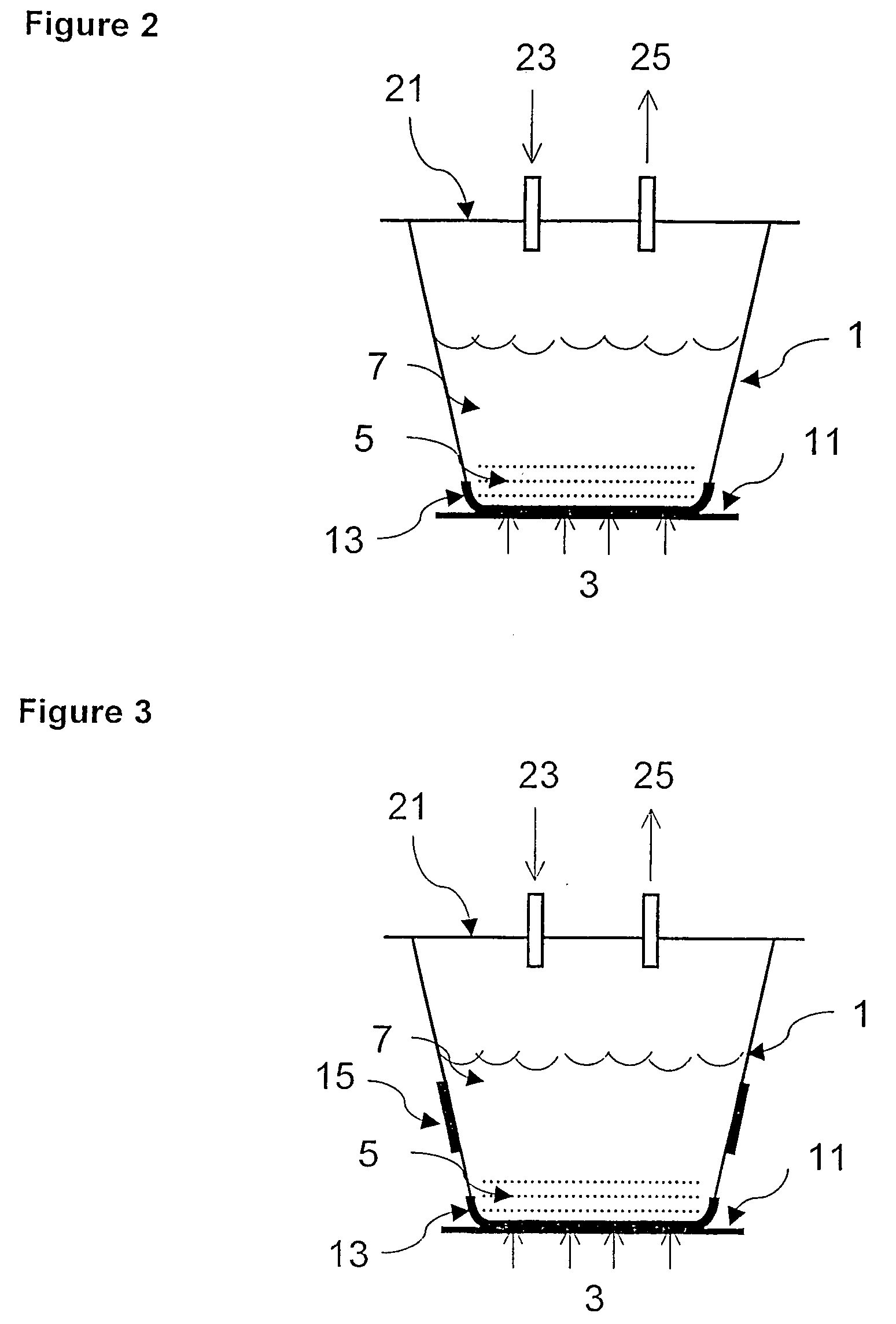

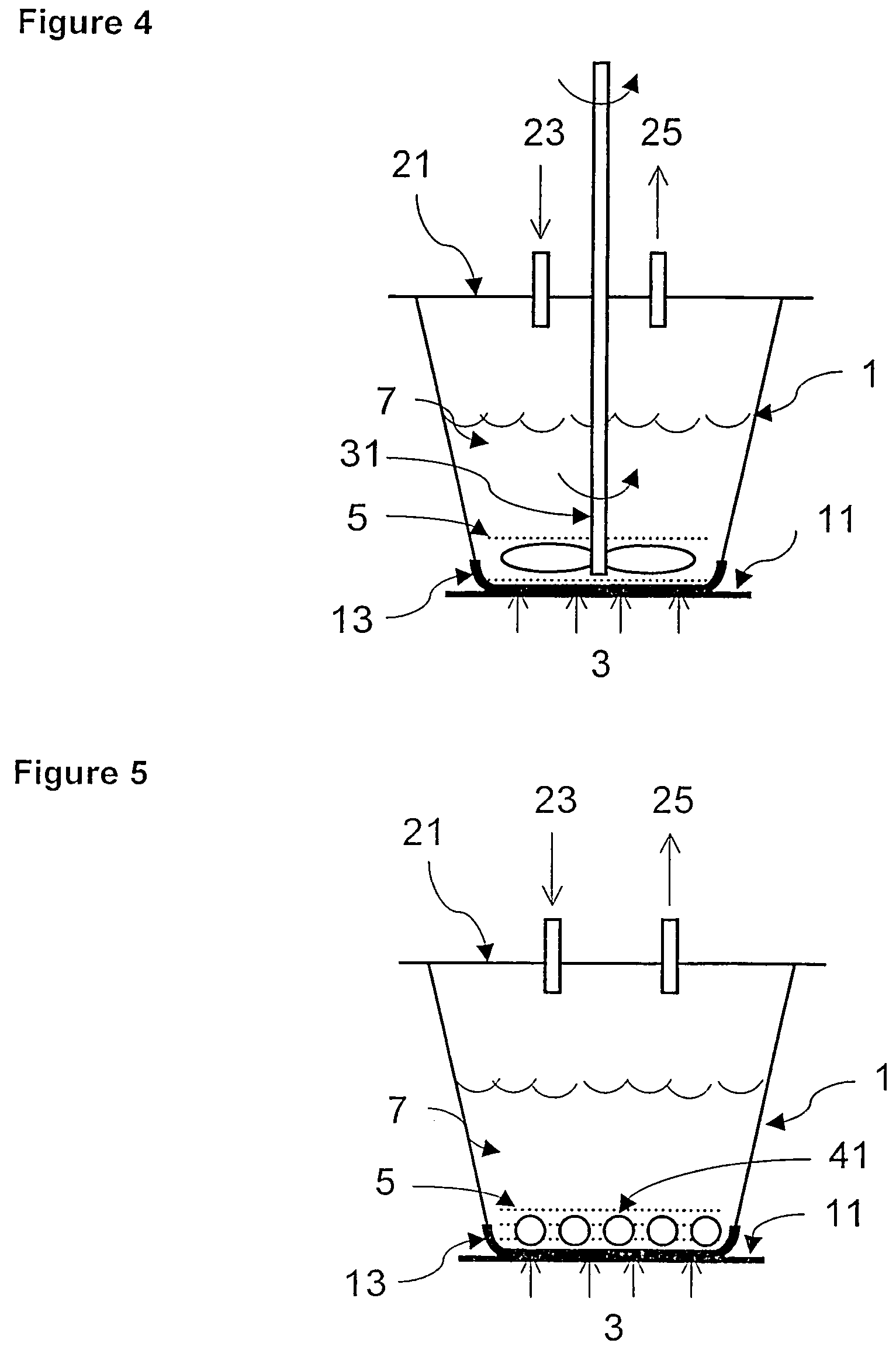

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

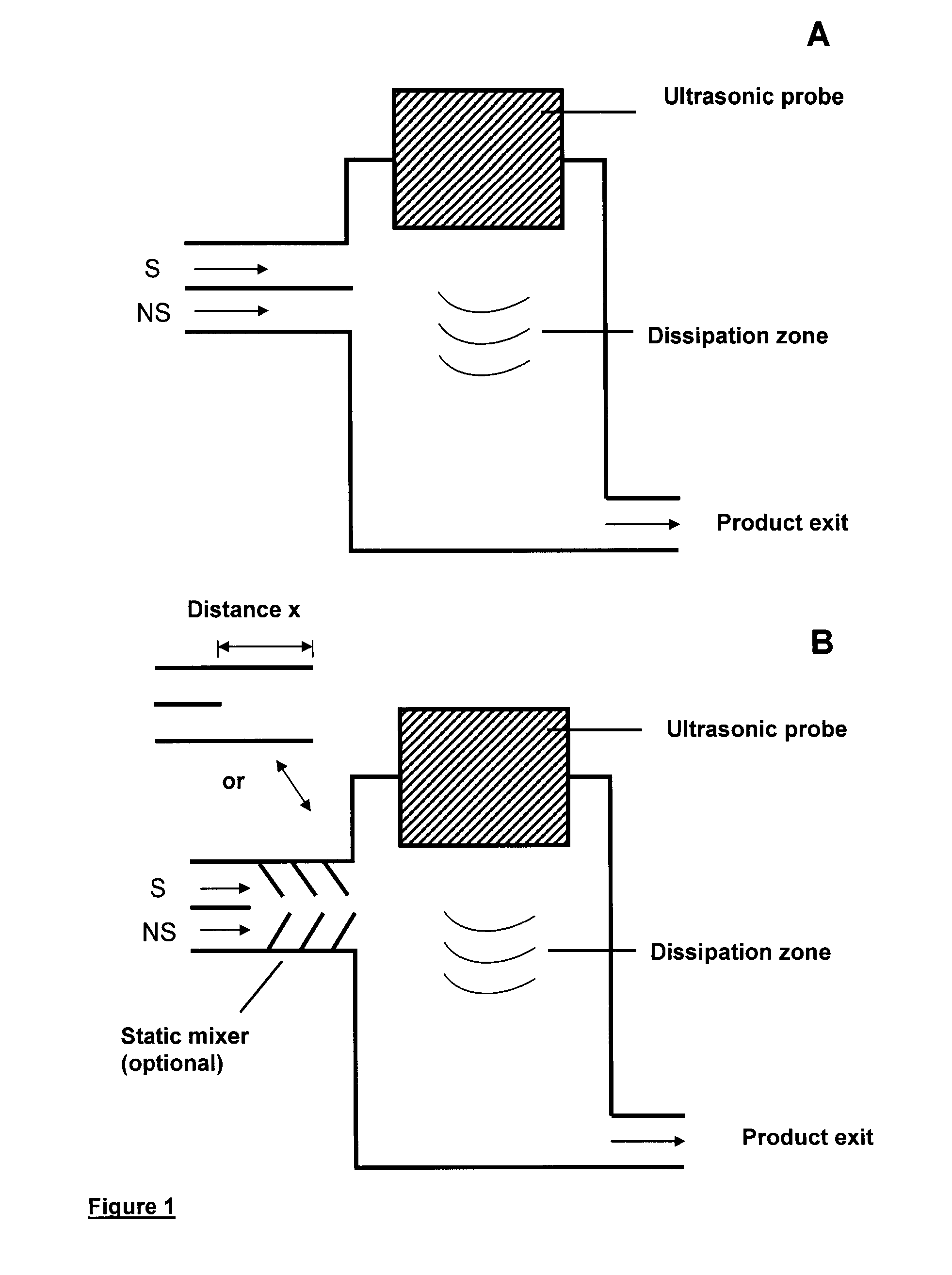

Method of forming nanoparticles and microparticles of controllable size using supercritical fluids and ultrasound

The current invention, Supercritical Antisolvent Precipitation with Enhanced Mass Transfer (SAS-EM) provides a significantly improved method for the production of nano and micro-particles with a narrow size distribution. The processes of the invention utilize the properties of supercritical fluids and also the principles of virbrational atomization to provide an efficient technique for the effective nanonization or micronization of particles. Like the SAS technique, SAS-EM, also uses a supercritical fluid as the antisolvent, but in the present invention the dispersion jet is deflected by a vibrating surface that atomizes the jet into fine droplets. The vibrating surface also generates a vibrational flow field within the supercritical phase that enhances mass transfer through increased mixing. Sizes of the particles obtained by this technique are easily controlled by changing the vibration intensity of the deflecting surface, which in turn is controlled by adjusting the power input to the vibration source. A major advantage of the SAS-EM technique is that it can be successfully used to obtain nanoparticles of materials that usually yield fibers or large crystals in SAS method. Microencapsulation via coprecipitation of two or more materials can also be achieved using the SAS-EM technique.

