High-adhesive force printing ink

A high-adhesion ink technology, applied in ink, household utensils, applications, etc., can solve problems that affect the health of users of printed materials, physical injuries of production workers, and injuries of printing workers, and achieve good glossy effects and good printing quality , Improve the effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

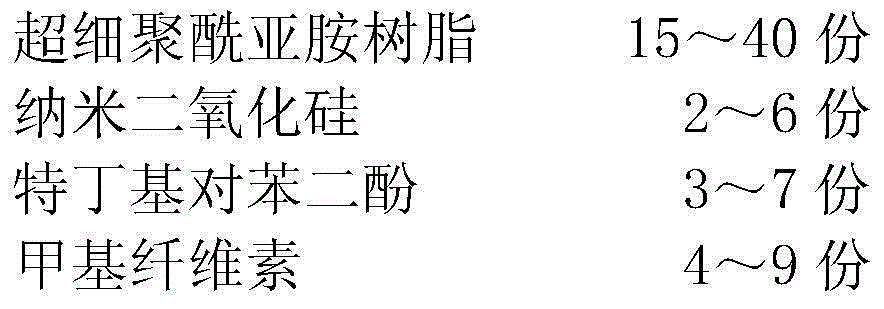

[0026] A kind of high-adhesive ink is made from the following raw materials in parts by weight:

[0027]

[0028] Mix ethanol and pentaerythritol and heat up to 75°C, add methyl cellulose, ultrafine polyimide resin and ultrafine polyimide resin in turn and stir evenly, then add nano-silica and titanium dioxide in turn, stir evenly, drop to normal temperature, and finally continue mechanical stirring for 30 minutes to obtain the finished product.

Embodiment 2

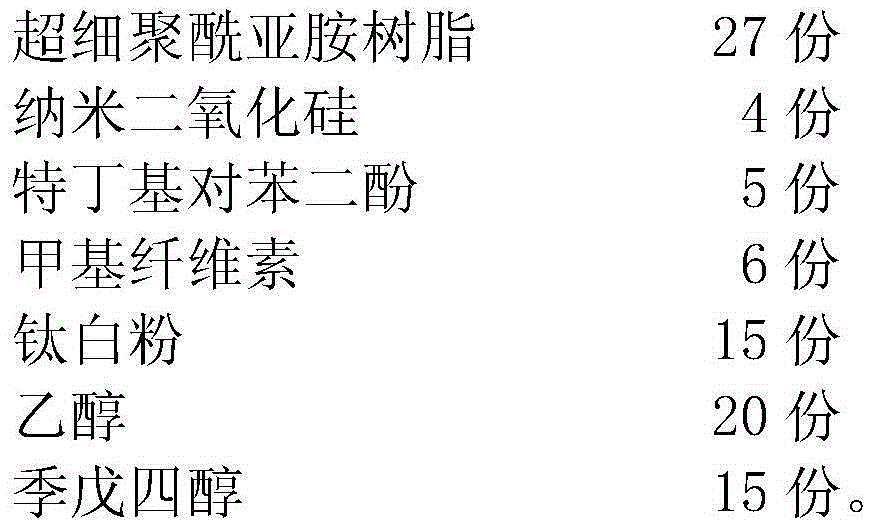

[0030] A kind of high-adhesive ink is made from the following raw materials in parts by weight:

[0031]

[0032] Mix ethanol and pentaerythritol and heat up to 80°C, add methyl cellulose, ultrafine polyimide resin and ultrafine polyimide resin in turn and stir evenly, then add nano silicon dioxide and titanium dioxide in turn, stir evenly, drop to normal temperature, and finally continue mechanical stirring for 40 minutes to obtain the finished product.

Embodiment 3

[0034] A kind of high-adhesive ink is made from the following raw materials in parts by weight:

[0035]

[0036] Mix ethanol and pentaerythritol and heat up to 85°C, add methyl cellulose, ultrafine polyimide resin and ultrafine polyimide resin in turn and stir evenly, then add nano silicon dioxide and titanium dioxide in turn, stir evenly, drop to normal temperature, and finally continue mechanical stirring for 45 minutes to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com