Patents

Literature

69results about How to "Bright effect is obvious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disposal method of electrolysis copper powder waste liquid and application thereof

ActiveCN101570367AGood flocculation effectWill not affect the purification effectWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteIron powder

The invention provides a disposal method of electrolysis copper powder waste liquid. The disposal method is characterized in that the electrolysis copper powder waste liquid orderly undergoes the disposals of precipitation separation, roasting oxidization and twice purification crystallization; and then the disposed copper-containing waste liquid is added with reducing iron powder for chemical replacement reaction so as to obtain copper immersion plate powder formed on the surface of the reducing iron powder. The disposal method achieves the aim of fully utilizing resources, saving energy, reducing exhaustion, consumption and production cost and causing no harm to human bodies or pollution to the environment, and fully meets the requirement of taking a new road to industrialization and realizing sustainable development.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

Brass composite powder and preparation method thereof

The invention provides brass composite powder, which is characterized in that the brass composite powder is prepared from 70 to 97 percent of copper and 3 to 30 percent of zinc in percentage by weight. The invention also provides a preparation method for the brass composite powder. The invention provides a substitute raw material with low cost and good product performance and quality for manufacture, application and development of the prior brass-based powder metallurgical products and parts.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

Glossy dried plum pectin powder

The invention discloses glossy dried plum pectin powder. The dried plum glossy pectin powder is prepared by burdening and mixing the following components in parts by weight: 35-40 parts of maltodextrin, 25-30 parts of white granulated sugar, 20-25 parts of maltitol, 15-20 parts of dried plum powder, 1-1.5 parts of pectin, 0.5-0.7 part of citric acid, 0.3-0.4 part of dried plum essence, 0.3-0.4 part of sodium citrate and 0.01-0.02 part of sodium copper chlorophyllin. The preparation of the glossy dried plum pectin by using the glossy dried plum pectin powder provided by the invention is simple, convenient and quick. Under high-speed stirring, the glossy dried plum pectin powder is slowly added to quantitative hot water being more than 80 DEG C, and then is dissolved and uniformly stirred to obtain the glossy dried plum pectin powder. The prepared glossy dried plum pectin powder is bright in color, remarkable in bright effect after being coated on the surface of a cake, smooth and natural in color, good in coating, hard to flow after being coated, fresh and fine in mouthtaste, moderate in sweet and sour, pure and thick in dried plum flavor, and appetite-tempting. The glossy dried plum pectin powder is a powder product, and easy to store and keep.

Owner:HARBIN GOLDIDEA SOFTWARE

Novel aluminum alloy plate as well as preparation method and application thereof

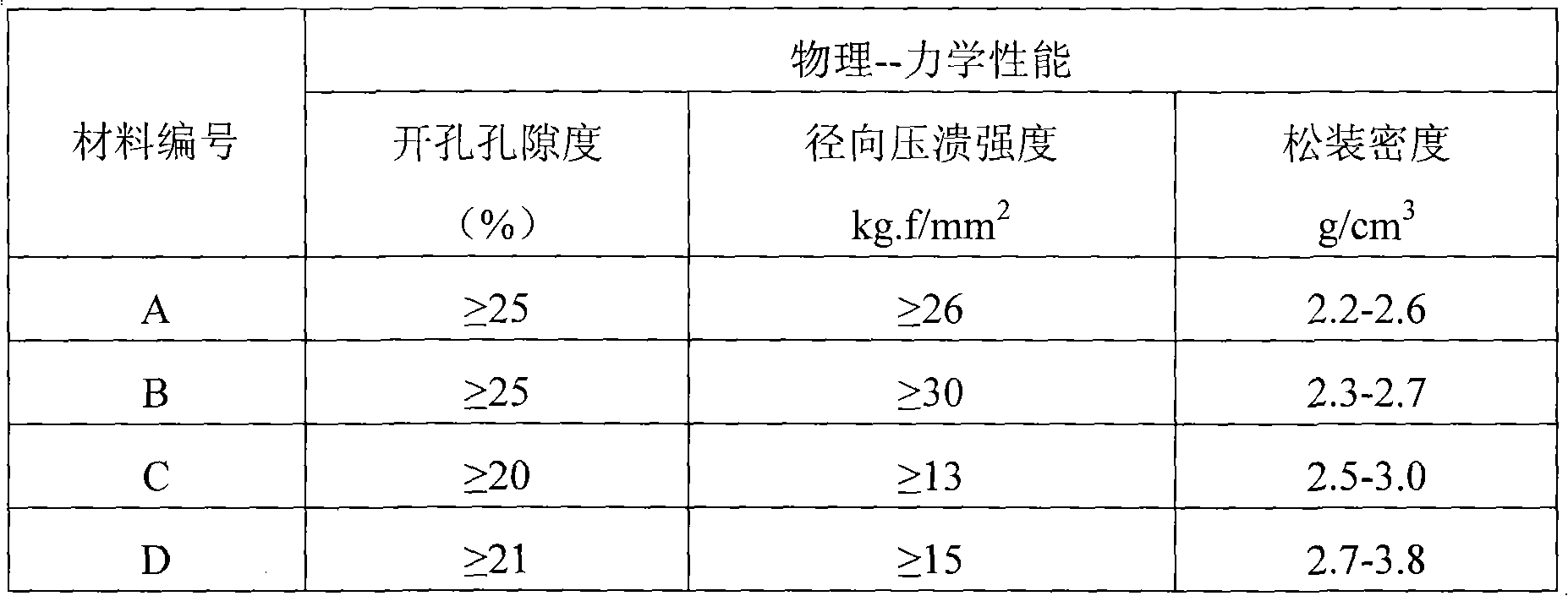

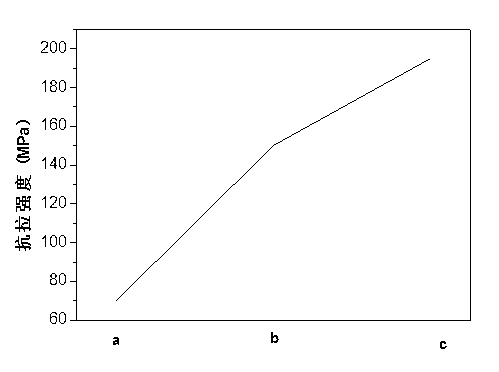

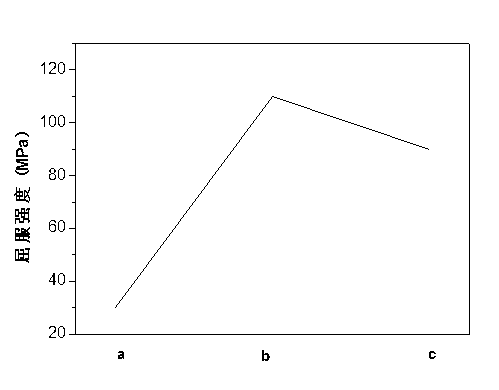

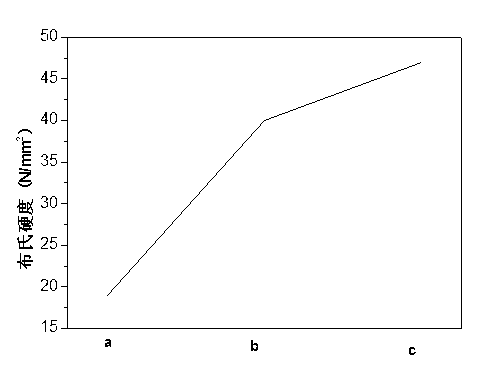

InactiveCN103014455AIncrease brightnessHigh tensile strengthVehicle componentsUltimate tensile strengthAluminium alloy

The invention relates to a novel aluminum alloy plate as well as a preparation method and an application of the novel aluminum alloy plate. The novel aluminum alloy plate is made from an Al-Mg alloy and is characterized in that the Al-Mg alloy comprises the following elements in percentage by weight: 0.8-1.0 percent of Mg, 0.14 percent of Si, 0.14 percent of Fe, 0.03 percent of Cu, 0.02 percent of Mn, 0.02 percent of Zn, 0.02 percent of Ti and the balance of Al. According to the novel aluminum alloy plate disclosed by the invention, with the adoption of the Al-Mg alloy, good surface performance of pure aluminum is kept, and the pure aluminum also has good mechanical properties such as tensile strength and rigidity; and the novel aluminum alloy plate is particularly suitable for manufacturing inner and outer decorations of vehicles, such as sill plates, lighting trims and labels.

Owner:SHANGHAI YINGHUI TECH DEV

Manufacturing method of brightening and smoothening agent

InactiveCN105111444AHigh temperature resistantNon-yellowingFibre treatmentOrganic synthesisTemperature resistance

The invention relates to a manufacturing method of brightening and smoothening agent, belonging to the fields of organic synthesis and macromolecular polymerization in chemical engineering and high polymer chemistry. The manufacturing method comprises the steps of preparing an ultra-high molecular weight linear silicone oil intermediate with aminos on two ends through basic catalyst equilibration reaction by virtue of organic silicone oligomers and an end-capping reagent, copolymerizing the ultra-high molecular weight linear silicone oil intermediate with diethylene glycol diglycidyl ether and a cationic etherifying agent to obtain specific silicone oil for the brightening and smoothening agent, compounding the specific silicone oil with polyethylene wax, and emulsifying by virtue of an emulsifying agent, glacial acetic acid and deionized water, so as to obtain the brightening and smoothening agent. By virtue of the technical scheme, the manufacturing method has the advantages and positive effects that the novel-structured specific silicone oil for the brightening and smoothening agent is firstly prepared and has stable performance of high temperature resistance, yellowing resistance and demulsification resistance. By virtue of the brightening and smoothening agent obtained by compounding silicone oil with polyethylene wax, a uniform adsorption film is easily formed on fabrics, and the processed fabrics have smooth hand feeling and a prominent brightening effect visually.

Owner:SHEYANG TIANYUAN CHEM IND CO LTD

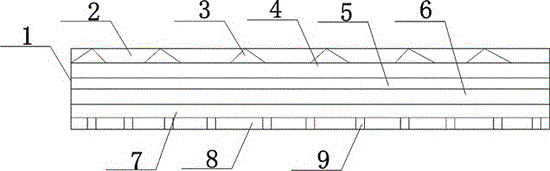

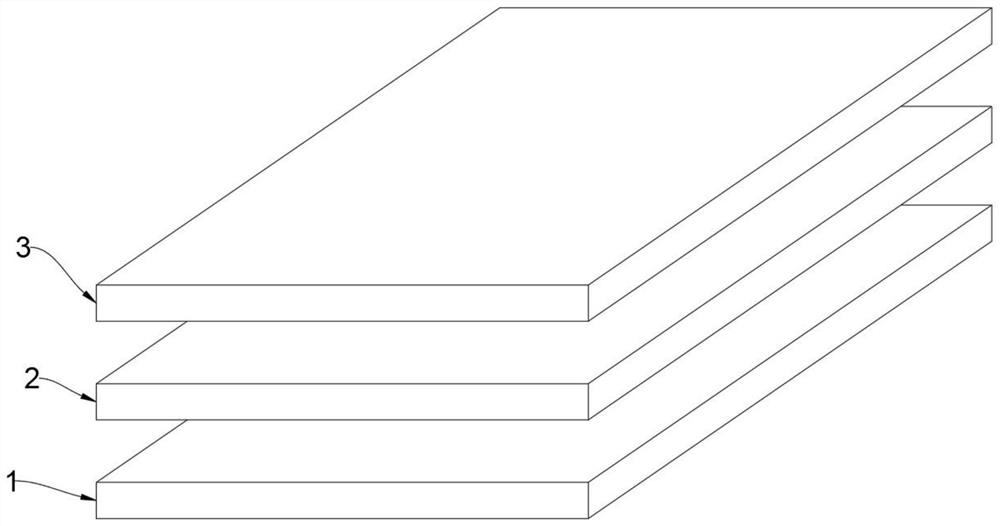

Decorative plate structure

InactiveCN104309255AGood structural simulation performanceBright effect is obviousCovering/liningsSynthetic resin layered productsEngineeringToughness

The invention discloses a decorative plate structure comprising a plate body; the plate body is provided with a basal plate layer, the basal plate layer is arranged close to the upper surface of the plate body, the basal plate layer and the plate body are fixedly connected, and the basal plate layer is internally provided with reinforcing plates; the reinforcing plates each have a triangular structure and are uniformly arranged in the basal plate layer; a fire-proof plate layer is arranged on the lower surface of the basal plate layer, the surface of the fire-proof plate layer is coated with a non-woven fabric layer, the lower surface of the fire-proof plate layer is provided with a thin wood plate layer, the thickness of the thin wood plate layer is less than that of the fire-proof plate layer, the thin wood plate layer is bonded with the fire-proof plate layer, the lower surface of the thin wood plate layer is provided with an anti-marble paint layer, and the thickness of the anti-marble paint layer is five to ten mm. The decorative plate structure has the advantages of good simulation performance, good bright effect, light weight, low cost, good toughness, difficult corrosion and deformation, quite high fire-proof and water-proof performance, tight interlayer structure, no generation of a lamination phenomenon, and easy cleanness, and has the service life enhanced.