Owner:UNIV AUBURN

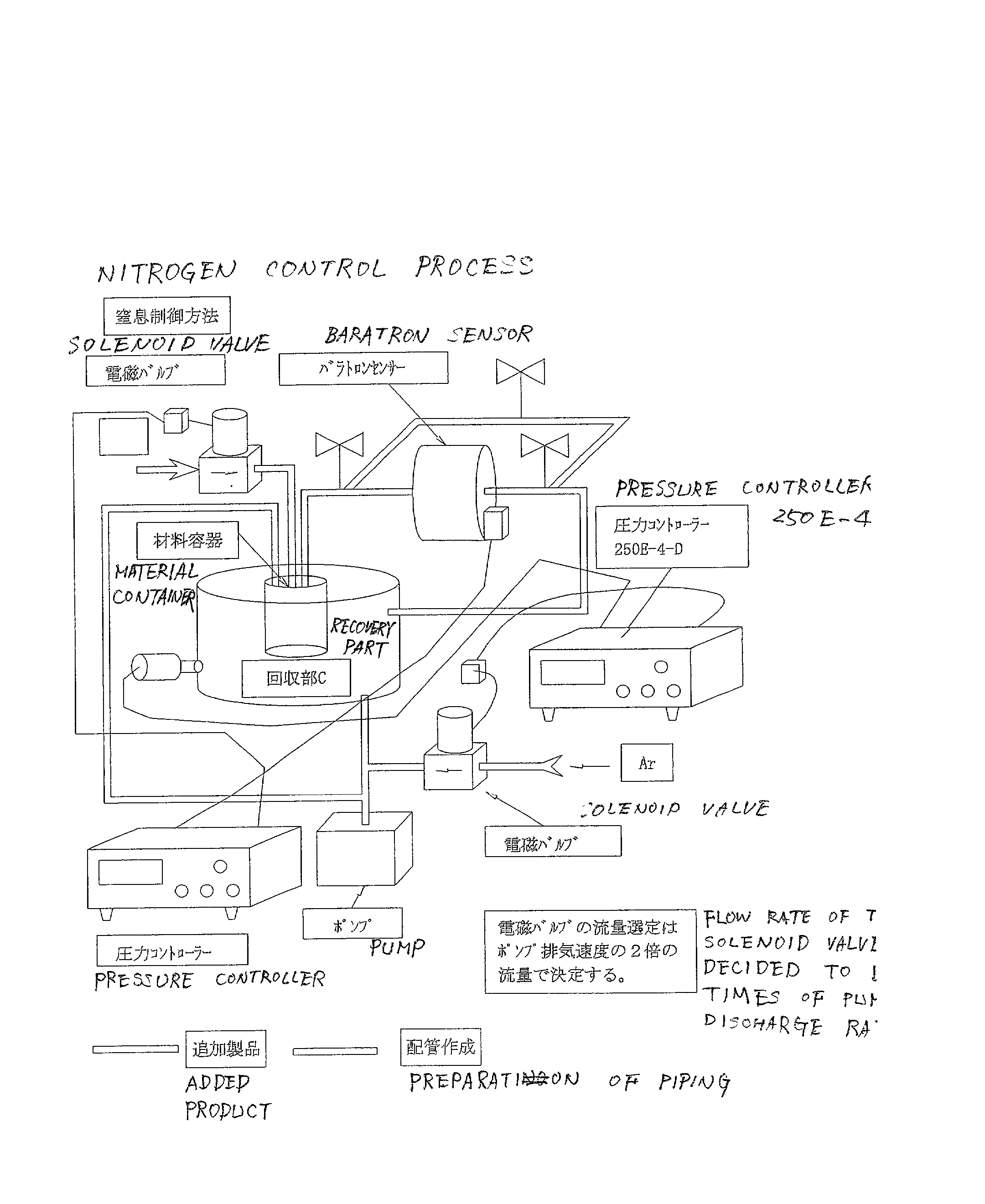

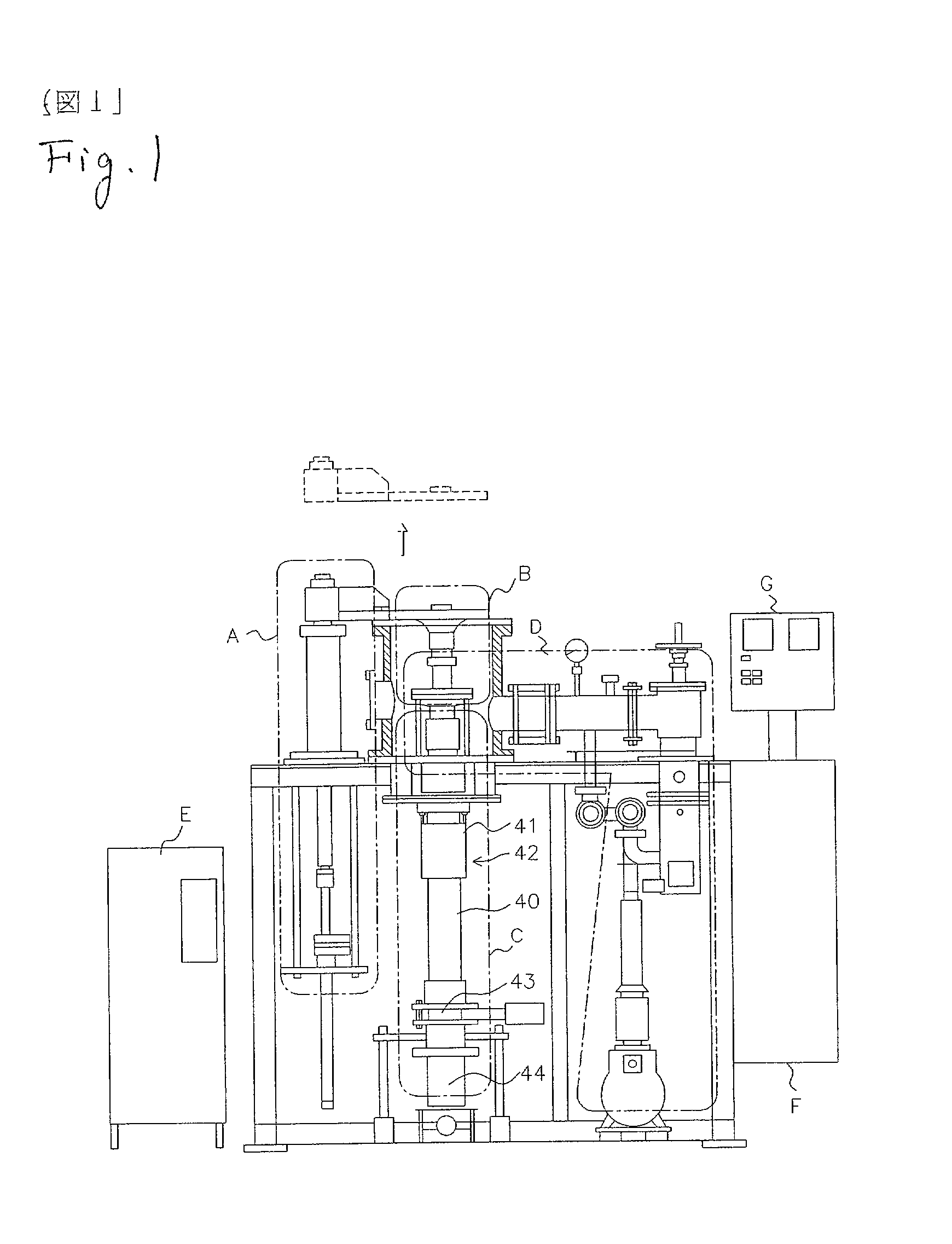

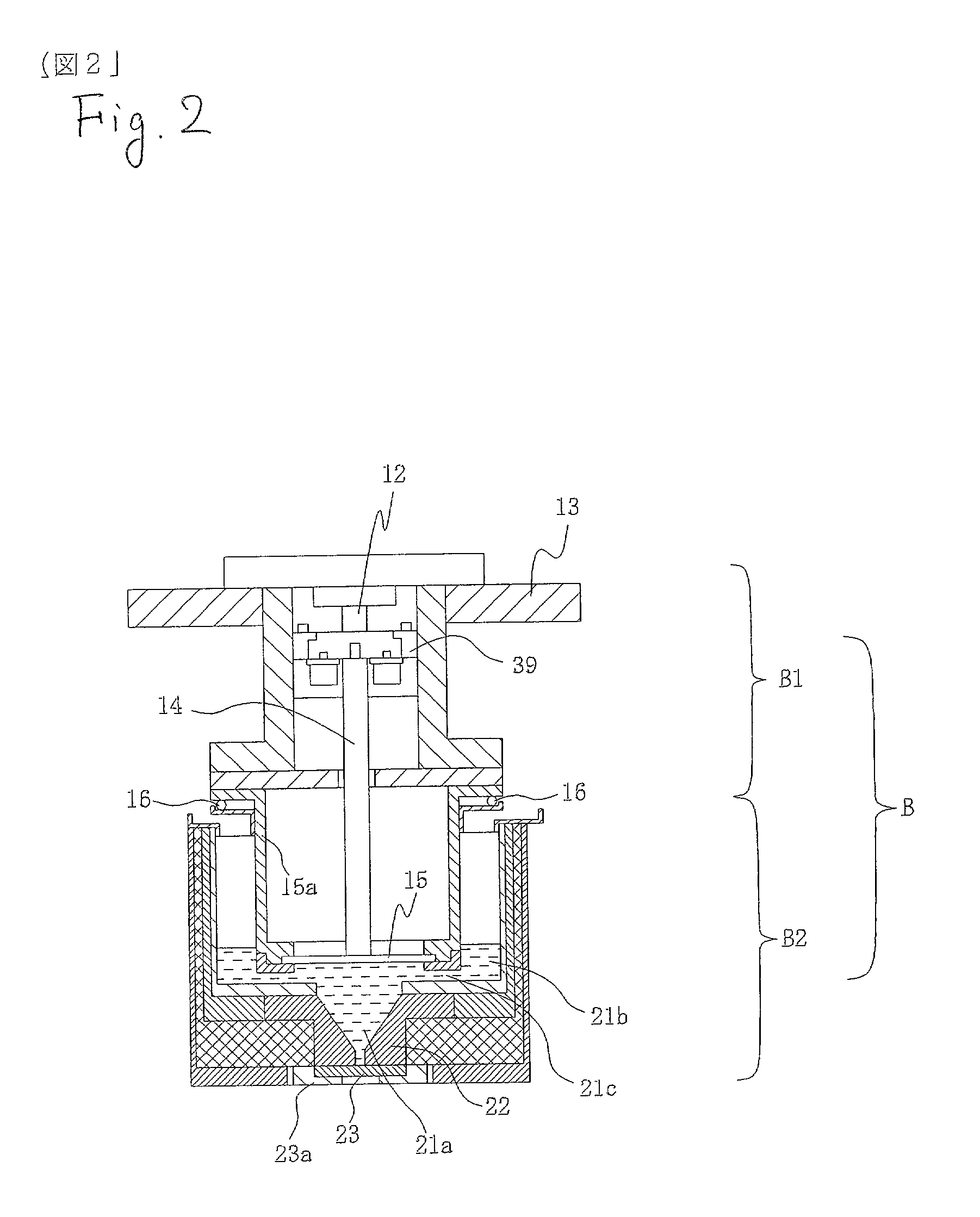

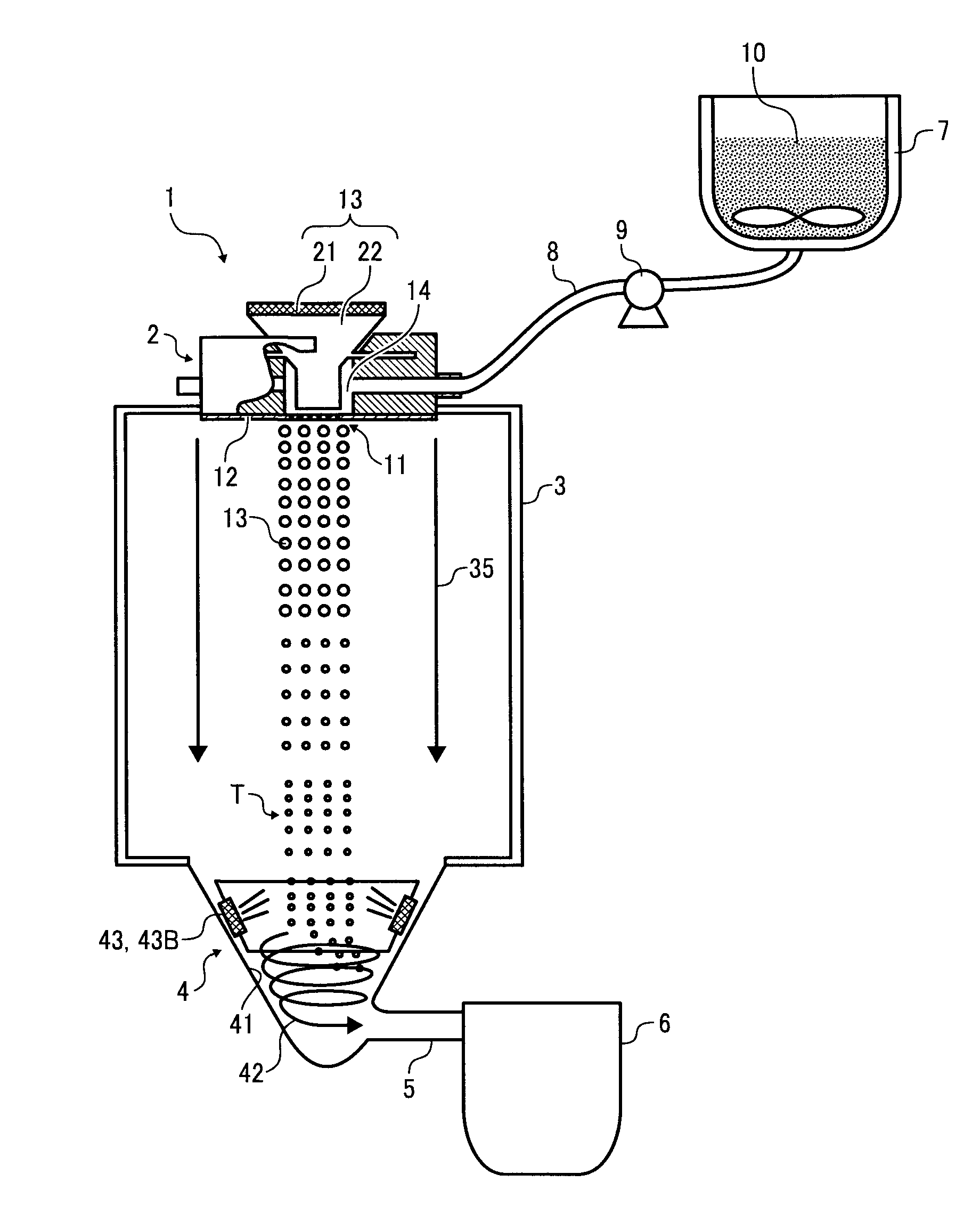

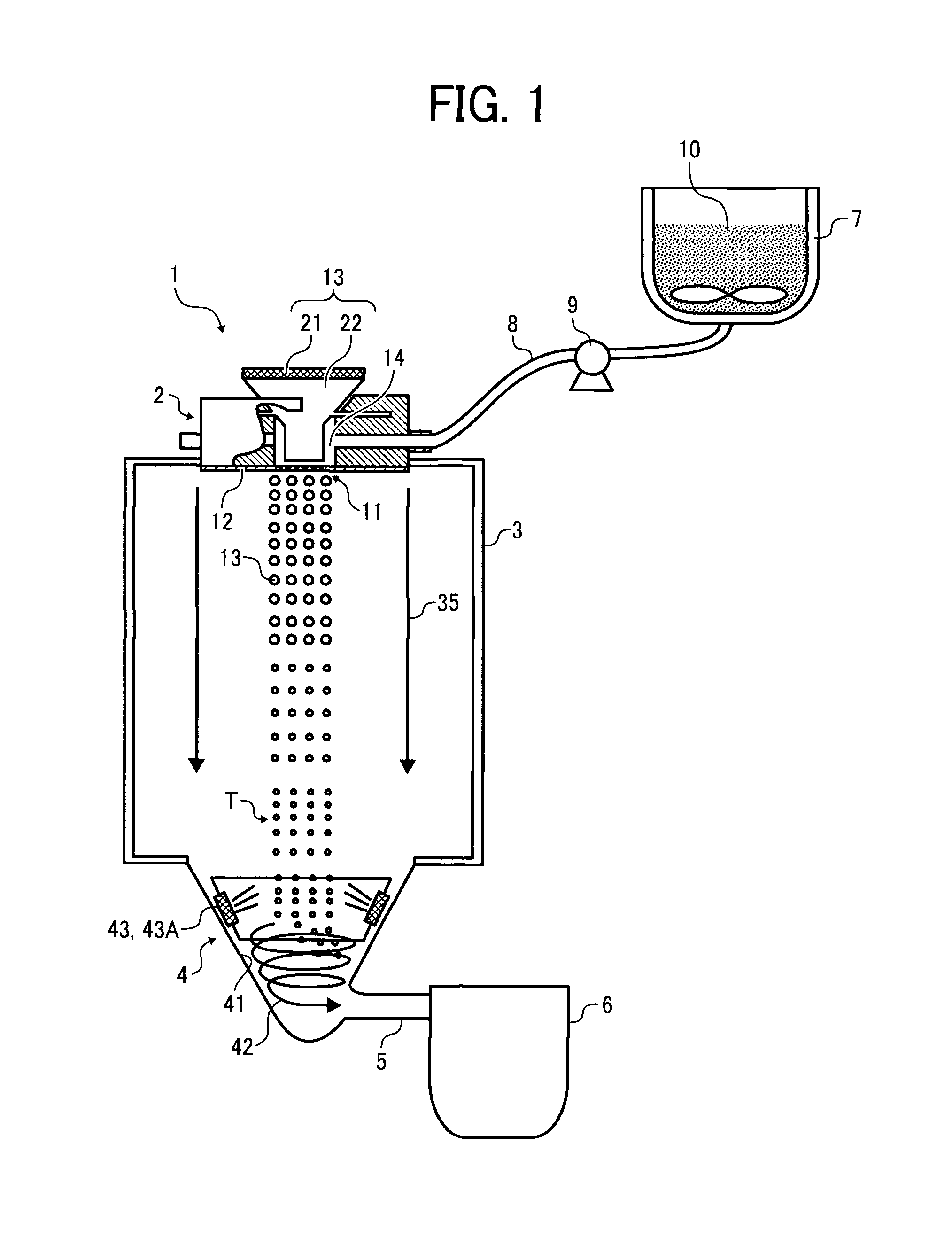

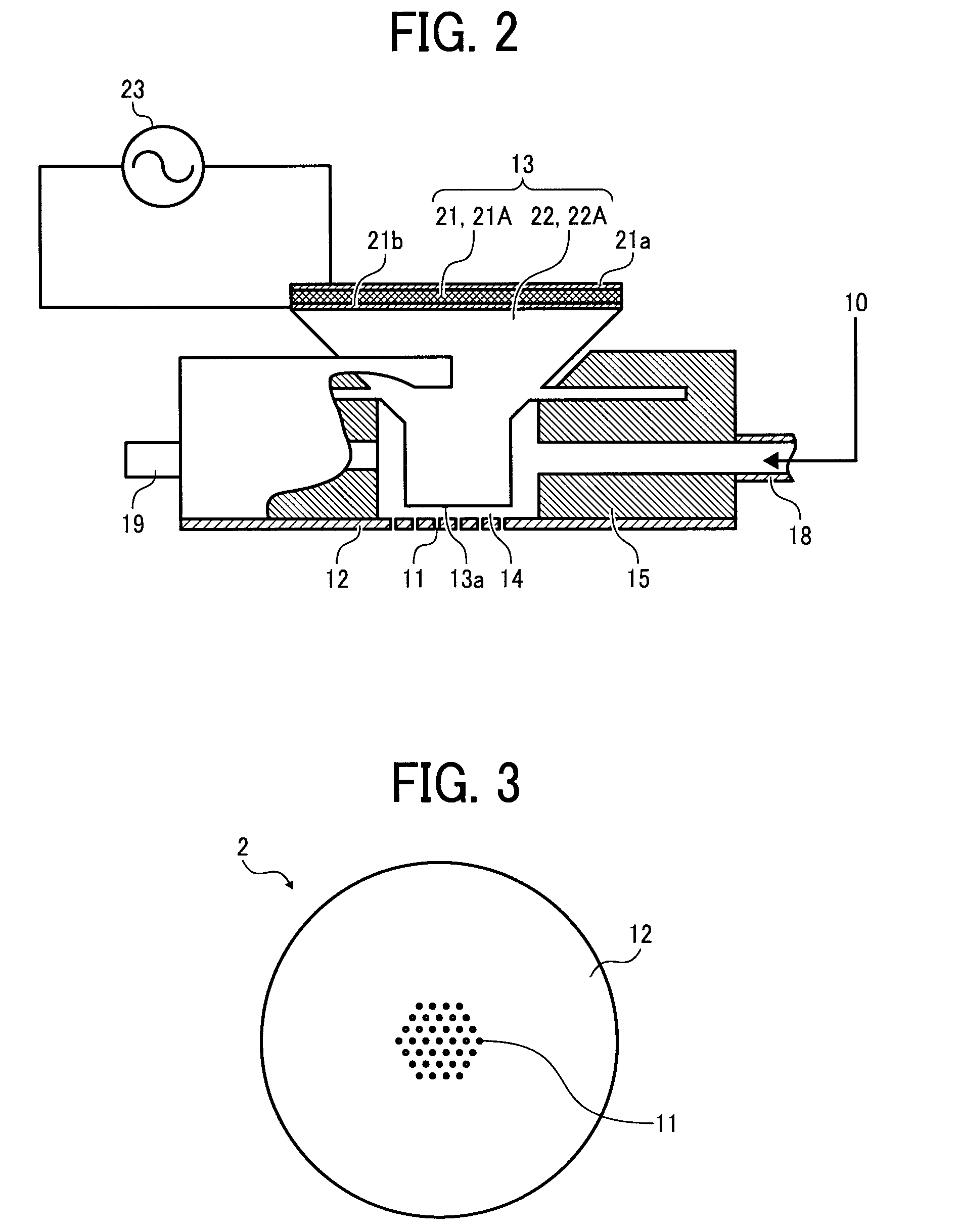

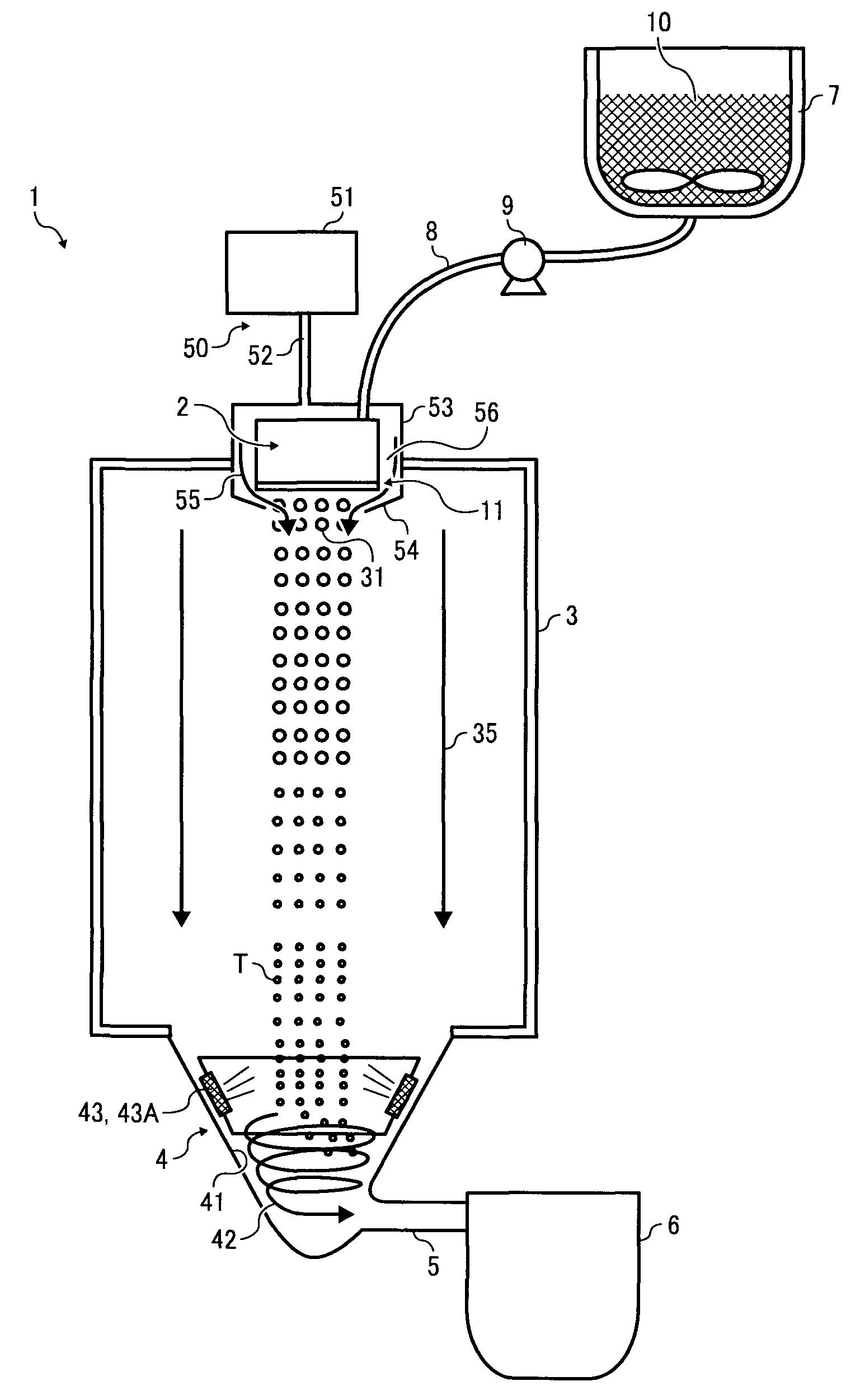

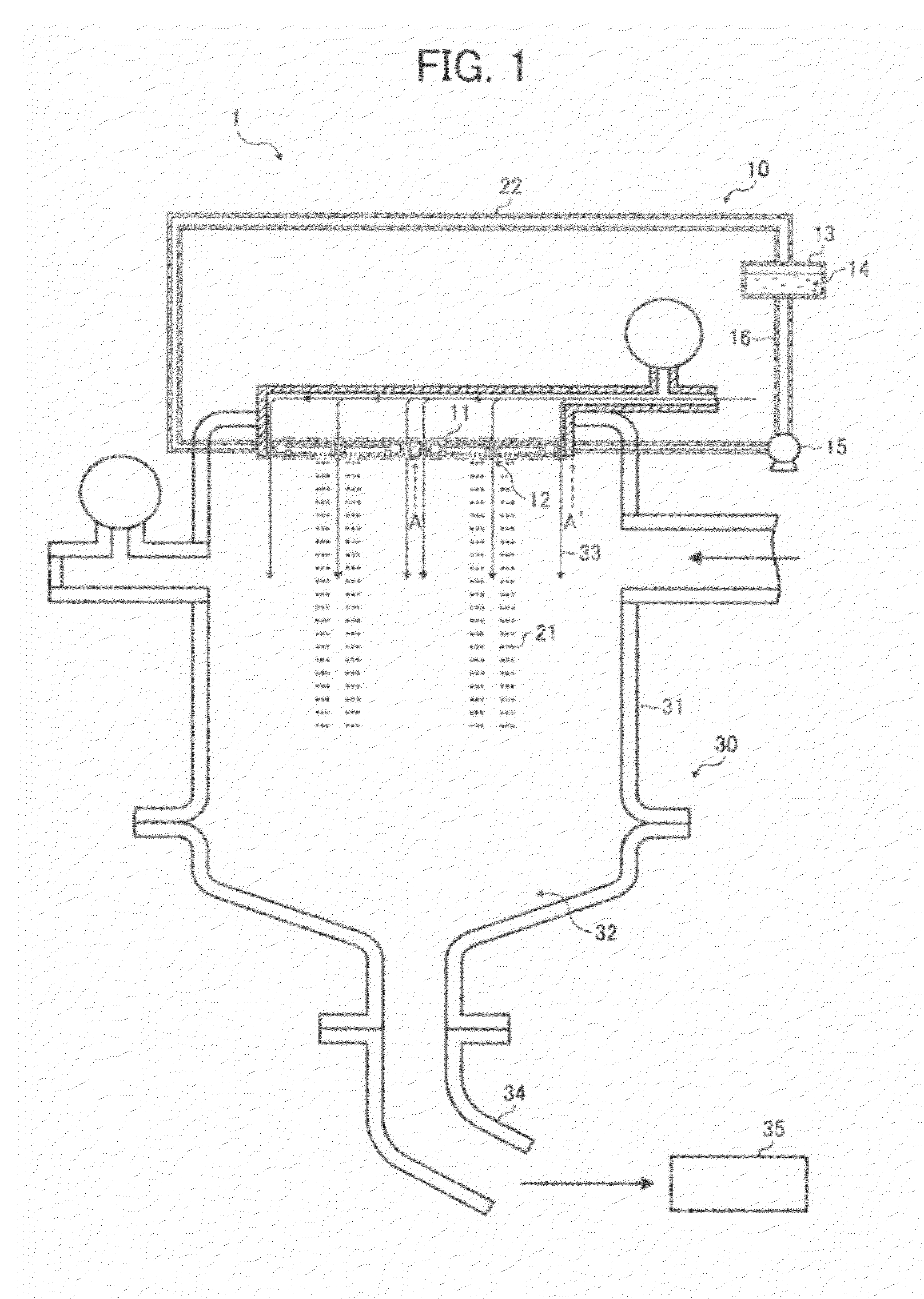

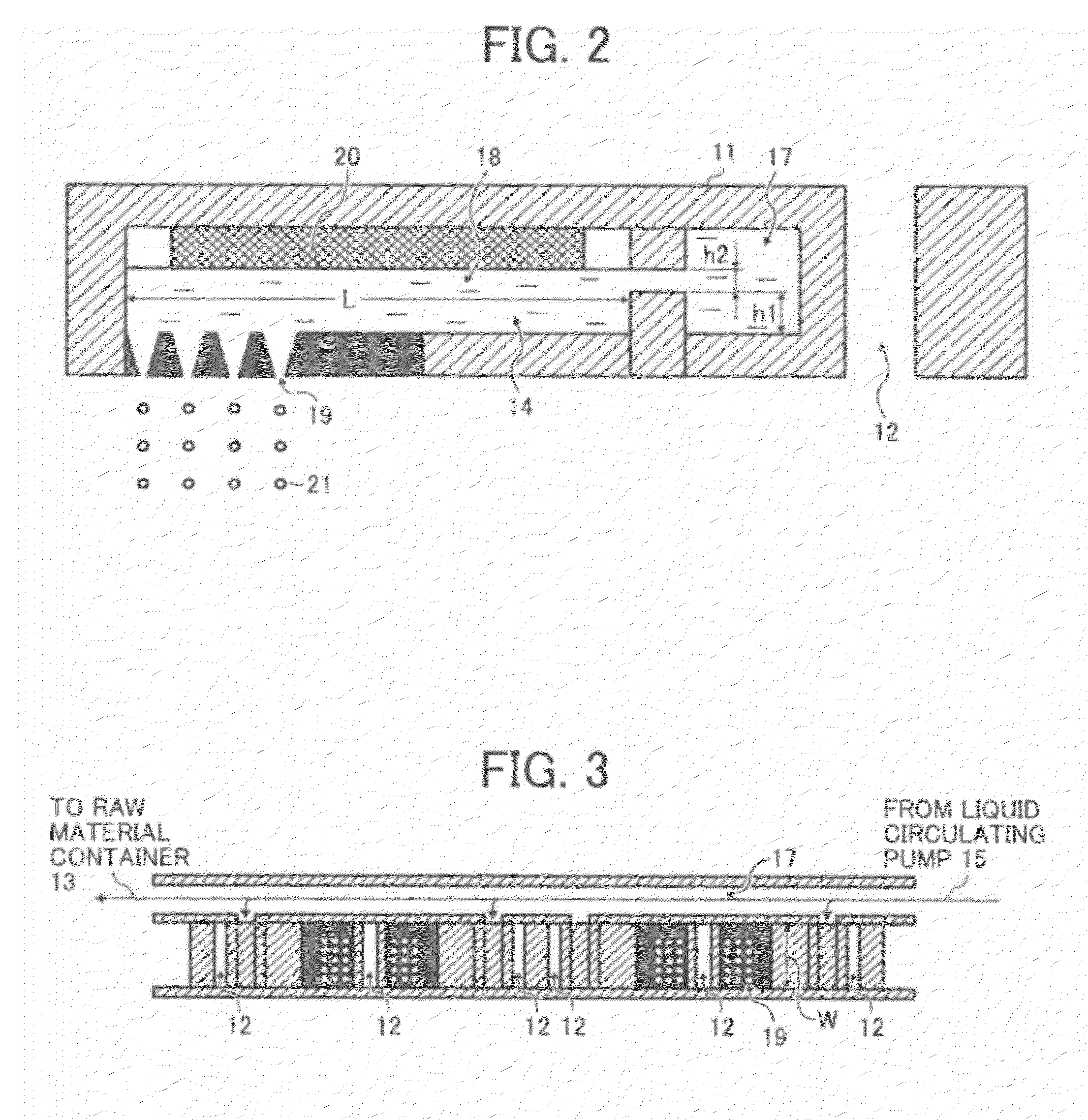

Production apparatus of monodisperse particle and production process of monodisperse particle and monodisperse particle produced by the process

InactiveUS20020089100A1Highly multi-purpose monodisperse particle industrially and cheaplyEasy to controlTransportation and packagingMetal-working apparatusMetallurgySlurry

It is the object to provide a production process of monodisperse particle in which monodisperse particle with uniform particle size (particle diameter) can be stably mass-produced, and monodisperse particle produced by this process, and its production apparatus. The supply pipe diameter deltaf is set to be greater than the orifice diameter deltao and the internal and external pressure of the slurry retention part b is controlled, and this allows to facilitate supply of the slurry through the supply pipe (21c), and continuously and efficiently supply the slurry, and then to produce monodisperse particle with uniform particle size (particle diameter).

Owner:KAWASAKI CORP KK

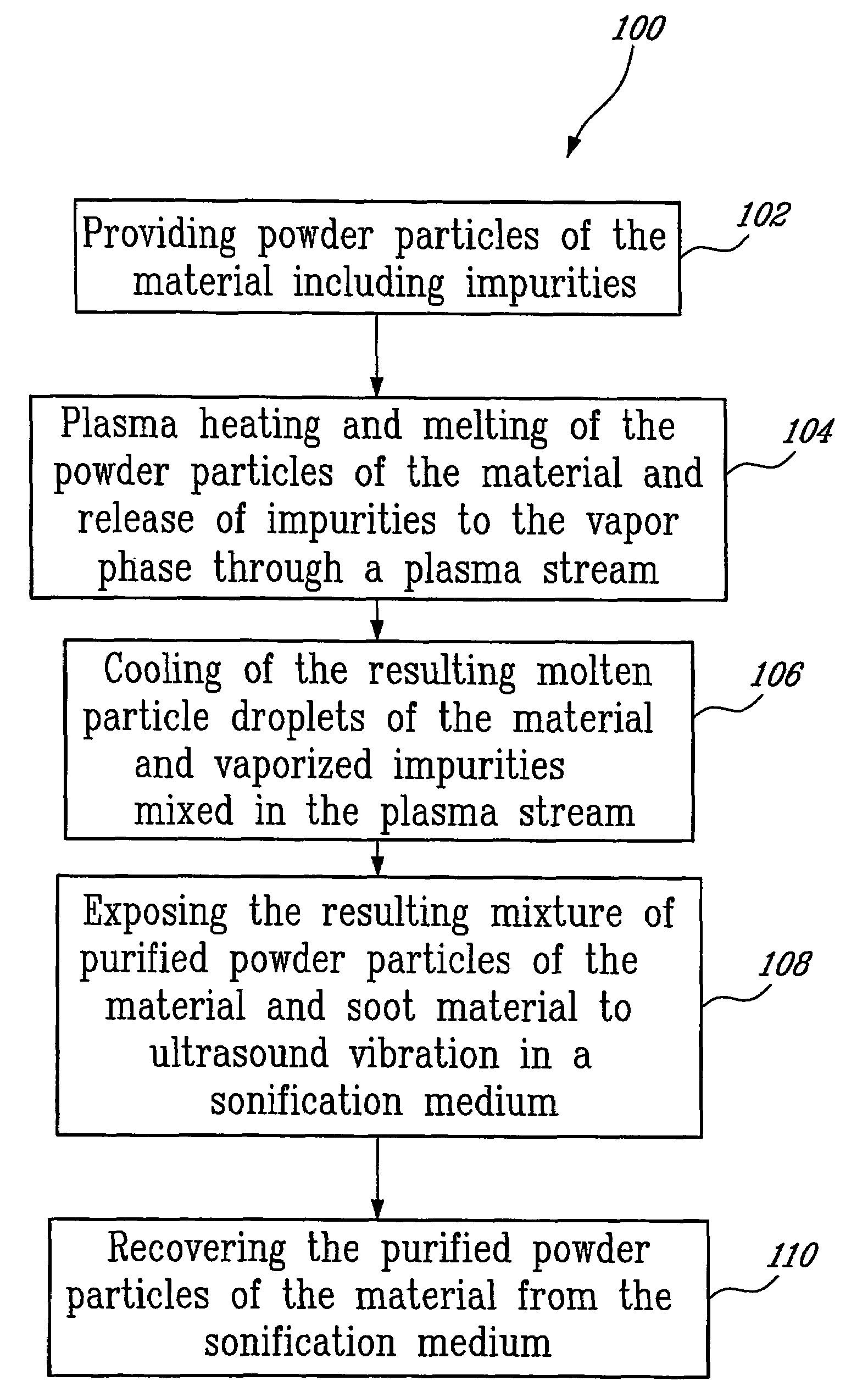

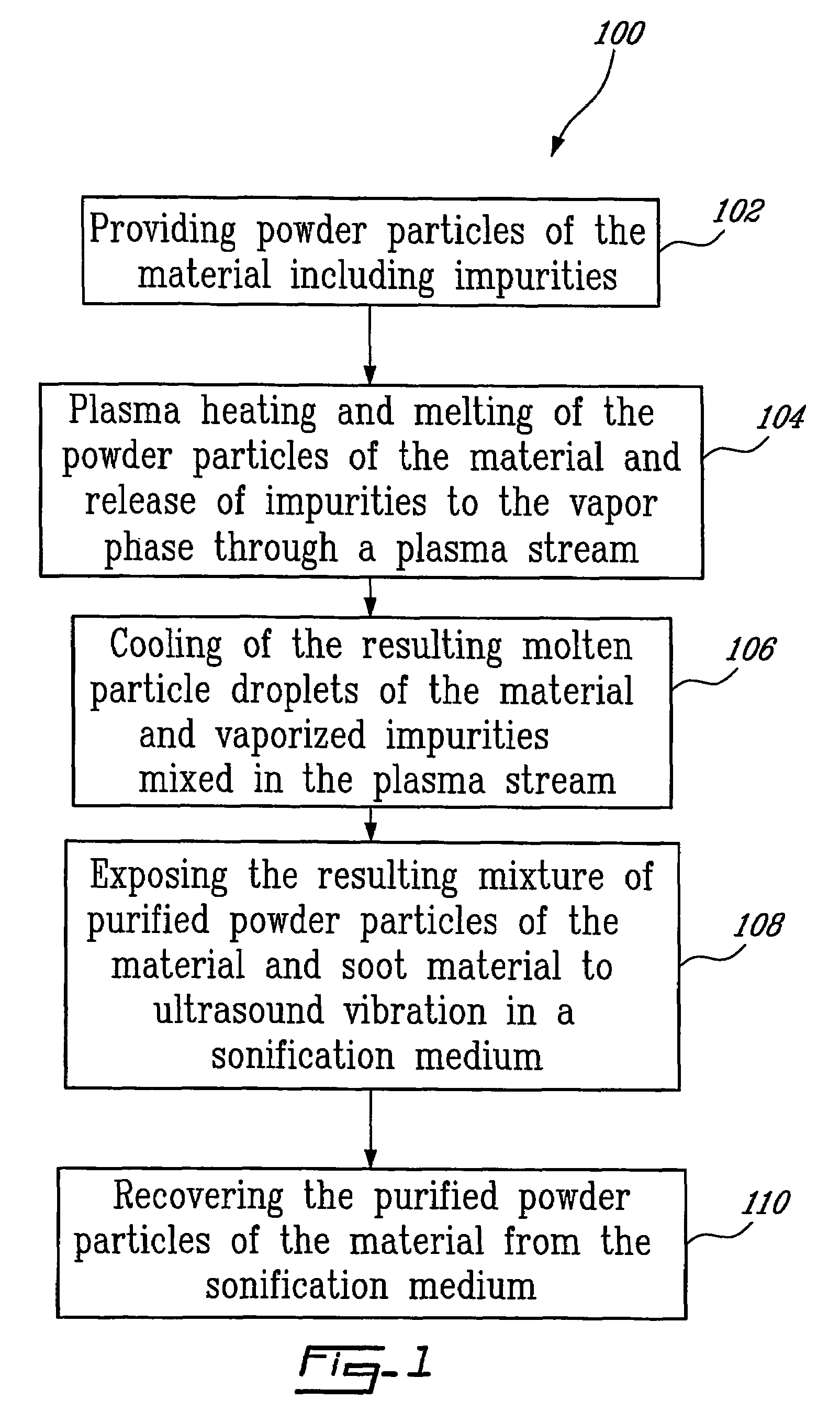

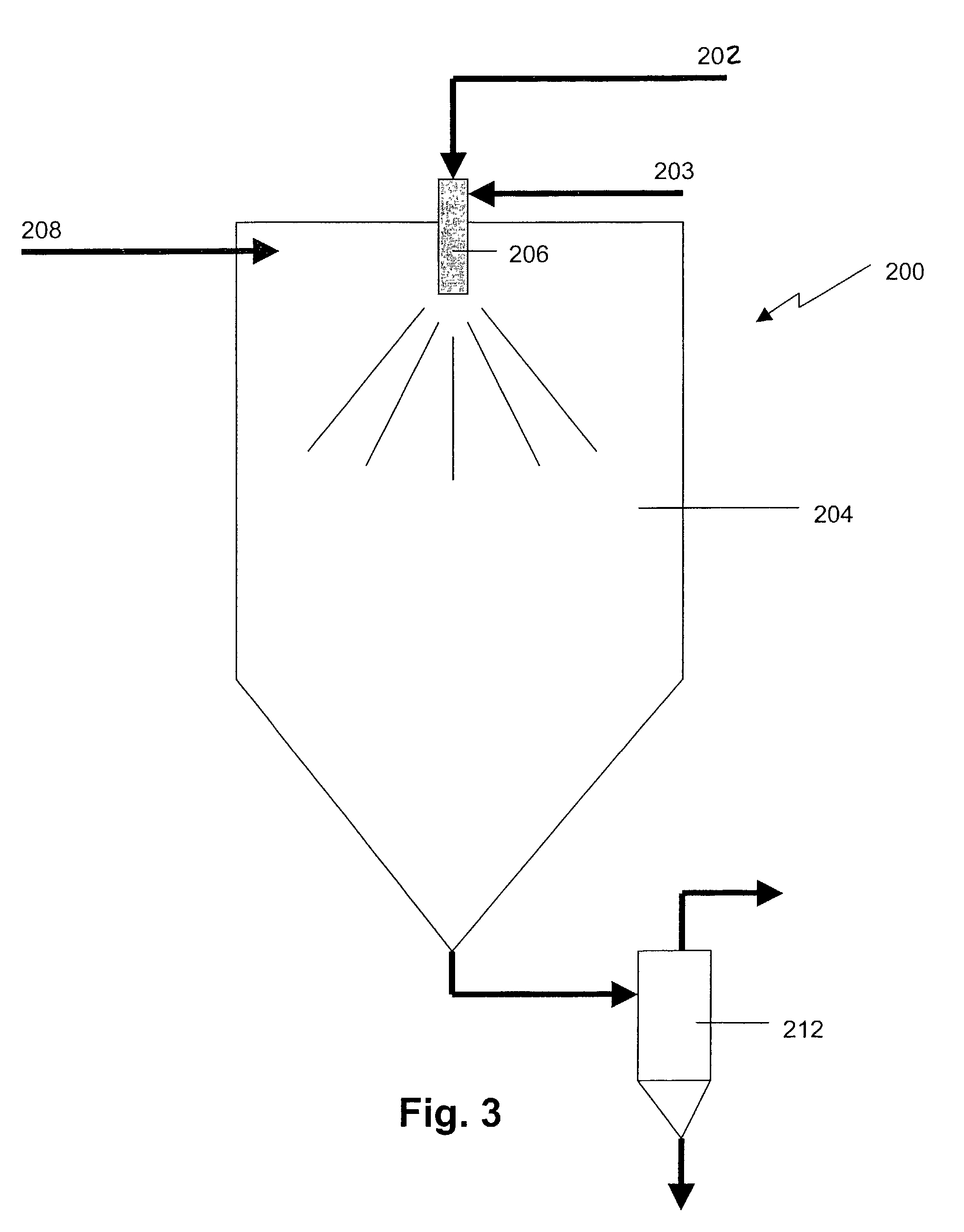

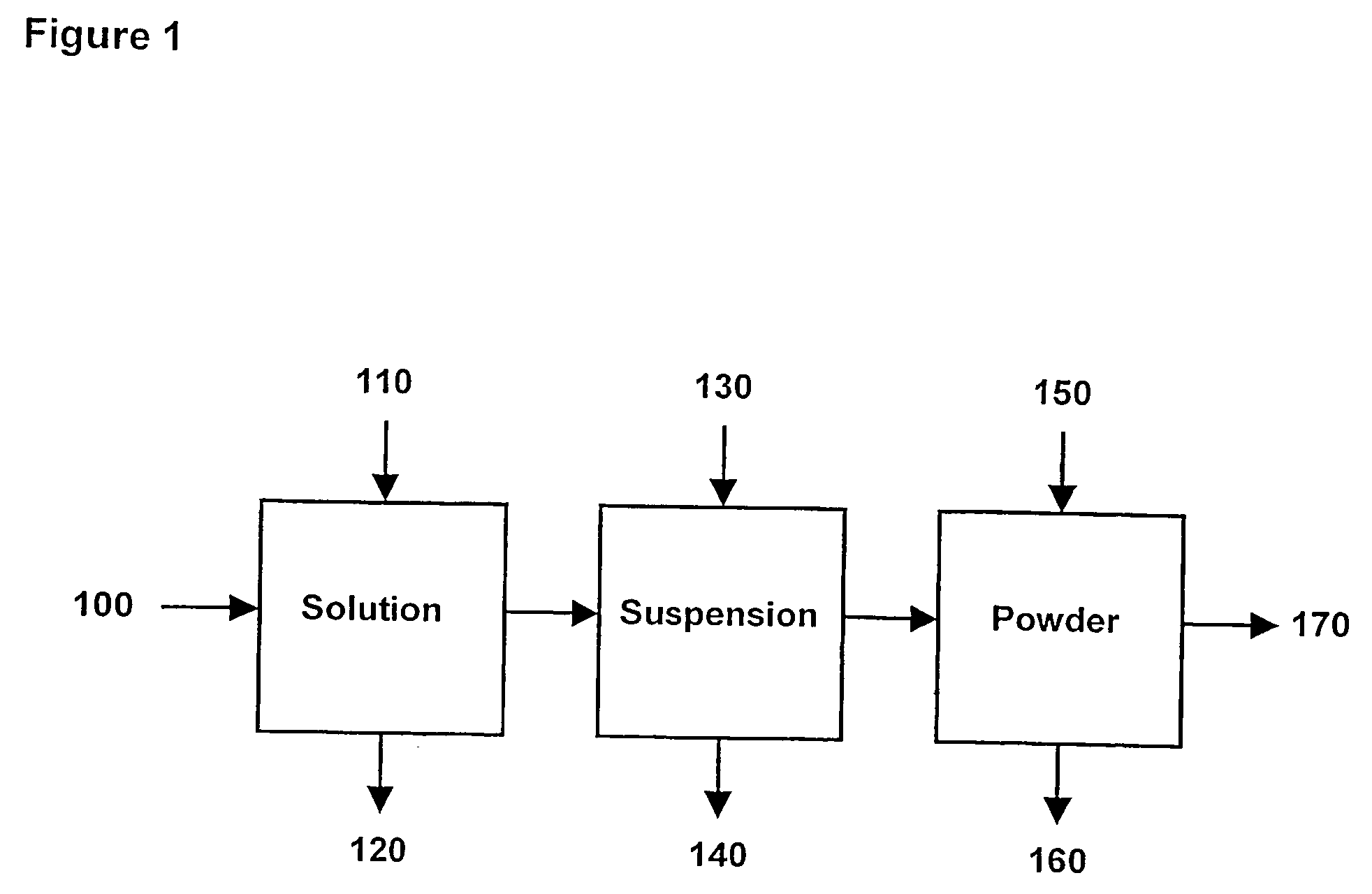

Process for the synthesis, separation and purification of powder materials

ActiveUS7572315B2Speed up the processTransportation and packagingMetal-working apparatusPurification methodsVaporization

Owner:TEKNA PLASMA SYST INC

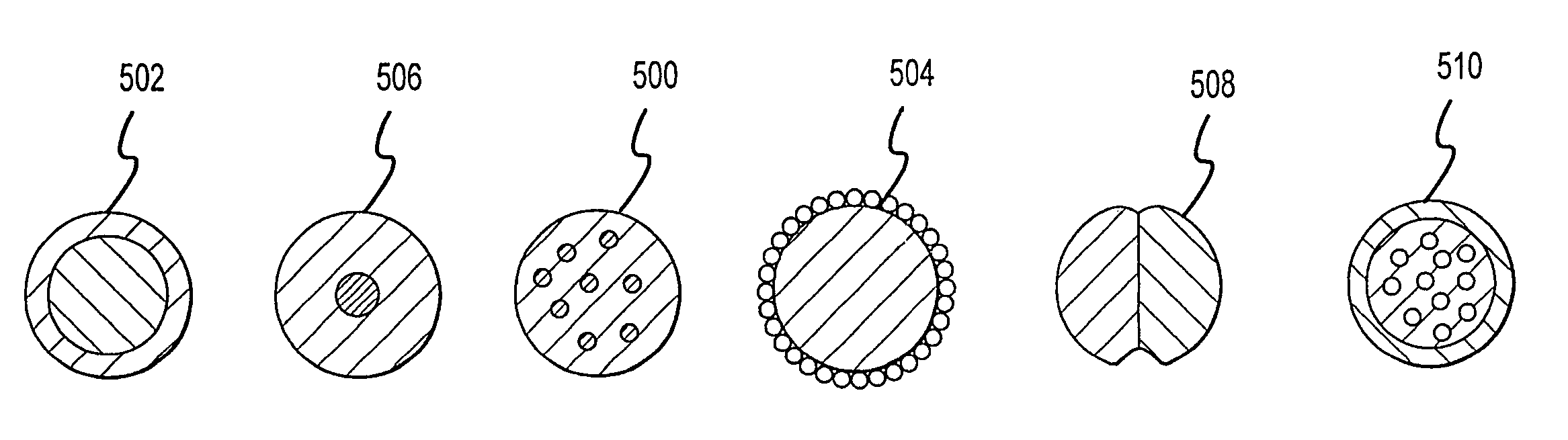

Coated nickel-containing powders, methods and apparatus for producing such powders and devices fabricated from same

InactiveUS20050097988A1High rateIncrease loadMaterial granulation and coatingGranule coatingSpherical morphologySmall particle

Nickel powder batches including coated nickel-containing particles and methods for producing the same. The coated nickel-containing particles having have a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the coated nickel-containing particles.

