Raw beef cutting machine

A cutting machine and beef technology, applied in meat cutting/trimming, processed meat, meat processing equipment, etc., can solve the problems of beef loss of nutrition, taste not delicious, cumbersome process, etc., to reduce labor intensity and protect nutrition Value, delicious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

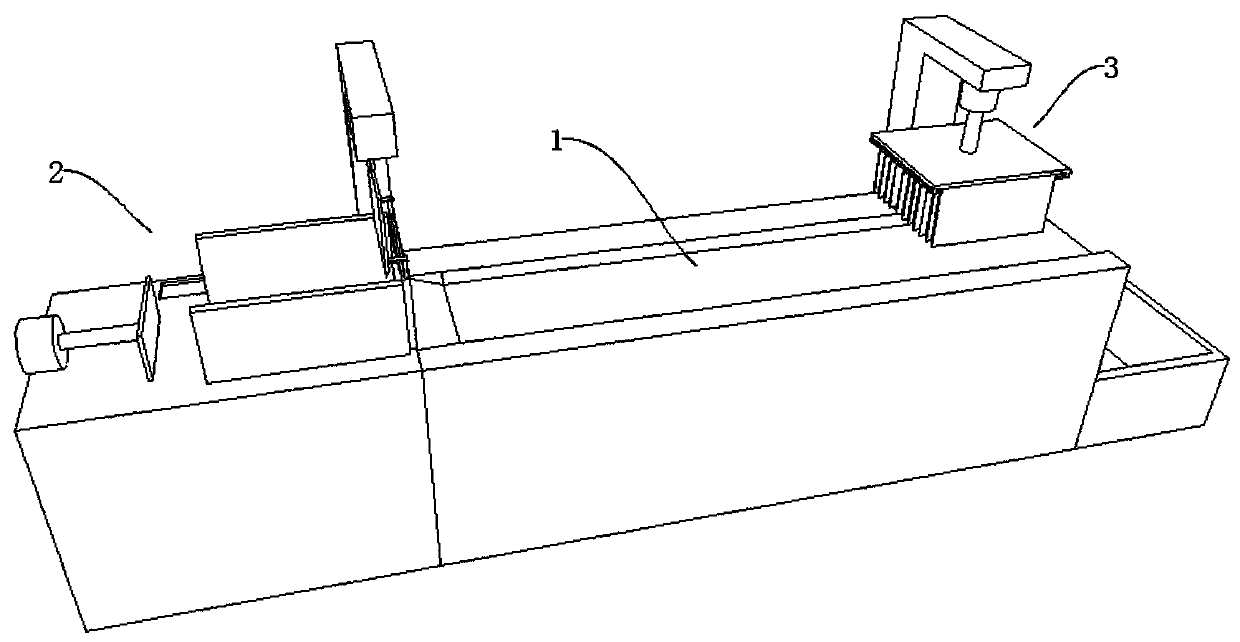

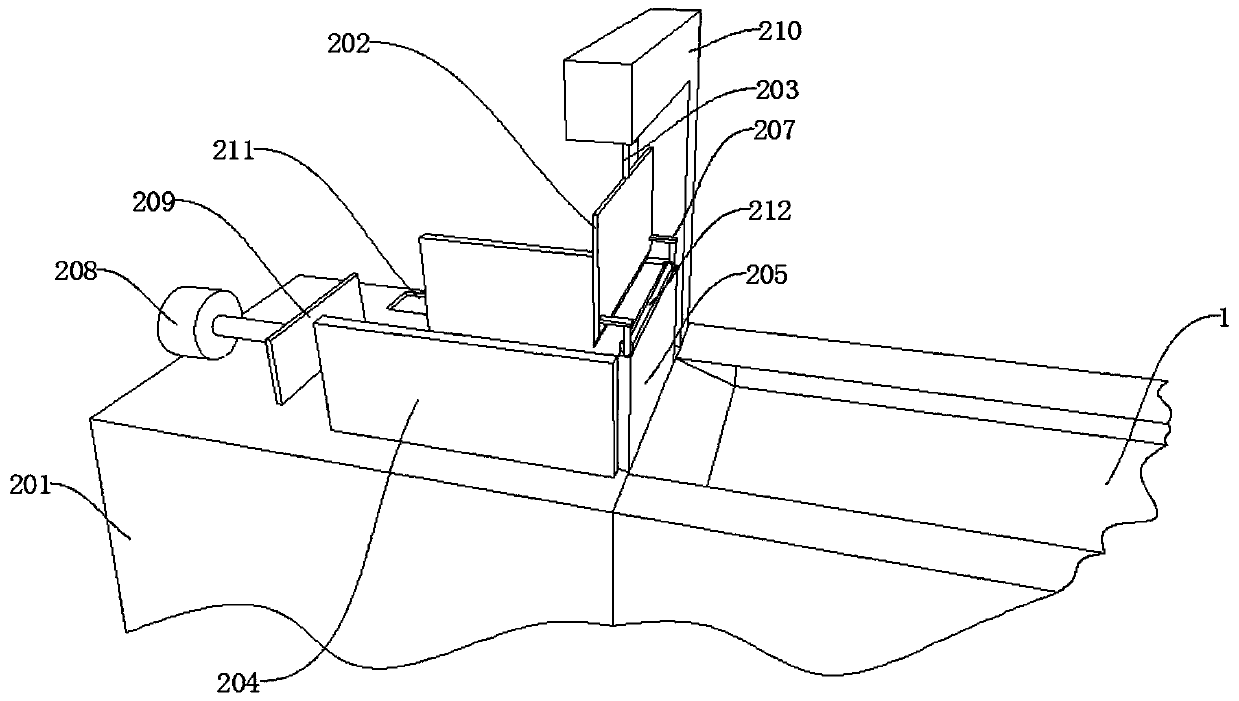

[0036] Please refer to Figure 1~6 This embodiment provides a cutting machine for cutting raw beef. The cutting machine includes a conveying mechanism 1. The feeding end of the conveying mechanism 1 is provided with a slicing mechanism 2 for slicing, and the slicing mechanism 2 and the conveying mechanism 1 discharge