Preparation of microcapsule humectant and application thereof to cigarette

A humectant and microcapsule technology, which is applied in the development and application of natural flavors, can solve the problems of no precedents in the application of microcapsule humectants for cigarettes, and achieve the goals of reducing dryness, improving comfort, and improving sensory quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

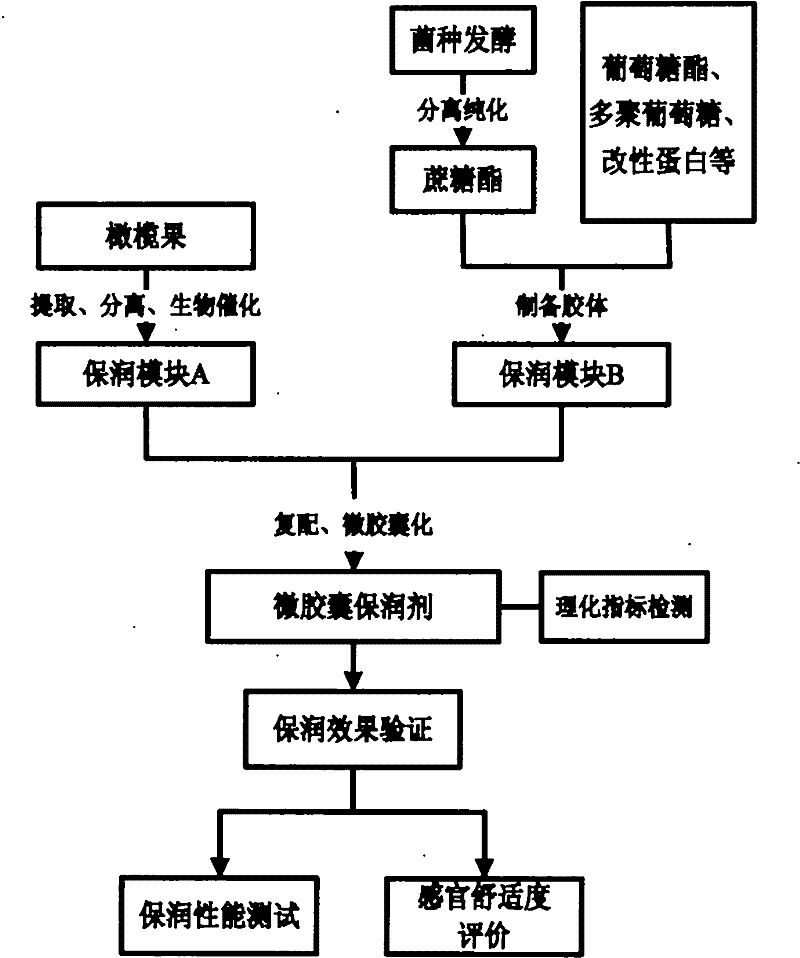

Method used

Image

Examples

Embodiment 1

[0025] 1. Remove the dust and leaves from the olive fruit, wash it with clean water, and crush it with a pulverizer. After the crushed pulp is homogenized, add 2 times the amount (v / v) of water and centrifuge for 20 minutes. Take the upper oil layer and put it into a brown bottle. Store away from light.

[0026] 2. Mix the oil layer and 3% lipase solution uniformly at a ratio of 1:1 (mass ratio), react in a water bath at 80° C. for 3 hours, and stir intermittently. After the mixture was completely reacted, it was extracted three times with distilled water, and the lower aqueous turbid liquid was discarded. Combine the oily matter in the upper layer, then add 3 times the volume of 95% ethanol, oscillate to dissolve it completely, centrifuge for 10 min, and take the supernatant. The supernatant was concentrated under reduced pressure until it had no alcohol and no water, and the moisturizing module A was obtained.

[0027] 3. Under the optimum fermentation conditions, the stra...

Embodiment 2

[0033] 1. Remove the dust and leaves from the olive fruit, wash it with clean water, and crush it with a pulverizer. After the crushed pulp is homogenized, add 3 times the amount (v / v) of water and centrifuge for 30 minutes. Take the upper oil layer and put it into a brown bottle. Store away from light.

[0034] 2. Mix the oil layer and 1% lipase solution uniformly at a ratio of 1:1 (mass ratio), react in a water bath at 80° C. for 5 hours, and stir intermittently. After the mixture was completely reacted, it was extracted three times with distilled water, and the lower aqueous turbid liquid was discarded. The upper layer oils were combined, then 3 times the volume of 95% ethanol was added, oscillated to dissolve completely, centrifuged for 20 min, and the supernatant was taken. The supernatant was concentrated under reduced pressure until it had no alcohol and no water, and the moisturizing module A was obtained.

[0035] 3. Under the optimum fermentation conditions, the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com