Owner:CABOT CORP

Membrane electrode assemblies for use in fuel cells

InactiveUS20030064265A1High purityImprove electrocatalytic activityGranule coatingCell electrodesCarbon compositesFuel cells

Owner:CABOT CORP

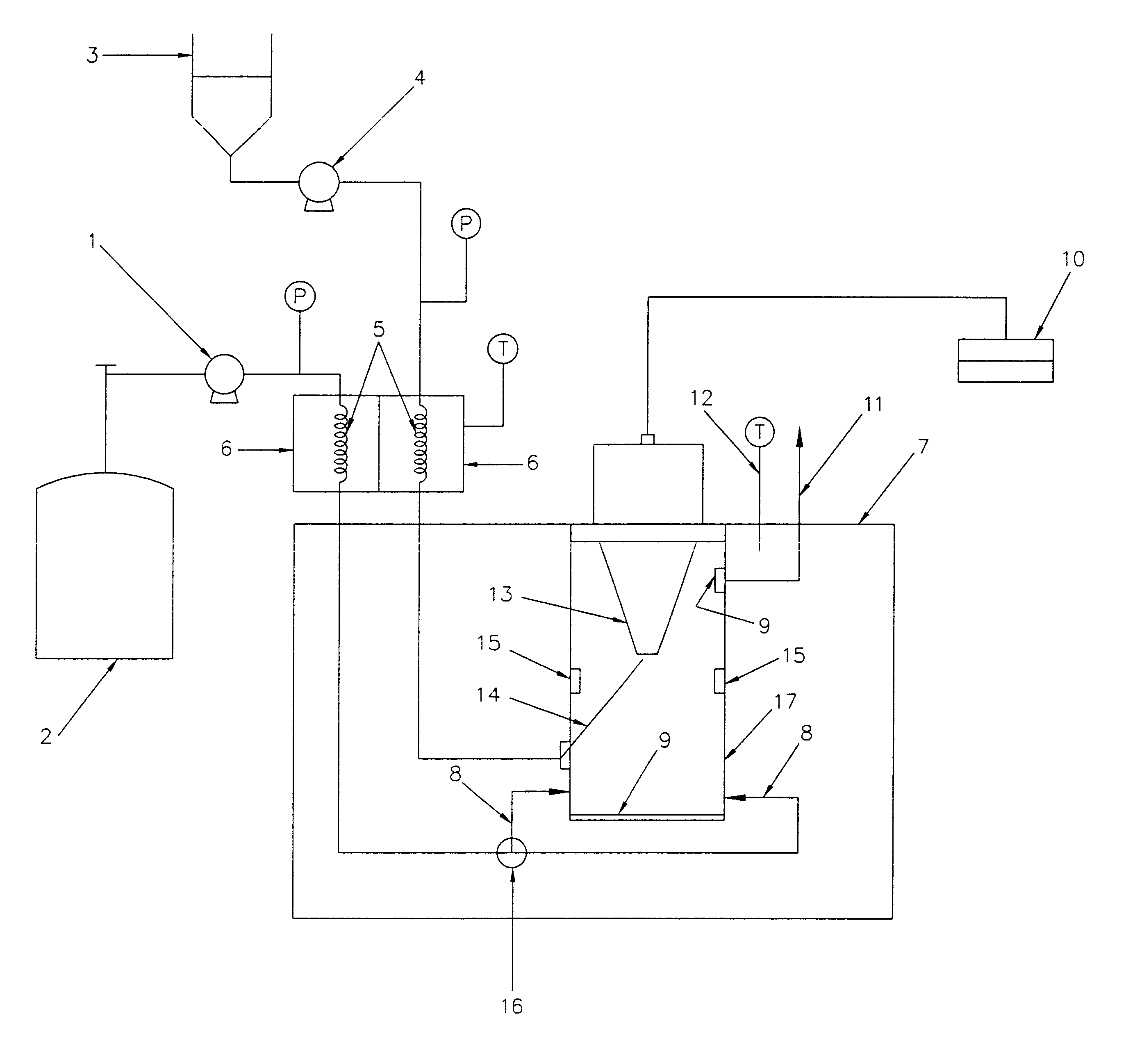

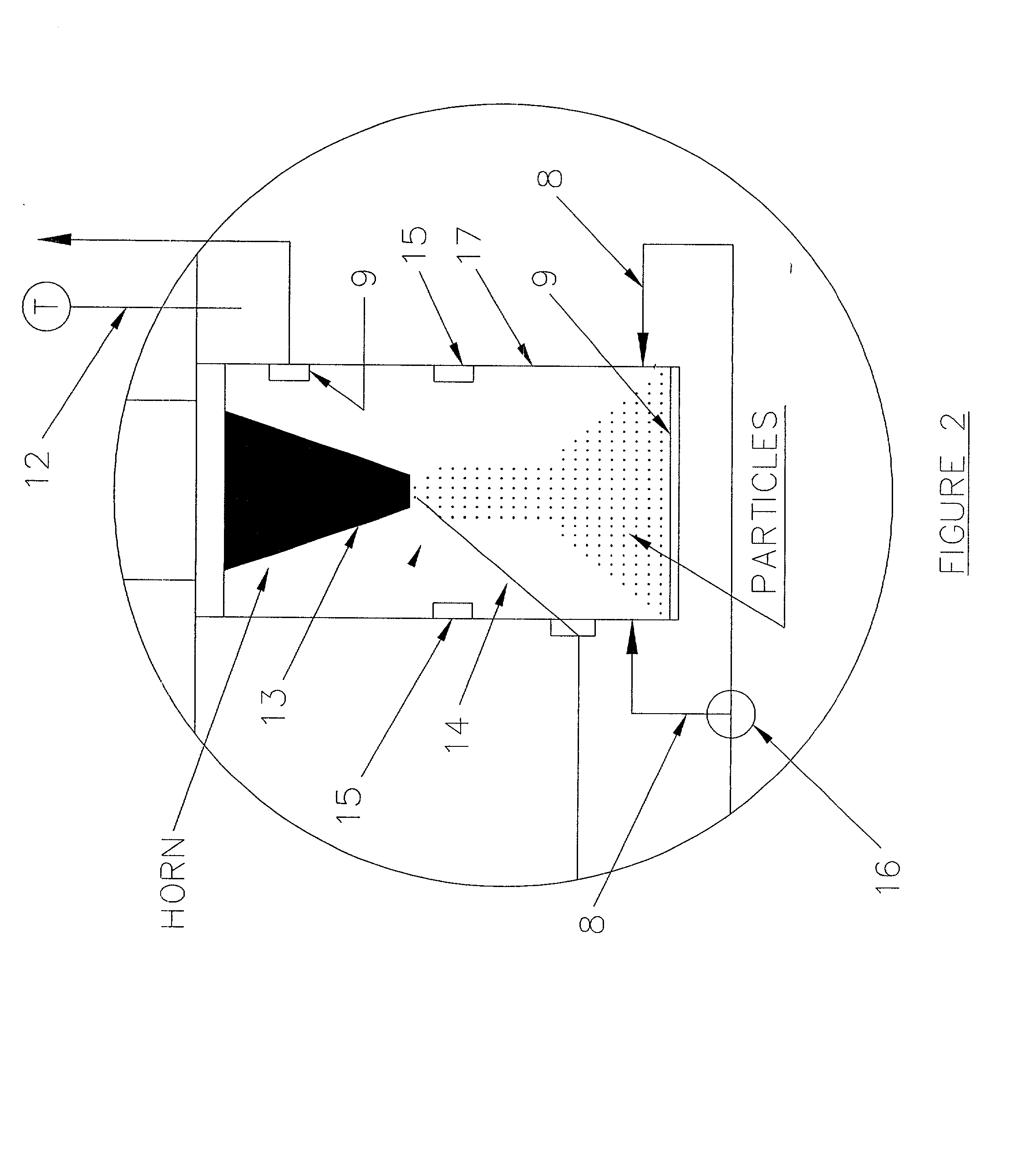

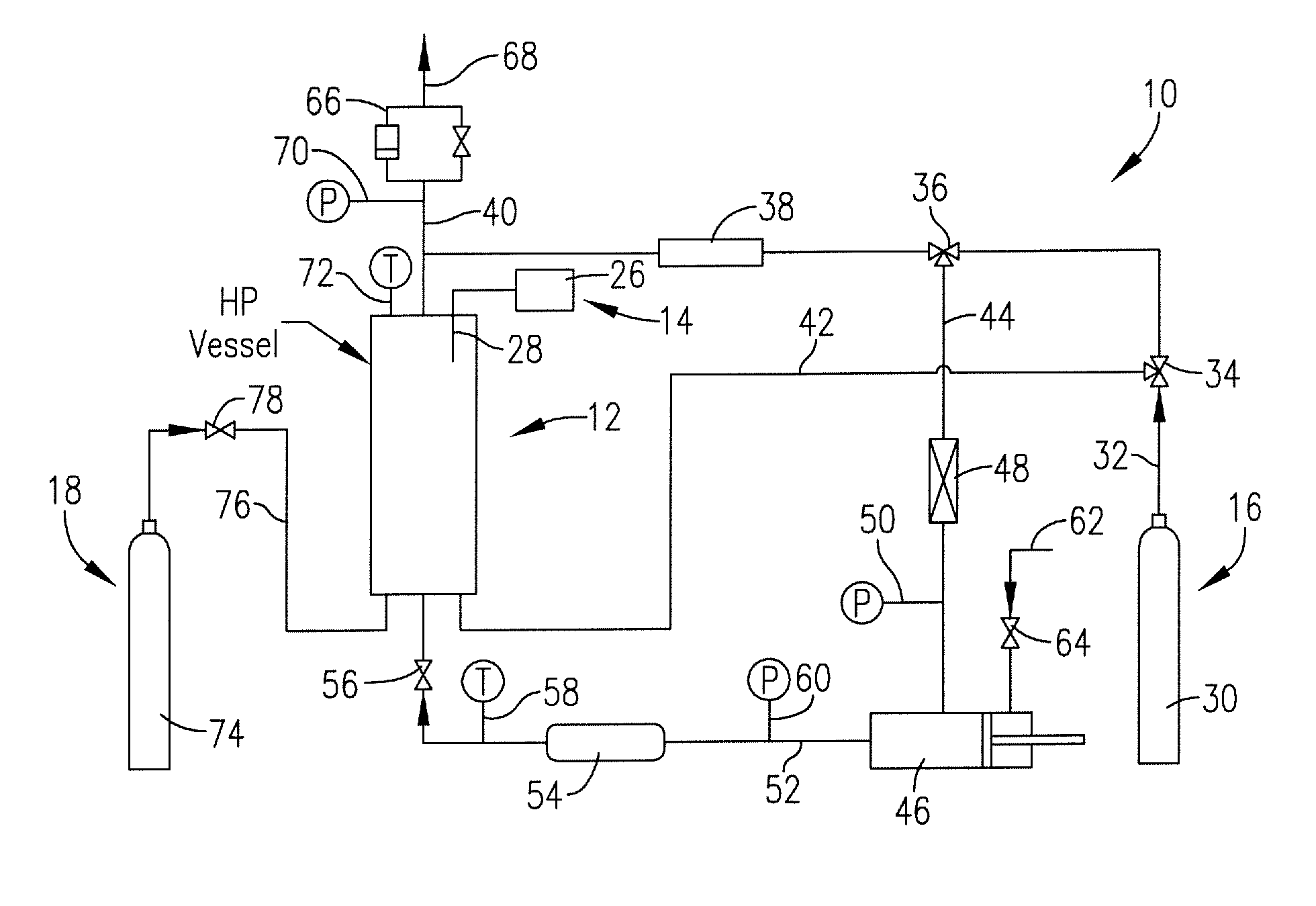

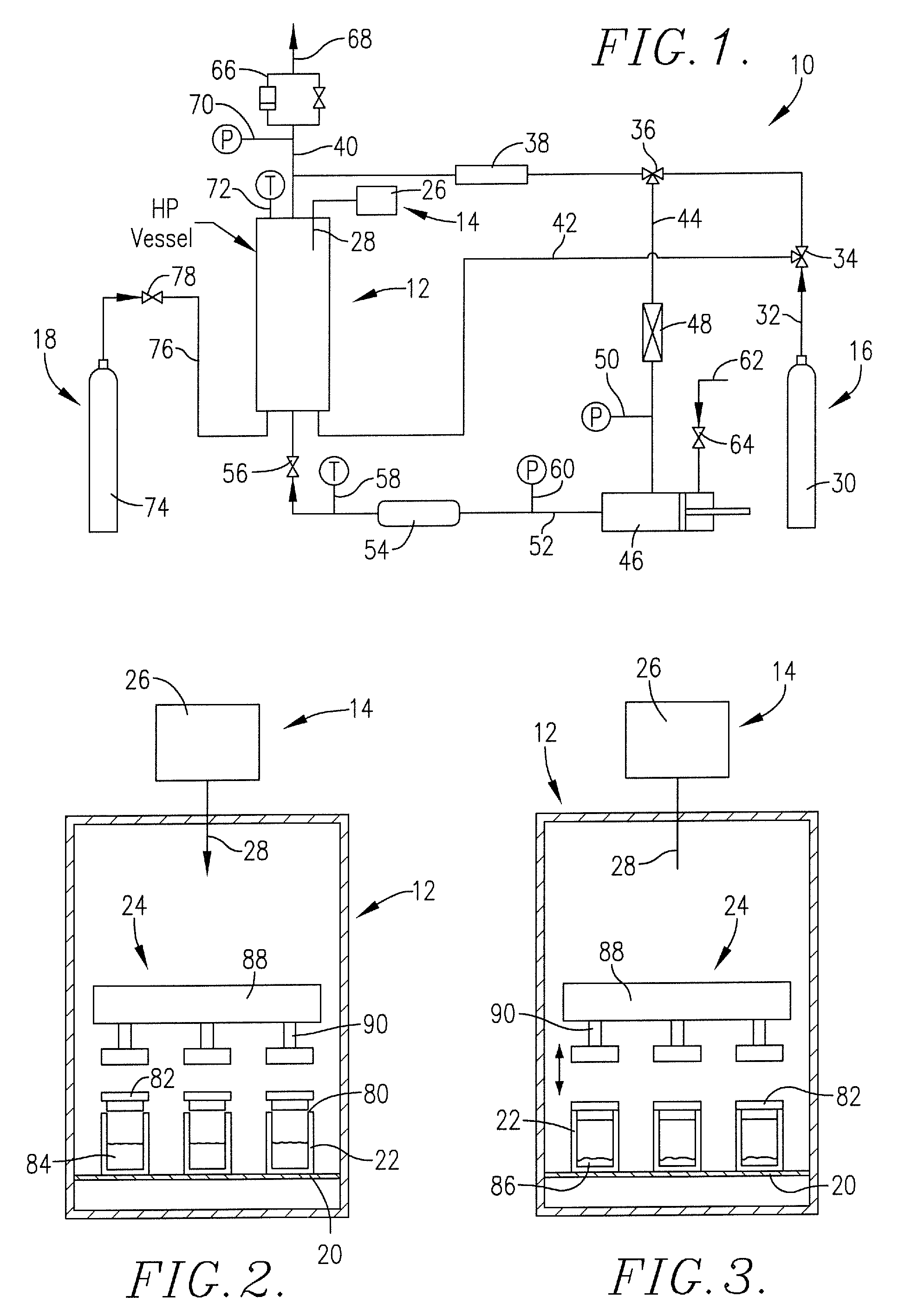

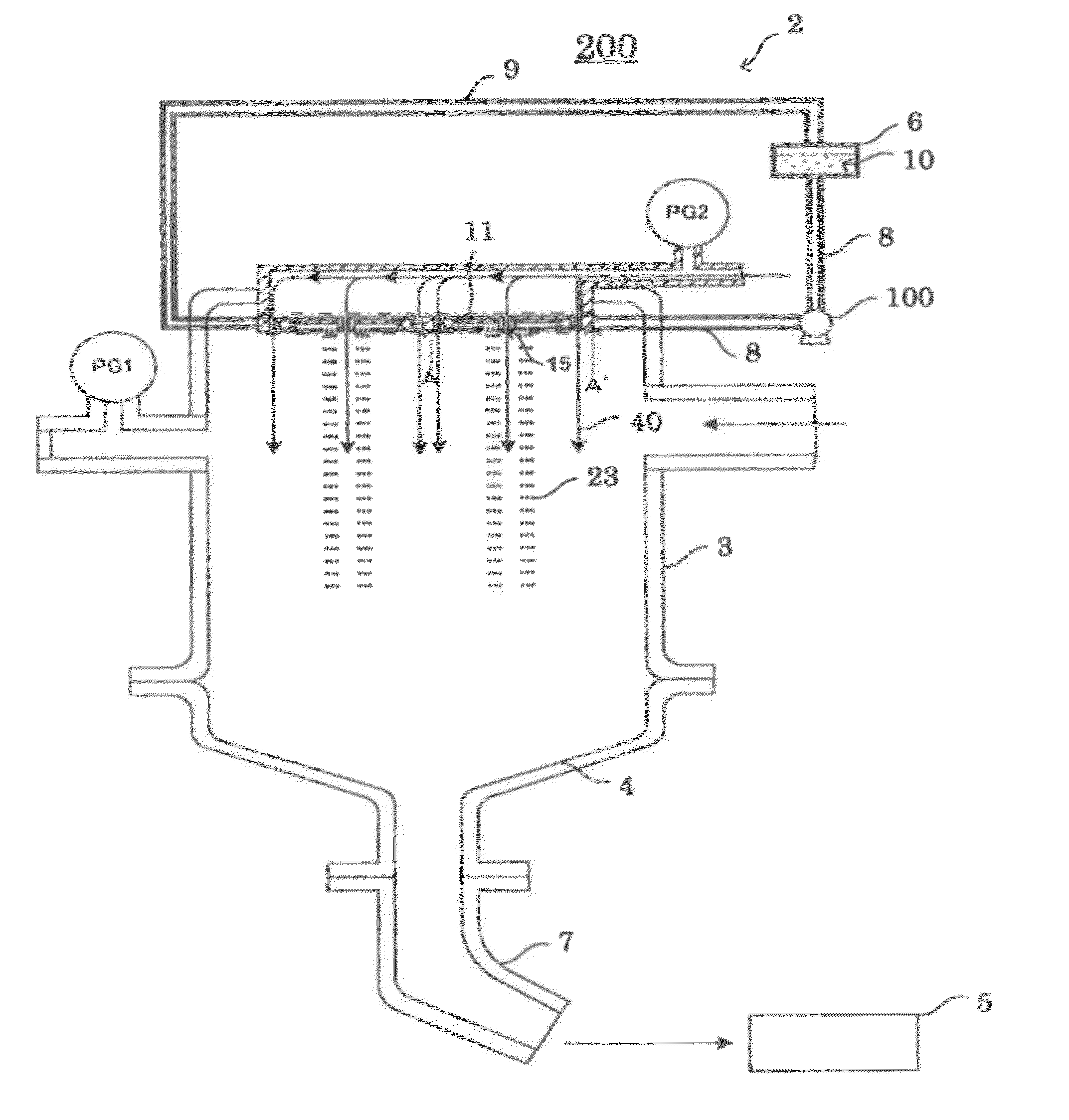

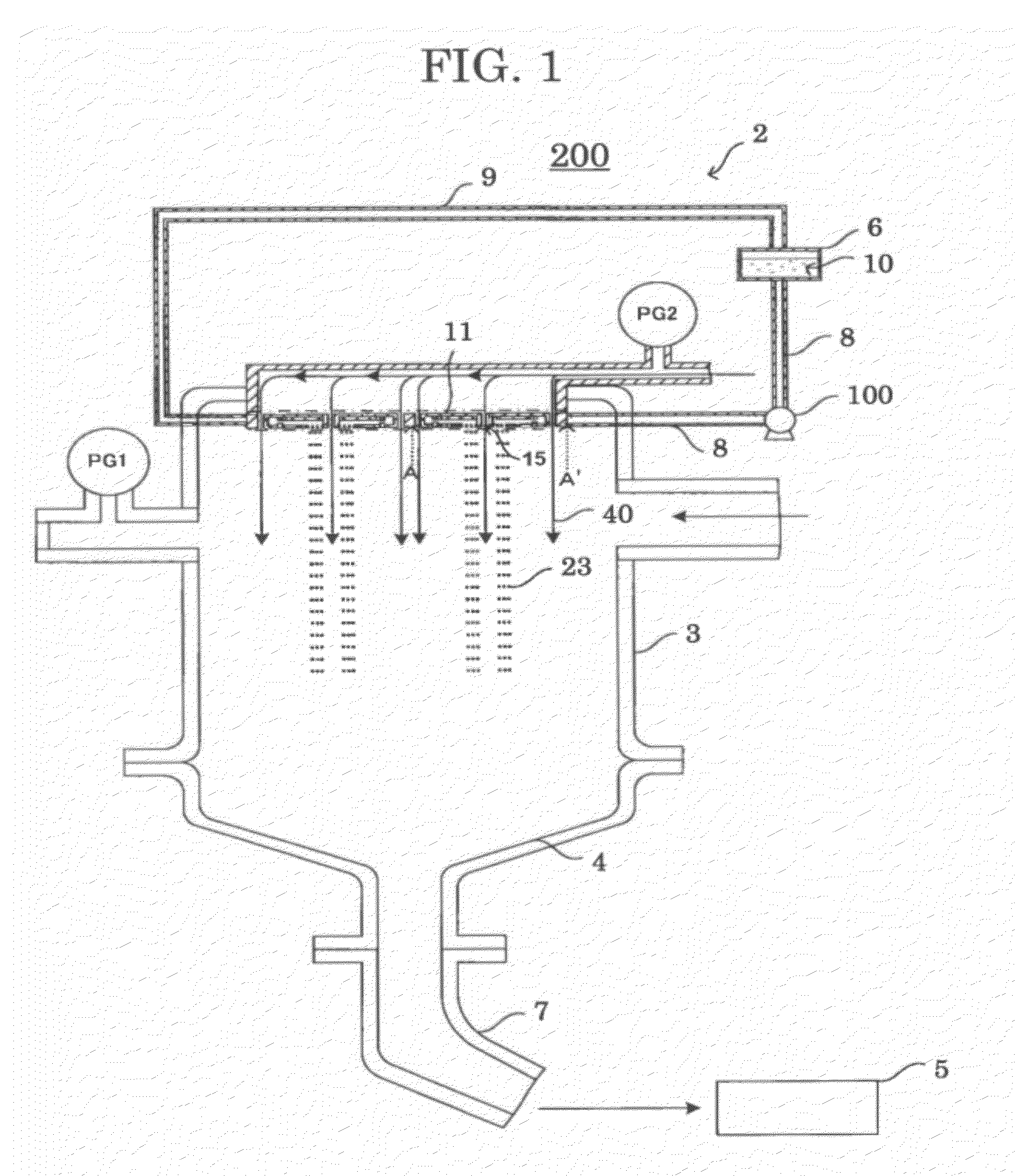

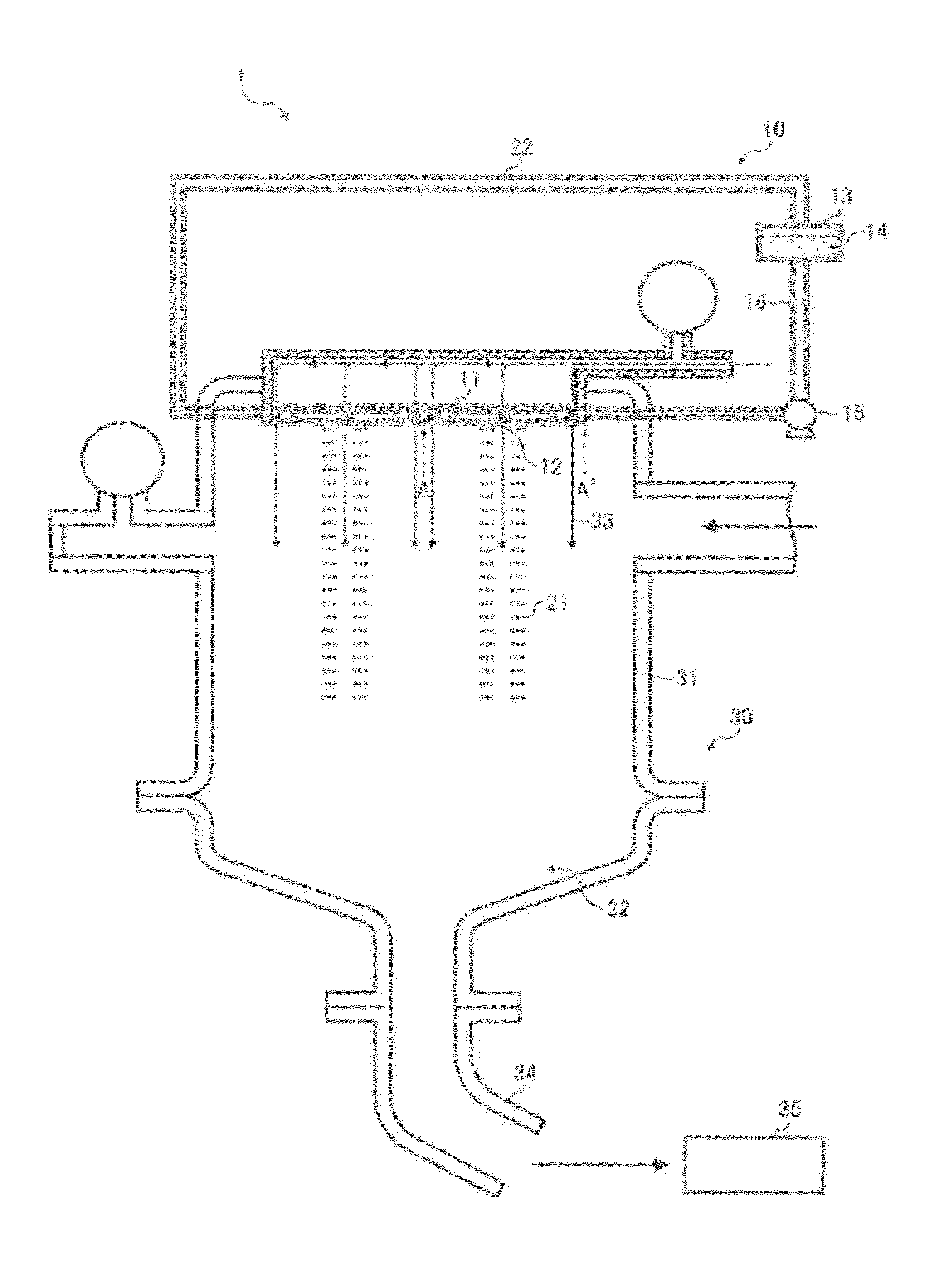

Method for precipitation of small medicament particles into use containers

ActiveUS7744923B2Preventing overflow of liquidPowder deliveryGranulation by liquid drop formationHigh energyProcess engineering

Commercially feasible methods for lyophobic precipitation of liquid-dispersed or dissolved material (e.g., medicaments) are provided wherein a plurality of individual, open containers (22) each containing a quantity (84) of a solution or dispersion are treated within a common pressurizable chamber (12). In this process, desired near-supercritical or supercritical temperature and pressure conditions are established for a selected antisolvent gas such as carbon dioxide, and an ultrasonic device (14) is actuated to generate high energy ultrasonic waves in the chamber (12). This leads to intense mixing of the antisolvent with the liquid solution or dispersion within the containers (22), with consequent solvent removal and material precipitation.