Owner:HENAN UNIV OF ECONOMICS & LAW

Treatment method and application of electrolytic copper powder waste liquid

ActiveCN102259994AGood flocculation effectWill not affect the purification effectWaste water treatment from metallurgical processMultistage water/sewage treatmentElectrolysisIron powder

The invention provides a treatment method for electrolytic copper powder waste liquid, which is characterized in that: the electrolytic copper powder waste liquid is sequentially subjected to treatment including precipitation separation, roasting oxidation and twice purification and crystallization; Adding reduced iron powder to the final copper-containing waste liquid for chemical replacement reaction to obtain copper immersion plating powder that forms a copper coating layer on the surface of the reduced iron powder. The invention achieves the purposes of fully utilizing resources, saving energy, reducing emissions, reducing production costs, not harming the human body and not polluting the environment, and fully meets the needs of taking a new industrialization road and sustainable development.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

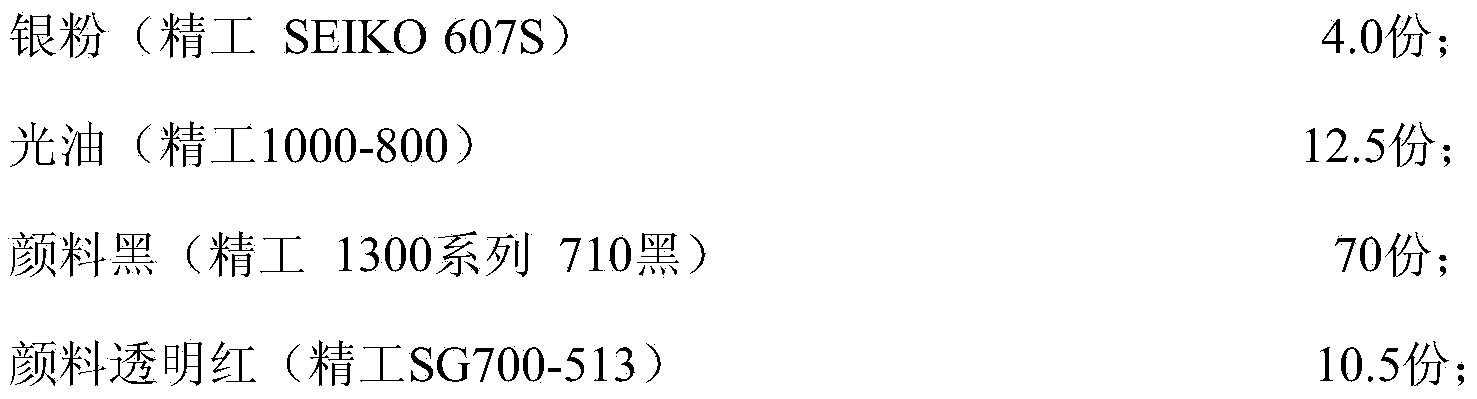

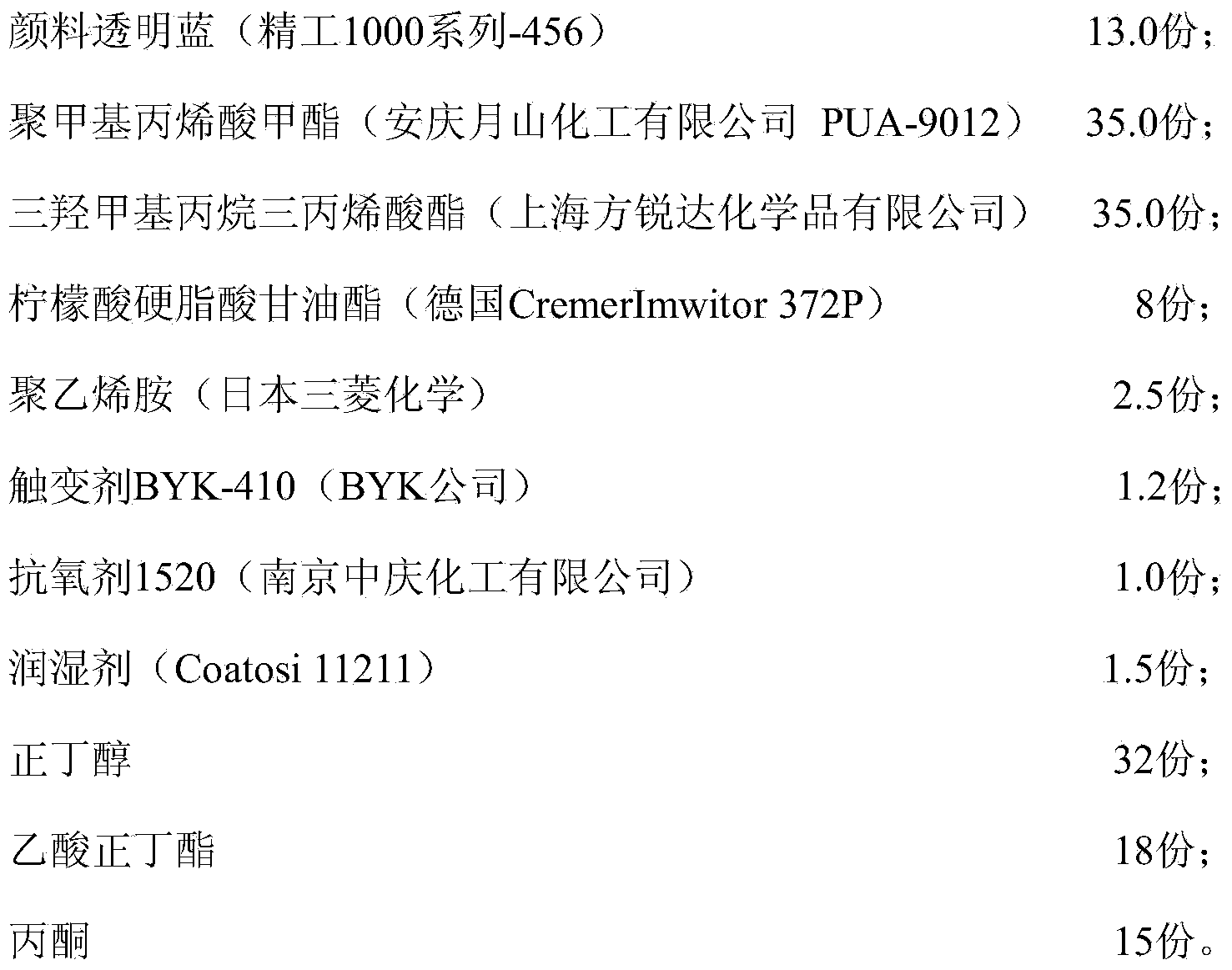

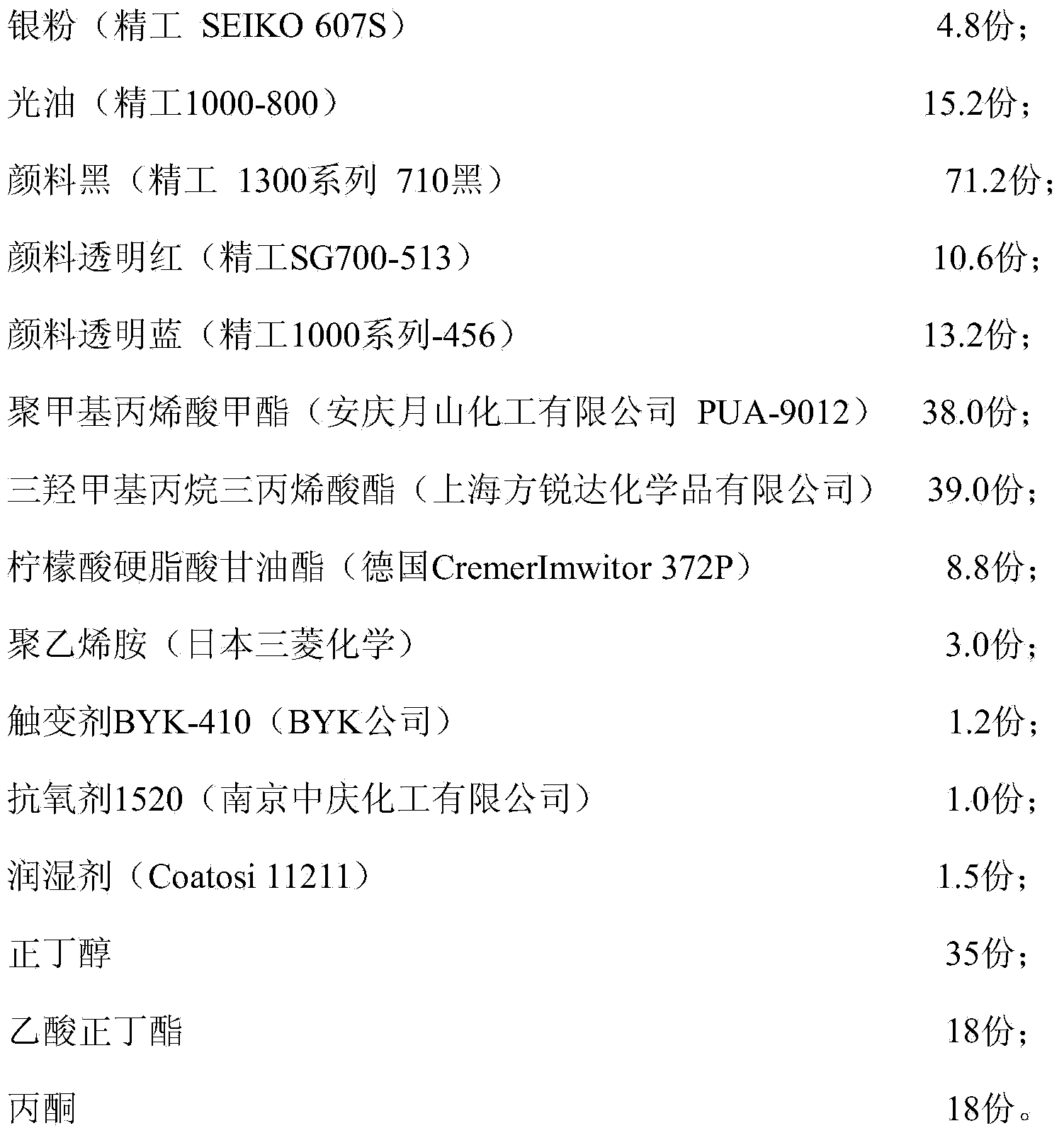

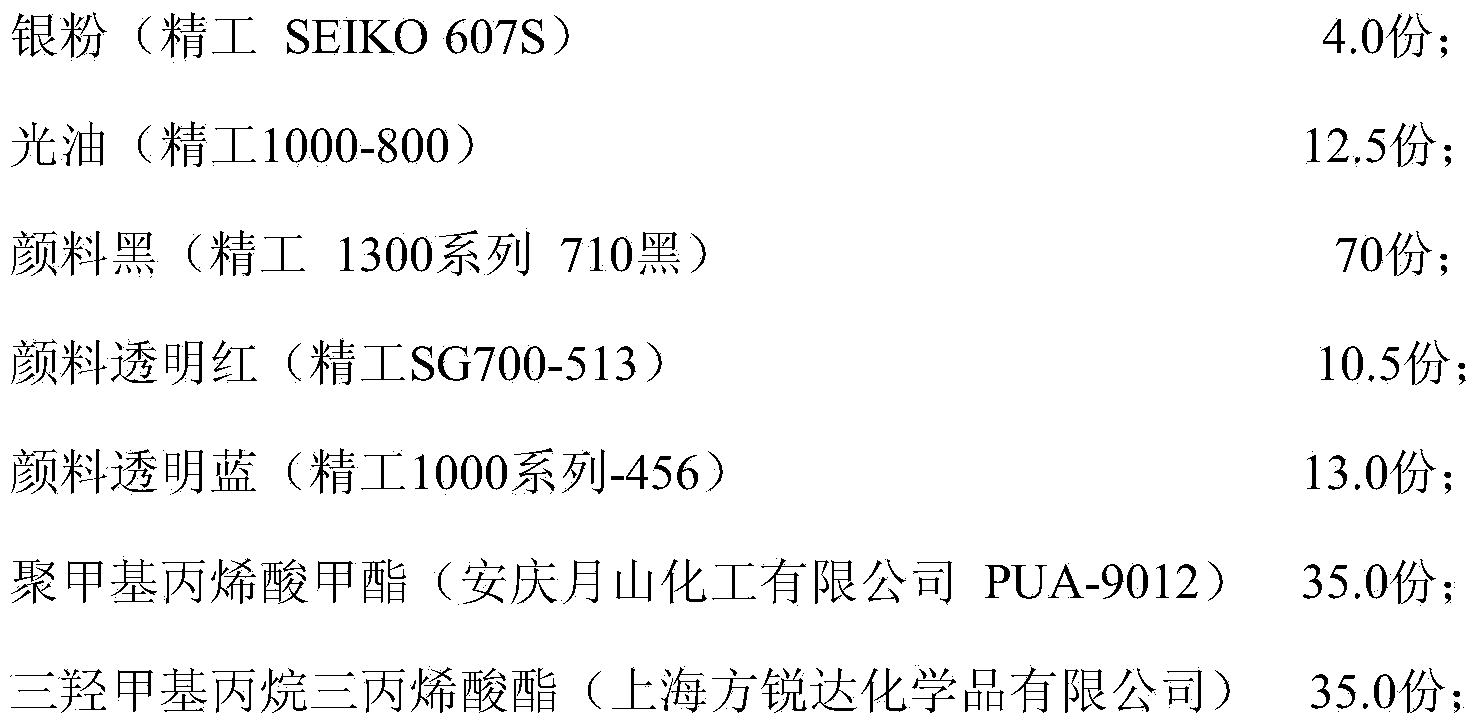

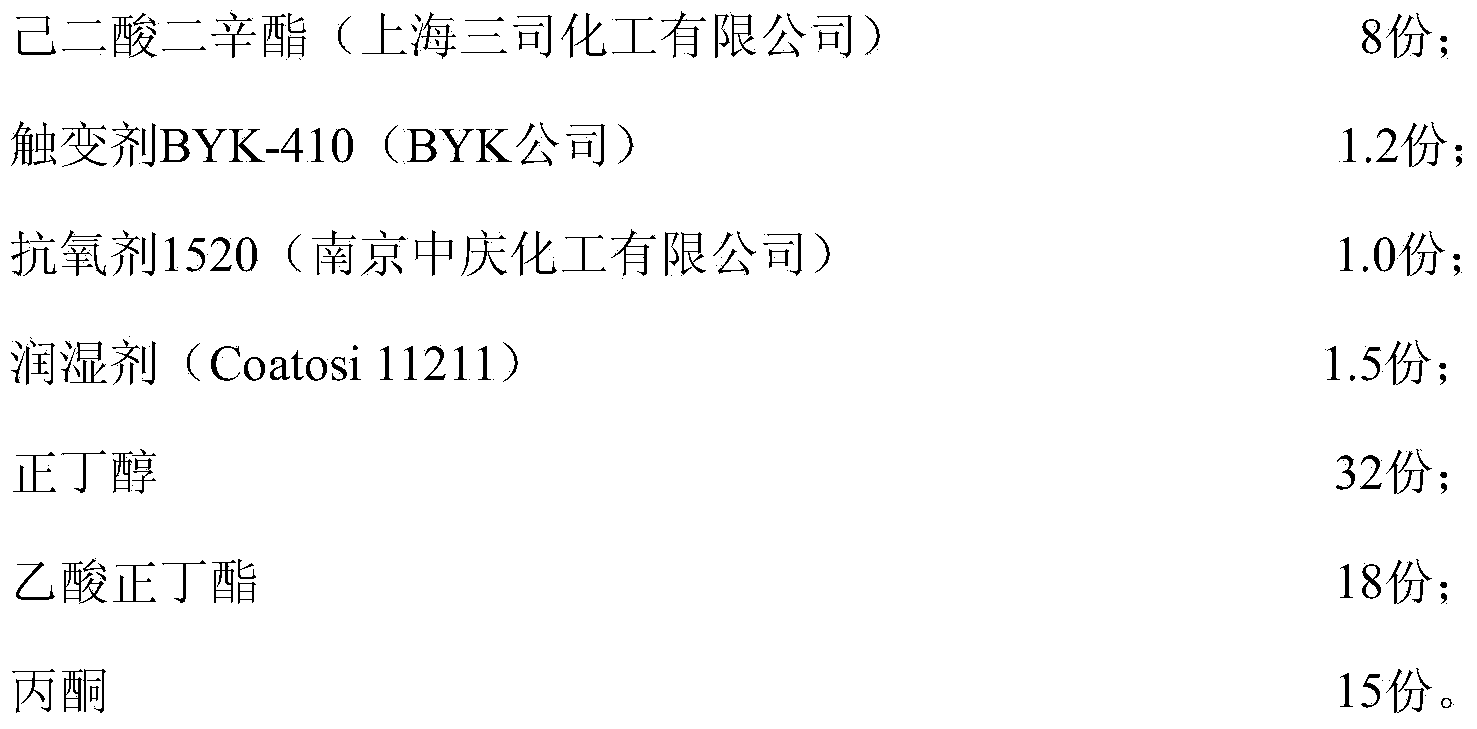

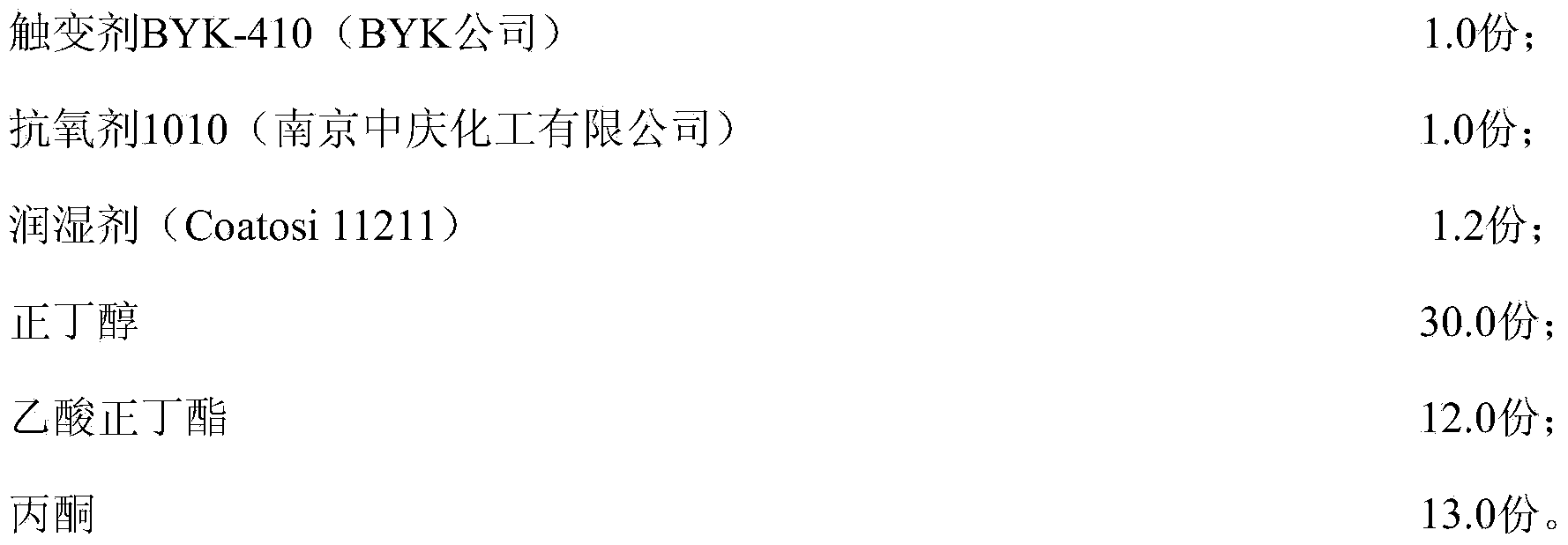

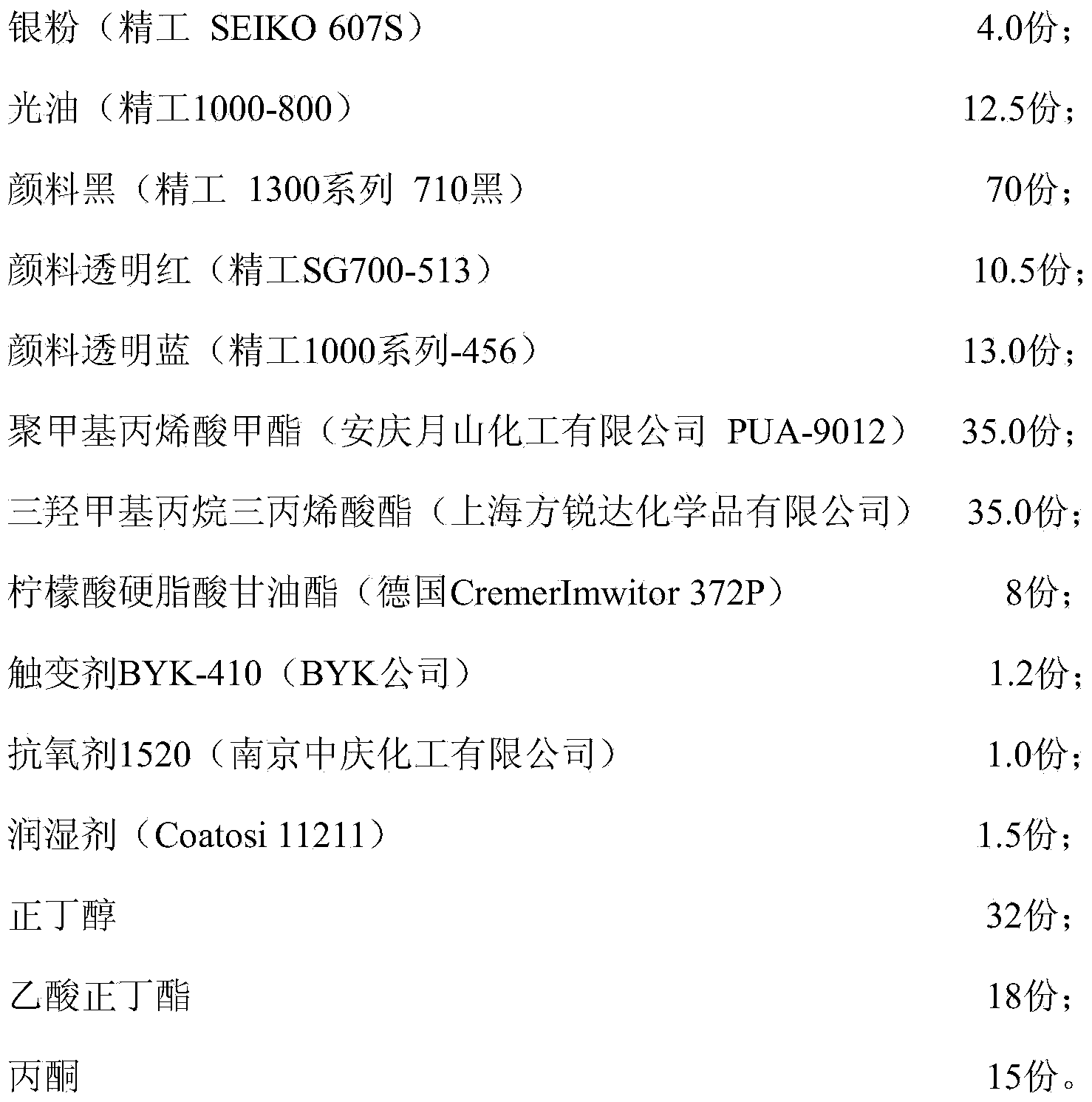

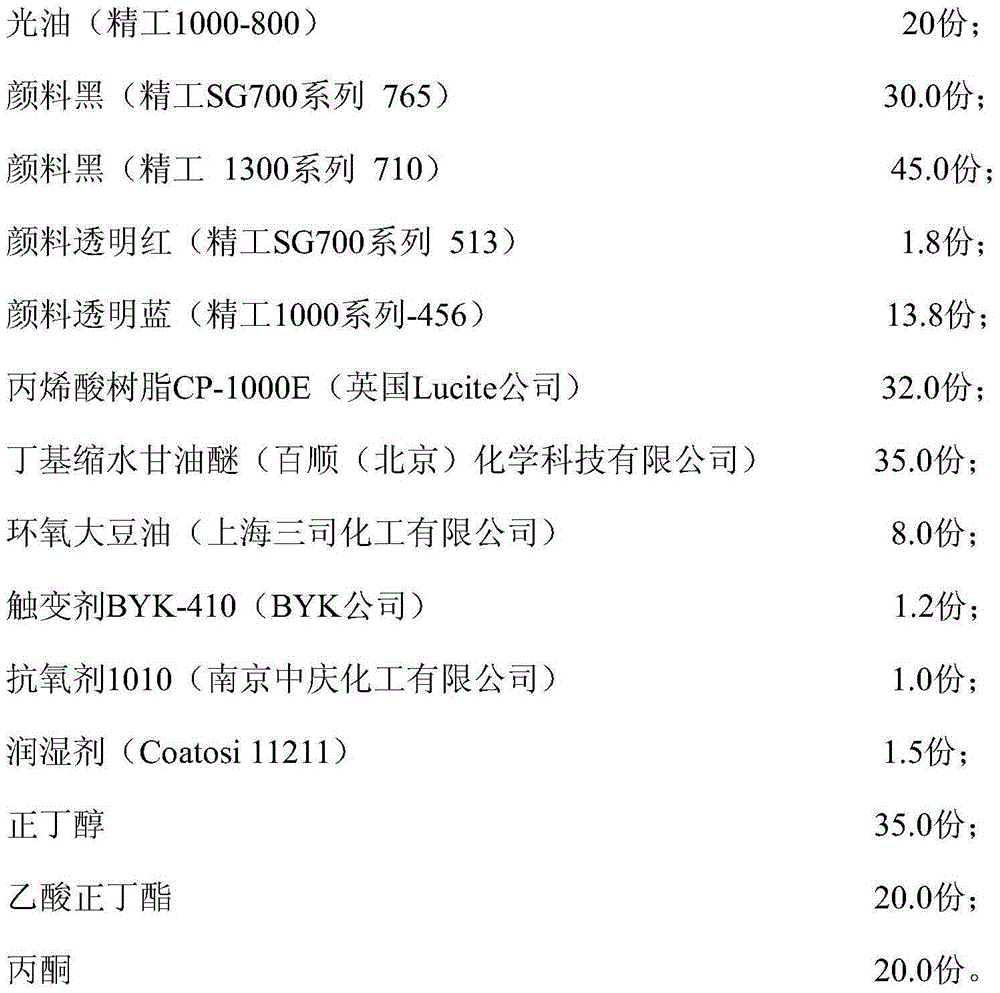

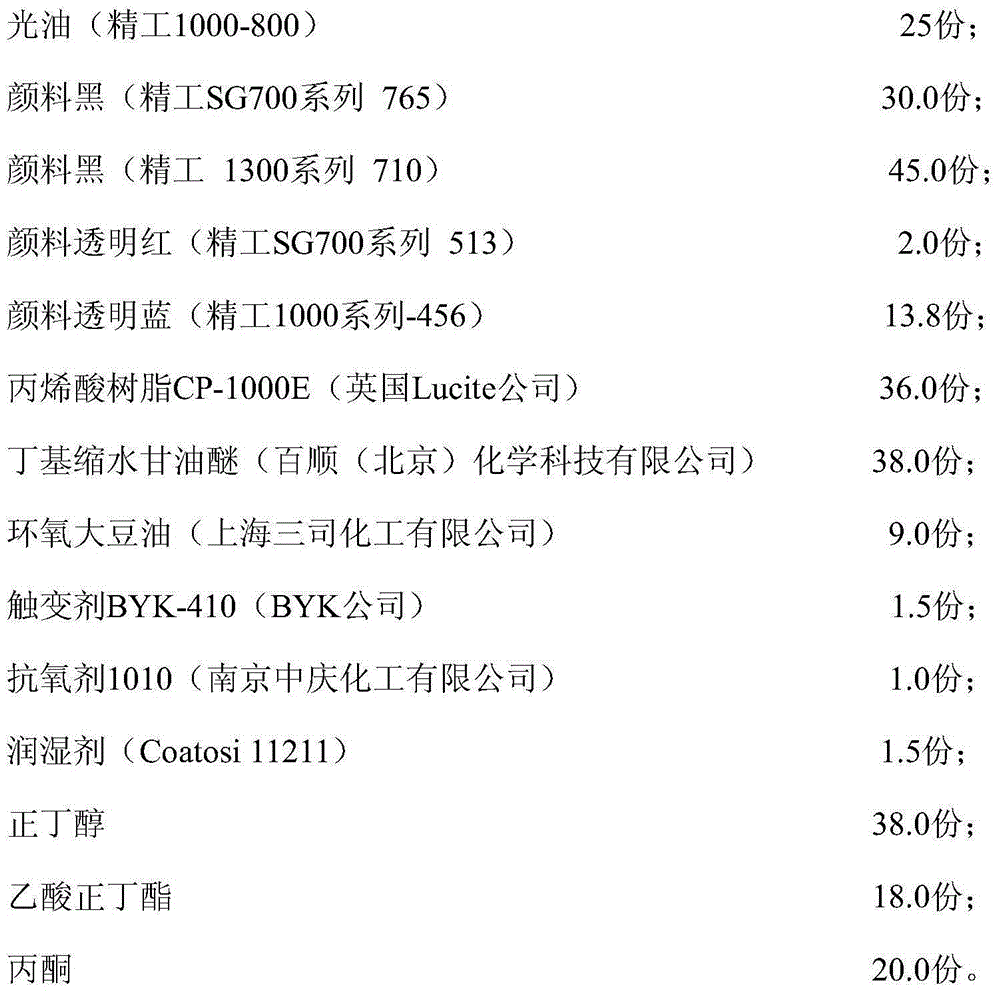

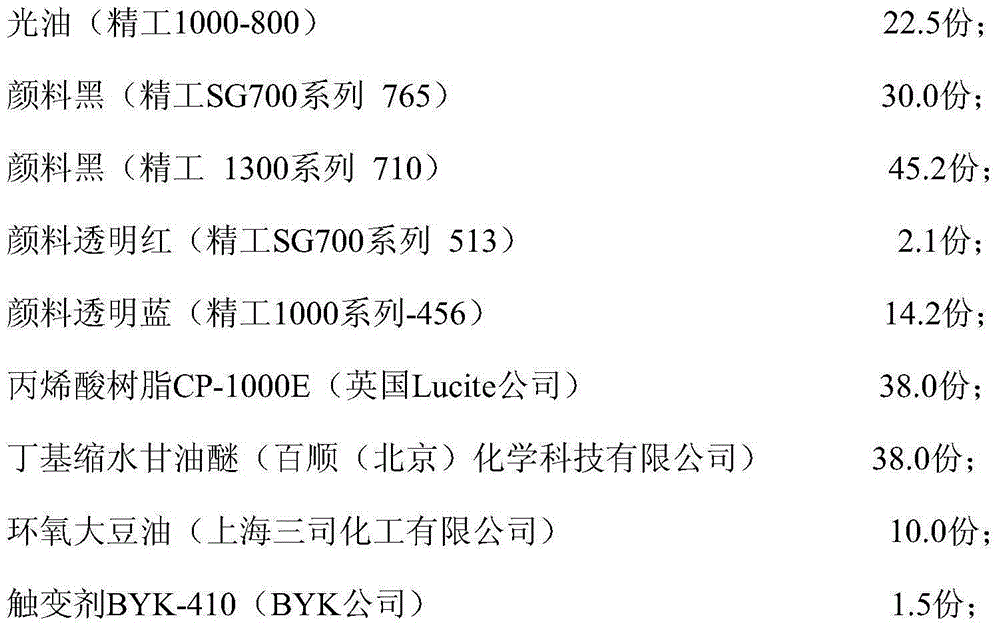

Matte black printing ink for silk-screen printing

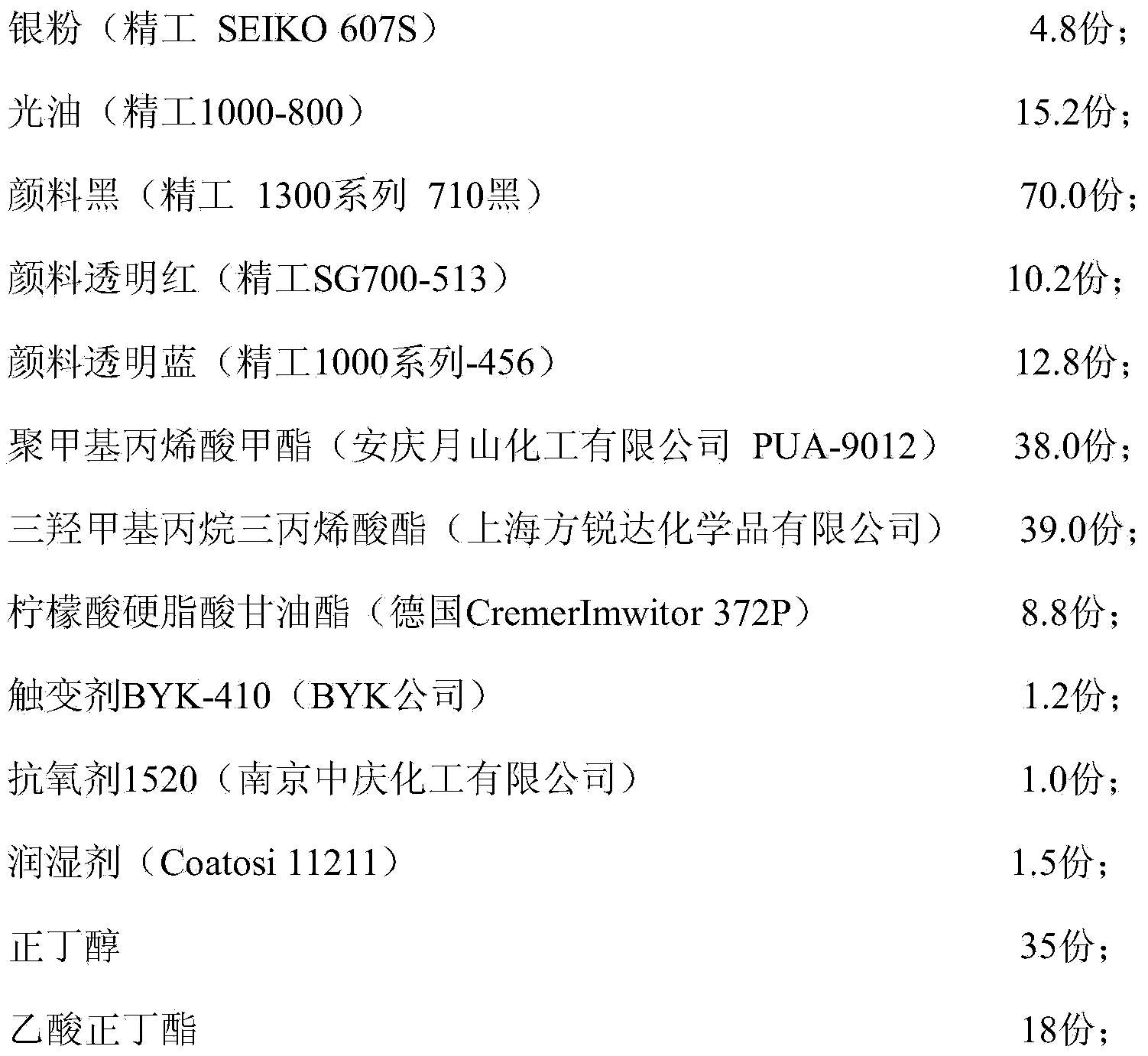

The invention relates to matte black printing ink for silk-screen printing. The printing ink comprises the following components in parts by weight: 3-5 parts of sliver powder, 10-16.5 parts of fine 1000-800 gloss oil, 70-72 parts of black pigments, 10.0-10.8 parts of transparent red pigments, 12.8-13.2 parts of transparent blue pigments, 32.0-40.0 parts of polymethyl methacrylate, 35.0-42.0 parts of trimethylolpropane triacrylate, 8.0-10.0 parts of glycerin citrate monostearate, 2.5-3.0 parts of polyvinylamine, and 65-75 parts of mixed solvent. The printing ink disclosed by the invention does not contain a phthalate and polyvinyl chloride resin plasticizer, but has flowing property equivalent to that in the prior art, has good storage stability, and has excellent adhesion for glass or a PMMA (polymethyl methacrylate) base material.

