Baijiu distiller's grain oil and preparation method and application thereof

A technology for liquor and spent oil, which is applied in the application, e-liquid filter, tobacco and other directions to achieve the effect of increasing the number of species and extraction rate, reducing the amount of use, and improving the extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

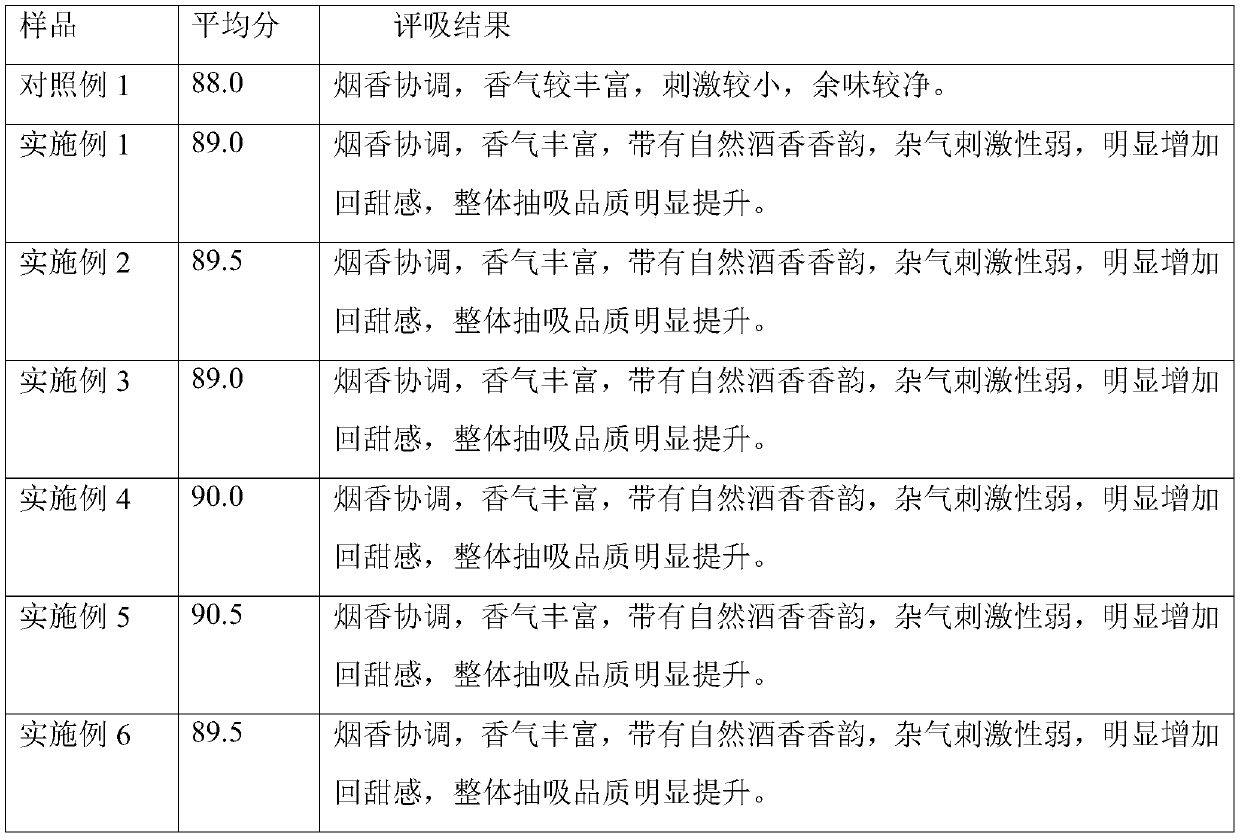

Examples

Embodiment 1

[0035] Take 1 kg of freshly discarded liquor grains, freeze at -10°C for 24 hours, add 1.5 kg of caprylic acid glyceride after mechanical crushing, ultrasonically extract for 1 hour at a temperature of 30-50°C, centrifuge at 4000rpm for 10 minutes, and add the residue after centrifugation 1.0 kilograms of caprylic acid glycerides, repeat above-mentioned steps, 2 centrifuges merge and obtain 2.2 kilograms of distilled spirits waste oil. Liquor waste oil is prepared into puffed beads according to the packaging process of puffed puffed puffs at the dosage of 10 mg / piece, and then the puffed puffs are added to cigarette filter rod tow through the filter rod forming process, and then rolled into cigarettes.

Embodiment 2

[0037] Take 0.5 kg of freshly discarded liquor grains, freeze at -18°C for 15 hours, mechanically crush them, add 2 kg of caprylic acid glycerides, conduct ultrasonic extraction at 30-50°C for 1 hour, centrifuge at 3000rpm for 30 minutes, and add the residue after centrifugation 2 kilograms of caprylic acid glycerides, repeat above-mentioned steps, 2 centrifugates merge and obtain 3.7 kilograms of distilled spirits waste oil. Liquor waste oil is prepared into puffed beads according to the packaging process of puffed puffed puffs at the dosage of 15 mg per piece, and then the puffed puffs are added to cigarette filter rod tow through the filter rod forming process, and then rolled into cigarettes.

Embodiment 3

[0039]Take 0.5 kg of fresh white wine grains, freeze at -30°C for 8 hours, after mechanical crushing, add 1 kg of olive oil, at a temperature of 30-50°C, perform ultrasonic extraction for 0.5 hours, centrifuge at 2500rpm for 30 minutes, add 1 kg of residue after centrifugation Olive oil, repeat above-mentioned steps, 2 centrifuges merge and obtain 1.8 kilograms of distilled grains oil. Liquor waste oil is prepared into puffed beads according to the packaging process of puffed puffed puffs at the dosage of 10 mg / piece, and then the puffed puffs are added to cigarette filter rod tow through the filter rod forming process, and then rolled into cigarettes. The smoking evaluation results show that the waste oil can endow cigarettes with a natural bouquet, enhance the aroma quality, reduce the irritation of miscellaneous gases, and increase the sweetness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com