Owner:CRITITECH INC

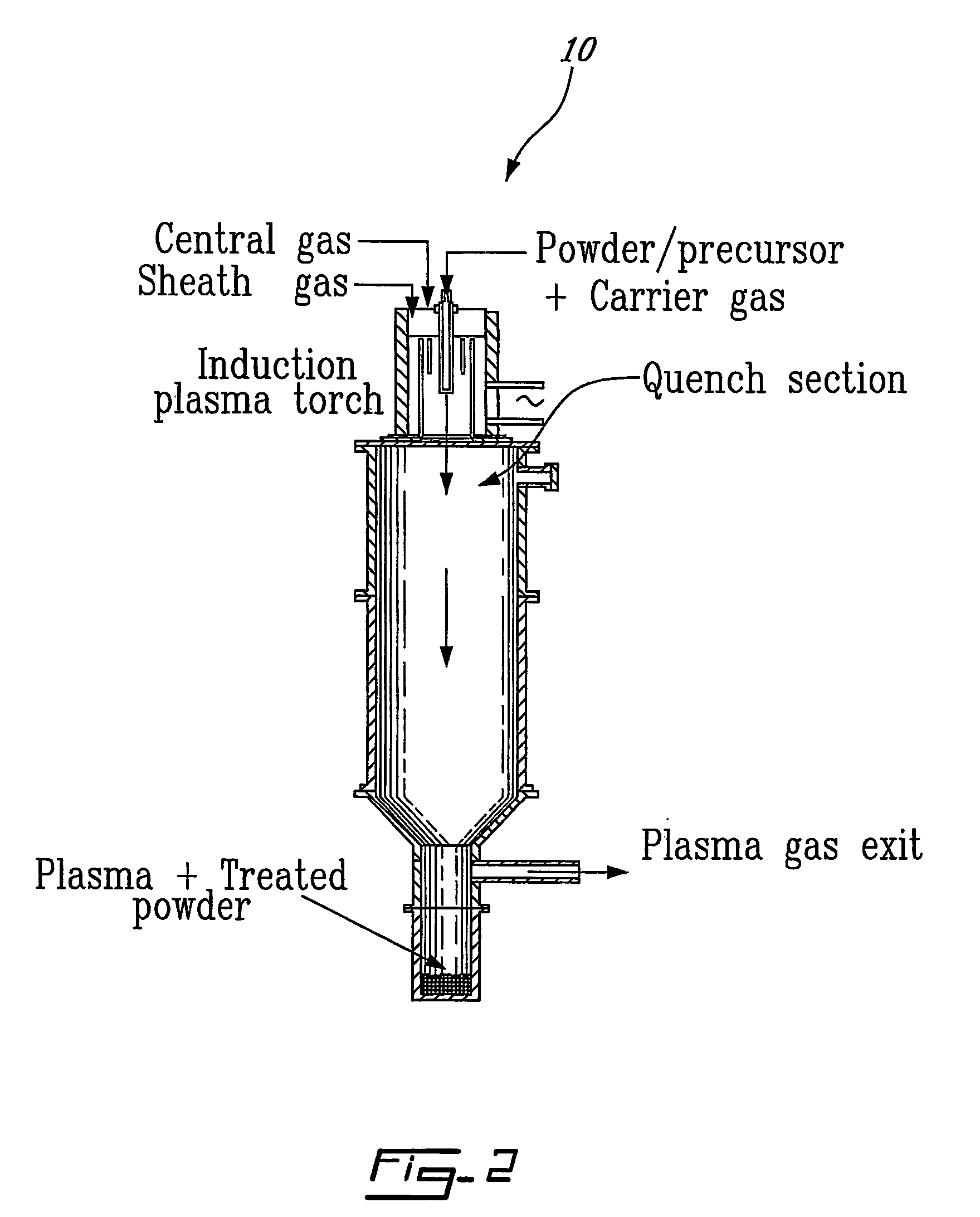

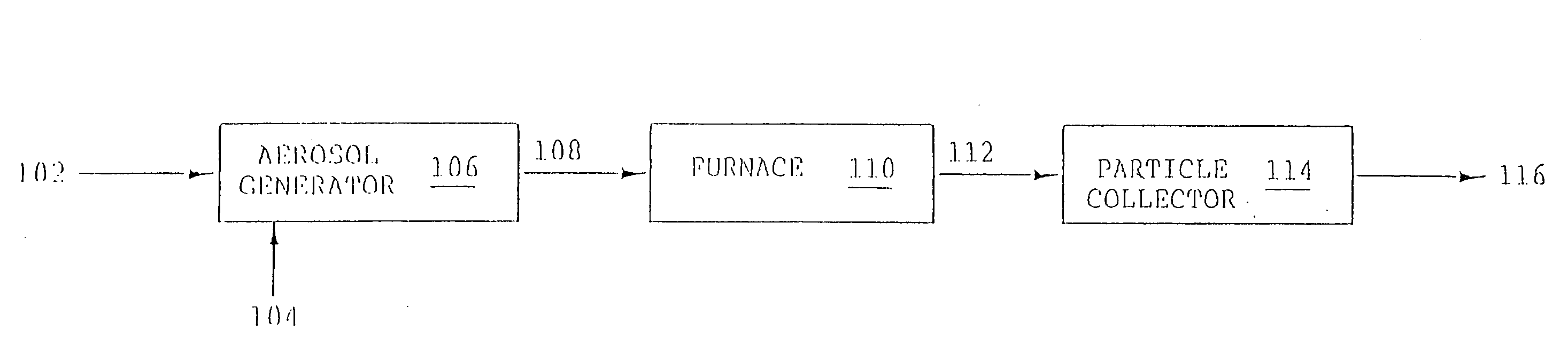

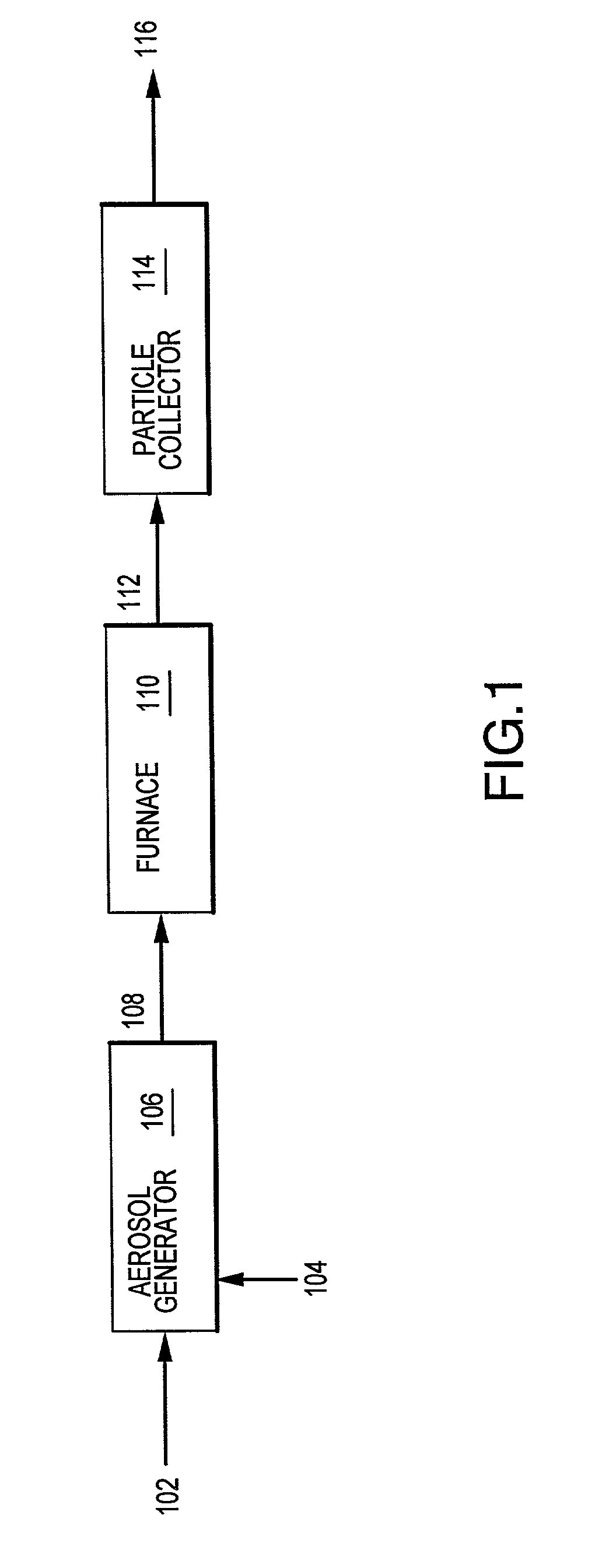

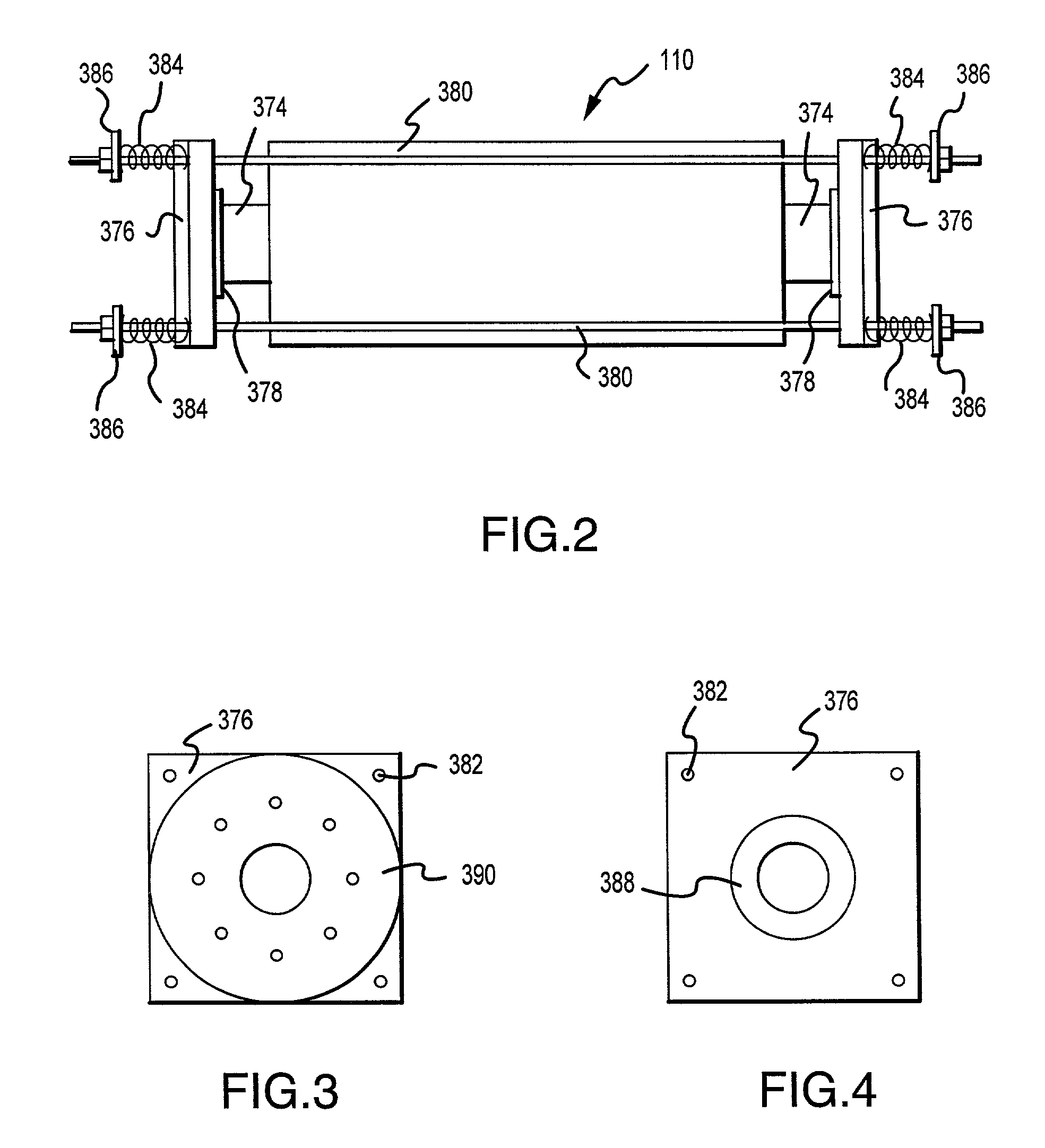

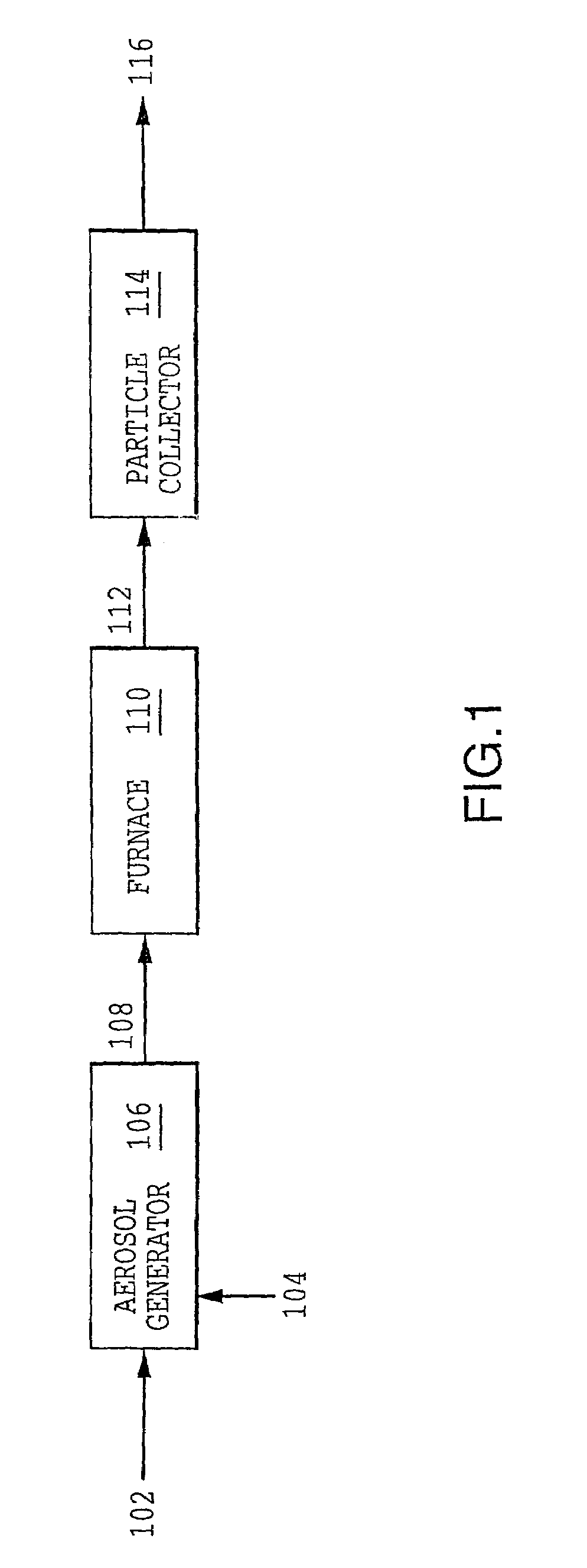

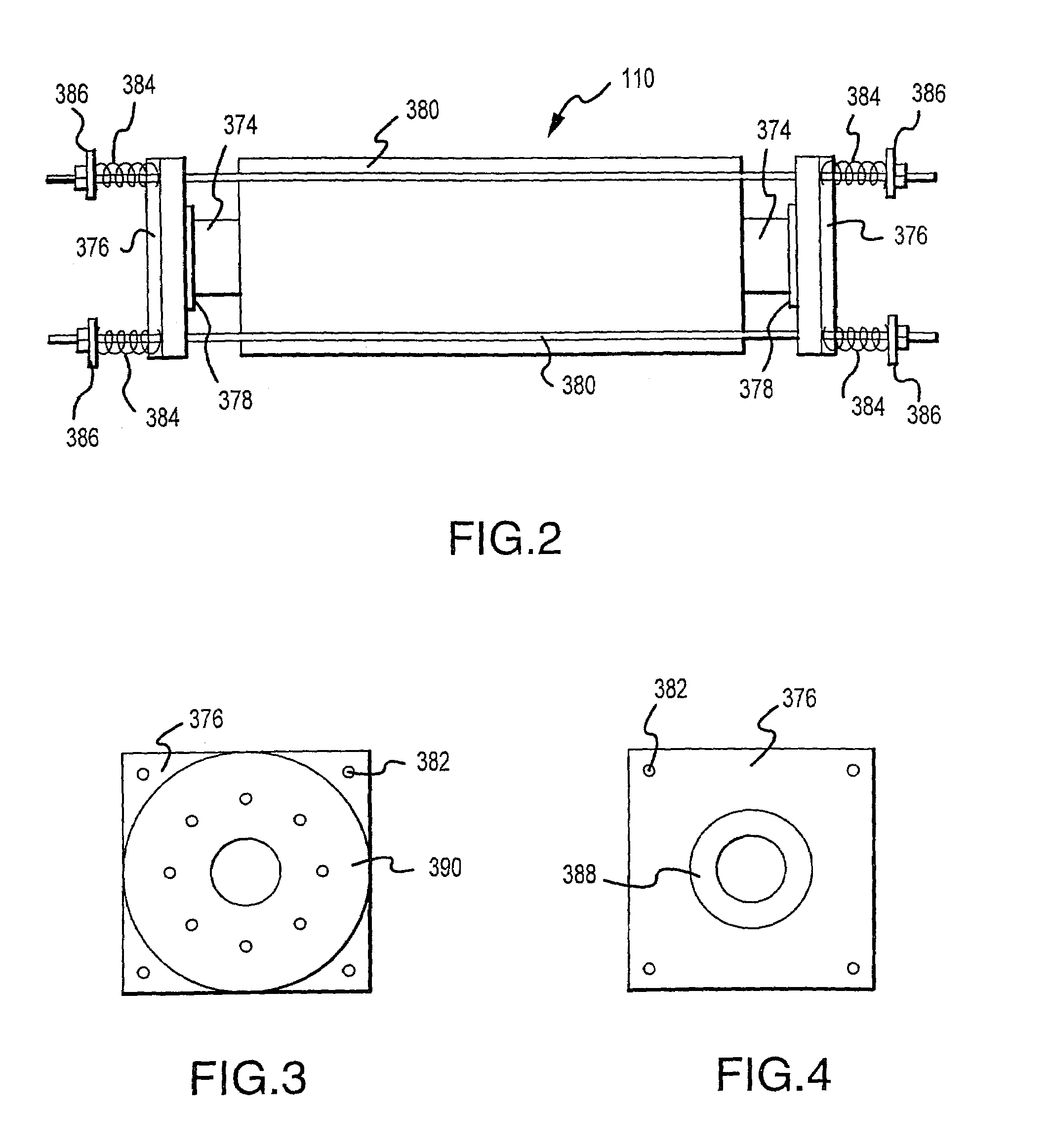

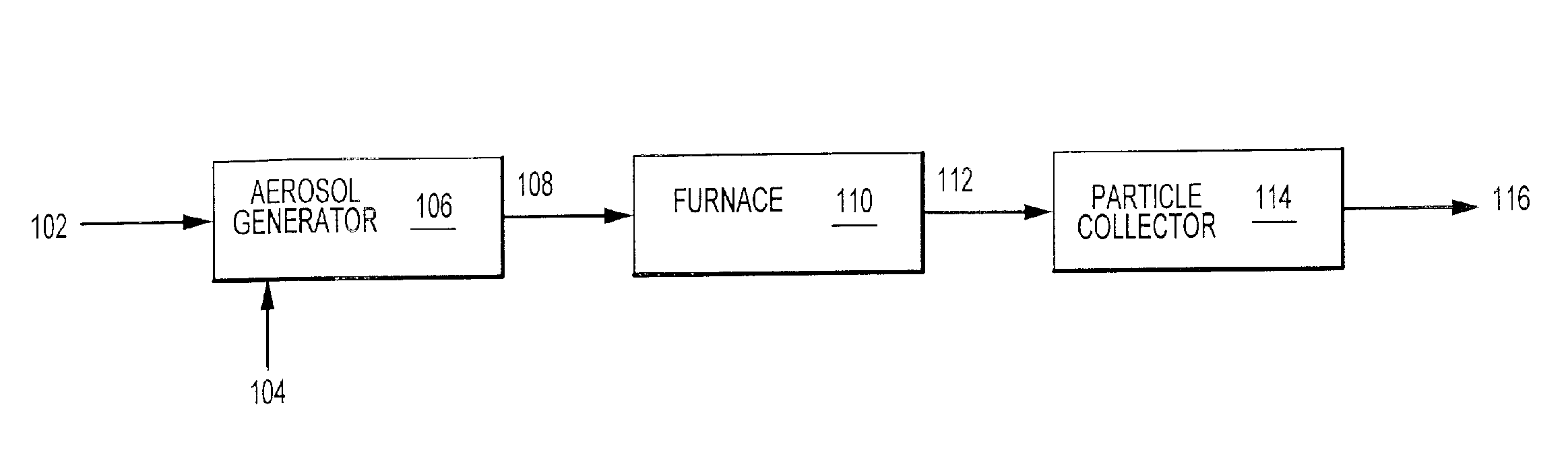

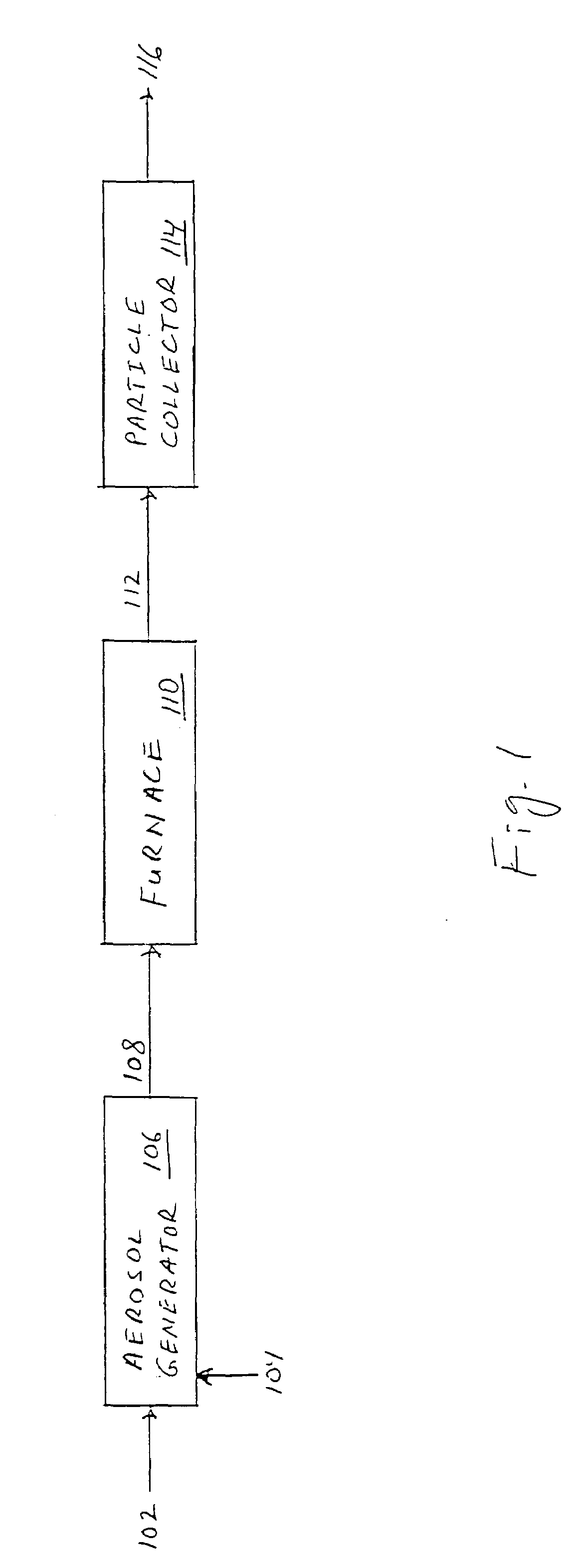

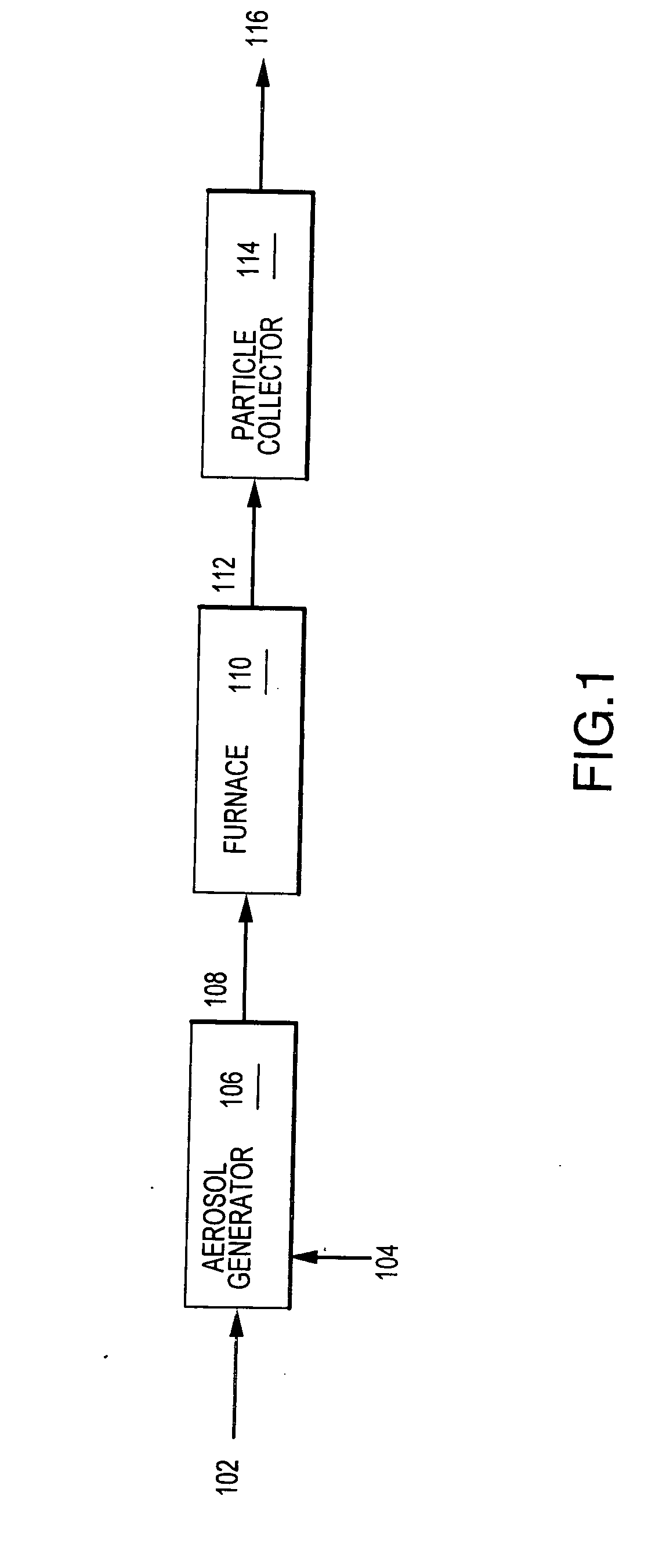

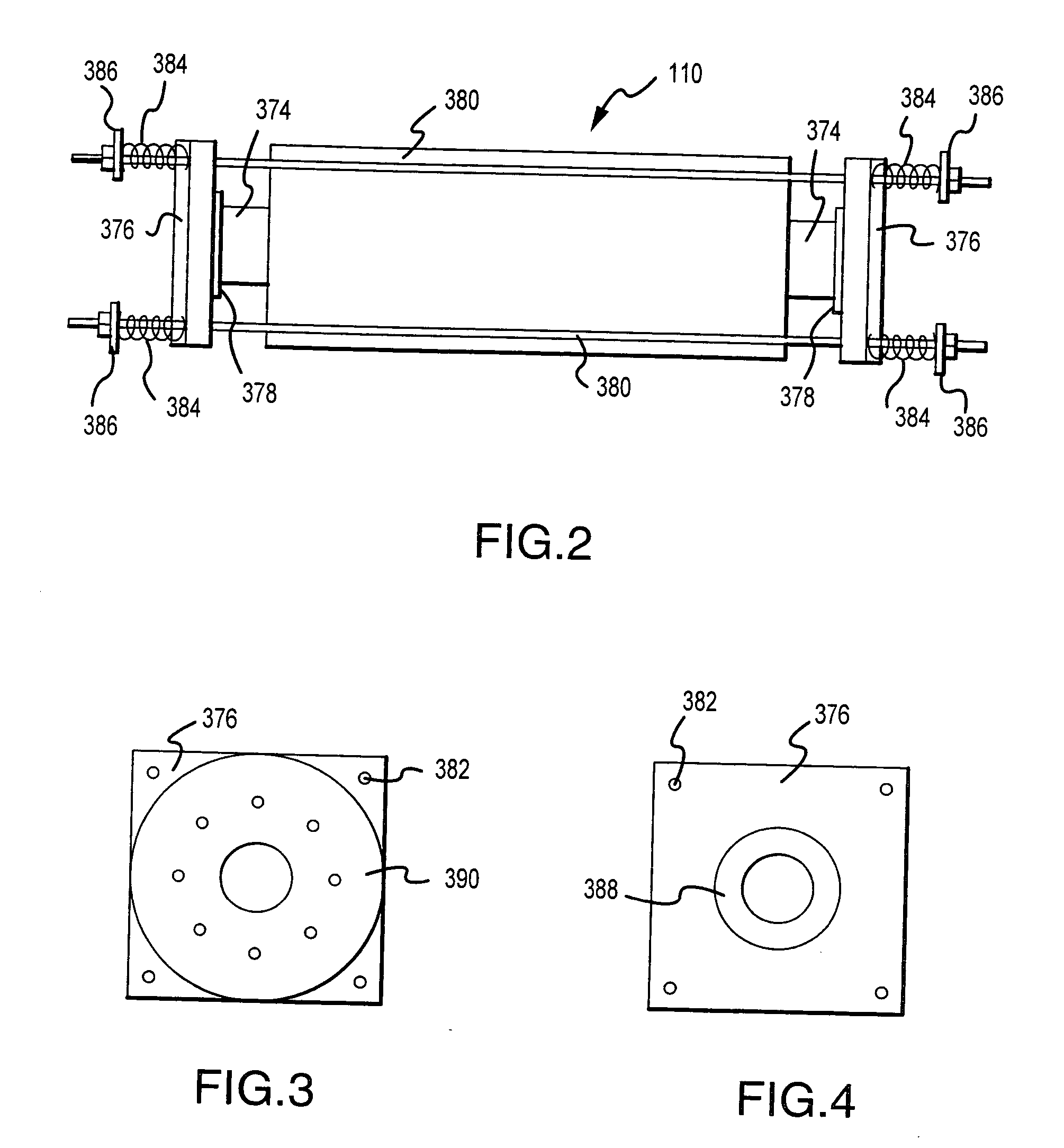

Aerosol method and apparatus, particulate products, and electronic devices made therefrom