There is a strip cutting mechanism 3 for cutting strips between the ends, and the sliced beef cut by the cutting mechanism 2 can be transferred to the strip cutting mechanism 3 through the conveying mechanism 1 for cutting, and after the cutting is completed, it is transferred by the conveying mechanism 1 Go to the next station, so as to realize the operation of slicing and cutting raw beef, realize the assembly line operation, reduce the labor intensity of labor, and improve the efficiency of actual production and processing.

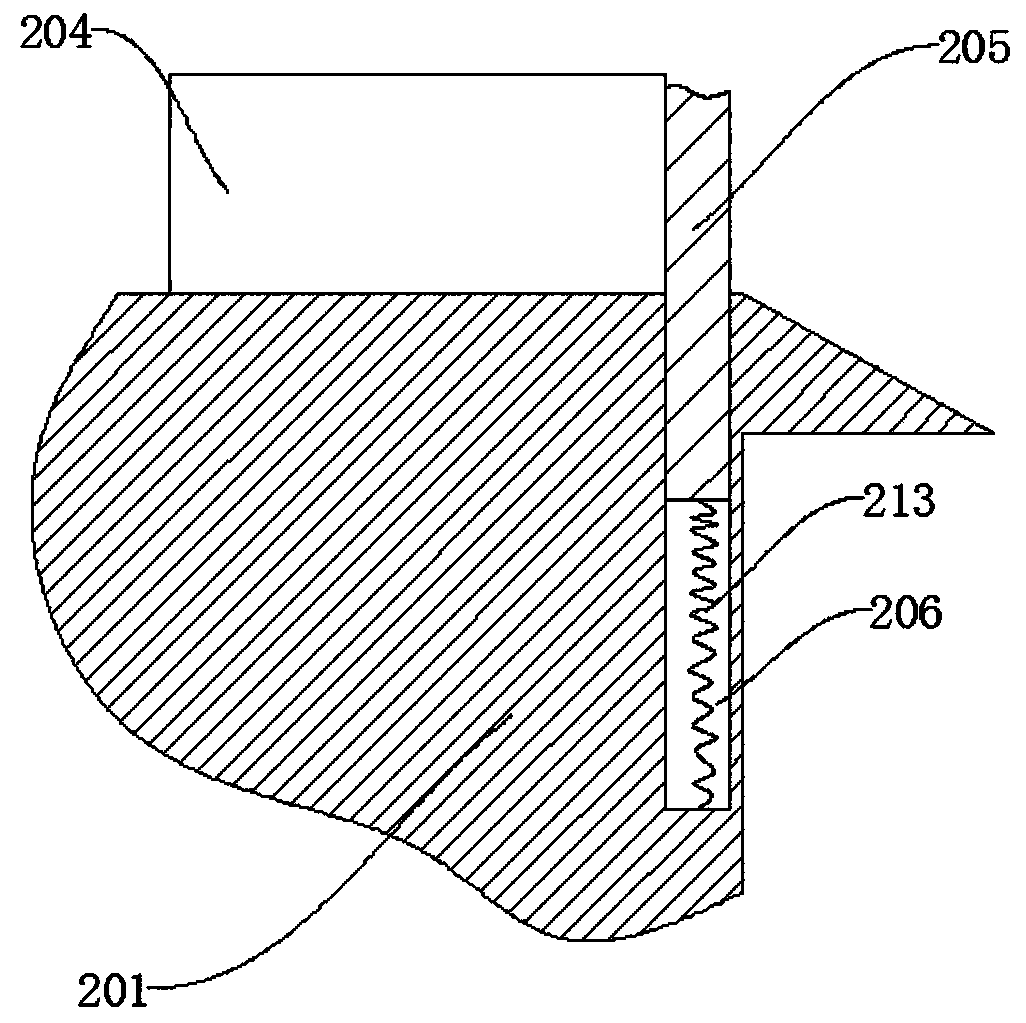

[0037] Among them, the slicing mechanism 2 includes a supporting table 201, a first cutting knife 202, and a first driving device 203. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com