Owner:SUZHOU ANJIE TECH

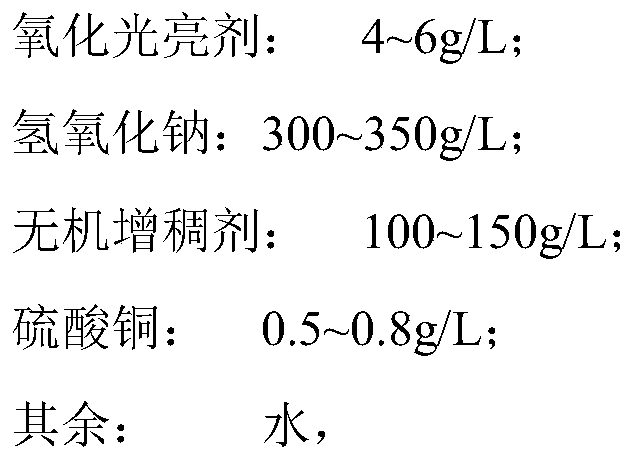

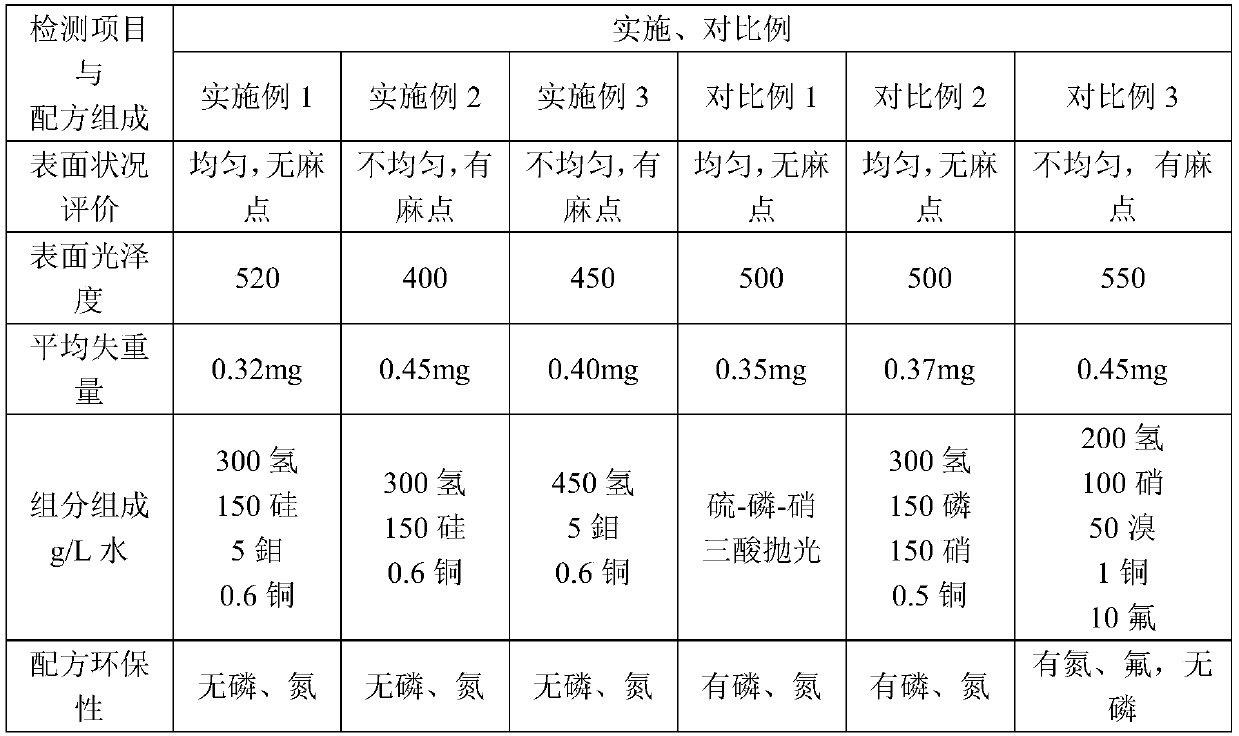

Alkaline chemical polishing liquid for aluminum alloy

The invention discloses alkaline chemical polishing liquid for aluminum alloy and especially discloses alkaline chemical polishing liquid which is free of phosphorus and nitrogen components. The alkaline chemical polishing liquid comprises 4 g / L to 6 g / L of an oxidization brightener, 300 g / L to 350 g / L of sodium hydroxide, 100 g / L to 150 g / L of an inorganic thickening agent, 0.5 g / L to 0.8 g / L ofcopper sulfate and the balance water; the oxidization brightener is selected from one or several of molybdate, tungstate and silicon-molybdenum heteropolyacid salt; and the inorganic thickening agentis selected from sodium carbonate or sodium silicate. The chemical polishing liquid disclosed by the invention entirely contains no components such as phosphorus, nitrogen or fluorine which is harmfulto environment; the polished surface of an obtained sample is uniform in surface gloss, exquisite and beautiful; moreover the polishing brightness is high; weight loss is small; and the alkaline chemical polishing liquid meets the requirements, on polishing quality, of relevant electronic products. The alkaline chemical polishing liquid disclosed by the invention can be used for replacing the original acidic or alkaline phosphorus and nitrogen containing polishing liquid, completely eliminates the pollution caused by emission of phosphorus and nitrogen in waste liquid of the chemical polishing liquid to a water environment and improves polishing production efficiency and the economical efficiency of an enterprise.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Red brown silver light ink for silk screen printing

ActiveCN103589238AImprove adhesionImprove scratch resistanceInksPolymethyl methacrylateMelamine formaldehyde resin