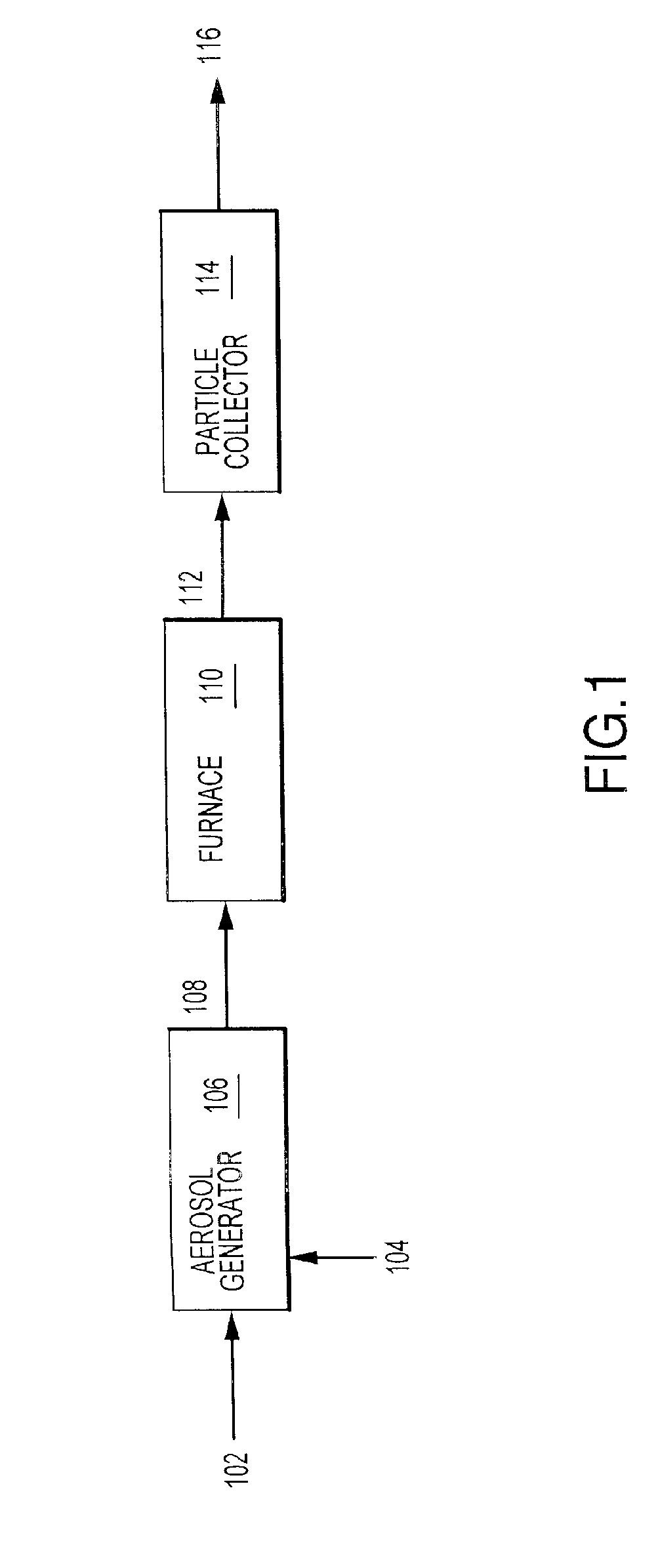

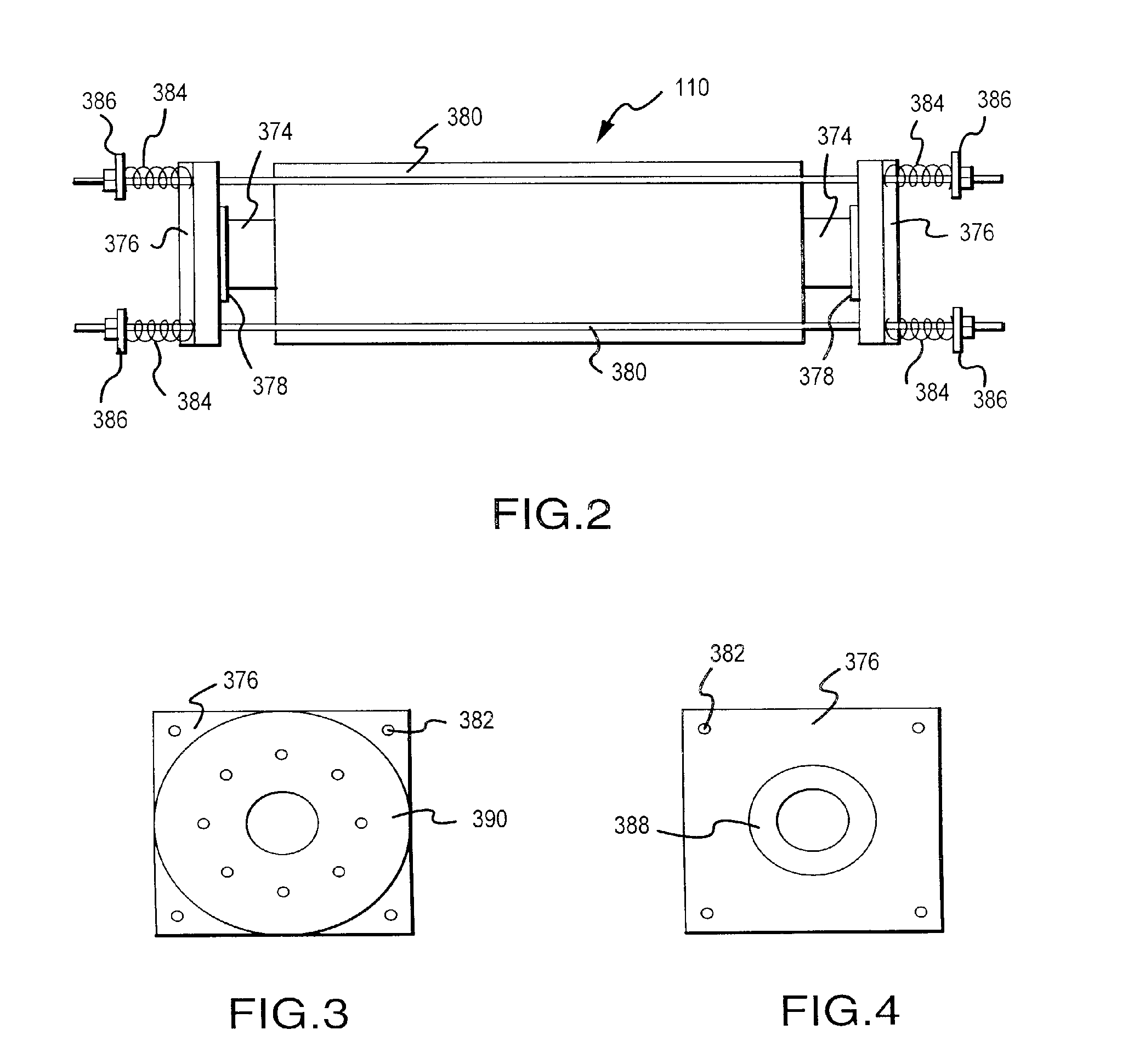

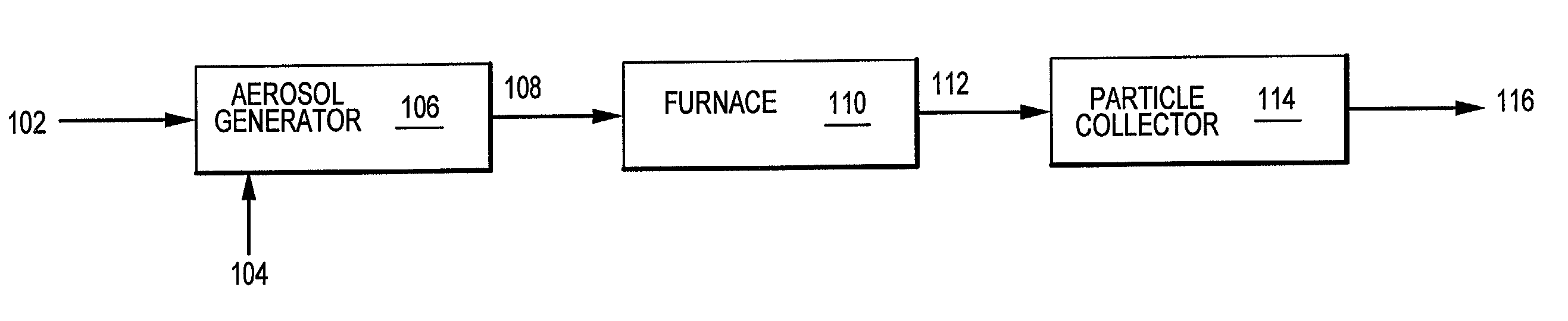

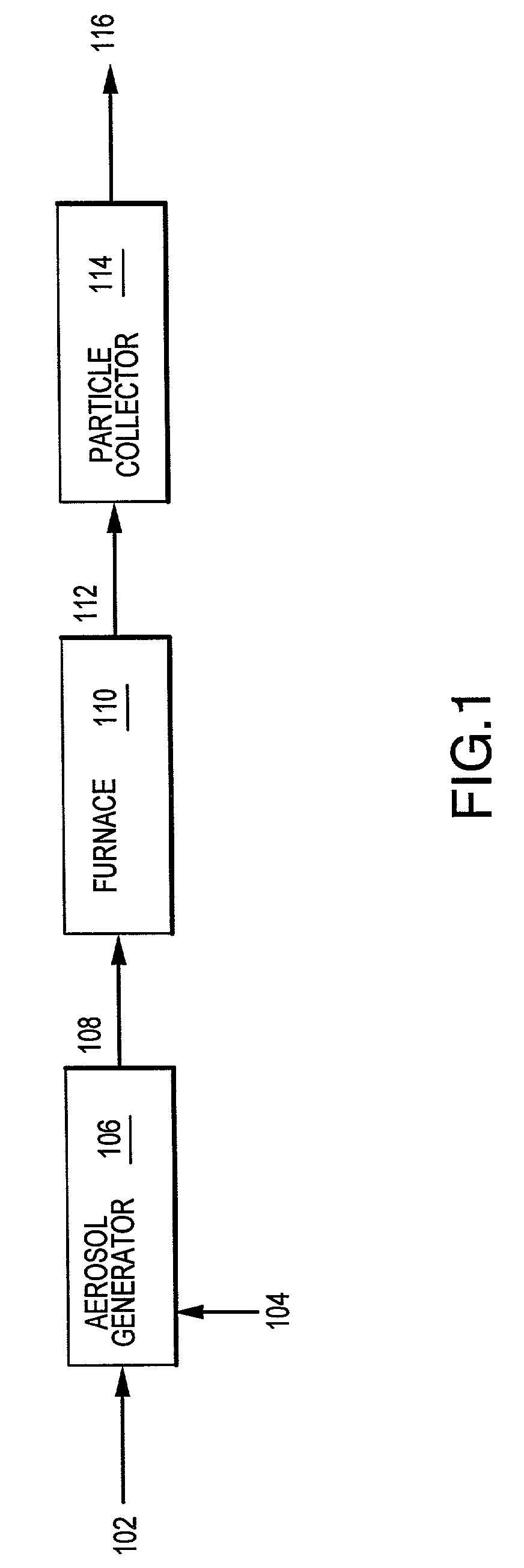

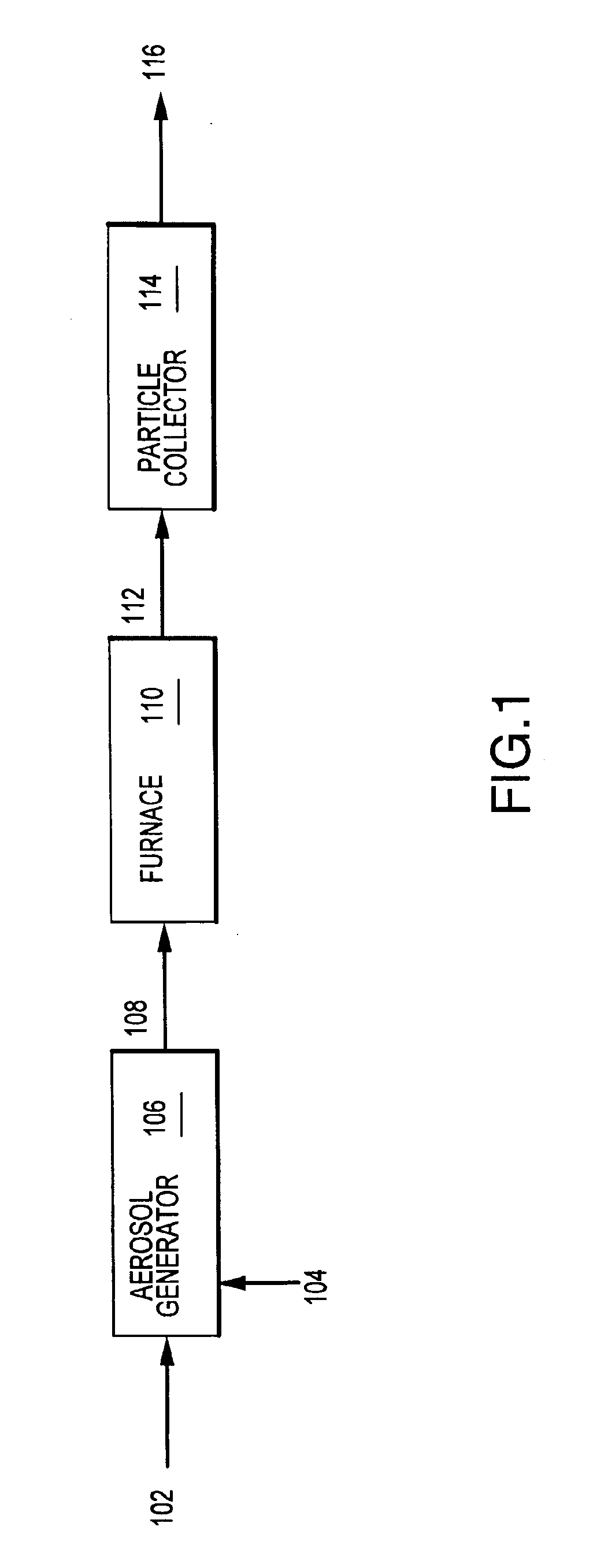

Metal-carbon composite powders and methods for producing metal-carbon composite powders. The powders have a well-controlled microstructure and morphology and preferably have a small average particle size. The method includes forming the particles from an aerosol of powder precursors. The invention also includes novel devices and products formed from the composite powders.

Owner:CABOT CORP

Coated silver-containing particles, method and apparatus of manufacture, and silver-containing devices made therefrom

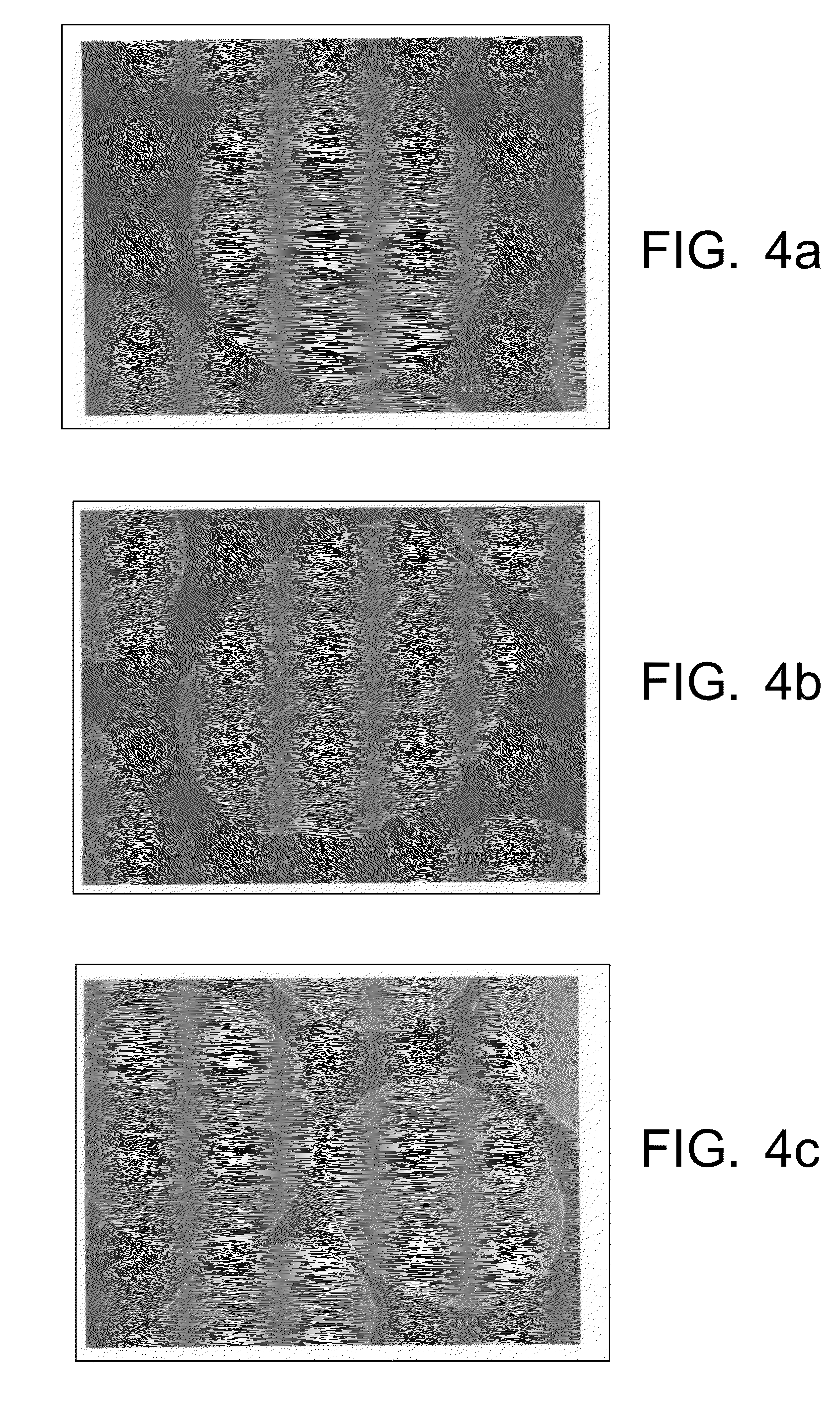

InactiveUS20050061107A1Increase loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

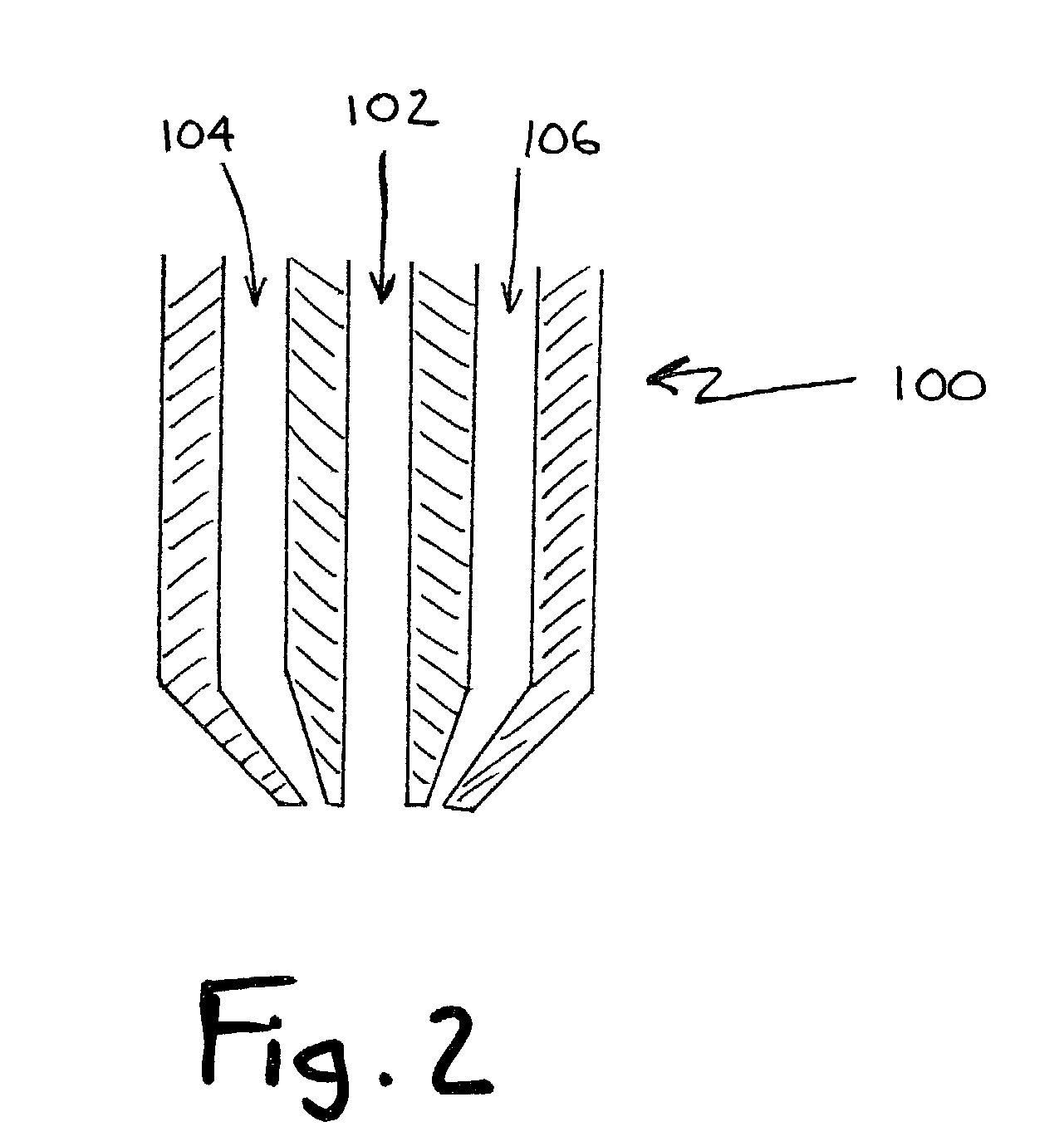

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

Proppant particles formed from slurry droplets and method of use

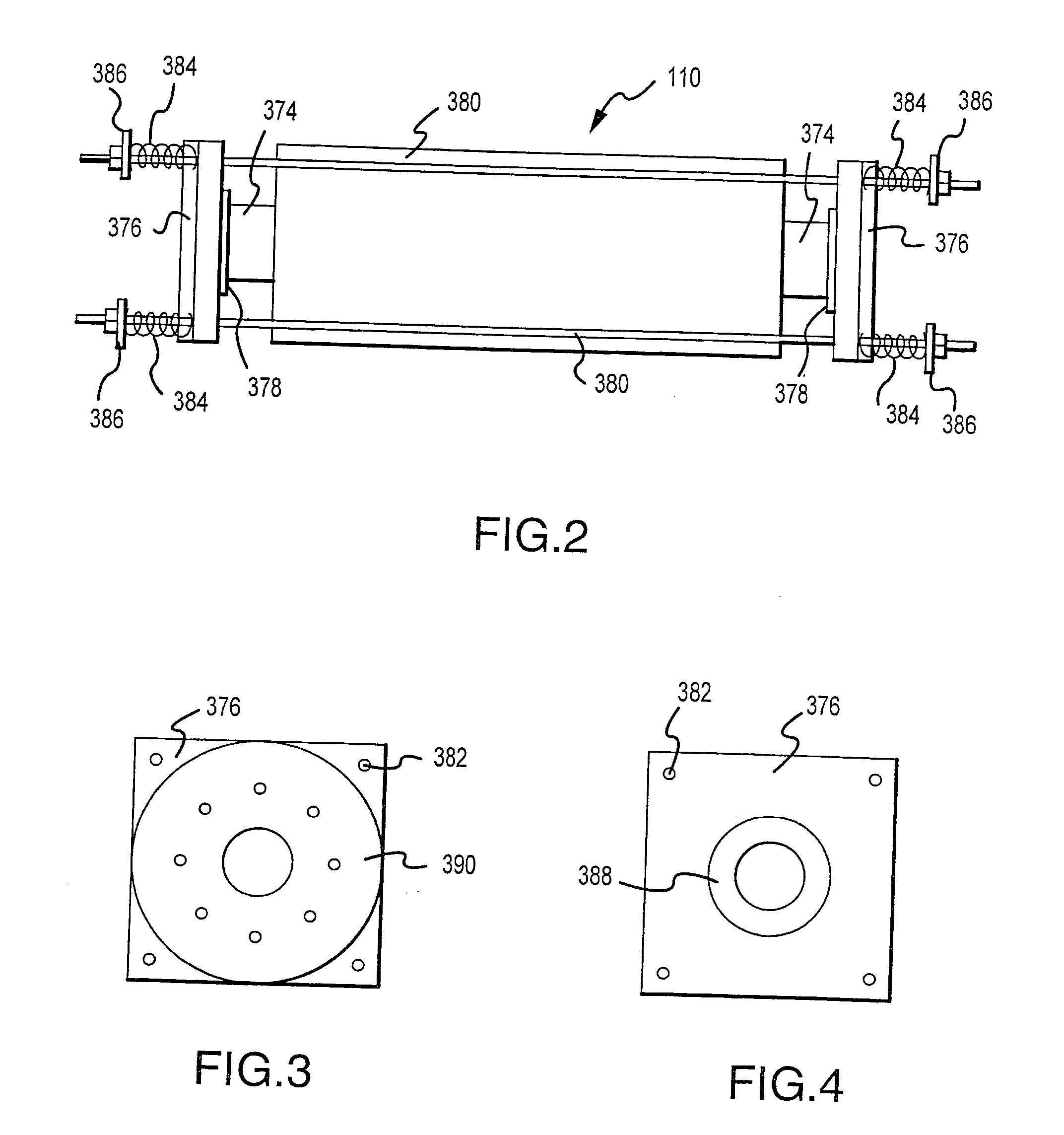

Proppant material for hydraulic fracturing is provided. The particles of the proppant are formed by drip casting. A slurry of finely divided ceramic particles is flowed through nozzles and formed into droplets under the influence of vibration. Uniform sized, smooth surface, spherical green particles are formed. The green particles are dried and sintered to form the proppant. The proppant is used in the process of hydraulic fracturing of wells.

