Modified acrylic resin energy-saving and environment-friendly coating for microwave oven shell

An acrylic resin, energy-saving and environment-friendly technology, applied in anti-corrosion coatings, conductive coatings, coatings, etc., can solve problems such as unfavorable human health, economic losses, environmental pollution, etc., achieve good environmental protection effects, ensure quality, and reduce VOCs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be further described below through specific examples, but the examples do not limit the protection scope of the present invention.

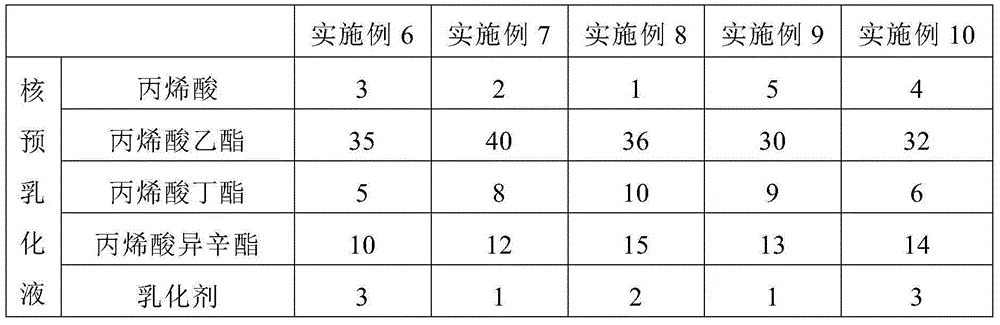

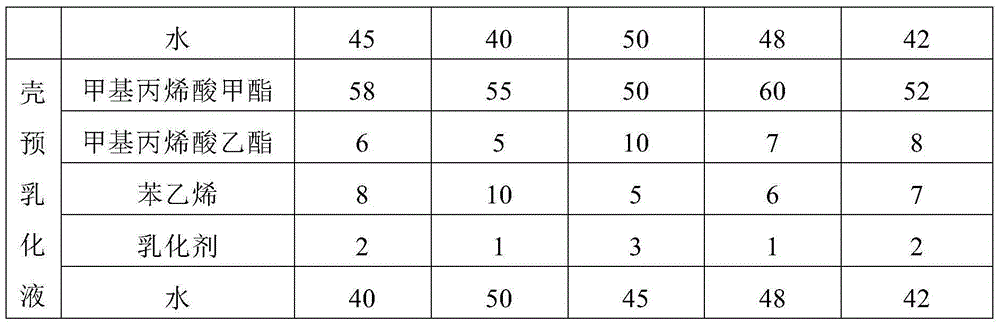

[0032] Table 1 is a list of mass fractions of components in a modified acrylic resin energy-saving and environment-friendly coating for a microwave oven casing according to an embodiment of the present invention. Table 2 is the preparation nano-SiO described in the embodiment of the present invention 2 List of core and shell pre-emulsion ingredients in modified acrylic resins. Table 3 is a list of performance parameters of a modified acrylic resin energy-saving and environment-friendly coating for a microwave oven casing according to an embodiment of the present invention. Table 4 is a list of coating performance parameters after a modified acrylic resin energy-saving and environment-friendly coating for a microwave oven casing according to an embodiment of the present invention is rolled on the surface of a micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com