The invention relates to a red brown silver light ink for silk screen printing. The red brown silver light ink comprises the following components in parts by weight: 25 parts of silver powder, 75 parts of transparent red ink, 15 parts of transparent yellow ink, 20 parts of transparent blue ink, 30 parts of melamino-formaldehyde resin, 20 parts of a curing agent, 5 parts of isophorone, 5 parts of polytetrahydrofuran diol with 800-1000 of molecular weight, and 2 parts of ammonium citrate tribasic, wherein the curing agent is selected from diethylene glycol acrylate, 1, 4-butyl glycol acrylate or trimethylolpropane triacrylate. The red brown silver light ink provided by the invention adopts unsaturated olefinic bond type compounds with more than two acyloxy radicals in molecules as the curing agent, so that the light ink has excellent adhesion on glass and PMMA (Polymethyl Methacrylate) plastic, scrape resistance and resistance to water or solvent.

Owner:SUZHOU ANJIE TECH

Wine red high-gloss environmental ink and preparation method thereof

ActiveCN103613994AIncreased durabilityImprove solubilityInksEnvironmental resistanceMethyl carbonate

The invention relates to a wine red high-gloss environmental ink, comprising the following raw materials in parts by weight: 10 parts of silver powder, 60 parts of pigment red 149, 20 parts of pigment red 206, 60 parts of castor oil alkyd resin, 20 parts of melamine formaldehyde resin, 5 parts of triammonium citrate, 5 parts of butyl glycidyl ether, 0.5 part of coconut oil fatty acid diethanolamide, 0.5 part of 2,6-di-tertiary butyl methyl phenol and 80 parts of a mixed solvent. The mixed solvent of dimethyl carbonate and trimethylolpropane is adopted, so that the environmental ink basically does not contain toxic chemical substances such as benzene and toluene is excellent in environmental performance, has excellent dissolving and dispersing performances on resin and pigment, not only gives good durability of the ink, but also displays fairly good printing quality. The environmental ink disclosed by the invention is applicable to silk-screen printing of glass and a polymethyl methacrylate (PMMA) base material surface, and is vivid and bright in color, stable in adhesion property, and good in oil and alcohol resistance after the ink is dried.