Owner:CARBO CERAMICS

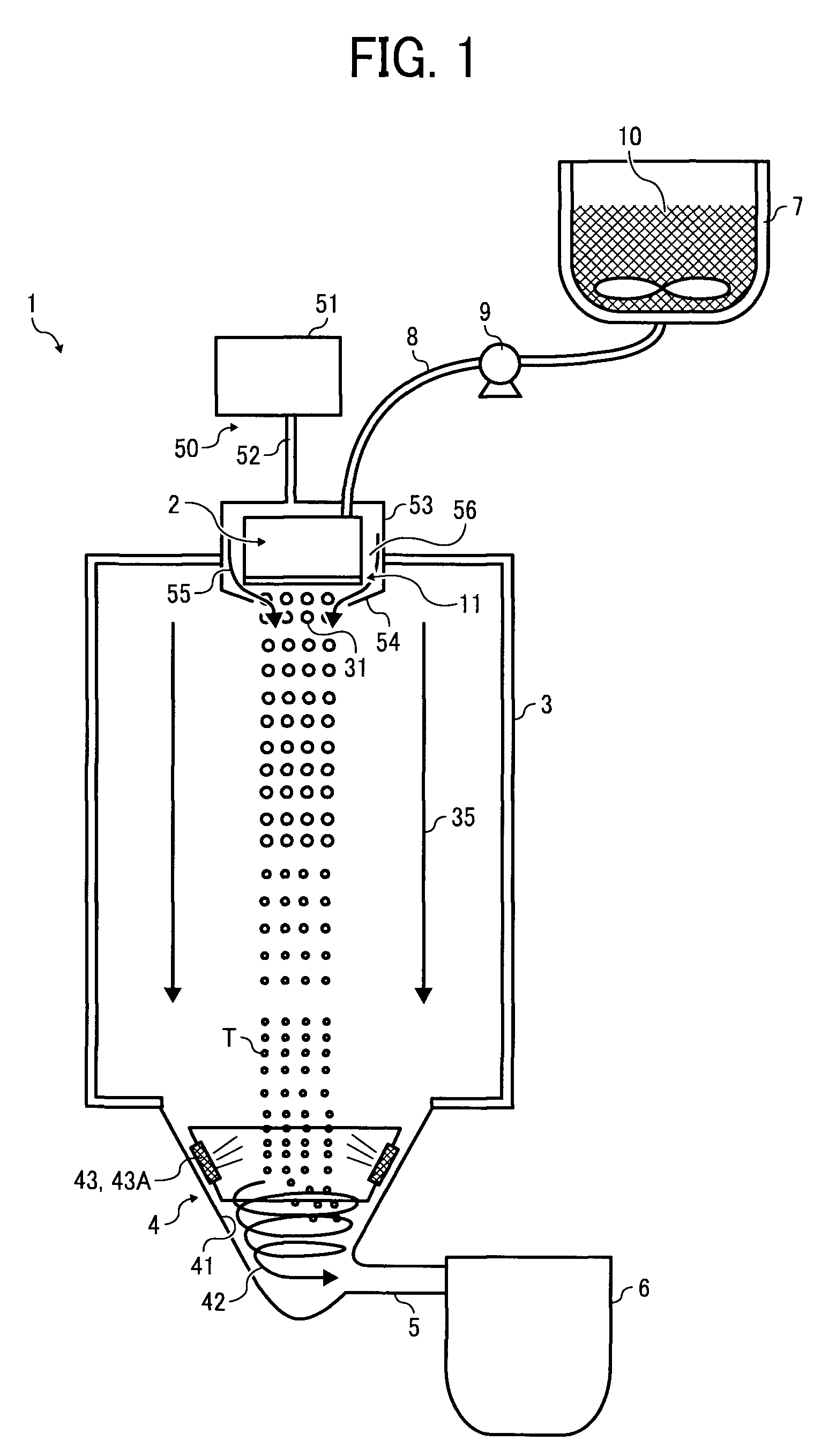

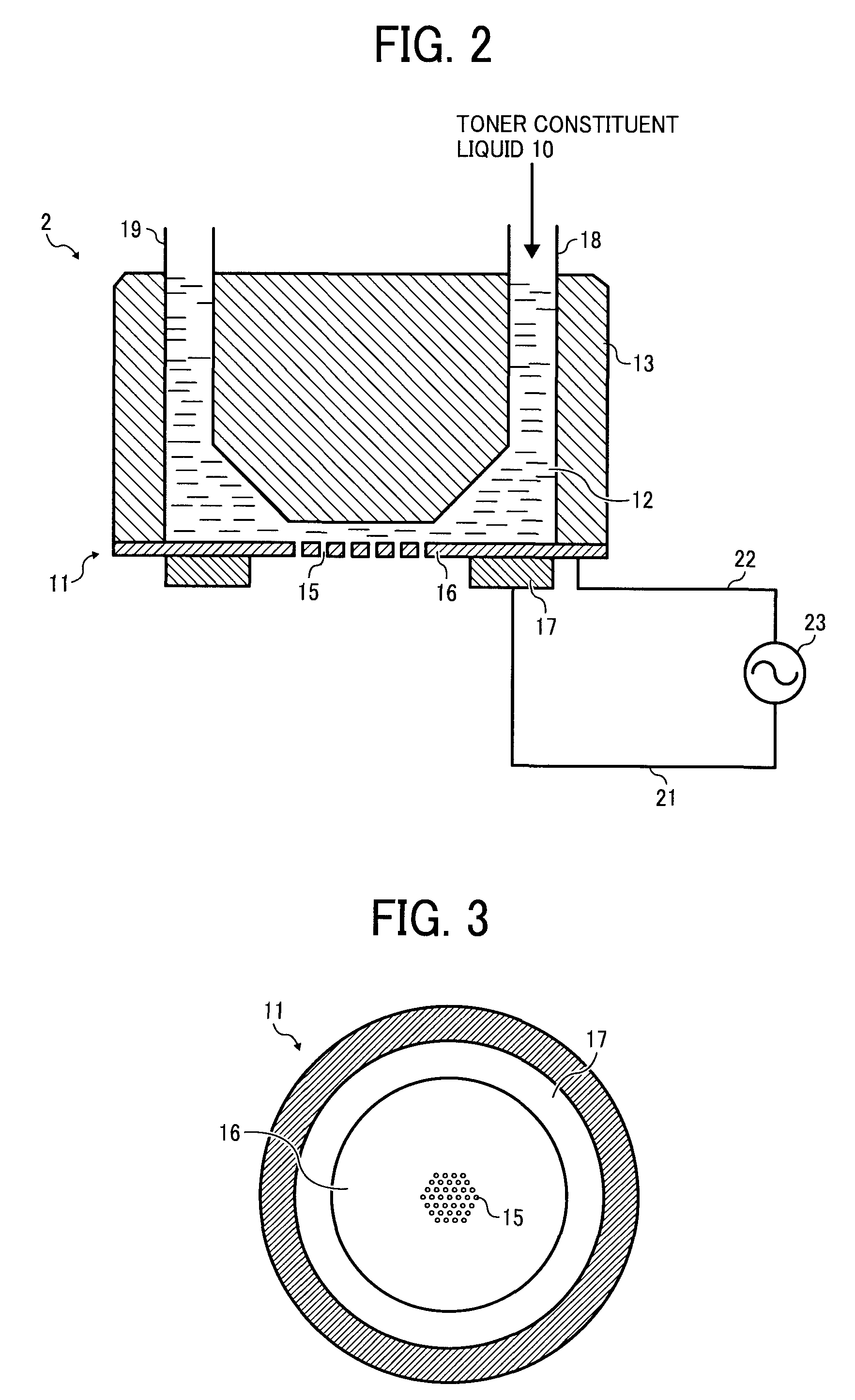

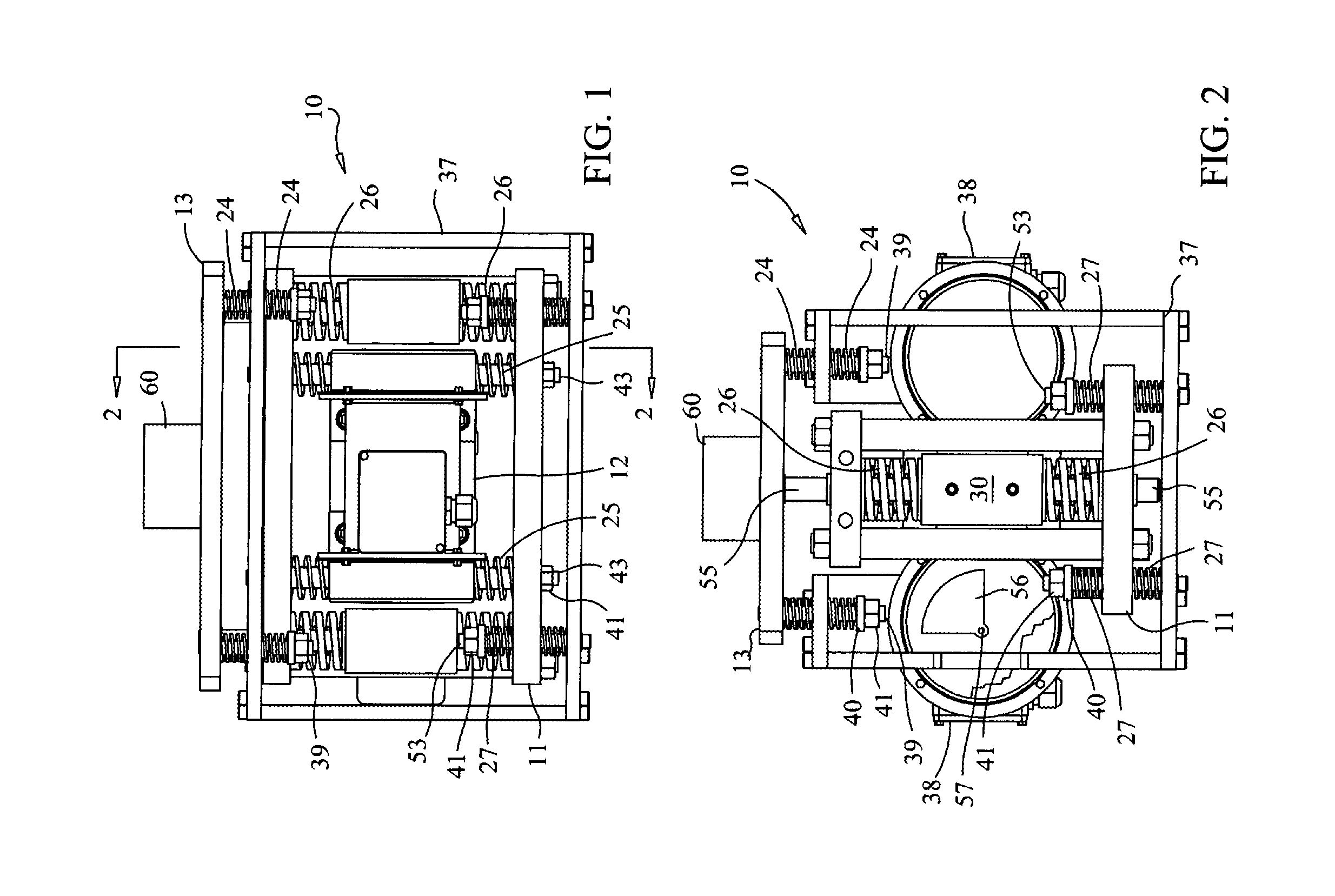

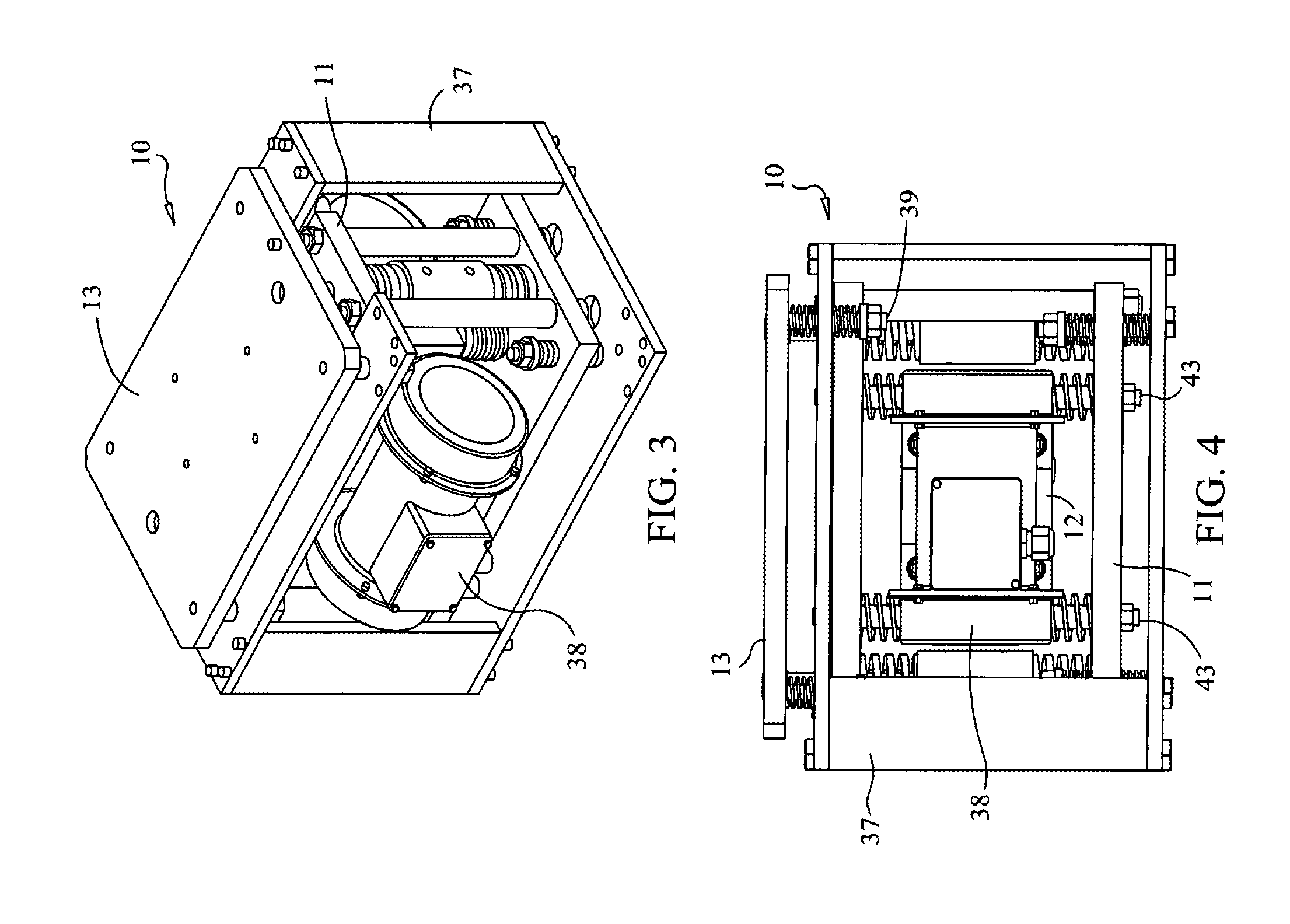

Toner preparation method and apparatus, and toner prepared thereby

InactiveUS20080248416A1Less variationEfficiently preparing a tonerBurnersPiezoelectric/electrostriction/magnetostriction machinesEngineeringAmplifier

A method of preparing a toner, including periodically dripping and discharging a droplet of a toner constituent liquid including a resin and a colorant; and solidifying and granulating the droplet, wherein the dripper includes a thin film including plural nozzles; and an oscillator including an oscillation generator generating an oscillation; and an oscillation amplifier, including an oscillation surface facing the thin film in parallel therewith, amplifying the oscillation, and wherein the toner constituent liquid is fed between the thin film and the oscillation surface.

Owner:RICOH KK

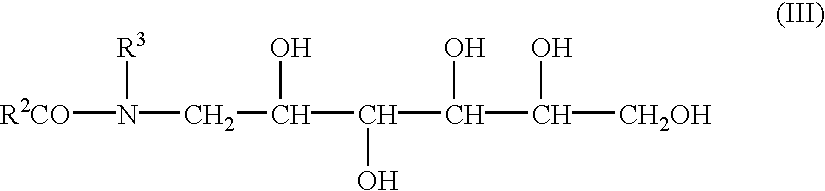

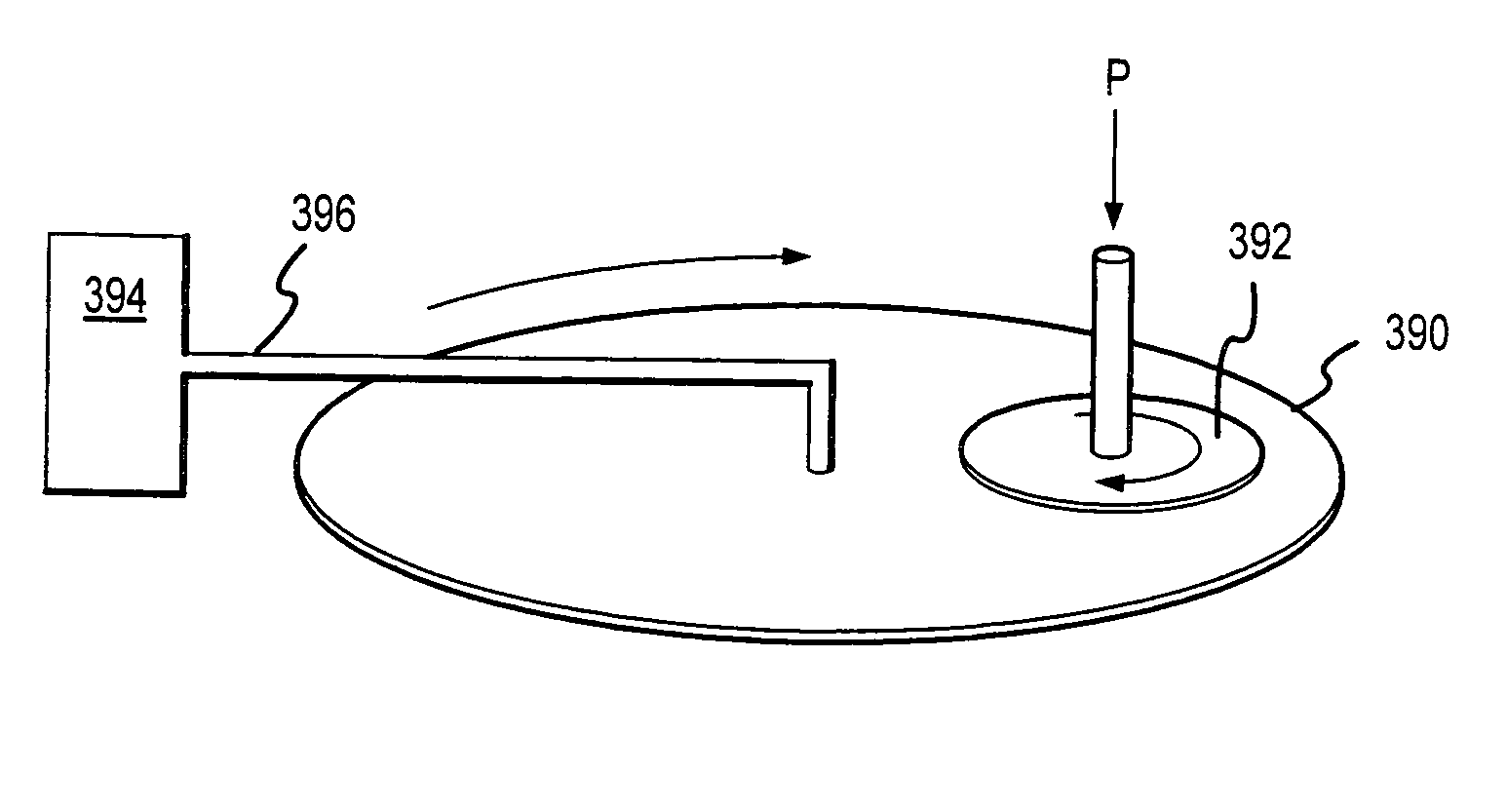

Granular solid with monodisperse particle size distribution

InactiveUS20030113354A1Improve solubilityLow costBiocideCosmetic preparationsCosmetic ingredientRoom temperature

A granular solid with monodisperse particle size distribution is disclosed, which may be obtained by melting an essentially anhydrous composition, which is solid at room temperature and made from at least one cosmetic ingredient. A flow of the melt is dispersed into droplets by means of a casting plate and vibration and said droplets contacted with a cooling medium, which causes the solidification thereof.

Owner:COGNIS DEUT GMBH & CO KG

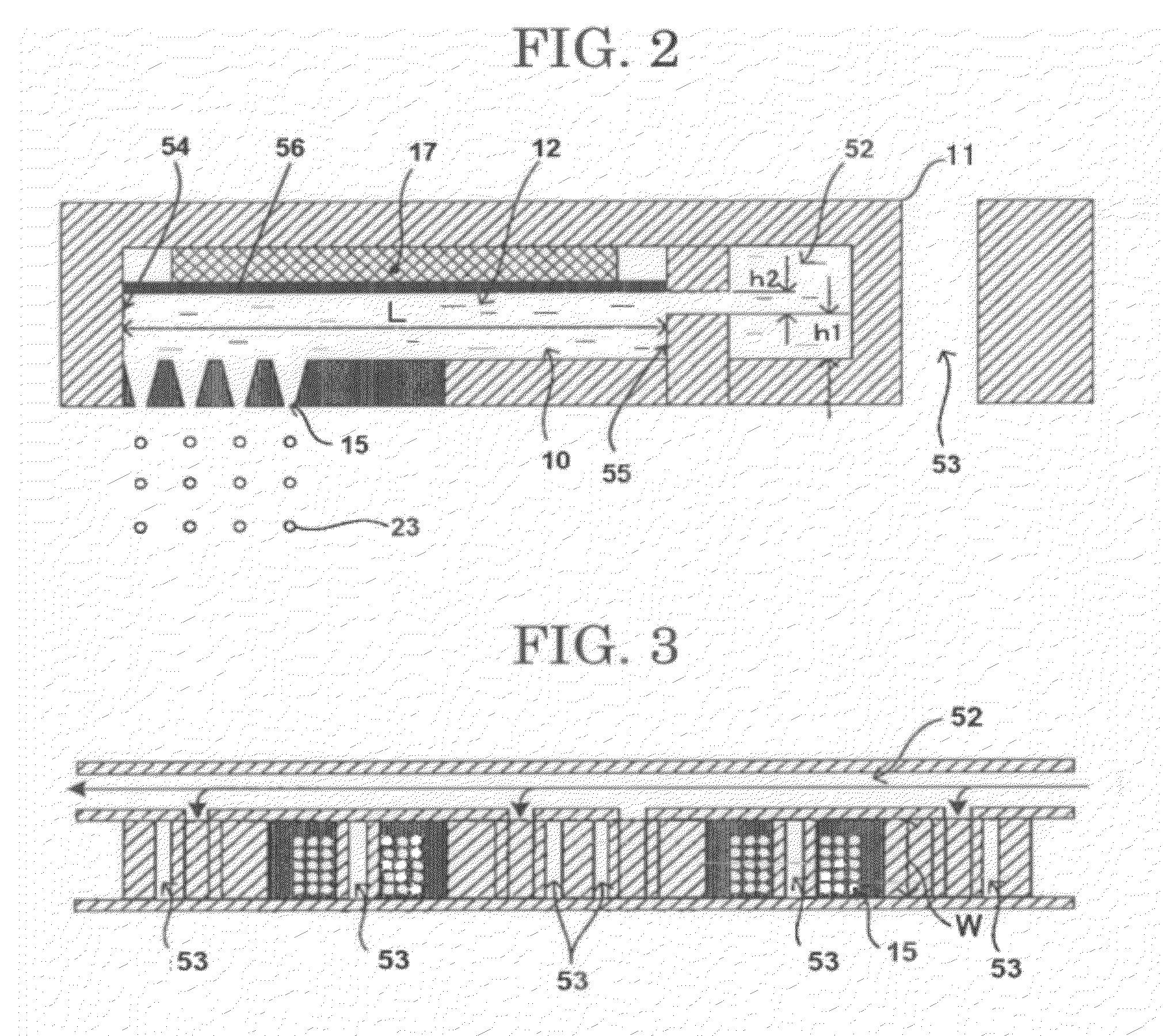

Method and apparatus for manufacturing toner and toner manufactured by the apparatus and method

ActiveUS20080286680A1Efficiently and reliably manufacturingQuality improvementGranulation by liquid drop formationAuxillary shaping apparatusEngineeringColoring agents

A method for manufacturing a toner, including periodically forming liquid droplets of a toner constituent liquid comprising a resin and a colorant by vibrating a thin film having a plurality of holes provided on a retention part thereof to discharge the liquid droplets of the toner constituent liquid from the plurality of holes and forming toner particles by solidifying the liquid droplets discharged from the plurality of holes. In periodically forming the liquid droplets of the toner constituent liquid, a flow of gas in a direction of discharge of the liquid droplets is formed by a gas flow generation unit provided downstream from the thin film relative to the direction of discharge of the liquid droplets, including a tapered part forming an aperture corresponding to a hole formation area of the thin film.

Owner:RICOH KK

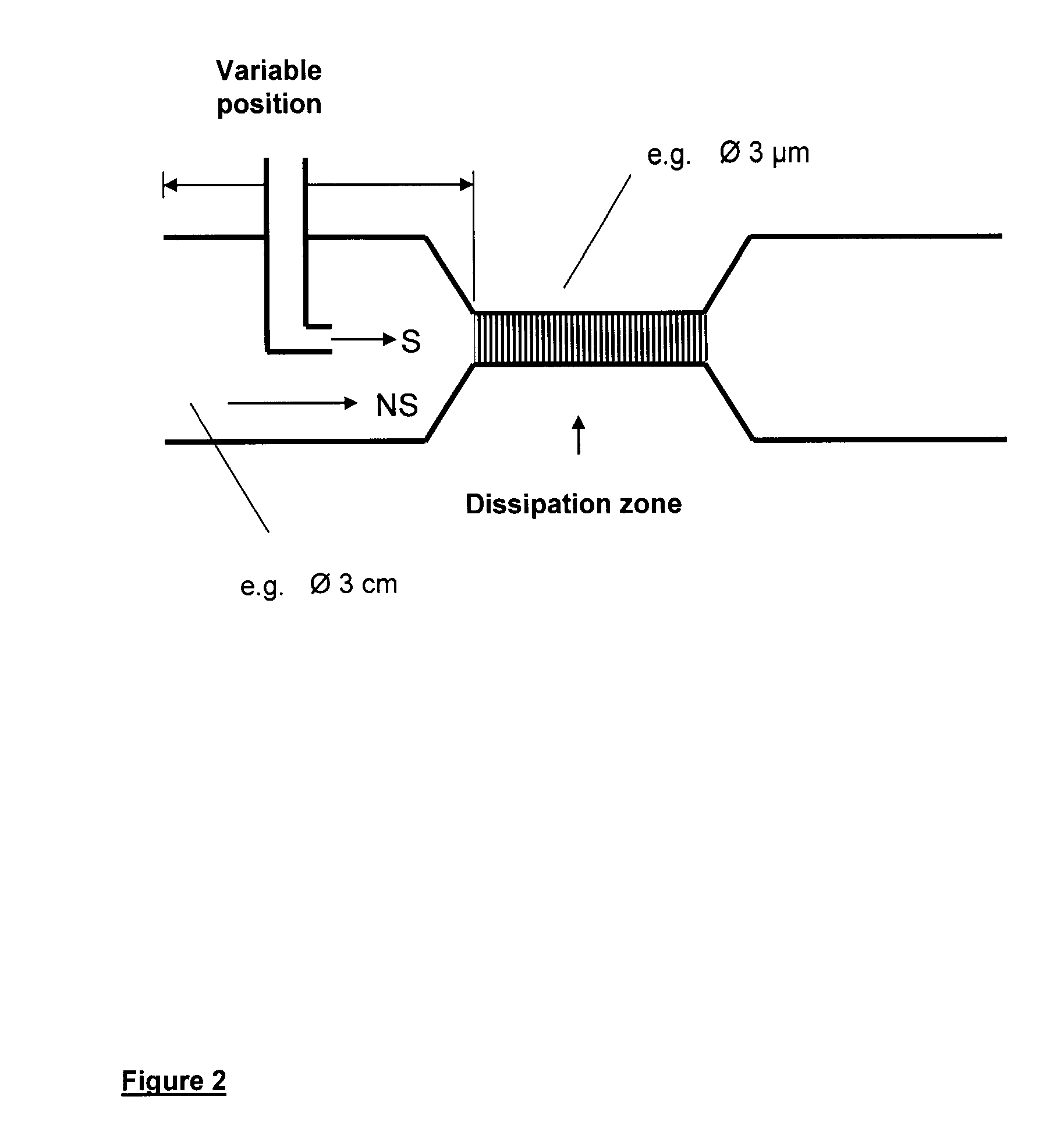

Method and device for producing very fine particles and coating such particles

Disclosed are methods and devices for producing very fine particles which are then coated with protective polymers in another step of the process. The particles are produced using a method in which a liquid flow comprising a particle-free liquid 1 that contains the active substance in a dissolved form is combined with a second liquid flow comprising a liquid 2 in a high-energy zone or no sooner than two seconds before reaching the high-energy zone. Said two liquids can be mixed with each other while the active substance dissolved in liquid 1 is insoluble or more difficult to dissolve in liquid 2 than in liquid 1 and settles in the form of particles in the high-energy zone or within a maximum of 2 seconds before reaching the high-energy zone when the two liquids are mixed. The obtained particles are introduced into an aqueous outer phase which contains the coating materials in a dissolved form and are then subjected to a drying step such that said materials settle on the particles as a closed coating. The coated particles are protected from damaging influences and are provided with modified release kinetics compared to uncoated particles.

Owner:ABBVIE DEUTSHLAND GMBH & CO KG

Nickel powders, methods for producing powders and devices fabricated from same

InactiveUS20050262966A1High crystallinityHigh rateGranule coatingCell electrodesSpherical morphologyMetal powder

Nickel powder batches and methods for producing nickel powder batches. The powder batches include particles having a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the nickel metal powders.

Owner:CABOT CORP

Method for making a film from silver-containing particles

InactiveUS7004994B2High rateIncrease loadMaterial granulation and coatingGranule coatingPolymer scienceDroplet size

Provided are silver-containing powders and a method and apparatus for manufacturing the silver-containing particles of high quality, of a small size and narrow size distribution. An aerosol is generated from liquid feed and sent to a furnace, where liquid in droplets in the aerosol is vaporized to permit formation of the desired particles, which are then collected in a particle collector. The aerosol generation involves preparation of a high quality aerosol, with a narrow droplet size distribution, with close control over droplet size and with a high droplet loading suitable for commercial applications.

Owner:CABOT CORP

Process of forming and modifying particles and compositions produced thereby

Owner:NANOSHIFT LLC

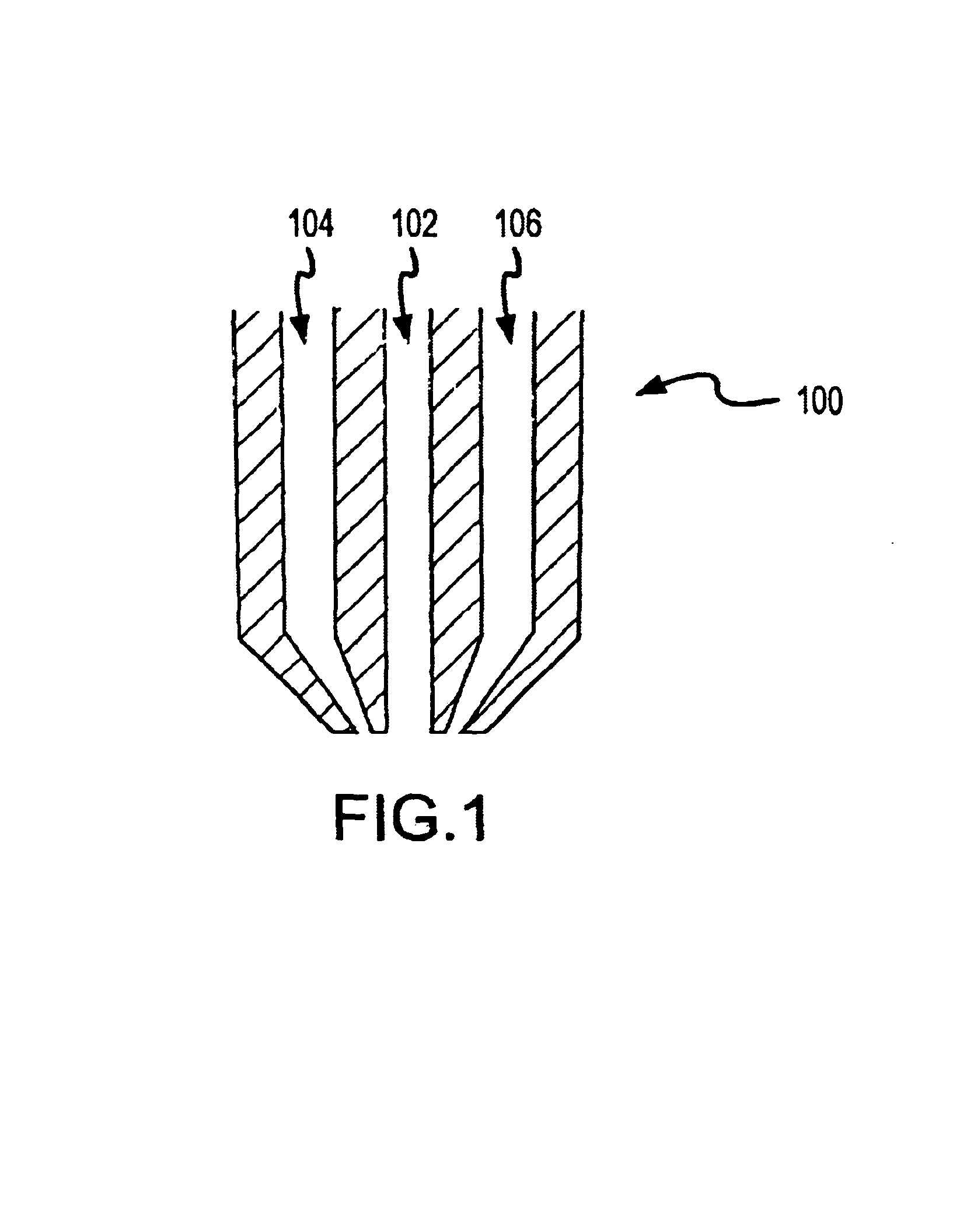

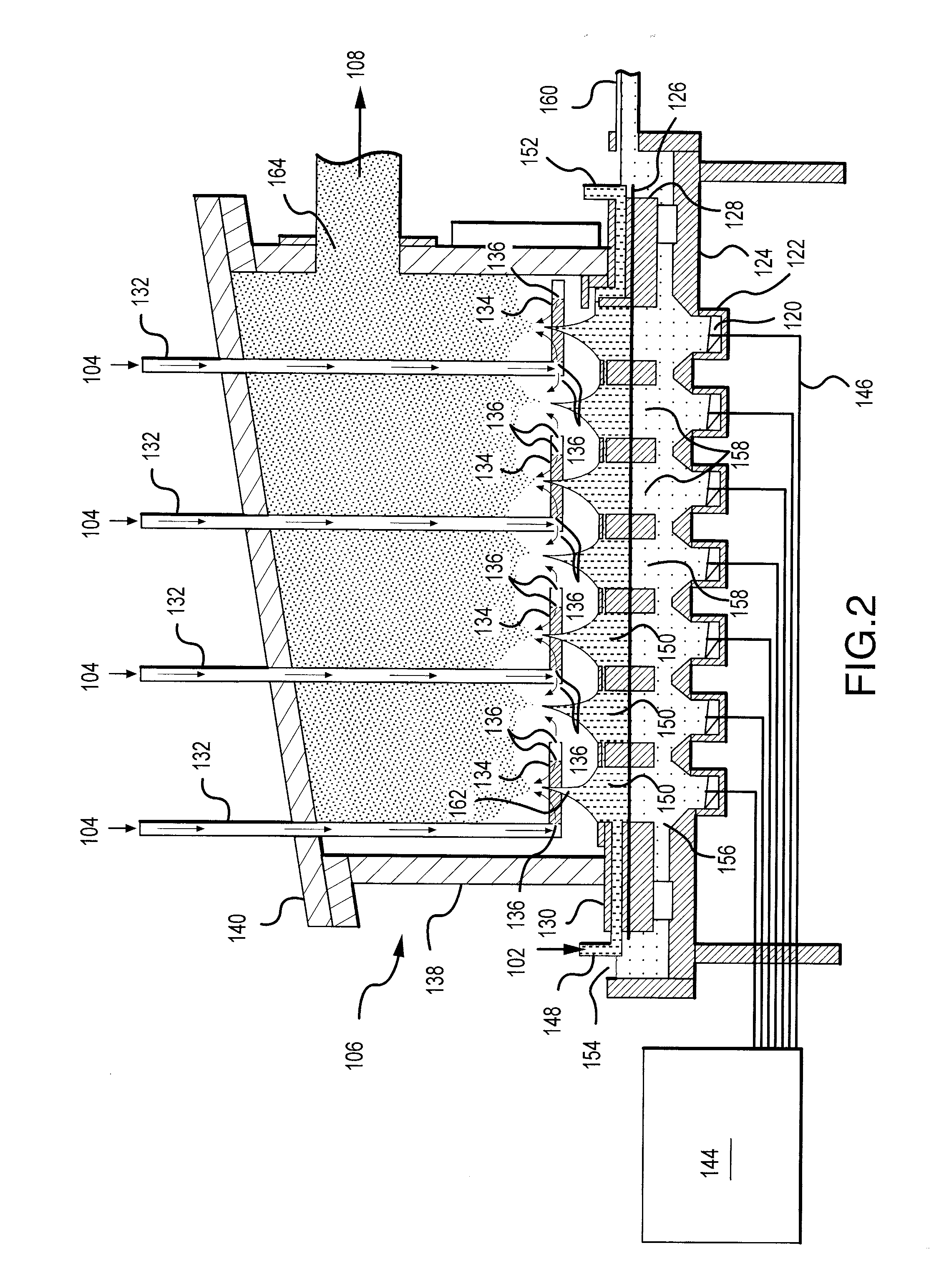

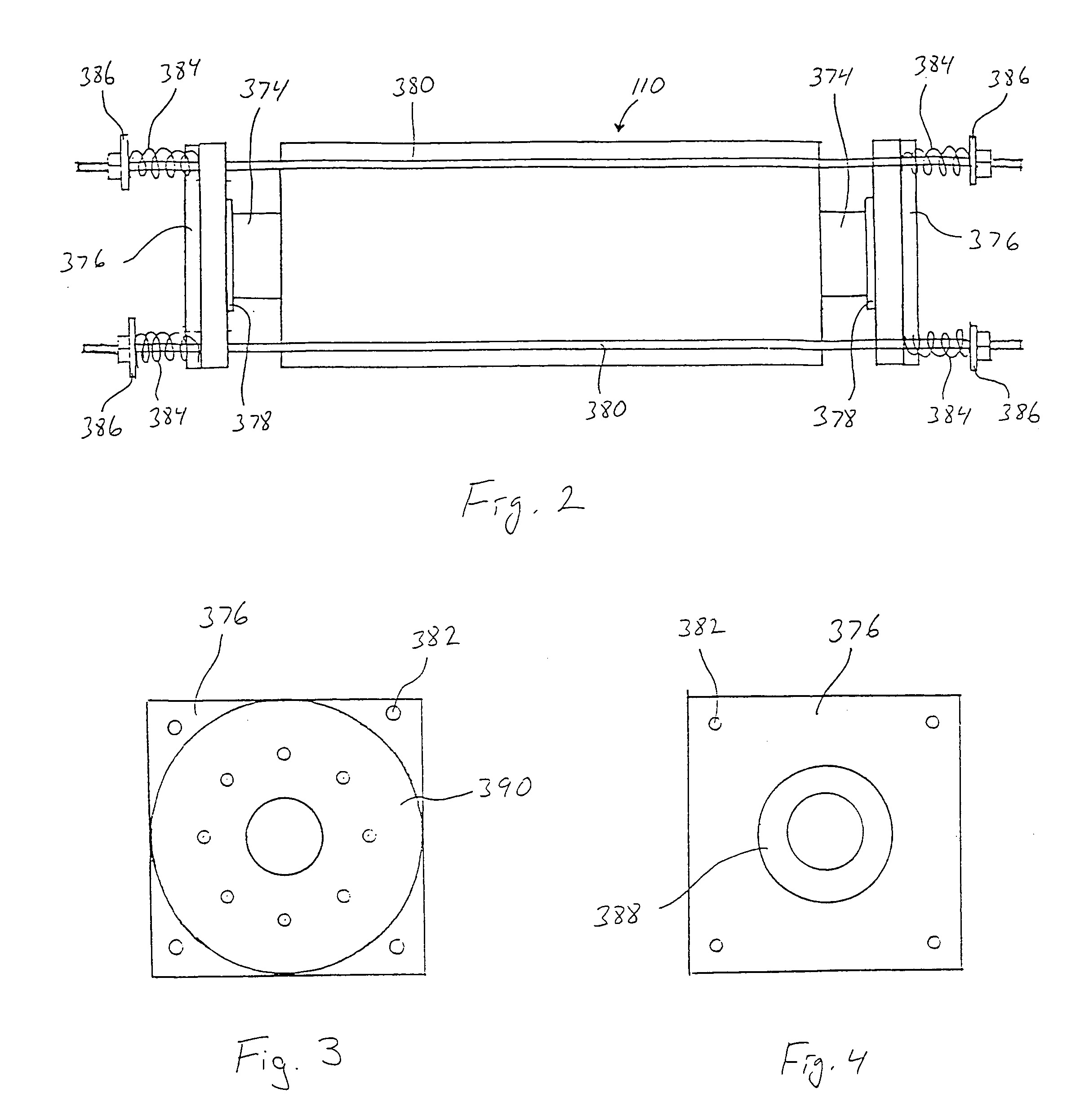

Aerosol method and apparatus, coated particulate products, and electronic devices made therefrom

