High-precision numerical control pin machine

A high-precision, pin-shaft technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., to improve product quality and production efficiency, reduce costs, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

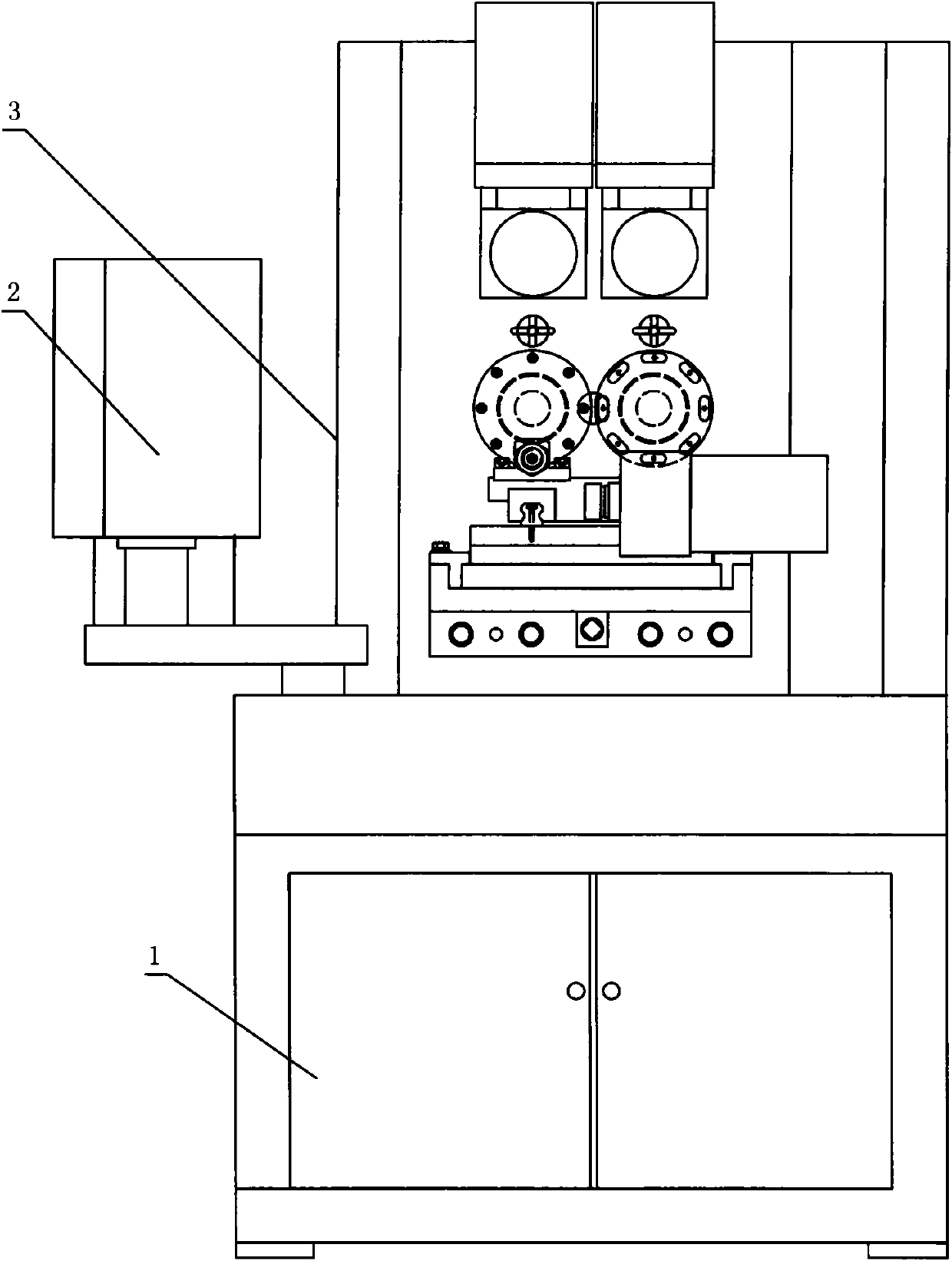

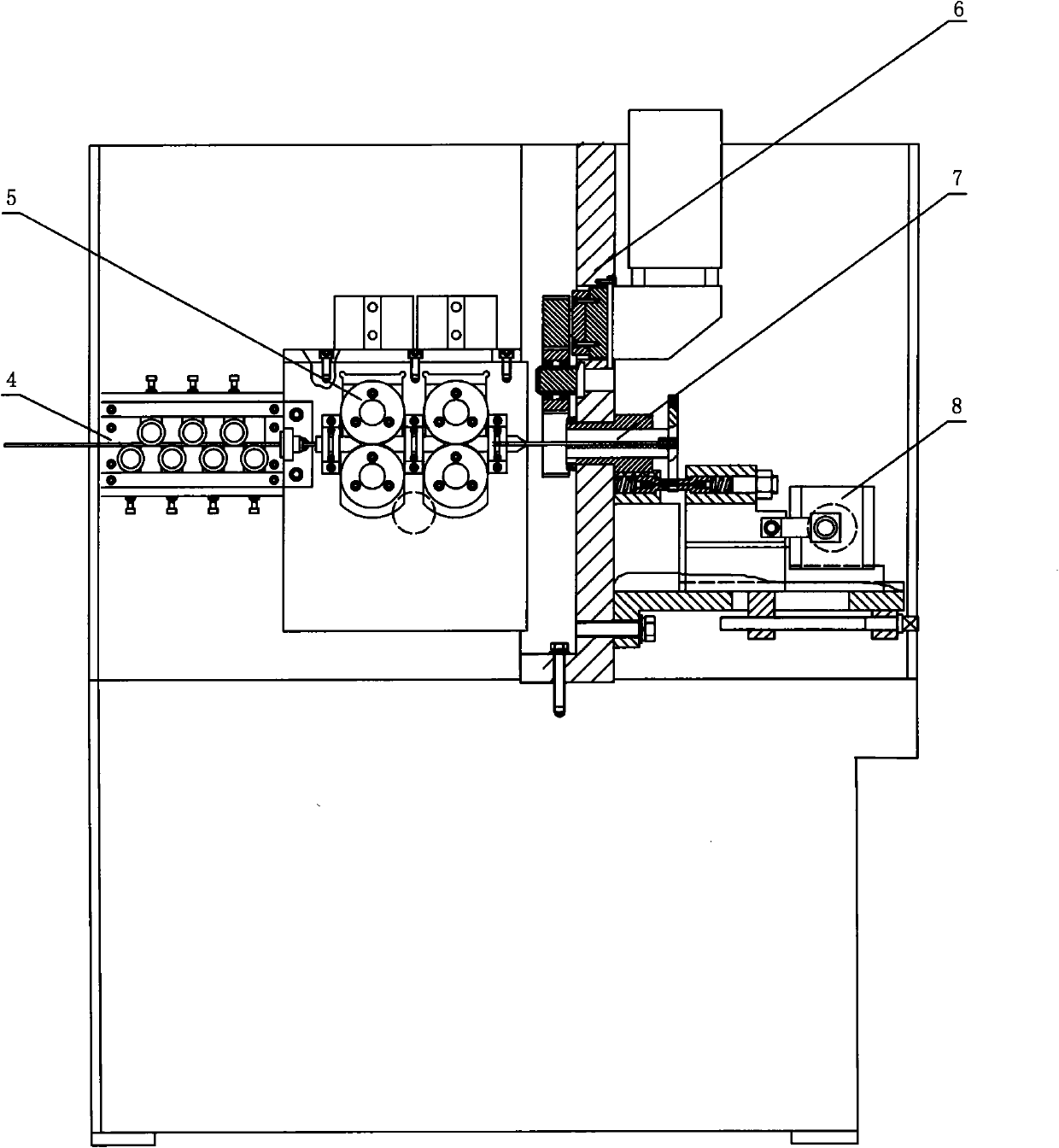

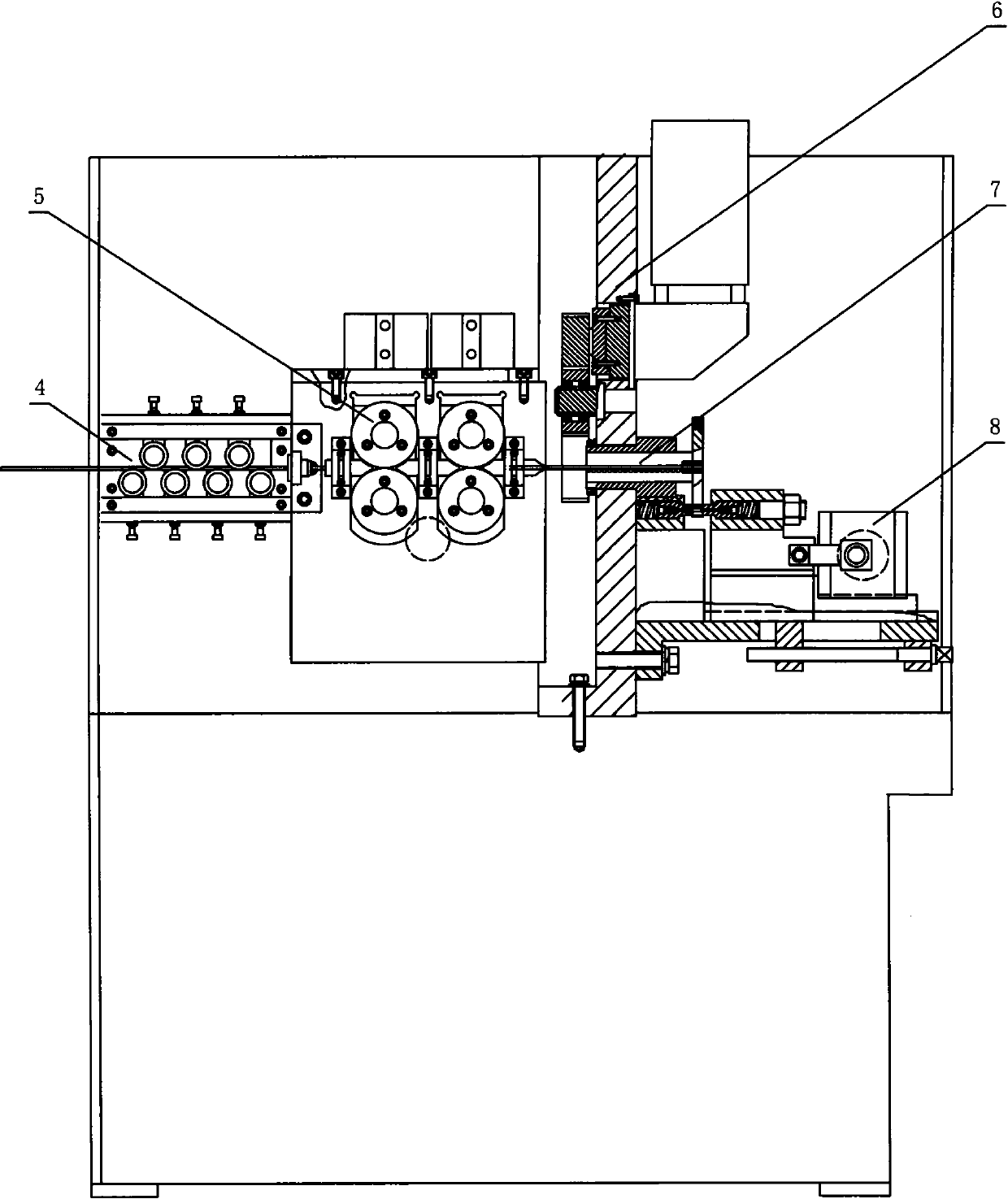

[0011] exist figure 1 , figure 2 Middle: The main body of the machine tool 3 is a cuboid frame structure welded by steel plates, the lower end is provided with a base 1, the left side of the machine tool main body 3 is provided with a straightening mechanism 4, and the right side of the straightening mechanism 4 is provided with a wire feeding mechanism 5. The mechanism 5 is provided with a pipe joint, which is connected with the air pipe of the air compressor, and the right side of the wire feeding mechanism 5 is provided with a main wallboard 6, and the right side of the main wallboard 6 is provided with two cutting mechanisms 7, and the cutting mechanism 7 is provided with There is a cutting die, the right side of the cutting mechanism 7 is provided with an extruding mechanism 8, and the extruding mechanism 8 is provided with two fixed extruding dies and two movable extruding punches, the fixed extruding die is located on the left side of the cutting die, and the extruding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com