Owner:SUZHOU ANJIE TECH

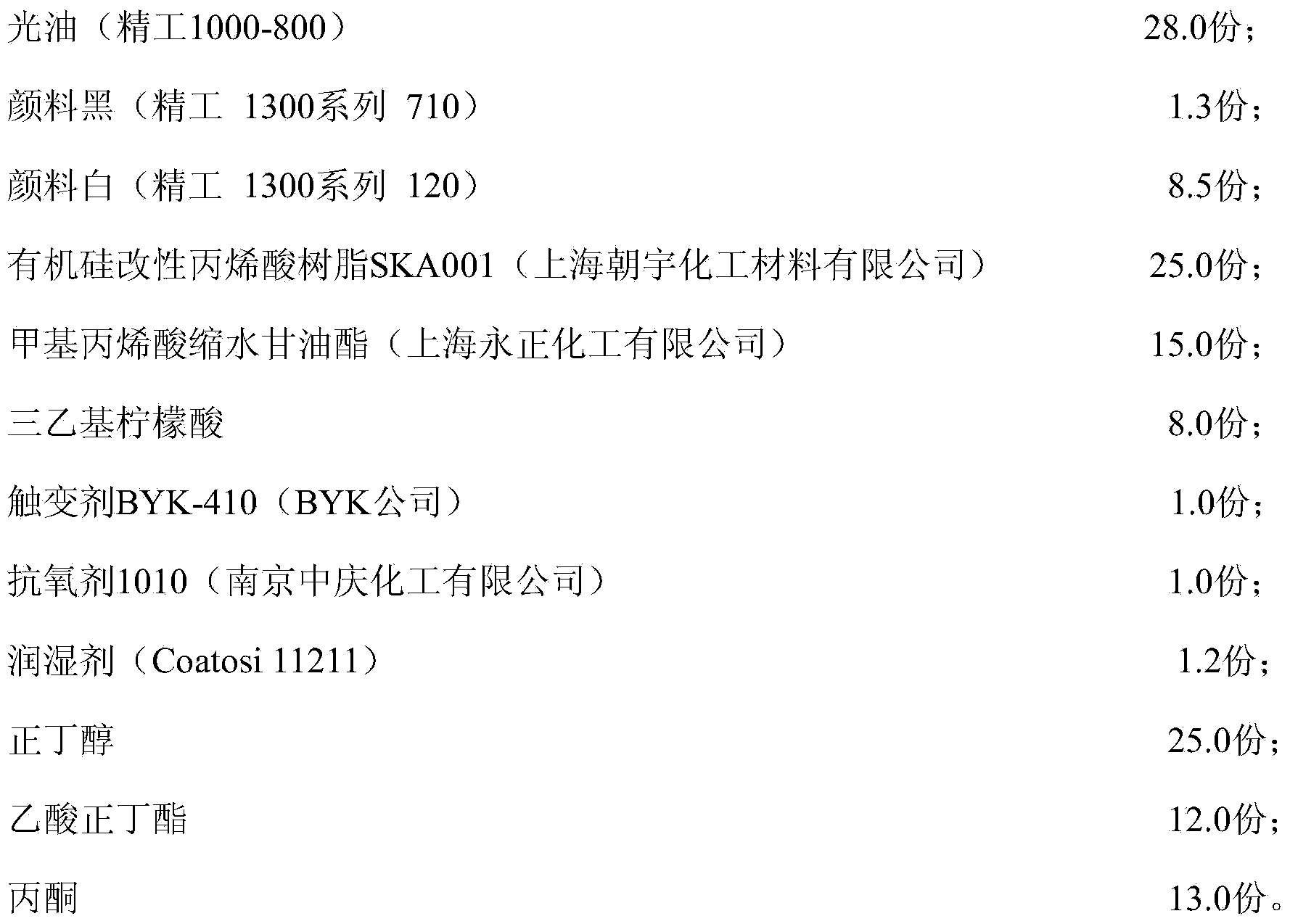

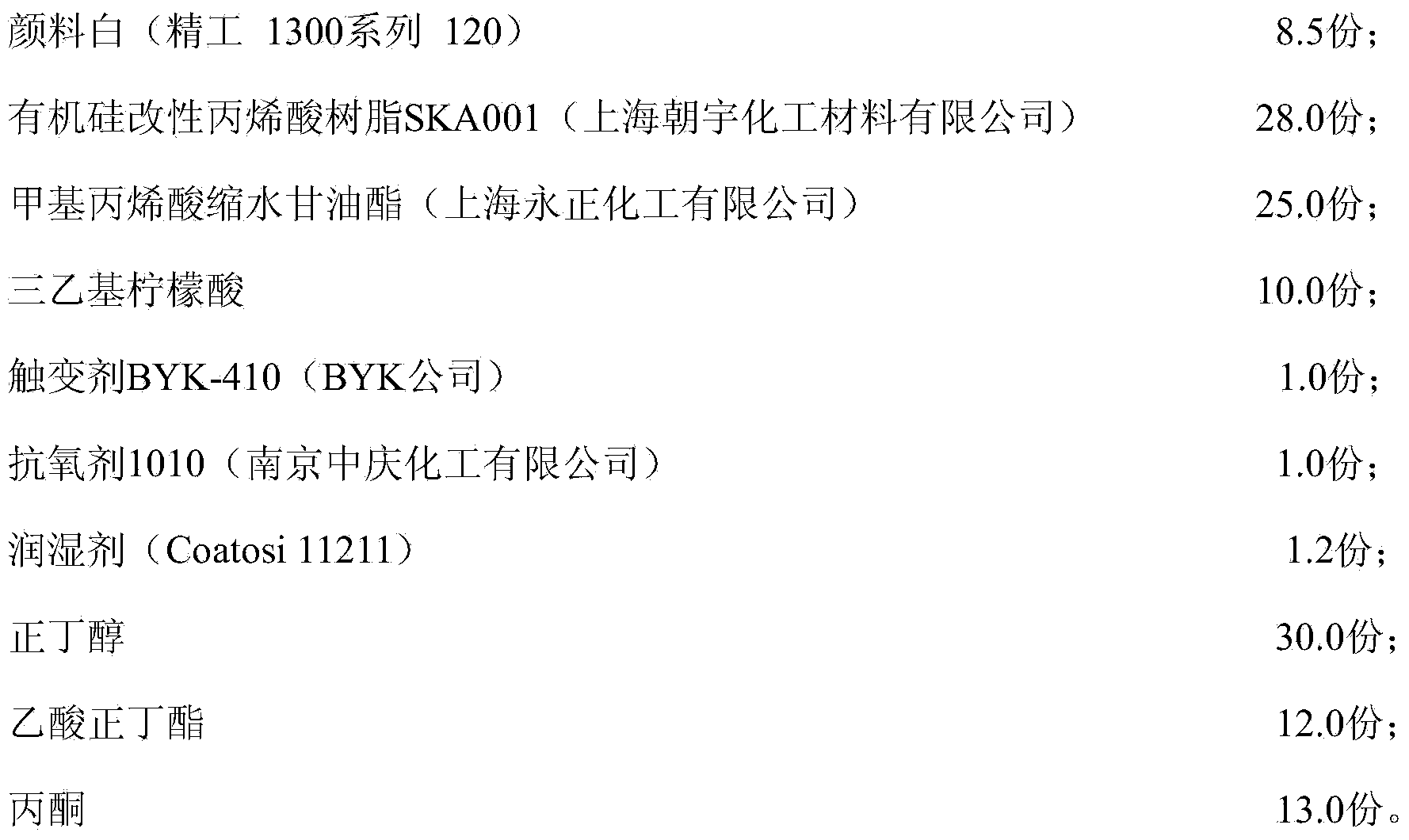

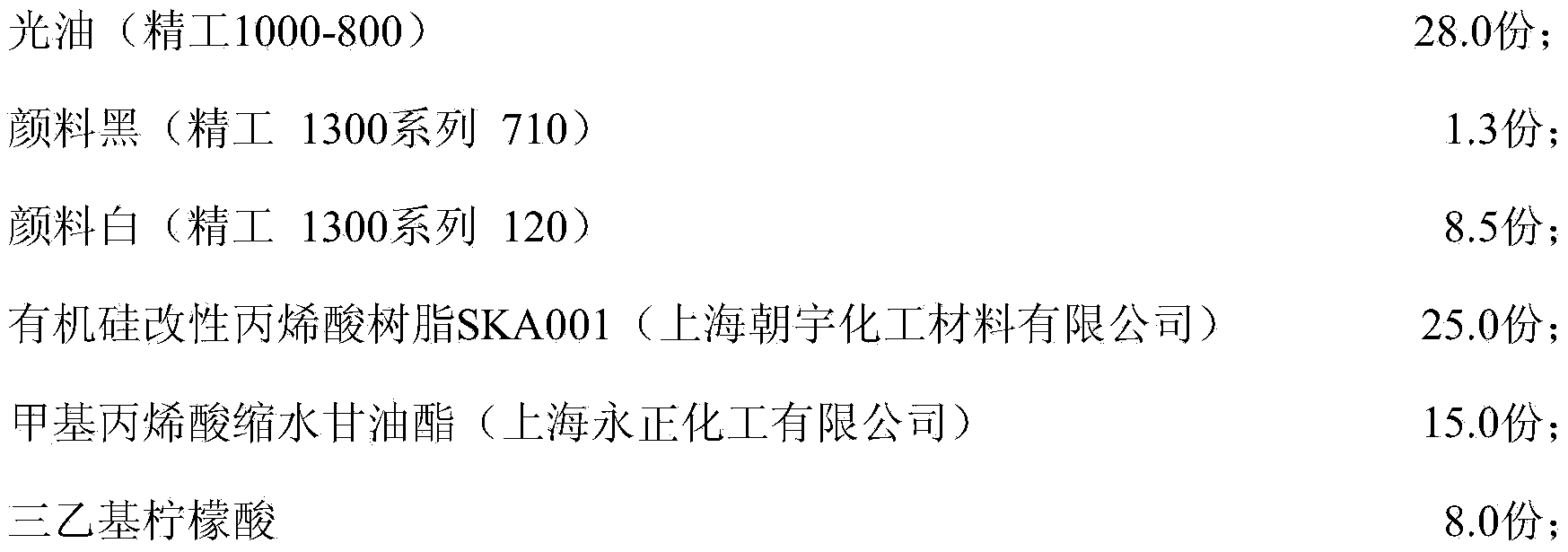

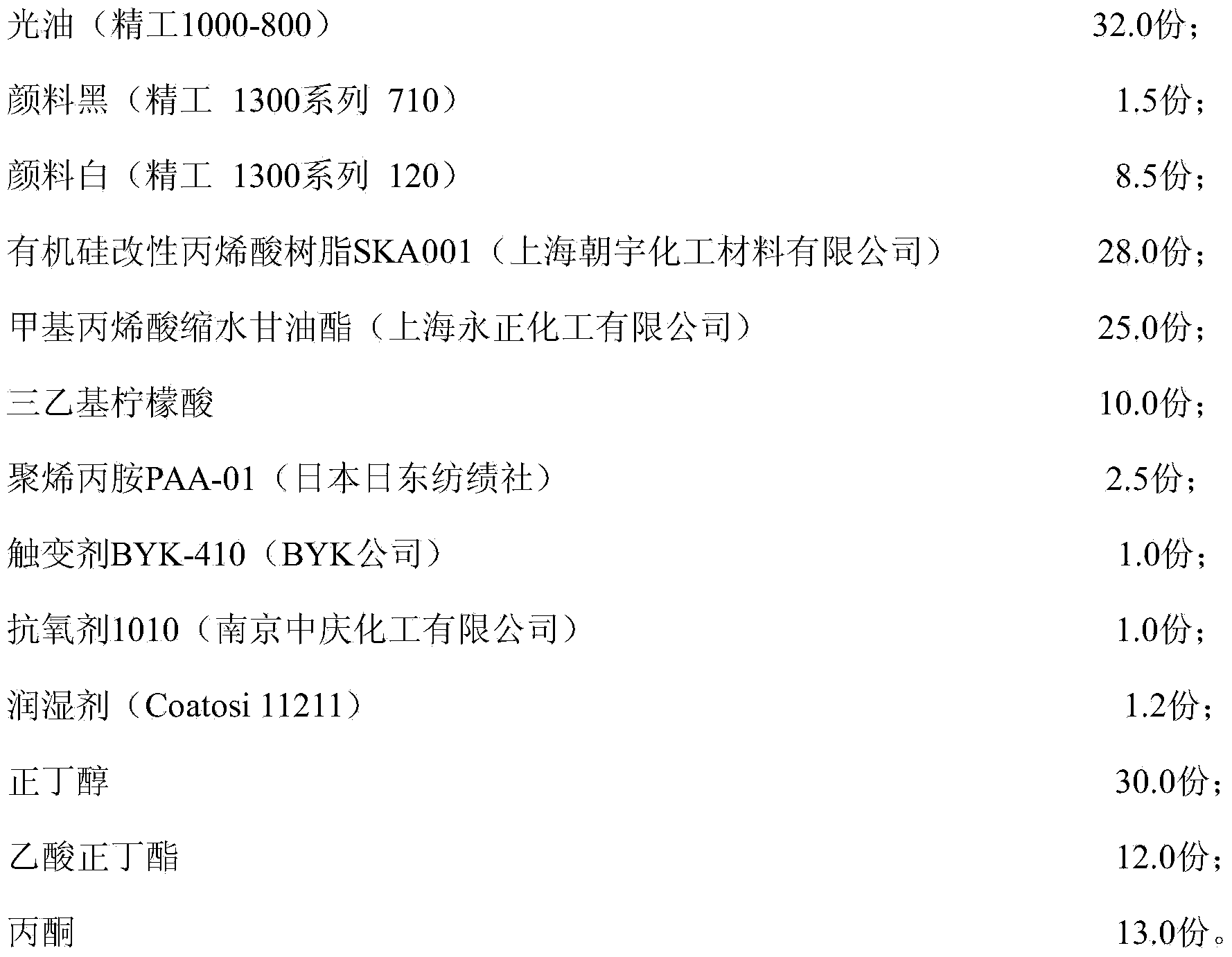

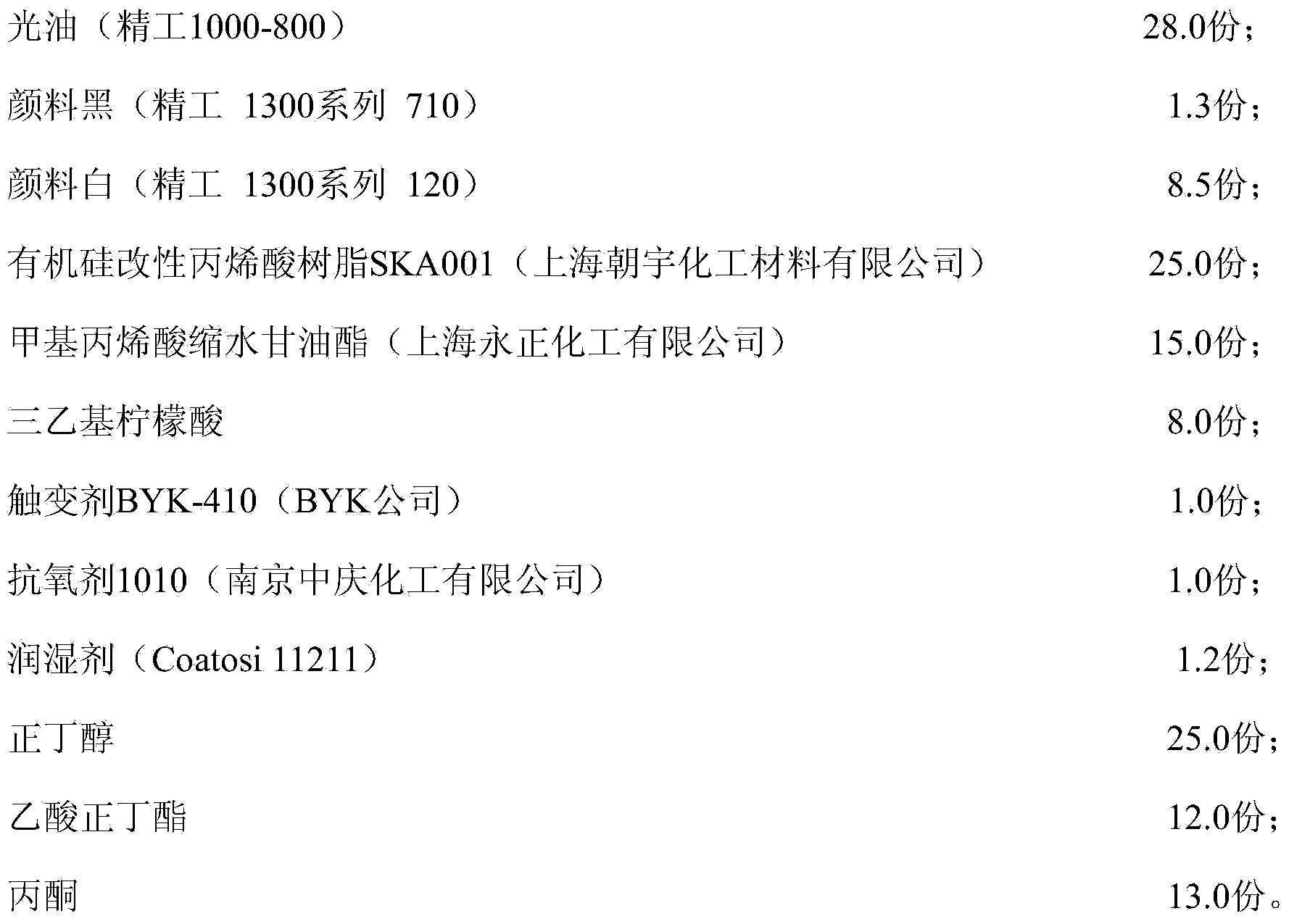

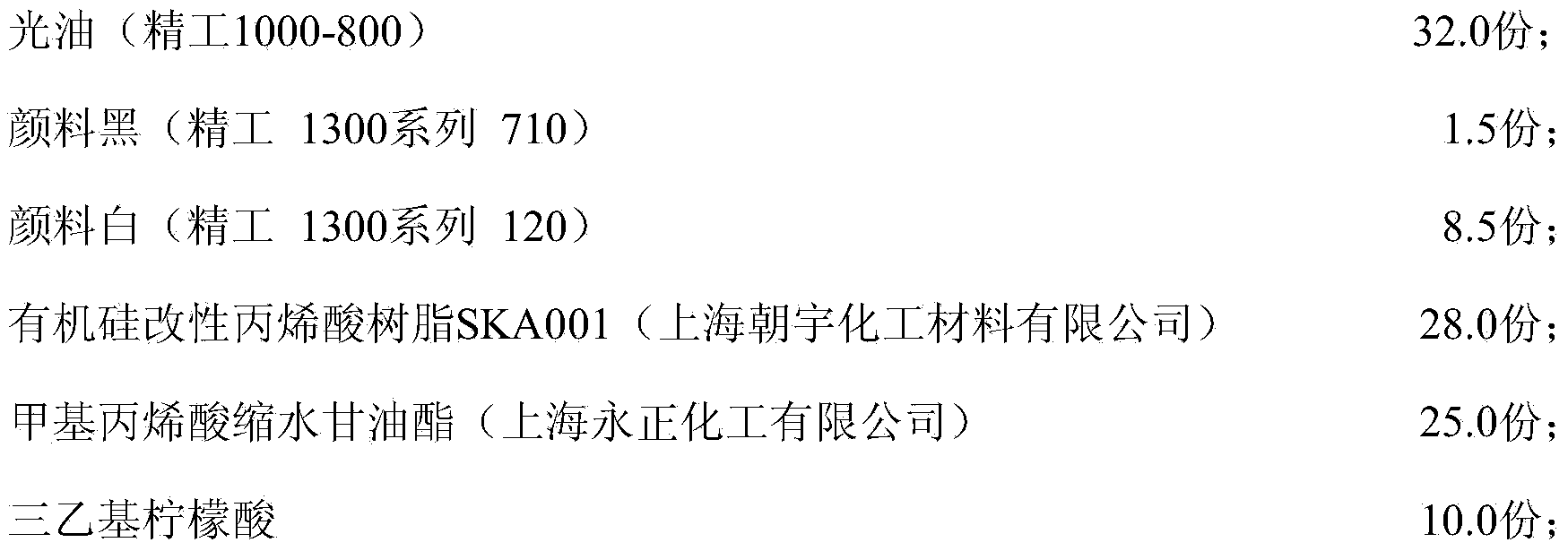

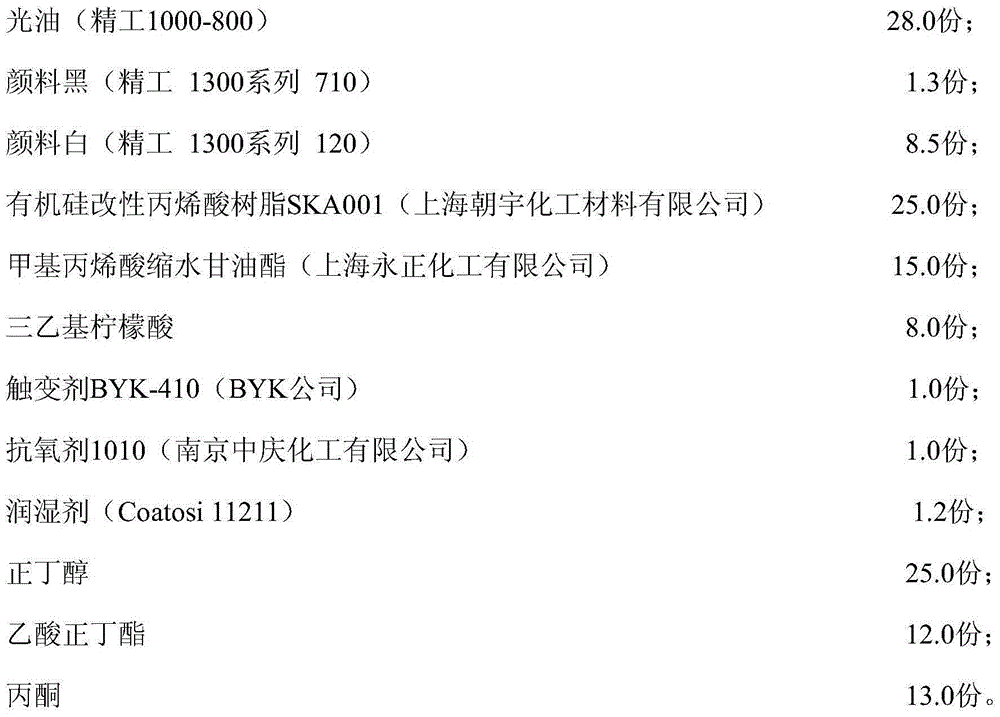

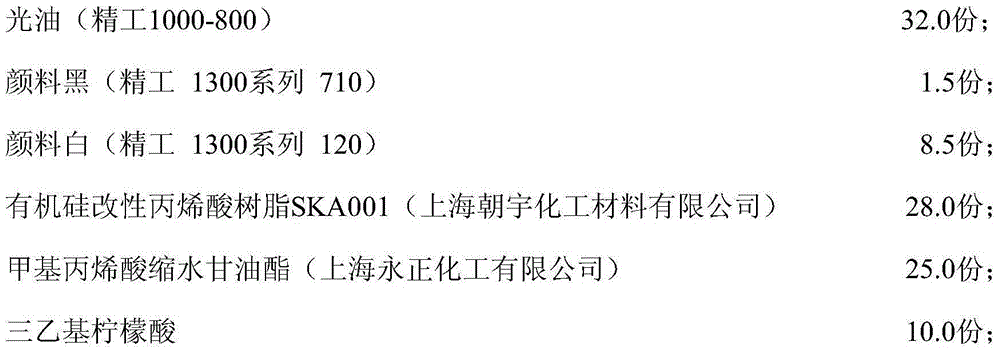

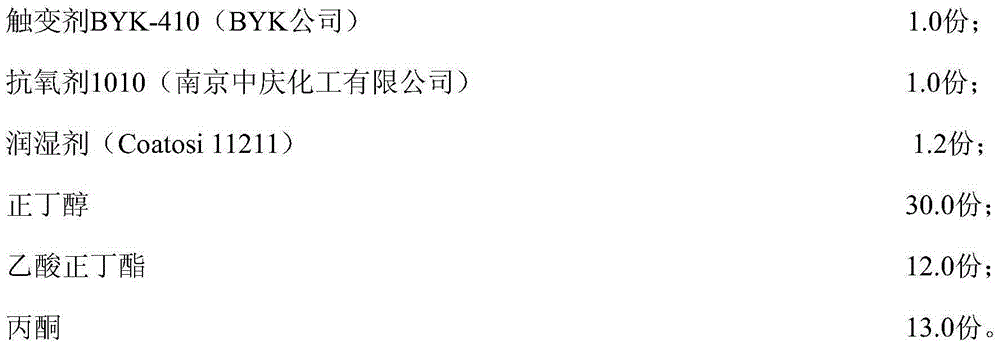

Semitransparent grey environment-friendly ink

The invention relates to semitransparent grey environment-friendly ink. The semitransparent grey environment-friendly ink comprises 28.0-32.0 parts of refined 1000-800 gloss oil, 1.3-1.5 parts of black pigment, 8.5-8.7 parts of white pigment, 25.0-28.0 parts of organosilicone modified acrylic resin, 15.0-25.0 parts of glycidyl methacrylate, 8.0-10.0 parts of triethyl citrate and 50-60 parts of mixed solvent by weight. The semitransparent grey environment-friendly ink does not contain plasticizers including phthalate and polyvinyl chloride resin but has flow property equivalent to that of the prior art, and has good storage stability and film-forming property.

Owner:SUZHOU ANJIE TECH

Preparation method of bright black ink for screen printing

The invention relates to a preparation method of bright black ink for screen printing. The preparation method comprises the following steps: (1) fully mixing a diluent with part of mixed solvent in a stirring manner, and dissolving the diluent to prepare a disperse solution; (2) fully mixing pigments with the disperse solution in a stirring manner, and wetting the pigments to prepare first mixed liquor; (3) fully mixing a hardening agent with the remaining mixed solvent in a stirring manner, and dissolving the hardening agent to prepare second mixed liquor; (4) fully mixing the first mixed liquor, the second mixed liquor, gloss oil, plasticizers and optional additives in a stirring manner to obtain mixed feed liquor; (5) milling the mixed feed liquor by adopting a sand mill to obtain the ink with fineness less than 5mu m. By adopting the preparation method, the surface tension between the pigments and resin can be reduced, the wettability of the pigments and resin can be improved, the ink milling effect can be reinforced, the dispersion time can be reduced, and the ink has good brightening effect and proper viscosity.