InactiveUS20050100666A1High rateIncrease loadMaterial granulation and coatingGranule coatingParticulatesUltrasonic sensor

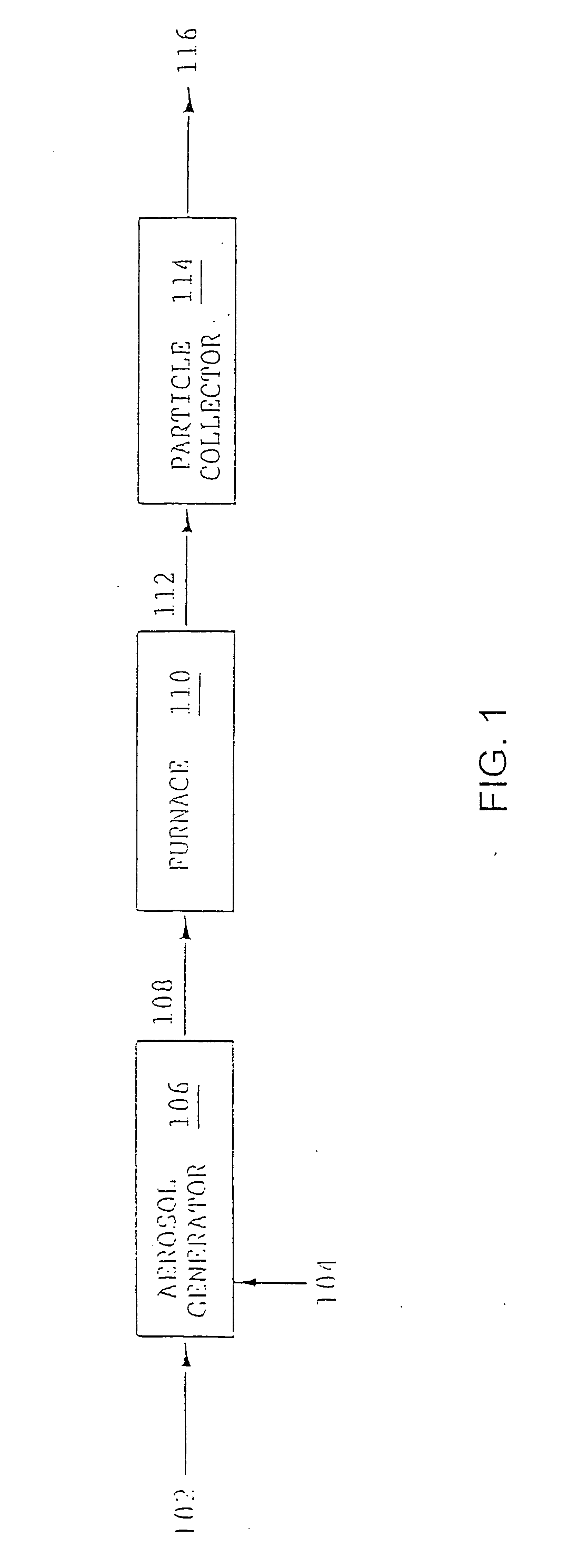

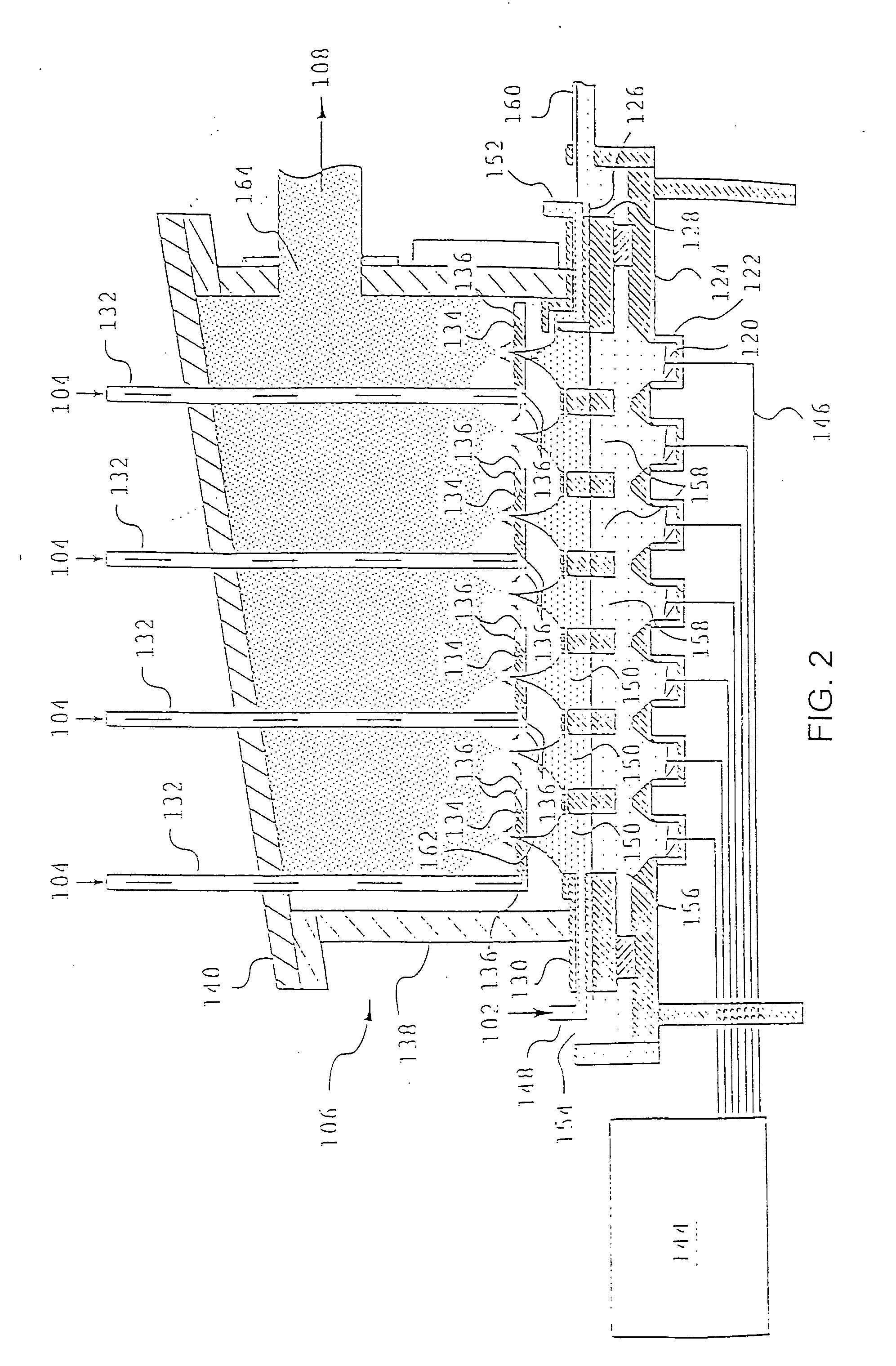

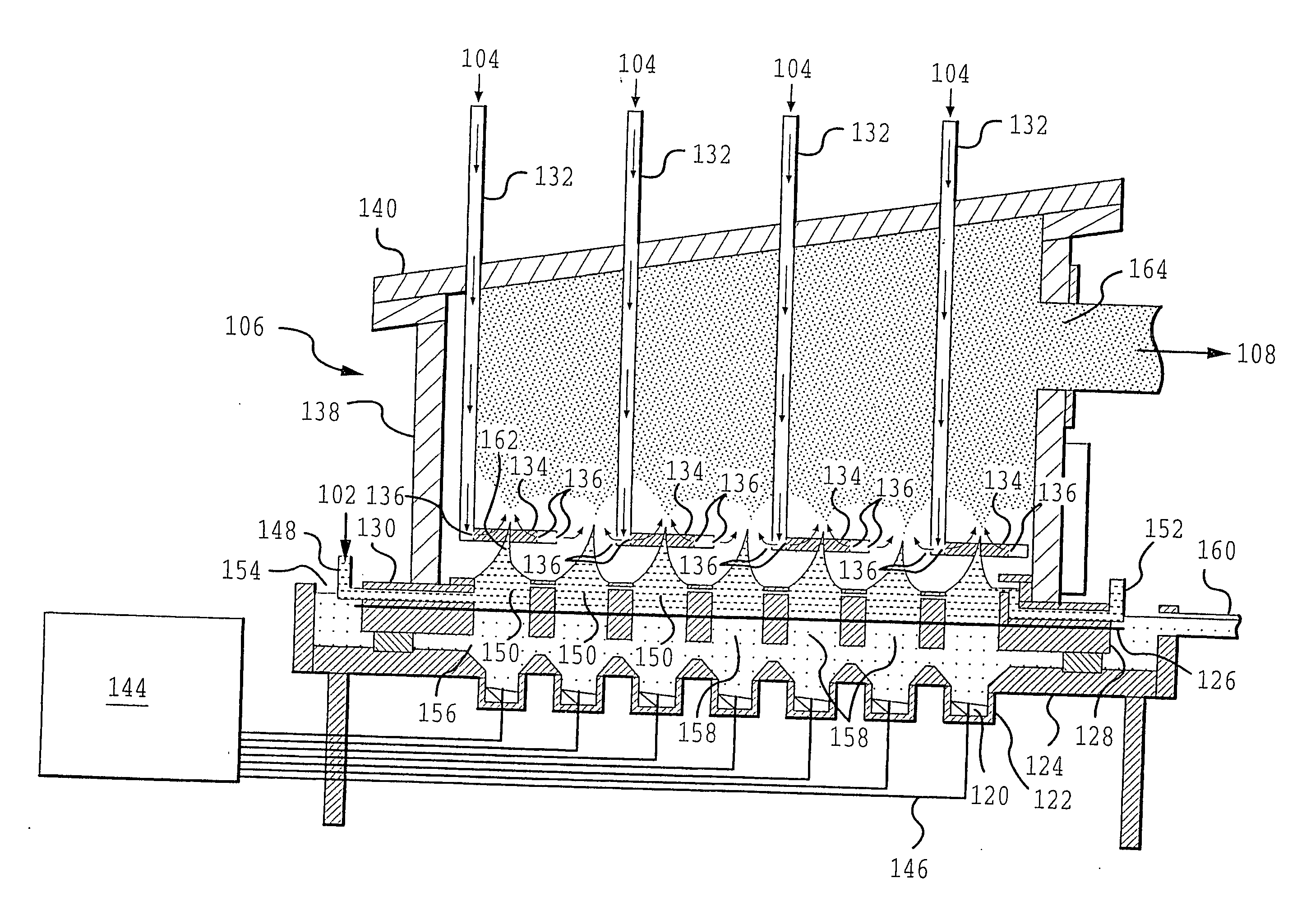

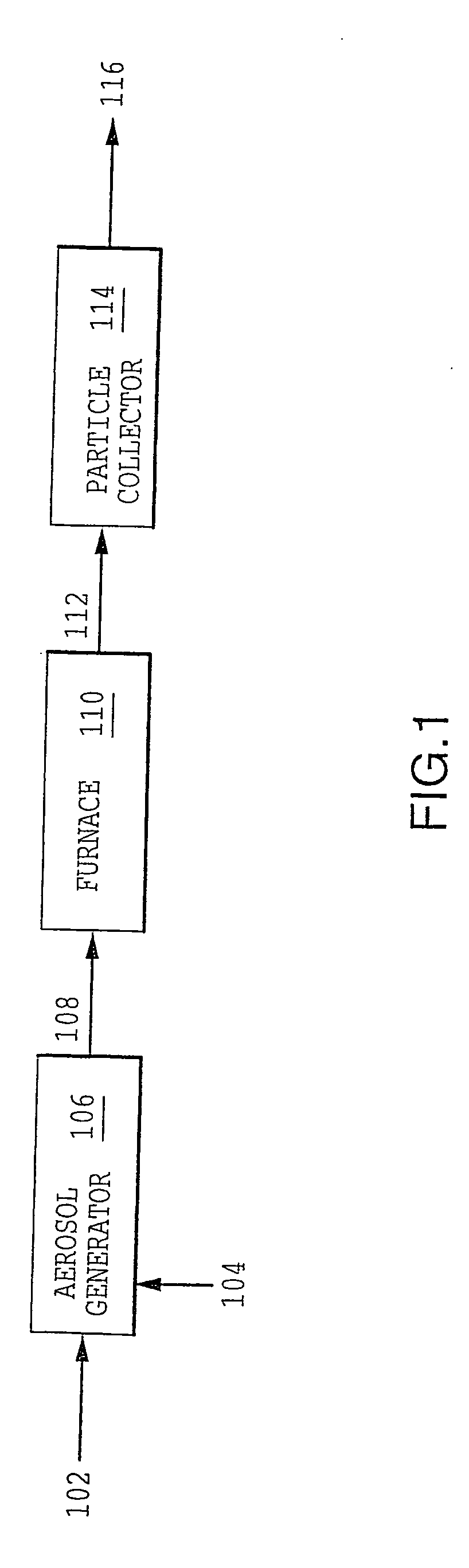

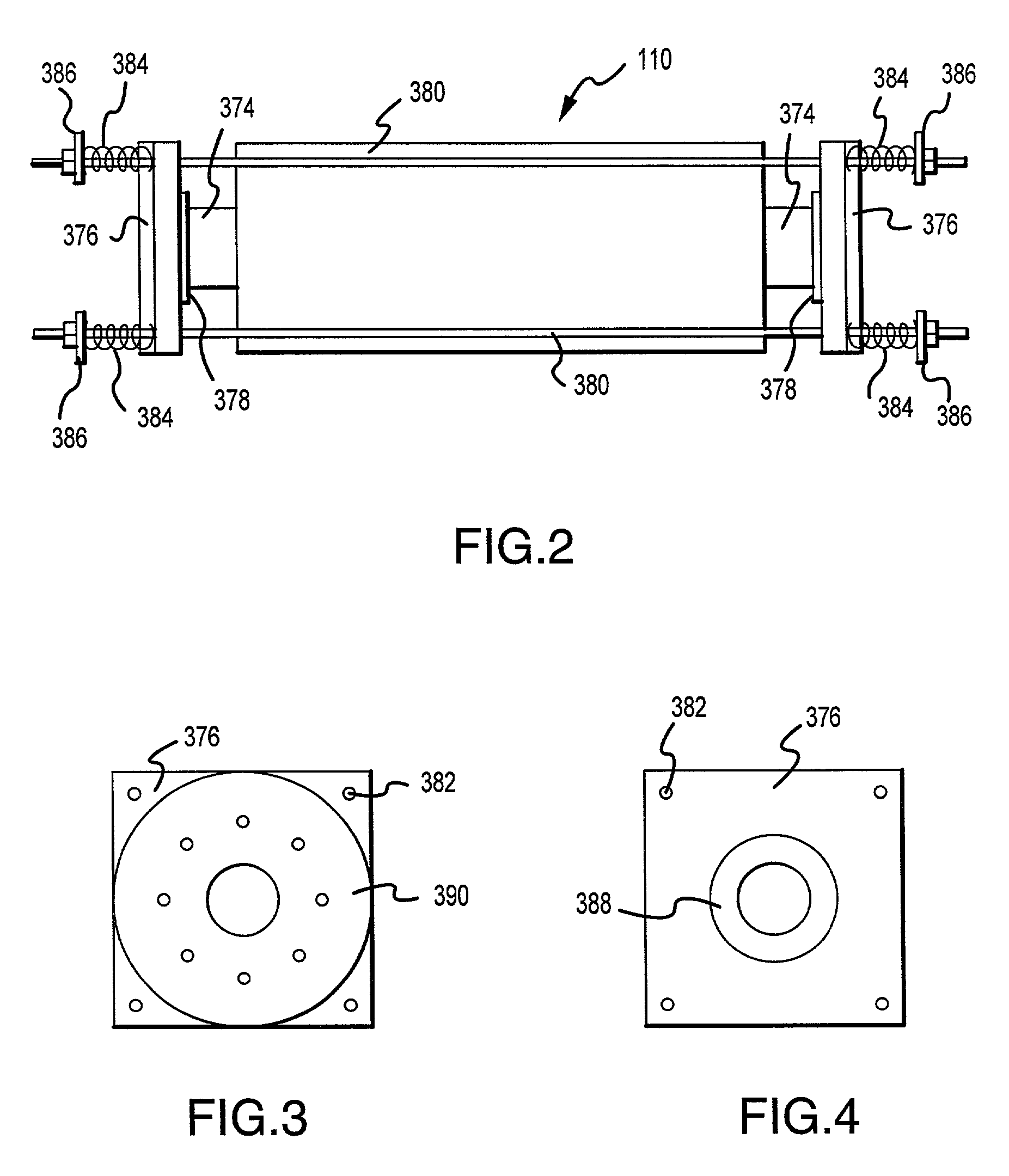

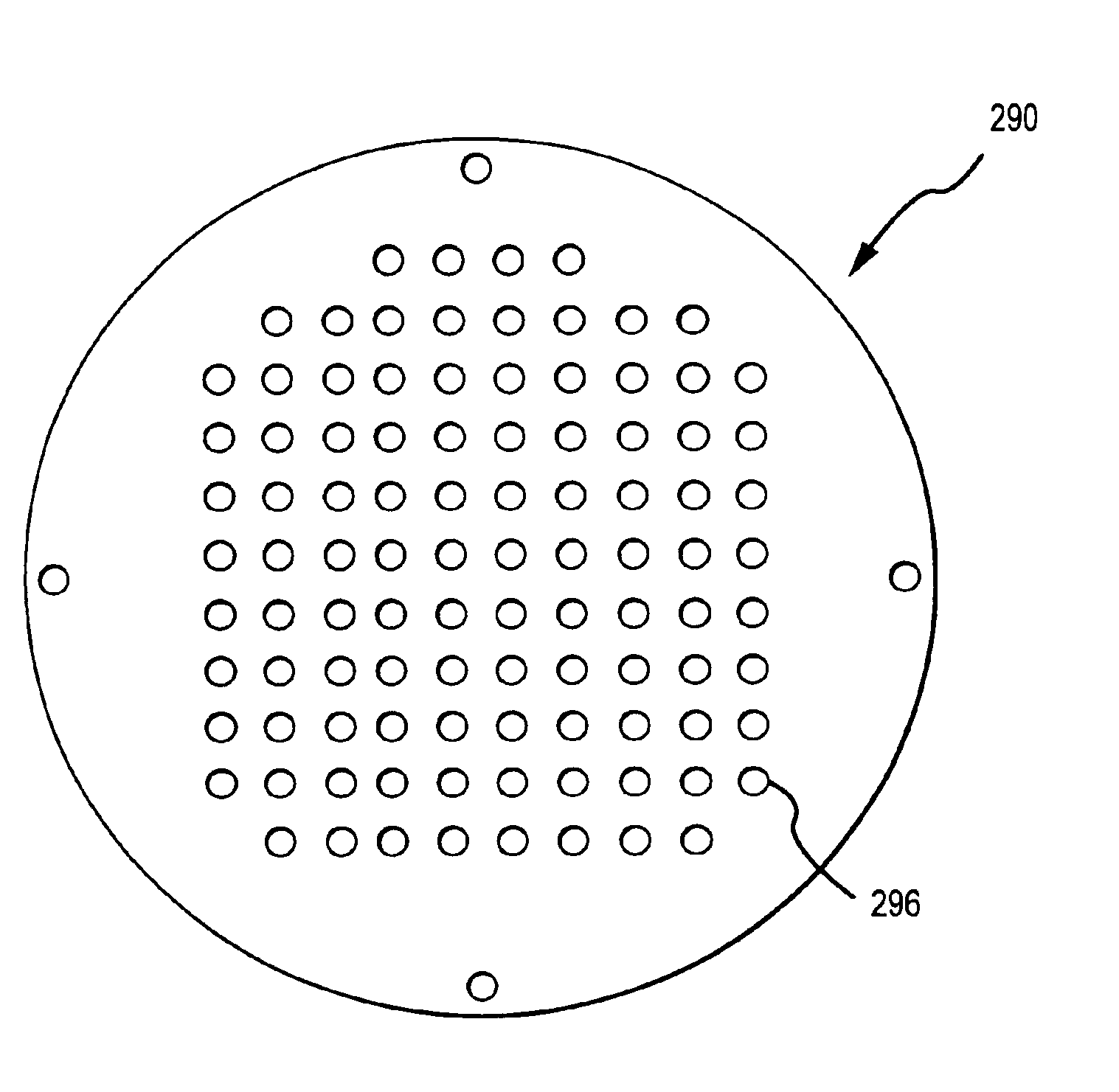

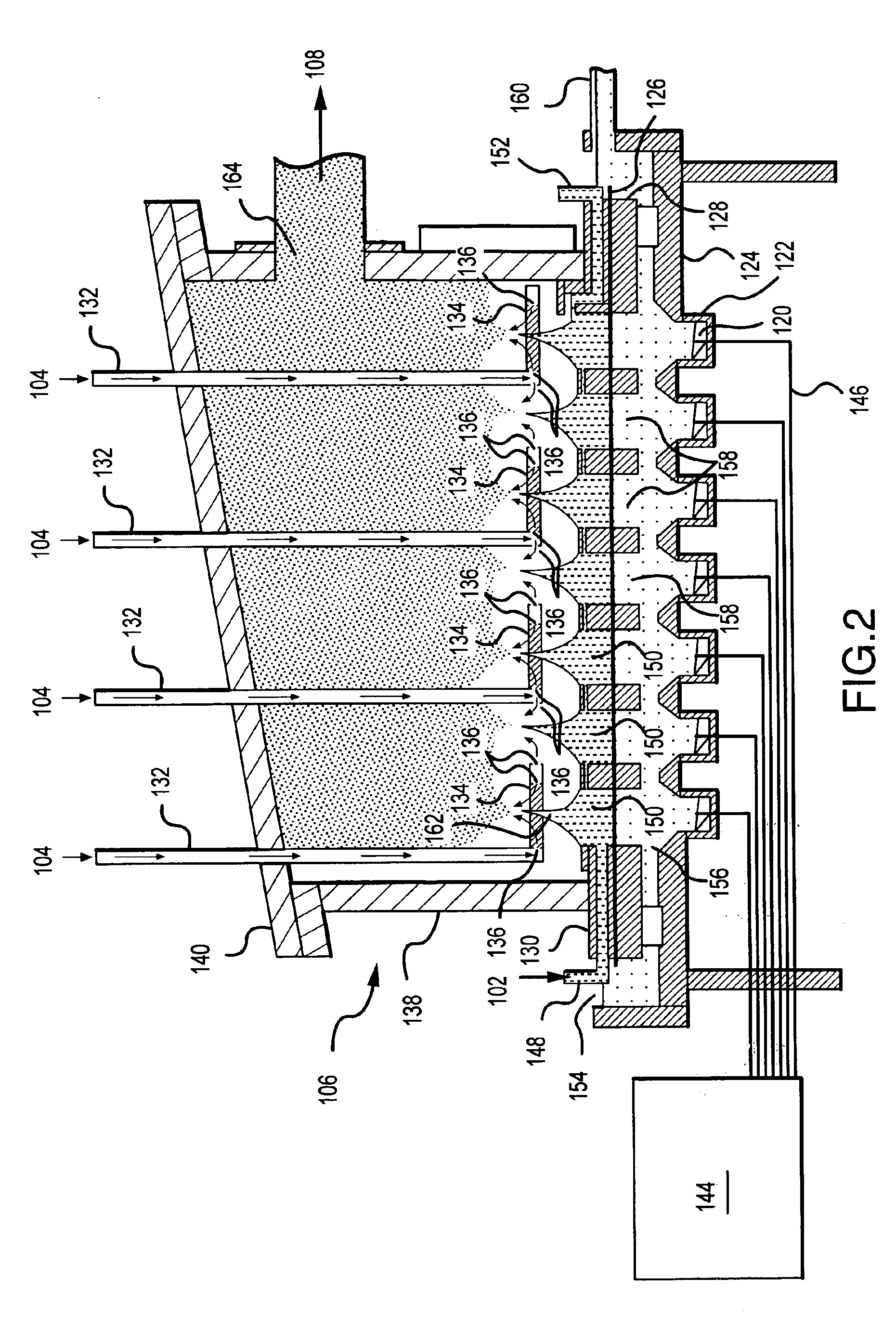

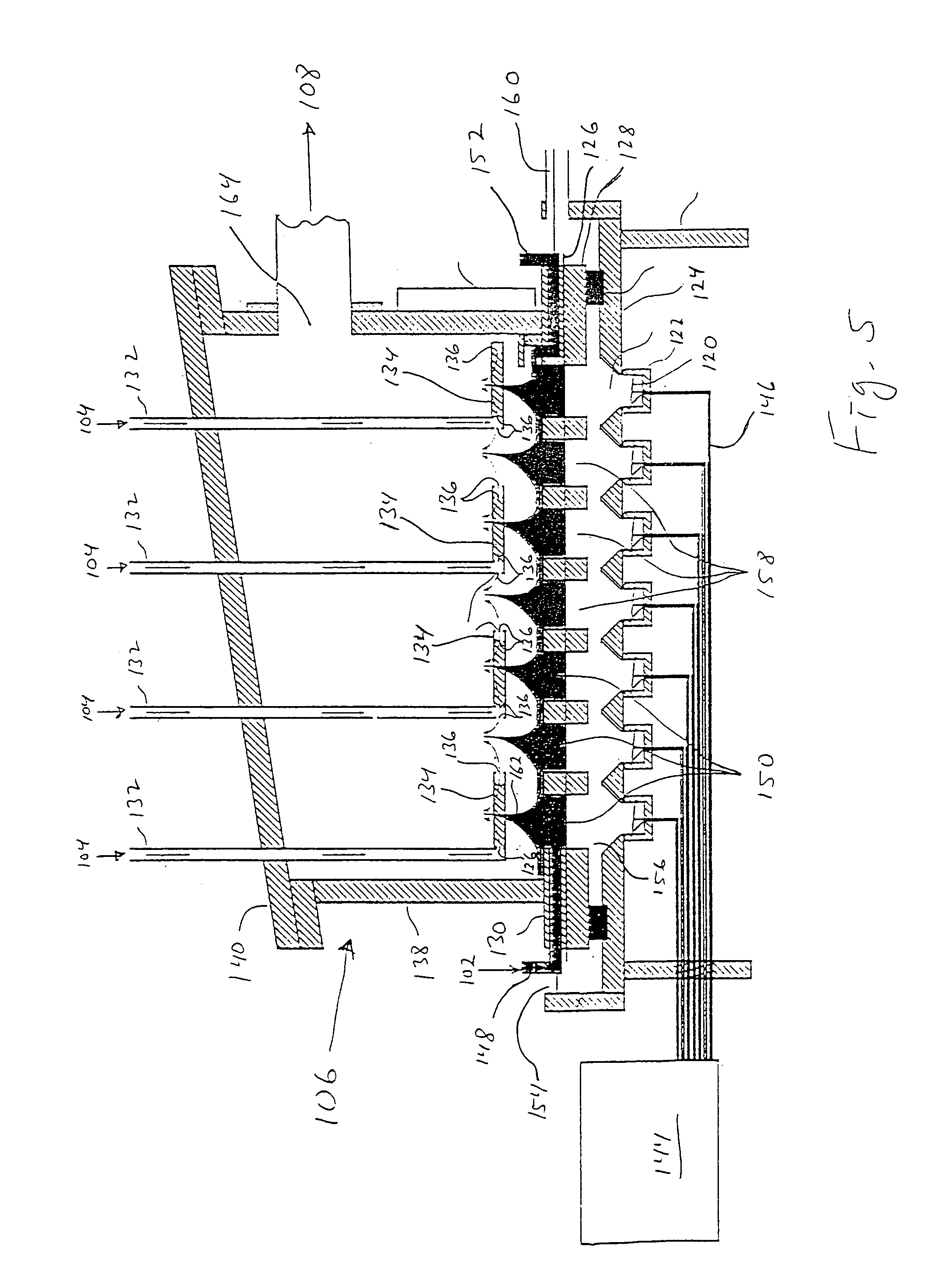

Provided is an aerosol method, and accompanying apparatus, for preparing powdered products of a variety of materials involving the use of an ultrasonic aerosol generator (106) including a plurality of ultrasonic transducers (120) underlying and ultrasonically energizing a reservoir of liquid feed(102) which forms droplets of the aerosol. Carrier gas (104) is delivered to different portions of the reservoir by a plurality of gas delivery ports (136) delivering gas from a gas delivery system. The aerosol is pyrolyzed to form particles, which are then cooled and collected. The invention also provides powders that include coated particles made by the method and devices made using the coated particles.