Owner:SUZHOU ANJIE TECH

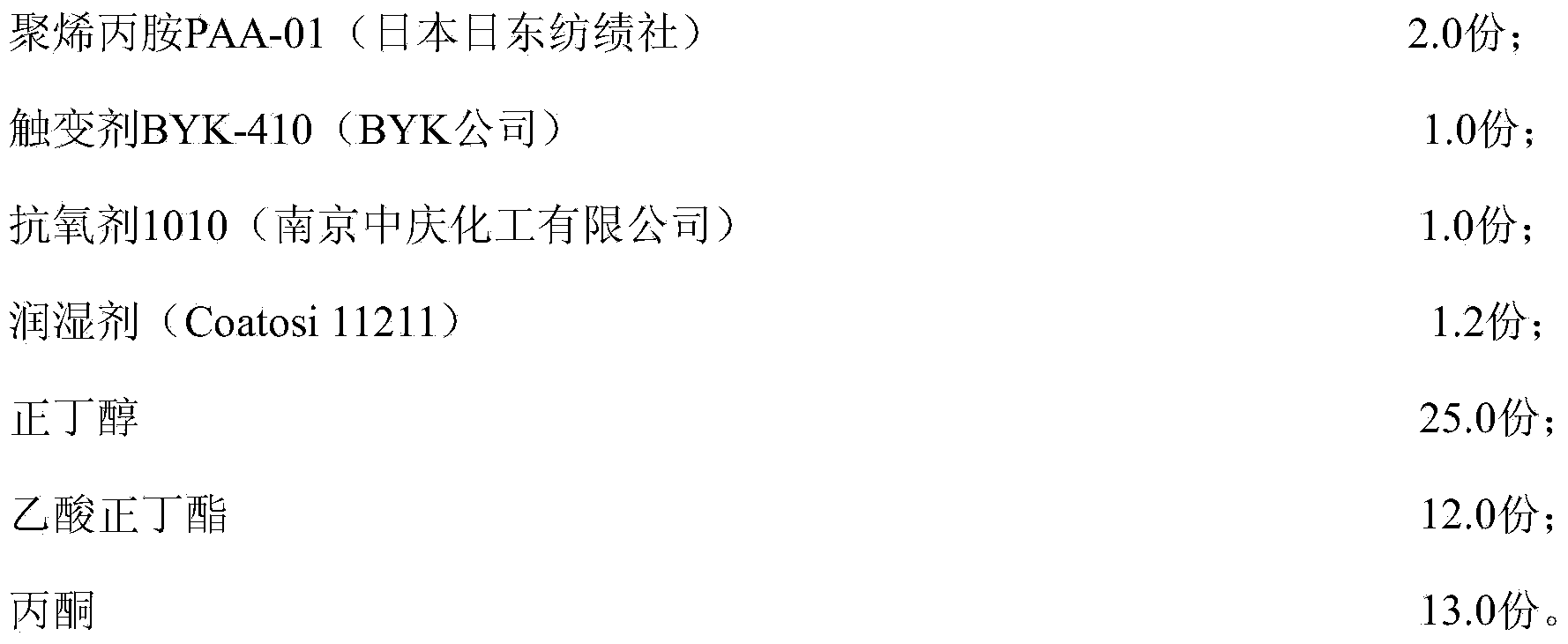

Semitransparent grey plasticizing ink for screen printing

The invention relates to semitransparent grey plasticizing ink for screen printing. The ink comprises 28.0-32.0 parts of refined 1000-800 gloss oil, 1.3-1.5 parts of black pigment, 8.5-8.7 parts of white pigment, 25.0-28.0 parts of organosilicone modified acrylic resin, 15.0-25.0 parts of glycidyl methacrylate, 8.0-10.0 parts of triethyl citrate, 2.0-2.5 parts of poly(allylamine) and 50-60 parts of mixed solvent by weight. The ink does not contain plasticizers including phthalate and polyvinyl chloride resin but has flow property equivalent to that of the prior art, and has good storage stability and excellent adhesion to glass or PMMA (polymethylmethacrylate) substrates.

Owner:SUZHOU ANJIE TECH

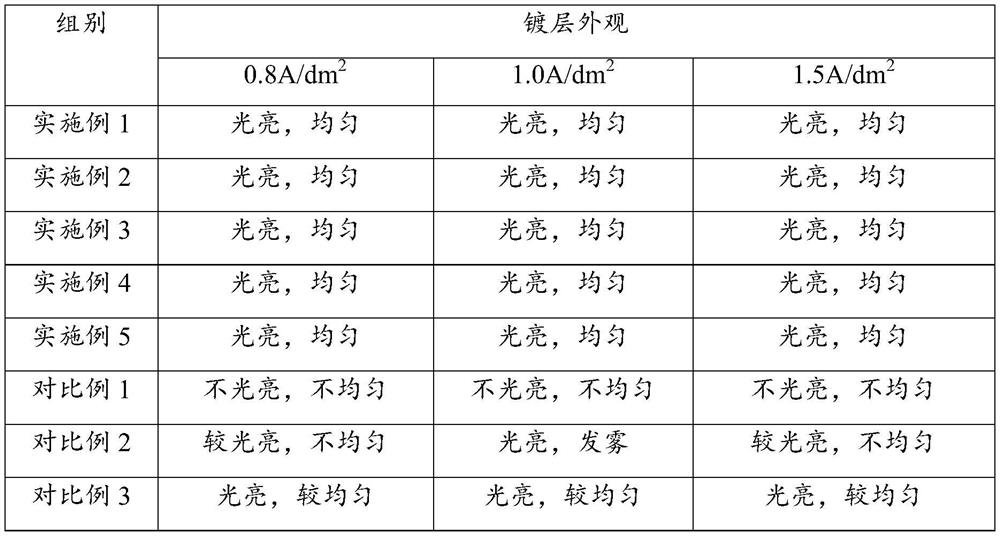

Silver plating solution brightener

InactiveCN109695047AImprove stabilityExcellent discoloration resistanceLauryl ether sulfateSilver plate

The invention discloses a silver plating solution brightener. The silver plating solution brightener is composed of the following raw materials: 5-8 parts of ethylene glycol butyl ether, 6-9 parts ofmagnesium stearate, 3-5 parts of disodium phosphate dodecahydrate, 5-7 parts of quartz powder, 4-6 parts of sodium lauryl ether sulfate, 3-5 parts of trisodium phosphate, 5-8 parts of isomeric alcoholethoxylates, 5-9 parts of hydroxyethylcellulose, 6-8 parts of naphtha, 5-7 parts of methylparaben, 6-8 parts of ethyl maltol, 3-5 parts of otcamethylcyclotetrasiloxane, 5-7 parts of phosphorus pentoxide, and 5-8 parts of ethylenediaminetetraacetic acid. The silver plating solution brightener has the advantages of bright coating mirror surface, high plating solution stability, hard coating, good anti-discoloration ability of the coating, ideal brightness effect and the like.