Owner:CABOT CORP

Nickel powders, methods for producing powders and devices fabricated from same

InactiveUS7097686B2High rateIncrease loadGranule coatingCell electrodesSpherical morphologyMetal powder

Nickel powder batches and methods for producing nickel powder batches. The powder batches include particles having a small particle size, narrow size distribution and a spherical morphology. The present invention is also directed to devices incorporating the nickel metal powders.

Owner:CABOT CORP

Cathodoluminescent phosphor powders, methods for making phosphor powders and devices incorporating same

InactiveUS6875372B1High crystallinitySmall particle sizeMaterial granulation and coatingGranule coatingMetallurgyEconomic production

Cathodoluminescent phosphor powders and a method for making phosphor powders. The phosphor powders have a small particle size, narrow particle size distribution and are substantially spherical. The method of the invention advantageously permits the economic production of such powders. The invention also relates to improved devices, such as cathodoluminescent display devices, incorporating the phosphor powders.

Owner:CABOT CORP

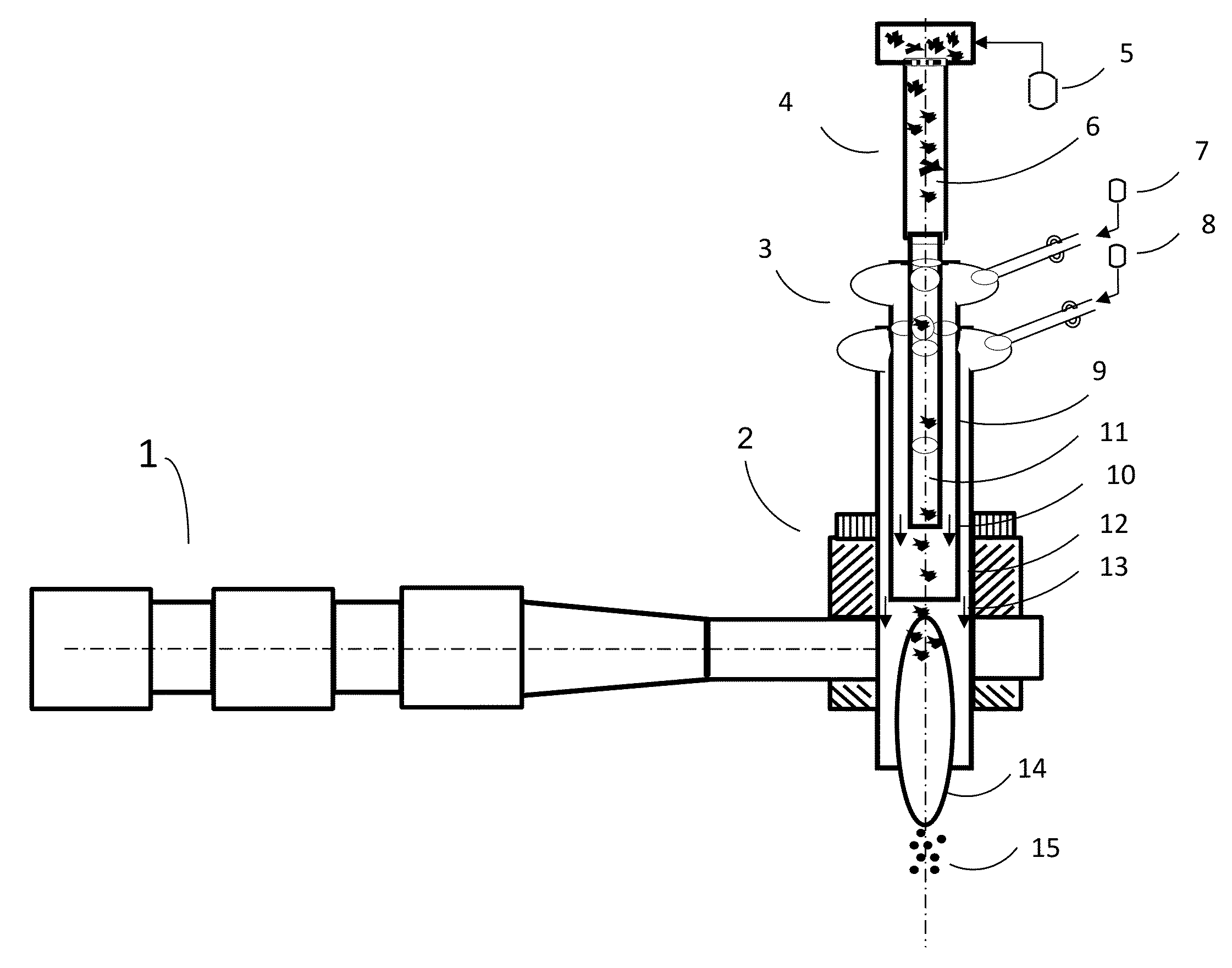

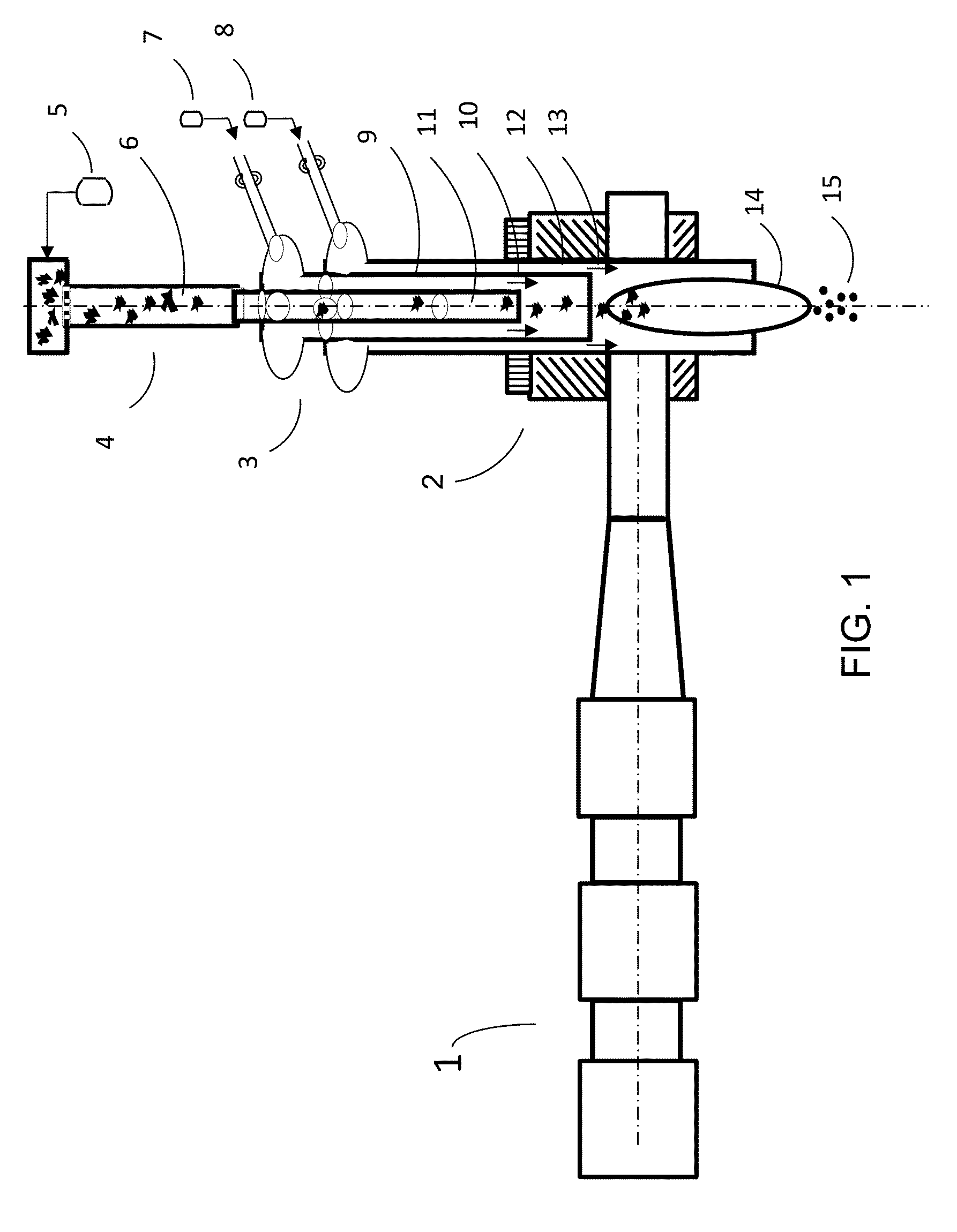

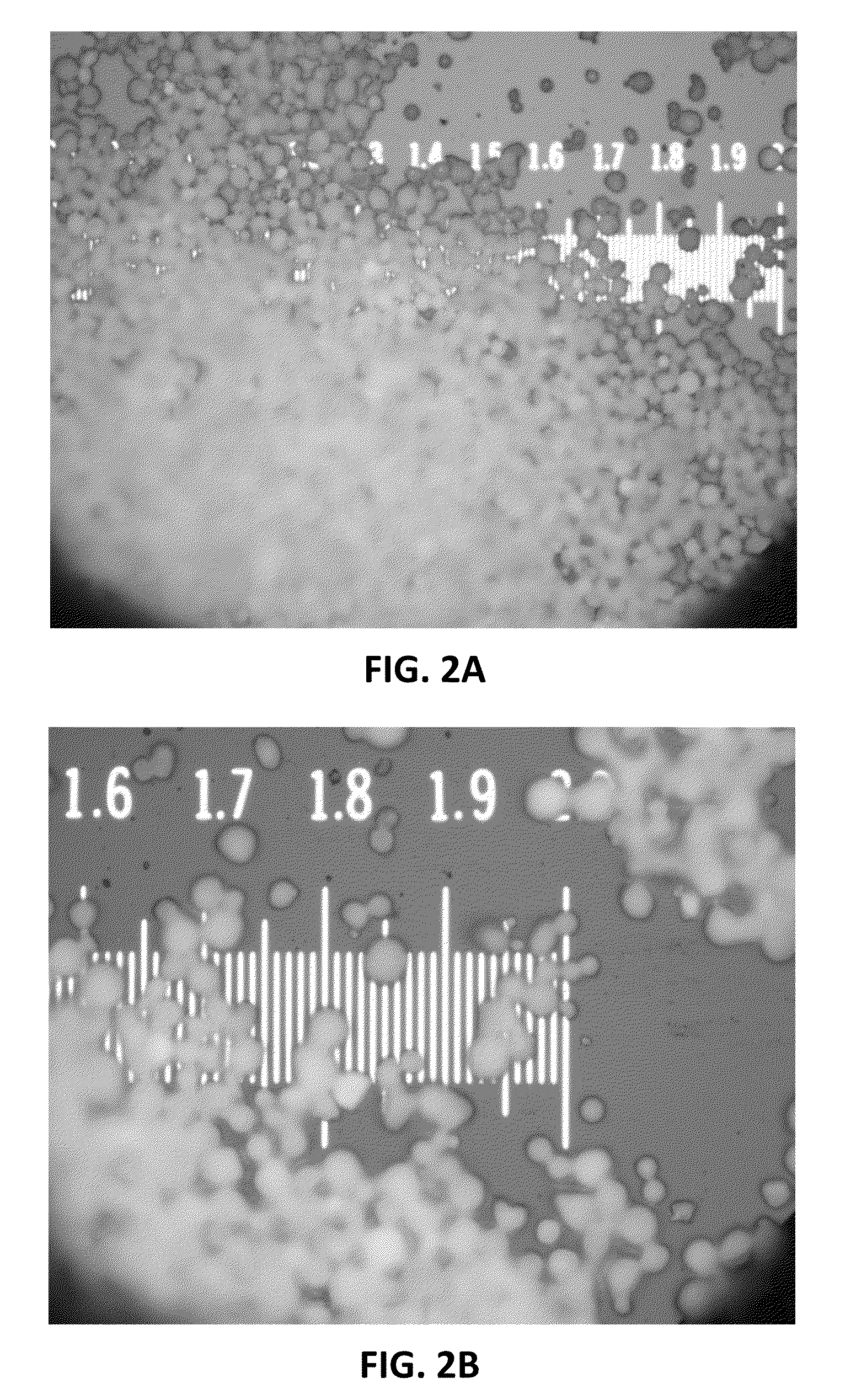

Method for densification and spheroidization of solid and solution precursor droplets of materials using microwave generated plasma processing

ActiveUS9206085B2Uniform densityUniform shapeMolten spray coatingGranulation by liquid drop formationBody fluidMaterial distribution

A method for processing feed material to produce dense and spheroidal products is described. The feed material is comprised of powder particles from the spray-drying technique or solution precursor droplets from ceramic or metallic materials. The feed material is processed using plasma generated from a microwave. The microwave plasma torch employed is capable of generating laminar flow during processing which allows for the production of spheroidal particles with a homogenous materials distribution. This results in products having improved thermal properties, improved corrosion and wear resistance and a higher tolerance to interface stresses.

Owner:6K INC

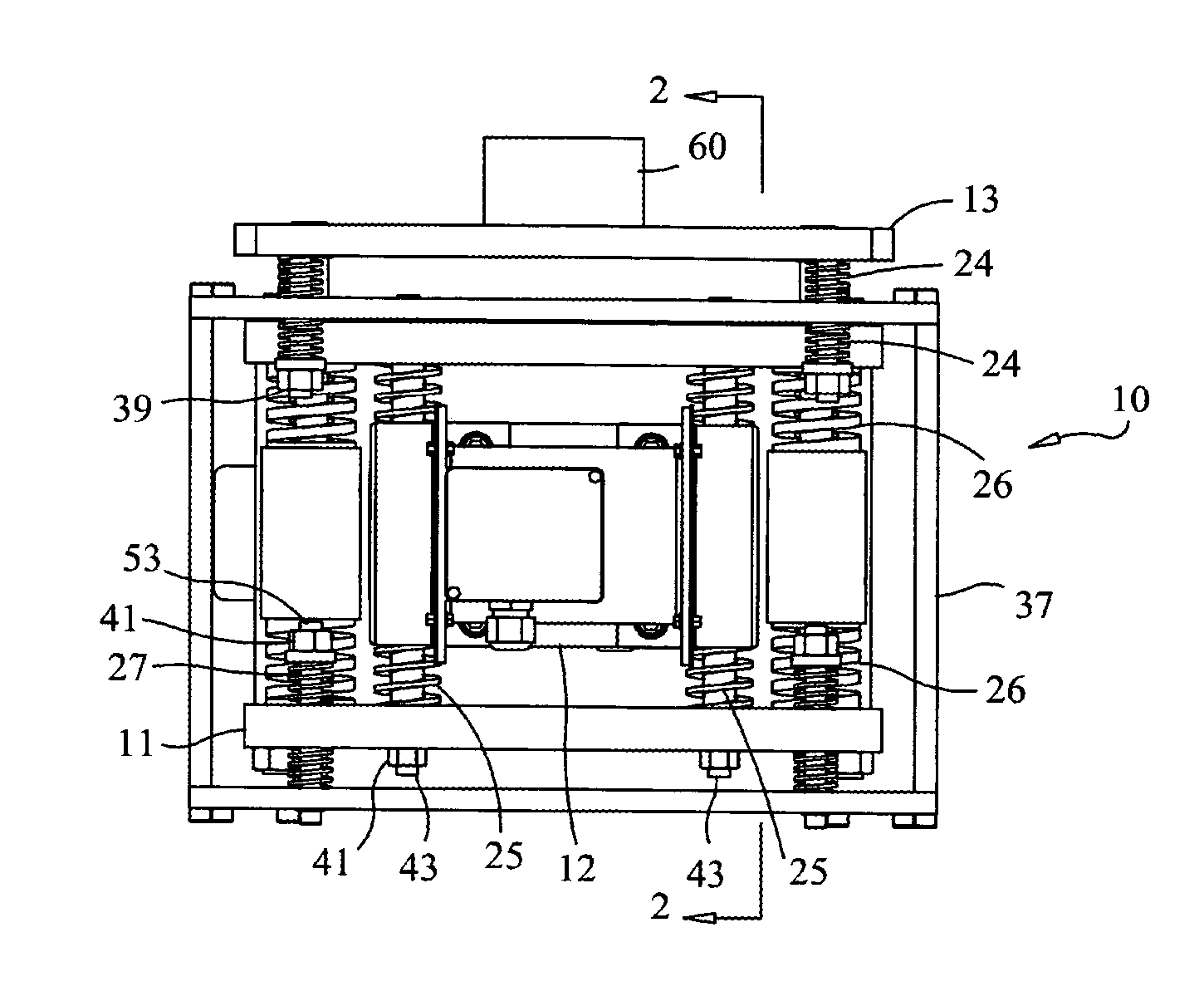

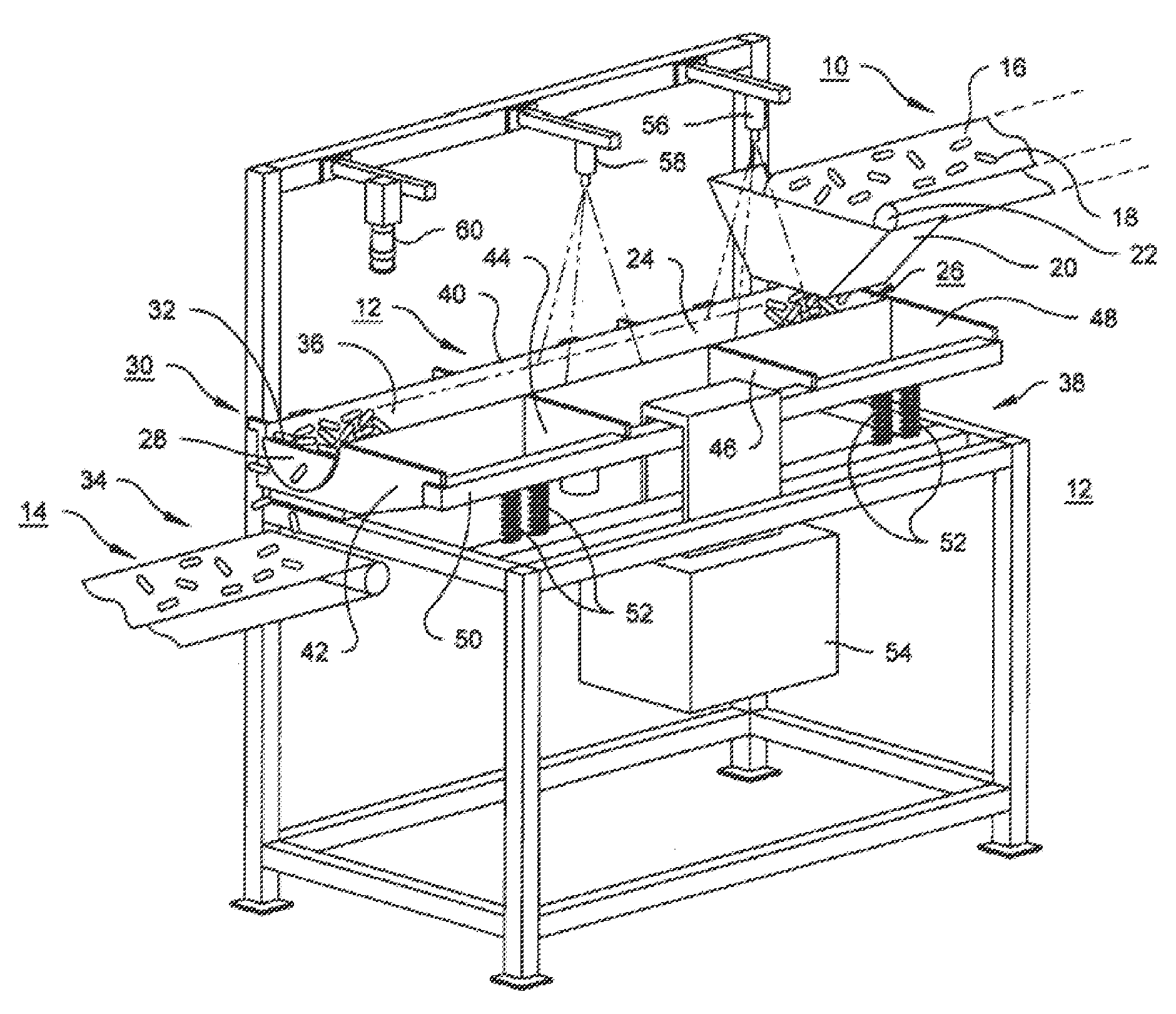

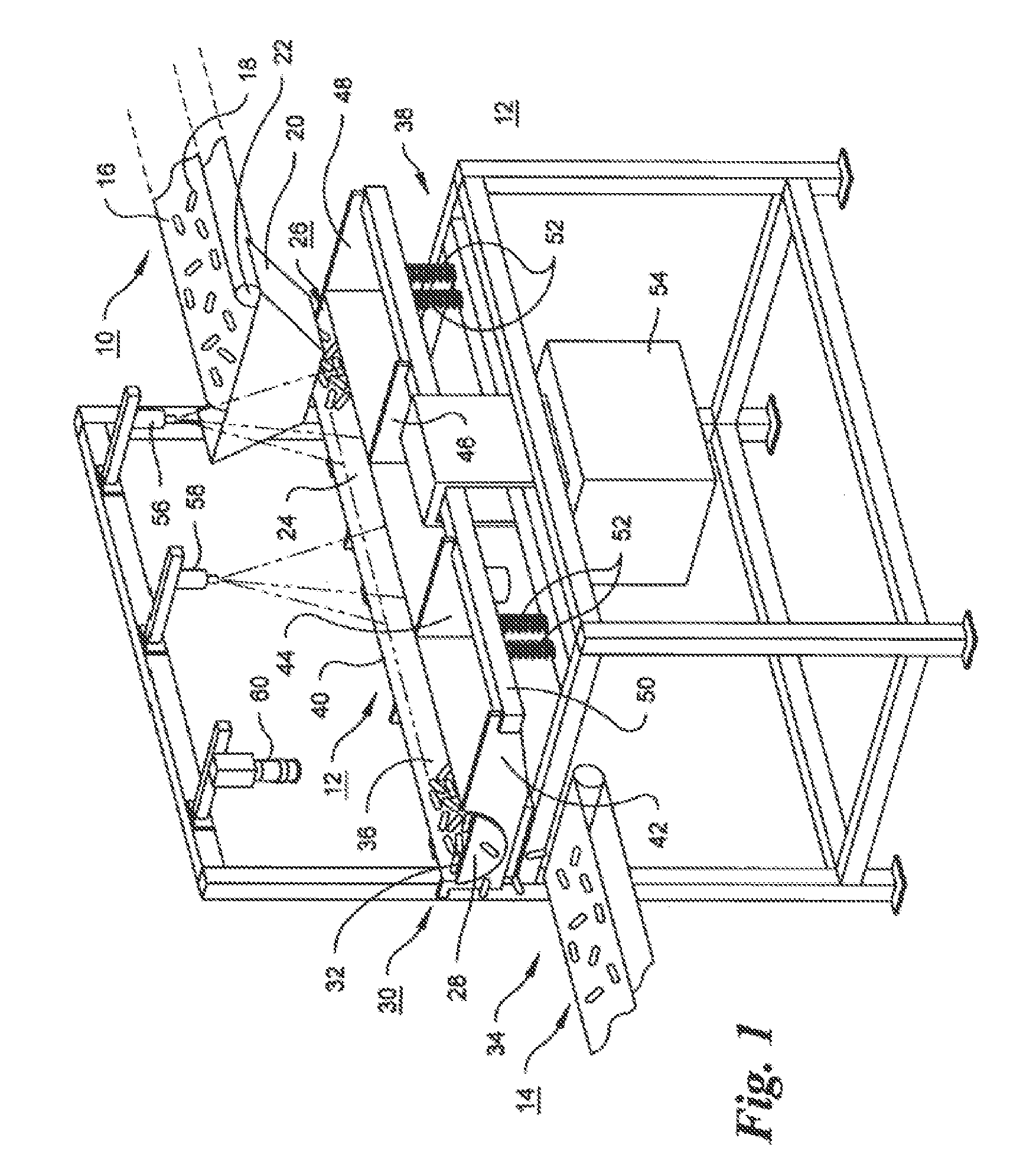

Mechanical system that fluidizes, mixes, coats, dries, combines, chemically reacts, and segregates materials

The present application is directed towards systems for adding components to materials being fluidized in a vibratory mixer by use of atomizers or sprayers. A mechanical system can fluidizes, mix, coat, dry, combine, or segregate materials. The system may comprise a vibratory mixer, mixing vessel containing a first material and a sprayer to introduce a second material. The vibratory mixer may generate a fluidized bed of a first material and the sprayer, coupled to the mixing vessel, may introduce a second material onto the fluidized bed to mix the materials in a uniform and even fashion.

Owner:RESODYN CORP

Method and apparatus for producing toner

ActiveUS20120070777A1Efficient productionGood monodispersityGranulation by liquid drop formationAuxillary shaping apparatusEngineeringPolyresin

An apparatus for producing a toner, including a liquid droplet-forming unit configured to discharge a toner composition liquid containing at least a resin and a colorant at a uniform discharge speed from a plurality of discharge holes some of which have different shapes from each other to thereby form liquid droplets, and a particle-forming unit configured to solidify the liquid droplets of the toner composition liquid to thereby form particles.

Owner:RICOH KK

Photoluminescent phosphor powders, methods for making phosphor powders and devices incorporating same

InactiveUS20070138438A1Small particle sizeHigh crystallinityMaterial granulation and coatingGranule coatingPhotoluminescenceEconomic production

Owner:SICPA HLDG SA

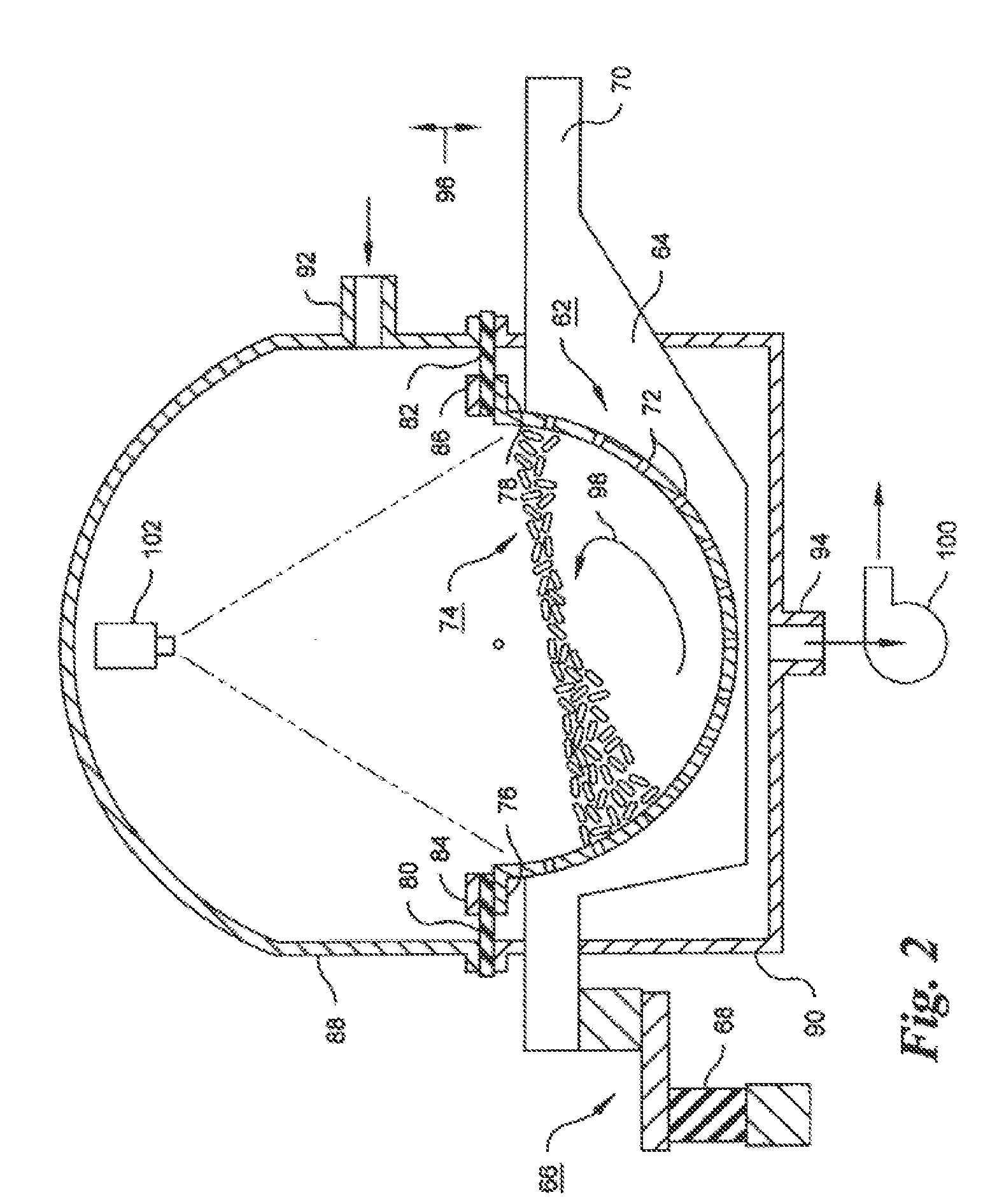

Continuous Coating of Pellets

A continuous dosage form coating apparatus uses vibrational impulses to maintain a dosage forms in a fluid state to expose them to a coating material atomized by spraying.

Owner:GLAXO SMITHKLINE LLC

Method of manufacturing toner, toner manufacturing apparatus, and method of manufacturing resin particles

ActiveUS20120094231A1Granulation by liquid drop formationAuxillary shaping apparatusNozzleEngineering

A method of manufacturing toner is provided, including discharging a toner constituents liquid from multiple nozzles to form liquid droplets and solidifying the liquid droplets into toner particles. The multiple nozzles satisfy the following formula:2.5≦p / d≦7.5wherein d represents an outlet diameter of each nozzle and p represents an interval between two nozzles.

Owner:RICOH KK

Copper powders methods for producing powders and devices fabricated from same

InactiveUS7316725B2High crystallinityHigh rateMaterial nanotechnologyMaterial granulation and coatingPowder methodSpherical morphology

Copper metal powders, methods for producing copper metal powders and products incorporating the powders. The copper metal powders have a small particle size, narrow size distribution and a spherical morphology. The method includes forming the metal particles in a continuous manner.

Owner:CABOT CORP

Production of encapsulated nanoparticles at high volume fractions

InactiveUS20120165410A1Appropriate useEasy to separatePowder deliveryBiocideParticulatesNanoparticle

Owner:ICEUTICA PTY LTD

Chemical-mechanical planarization slurries and powders and methods for using same

InactiveUS20050081998A1High rateIncrease loadRare earth metal oxides/hydroxidesMaterial granulation and coatingSpherical morphologySlurry

Chemical-mechanical planarization slurries and methods for using the slurries wherein the slurry includes abrasive particles. The abrasive particles have a small particle size, narrow size distribution and a spherical morphology and the particles are substantially unagglomerated.

Owner:CABOT CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com