Owner:冯维照

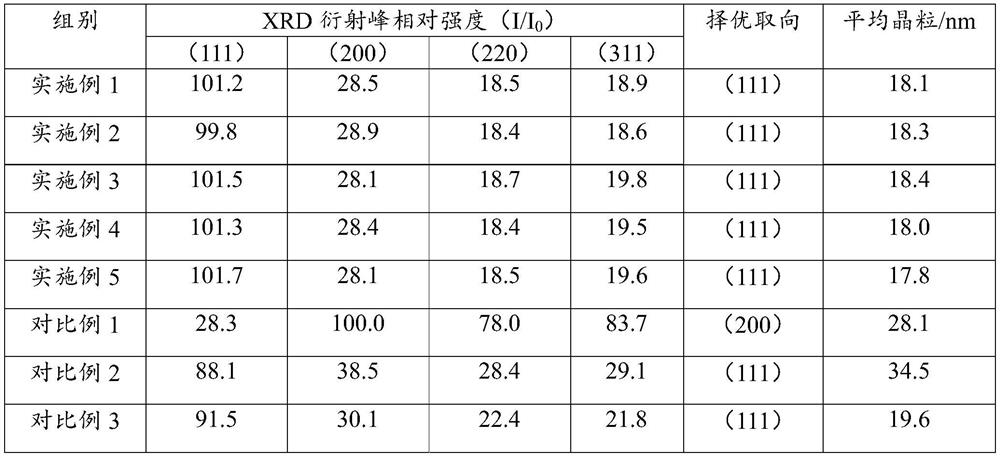

Cyanide-free silver plating brightening agent and preparing method thereof

The invention relates to the technical field of cyanide-free silver plating, in particular to a cyanide-free silver plating brightening agent and a preparing method thereof. Deionized water is adoptedas a solvent and comprises, by concentration, 10 g / L-25 g / L of sodium dodecyl dibenzenesulfonate, 1 g / L-2.5 g / L of HEDTA, 0.5 g / L-2.0 g / L of a stabilizing agent, 20 g / L-35 g / L of a dispersing agent,10 g / L-20 g / L of urea, 10 g / L-15 g / L of 1-benzyl-1,2,3,4-tetrahydroisoquinoline, and 30 g / L-45 g / L of a sulfur-bearing heterocyclic compound. By means of the cyanide-free silver plating brightening agent, the crystal orientation of a plating layer can be changed, grains are obviously refined, and the obtained plating layer is obvious in wear resistance and brightened effect and is not likely affected by current density.

Owner:GUANGZHOU SANFU NEW MATERIALS TECH

Glossy sea-buckthorn pectin powder

The invention discloses glossy sea-buckthorn pectin powder which comprises components in parts by weight as follows: 35-40 parts of maltodextrin, 25-30 parts of white granulated sugar, 20-25 parts of maltitol, 15-20 parts of sea-buckthorn powder, 1-1.5 parts of pectin, 0.3-0.5 part of citric acid, 0.3-0.4 part of sea-buckthorn essence, 0.1-0.15 part of sodium citrate and 0.02-0.04 part of gardenia yellow, and the glossy sea-buckthorn pectin powder is prepared by blending and mixing the components. Glossy sea-buckthorn pectin can be simply, conveniently and rapidly prepared by the glossy sea-buckthorn pectin powder. The glossy sea-buckthorn pectin powder is slowly added into quantitative hot water with the temperature higher than 80 DEG C while stirred rapidly, the powder is dissolved and uniformly stirred, and the glossy sea-buckthorn pectin is prepared; the prepared glossy sea-buckthorn pectin has bright color and luster, the glossy effect is obvious after the surface of a cake is coated with the glossy sea-buckthorn pectin, the color and the luster are bright and natural, the brushability is good, the glossy sea-buckthorn pectin is not prone to flow after coated, tastes fresh, delicate and moderate in sour and sweet, has pure and rich sea-buckthorn flavor and is appetizing; and the glossy sea-buckthorn pectin powder is a powdered product and is easier to store.

Owner:HARBIN GOLDIDEA SOFTWARE

Water-soluble electroplating brightener and preparation method thereof

The invention discloses a water-soluble electroplating brightener. The water-soluble electroplating brightening agent comprises the following raw materials of, in parts by weight, 15-25 mL / L of a mainbrightener, 12-20 mL / L of an auxiliary brightener, 1.5-3.5 mL / L of an inhibitor, 9-14 mL / L of a leveling agent and 0.7-1.2 mL / L of other auxiliaries according to the volume fraction of each raw material in each liter of electroplating solution. The water-soluble electroplating brightener is composed of 100% water-soluble raw material, does not need an organic solvent, and can effectively reduce environmental pollution and harm to the body of an electroplating worker; the hole filling effect on the surface of an electroplating (electrogalvanizing) base material is good, the glossiness of a plating layer is high, and the bright effect is excellent; in addition, except for achieving the bright effect, the electric current efficiency, the elongation, the tensile strength and other propertiesof the (electrogalvanizing) coating are not greatly improved.

Owner:浙江金欣新材料科技股份有限公司

Preparation method of matt black plasticizing ink

The invention relates to a preparation method of matt black plasticizing ink. The preparation method comprises the following steps: (1) mixing silver powder with gloss oil uniformly in a stirring manner to obtain a regulating material; (2) fully mixing a diluent with part of mixed solvent in a stirring manner, and dissolving the regulating material to prepare a disperse solution; (3) fully mixing pigments with the disperse solution in a stirring manner, and wetting the pigments to prepare first mixed liquor; (4) fully mixing a hardening agent with the remaining mixed solvent in a stirring manner, and dissolving the hardening agent to prepare second mixed liquor; (5) fully mixing the first mixed liquor, the second mixed liquor, the regulating material, plasticizers and optional additives in a stirring manner to obtain mixed feed liquor, and milling to obtain the plasticizing ink. By adopting the preparation method, the surface tension between the pigments and resin can be reduced, the wettability of the pigments and resin can be improved, the ink milling effect can be reinforced, the dispersion time can be reduced, and the ink has good brightening effect and proper viscosity.

Owner:SUZHOU ANJIE TECH

Bright silver red ink for silk screen printing

ActiveCN103589224AImprove adhesionImprove scratch resistanceInksPolymethyl methacrylatePotassium sodium tartrate

The invention relates to a bright silver red ink for silk screen printing. The bright silver red ink comprises the following components in parts by weight: 35 parts of pearl powder, 100 parts of transparent red ink, 42 parts of methallyl methacrylate, 20 parts of a curing agent, 5 parts of isophorone, 5 parts of polytetrahydrofuran diol with 800-1000 of molecular weight, and 2 parts of potassium sodium tartrate, wherein the curing agent is selected from diethylene glycol acrylate, 1, 4-butyl glycol acrylate or trimethylolpropane triacrylate. The bright silver red ink provided by the invention adopts unsaturated olefinic bond type compounds with more than two acyloxy radicals in molecules as the curing agent, so that the light ink has excellent adhesion on glass and PMMA (Polymethyl Methacrylate) plastic, scrape resistance and resistance to water or solvent.

Owner:SUZHOU ANJIE TECH

Preparation method of semitransparent grey environment-friendly ink

The invention relates to a preparation method of semitransparent grey environment-friendly ink. The preparation method comprises the following steps: (1) fully mixing a diluent with part of mixed solvent in a stirring manner, and dissolving the diluent to prepare a disperse solution; (2) fully mixing pigments with the disperse solution in a stirring manner, and wetting the pigments to prepare first mixed liquor; (3) fully mixing a hardening agent with the remaining mixed solvent in a stirring manner, and dissolving the hardening agent to prepare second mixed liquor; (4) fully mixing the first mixed liquor, the second mixed liquor, gloss oil, plasticizers and optional additives in a stirring manner to obtain mixed feed liquor; (5) milling the mixed feed liquor by adopting a sand mill to obtain the ink with fineness less than 5mu m. By adopting the preparation method, the surface tension between the pigments and resin can be reduced, the wettability of the pigments and resin can be improved, the ink milling effect can be reinforced, the dispersion time can be reduced, and the ink has good brightening effect and proper viscosity.

Owner:SUZHOU ANJIE TECH

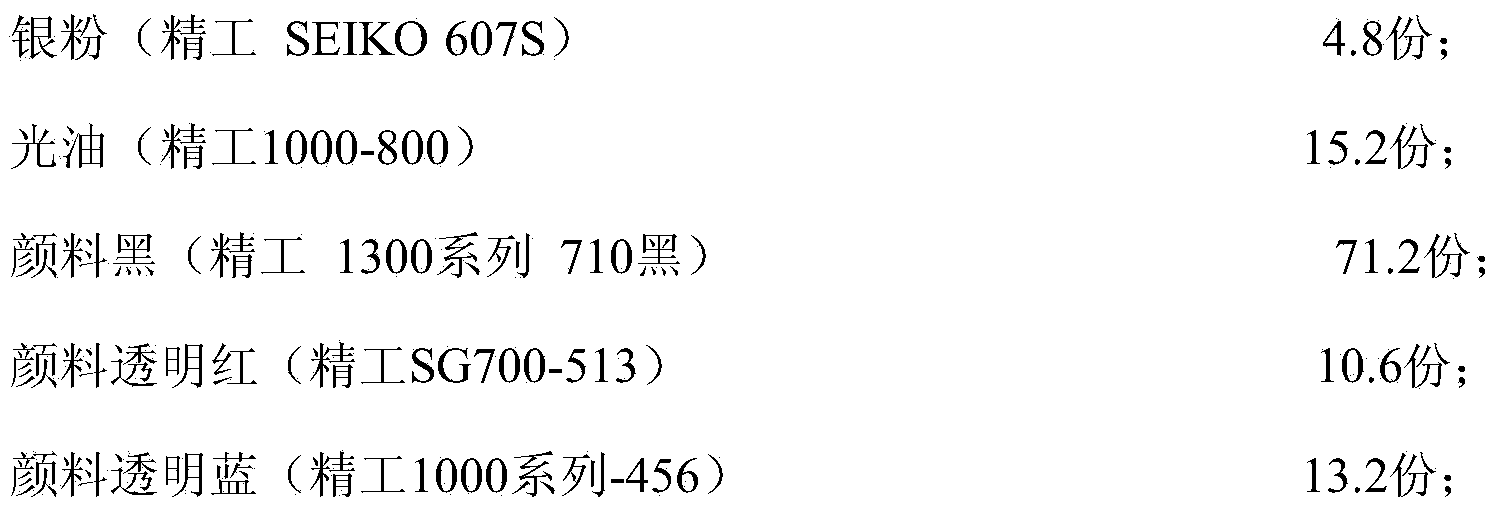

Matte black environment-friendly plasticizing ink

ActiveCN103911035AGood storage stabilityGood film formingInksPolyvinyl chloridePolymethyl methacrylate

The invention relates to a matte black environment-friendly plasticizing ink which contains the following components in parts by weight: 3-5 parts of silver powder, 10-16.5 parts of Seiko 1000-800 gloss oil, 70-72 parts of black pigment, 10.0-10.8 parts of transparent red pigment, 12.8-13.2 parts of transparent blue pigment, 32.0-40.0 parts of polymethyl methacrylate, 35.0-42.0 parts of trimethylolpropane triacrylate, 8.0-10.0 parts of stearin citrate and 65-75 parts of mixed solvent. The environment-friendly plasticizing ink is free of any phthalate or polyvinyl chloride resin plasticizer; and however, the environment-friendly plasticizing ink has equivalent flowing property to the prior art, and has favorable storage stability and favorable film-forming property.

Owner:SUZHOU ANJIE TECH

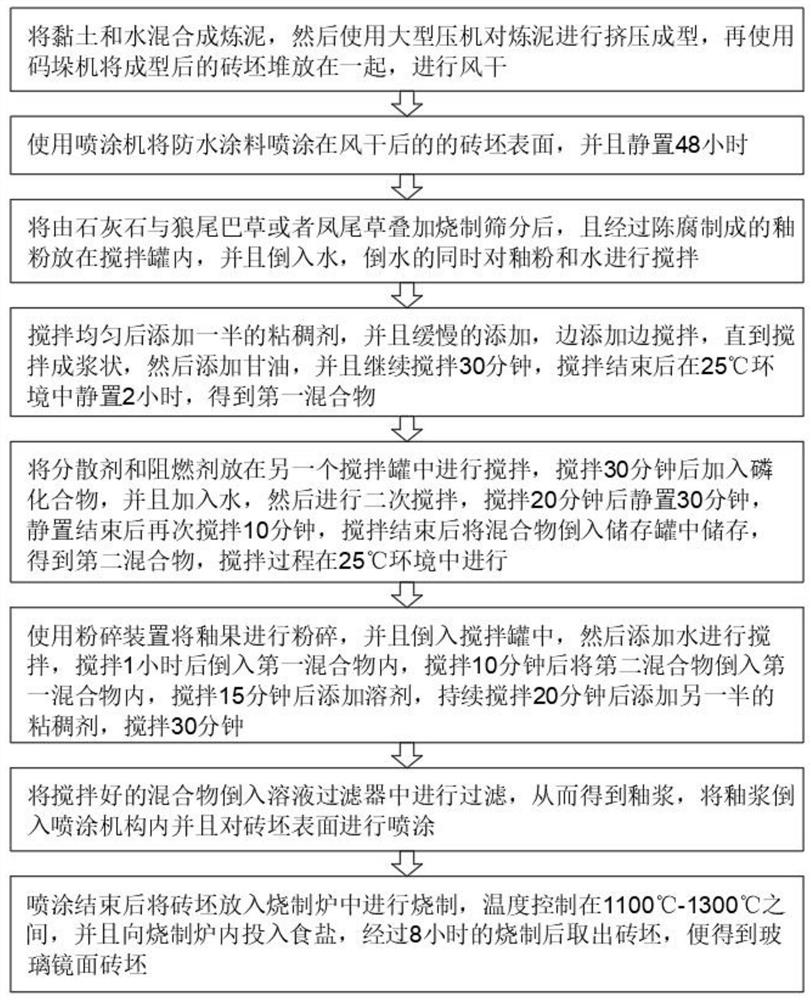

Glass mirror surface green brick with uniform surface glaze slip and manufacturing method thereof

The invention discloses a glass mirror surface green brick with uniform surface glaze slip and a manufacturing method thereof, relates to the technical field of ceramic glaze slip, and aims to solve the problem that the existing ceramic glaze slip is easy to flow after being sprayed and thus the glaze slip is inconvenient to uniformly spray on the green brick. The glass mirror surface green brick comprises a green brick body. The glass mirror surface green brick is characterized in that the outer wall of the green brick body is provided with a waterproof coating, the waterproof coating is connected with the green brick main body in a spraying manner, the outer wall of the waterproof coating is provided with glaze slip, the glaze slip is connected with the waterproof coating in a spraying manner, and the glaze slip is prepared from the following raw materials in percentage by weight: 35-55% of glaze powder; 30-60% of water; 10-15% of a dispersant; 5-10% of a flame retardant; 1-5% of a phosphorus compound; 5-10% of a thickener; 5-15% of salt; 30-50% of a solvent; 5-10% of glycerin; and 40-70% of glaze stone.

Owner:安徽昆仑新材料科技股份有限公司

Blackish green silver ink for silk screen printing

The invention relates to a blackish green silver ink for silk screen printing. The blackish green silver ink comprises the following components in parts by weight: 25 parts of silver powder, 5 parts of red ink, 25 parts of yellow ink, 85 parts of blue ink, 40 parts of hydroxyl fluoride silicon resin, 15 parts of curing agent, 5 parts of isophorone, 5 parts of propylene glycol polyether with 800-2000 of molecular weight, and 2 parts of ammonium citrate tribasic, wherein the curing agent is selected from diethylene glycol acrylate, 1, 4-butyl glycol acrylate or trimethylolpropane triacrylate. The blackish green silver ink provided by the invention adopts unsaturated olefinic bond type compounds with more than two acyloxy radicals in molecules as the curing agent, so that the light ink has excellent adhesion on glass and PMMA (Polymethyl Methacrylate) plastic, scrape resistance and resistance to water or solvent.

Owner:SUZHOU ANJIE TECH

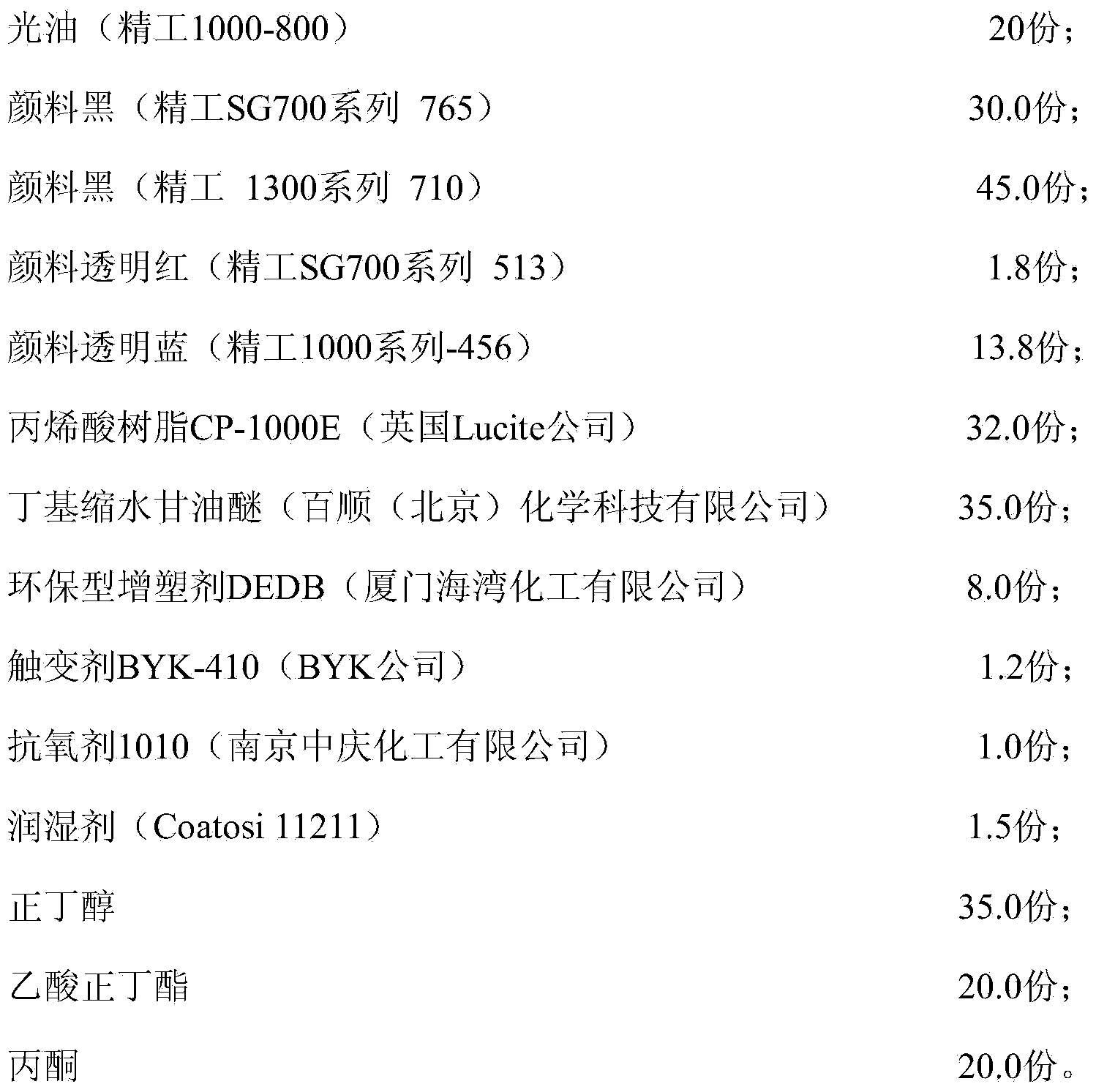

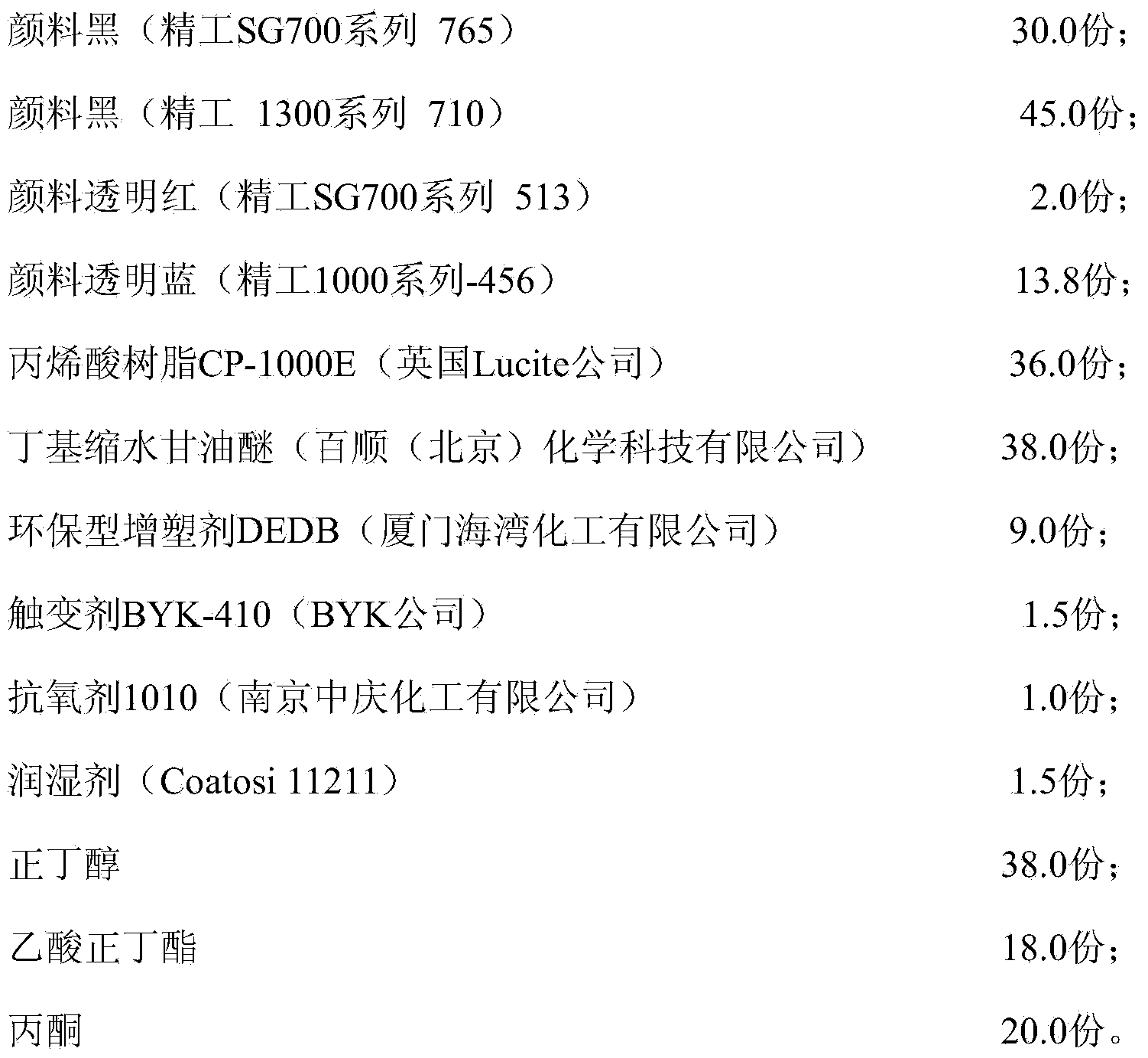

Gloss black ink for screen printing

The invention relates to gloss black printing ink for silk screen printing. The gloss black printing ink comprises the following components in parts by weight: 20 to 25 parts of refined 1000-800 gloss oil, 74 to 76 parts of black pigment, 1.8 to 2.2 parts of transparent red pigment, 13.5 to 14.5 parts of transparent blue pigment, 32 to 40 parts of crylic acid resin, 35 to 42 parts of butyl glycidyl ether, 8 to 10 parts of epoxy soybean oil and 75 to 80 parts of mixed solvent. The printing ink is free from containing phthalate and polyvinyl chloride resin plasticizer; and the mobility of the gloss black printing ink is equivalent to that of the prior art, the storage stability is good, and the film forming performance is good.

Owner:SUZHOU ANJIE TECH

Preparation method of semi-transparent gray environmental protection ink

The invention relates to a preparation method of semitransparent grey environment-friendly ink. The preparation method comprises the following steps: (1) fully mixing a diluent with part of mixed solvent in a stirring manner, and dissolving the diluent to prepare a disperse solution; (2) fully mixing pigments with the disperse solution in a stirring manner, and wetting the pigments to prepare first mixed liquor; (3) fully mixing a hardening agent with the remaining mixed solvent in a stirring manner, and dissolving the hardening agent to prepare second mixed liquor; (4) fully mixing the first mixed liquor, the second mixed liquor, gloss oil, plasticizers and optional additives in a stirring manner to obtain mixed feed liquor; (5) milling the mixed feed liquor by adopting a sand mill to obtain the ink with fineness less than 5mu m. By adopting the preparation method, the surface tension between the pigments and resin can be reduced, the wettability of the pigments and resin can be improved, the ink milling effect can be reinforced, the dispersion time can be reduced, and the ink has good brightening effect and proper viscosity.

Owner:SUZHOU ANJIE TECH

Silver plating brightening agent and preparing method thereof

The invention discloses a silver plating brightening agent and a preparing method thereof. The preparing method comprises the steps that (1) pyridinium propyl sulfobetaine, 1,4-butynediol, chitosan, nonylphenol polyoxyethylene ether, monopotassium phosphate, nitric acid, citric acid, anion surface active agents and water are mixed to obtain a mixture M1; (2), ammonia water is dropwise added into the mixture M1, the pH is adjusted to be 4.5-6, and a mixture M2 is obtained; and (3) heat treatment is conducted on the mixture M2, so that the silver plating brightening agent is obtained. The brightening effect of the silver plating brightening agent prepared through the method is excellent during electroplating, and a silver-plated layer obtained through electroplating is smooth and good in glossiness.

Owner:广州皓悦新材料科技有限公司

Hami melon bright surface jelly powder

InactiveCN103783336AEasy to makeEasy to manufactureSugar food ingredientsFood coatingFlavorChlorophyllin copper complex

The invention relates to hami melon bright surface jelly powder. The jelly powder comprises the following components in parts by weight: 35-40 parts of maltodextrin, 25-30 parts of white granulated sugar, 20-25 parts of maltitol, 15-20 parts of hami melon powder, 1-1.5 parts of pectine, 0.3-0.5 part of citric acid, 0.3-0.4 part of hami melon essence, 0.1-0.15 parts of sodium citrate, and 0.02-0.04 part of chlorophyllin copper complex sodium salt. The hami melon bright surface jelly powder is prepared by compounding and mixing the components. A hami melon bright surface jelly is prepared by the Hami melon bright-surface jelly powder in a simple, convenient and quick way. Under rapid stirring, the hami melon bright surface jelly powder is slowly added into a fixed amount of hot water with the temperature being more than 80 DEG C, is dissolved in the hot water and uniformly stirred to obtain the hami melon bright surface jelly. The prepared hami melon bright surface jelly has a bright color, after the surface of a cake is coated with the hami melon bright surface jelly, the bright effect of the jelly is obvious, and the color of the jelly is smooth and natural. The coating effect is good, and after the cake is coated with the jelly, the jelly does not easily run off. The jelly tastes fresh and exquisite, and moderate sour-sweet and has an unadulterated and heavy hami melon flavor, so that the jelly tempts the appetite. The hami melon bright surface jelly powder is a powder product, so that the hami melon bright surface jelly is relatively easy to store and keep.

Owner:HARBIN GOLDIDEA SOFTWARE

A kind of nano-silver additive for cyanide-free electroplating

Contain main brightener 60~80g / L, auxiliary brightener 10~20g / L, surface wetting agent 5~10g / L and protective agent 1~3g / L respectively in a kind of cyanide-free electroplating nano-silver additive of the present invention, wherein The main brightener consists of 25%~50% of γ-butene lactam, 10%~15% of polybutene diimide, 15%~35% of δ-pentene lactam, 10%~15% of It is composed of polyglutaconimide and 10%~15% of phthalimide. The additive of the present invention can effectively improve the brightness and discoloration resistance of the coating, and can achieve high brightness and grain refinement effects at room temperature, the coating brightness can reach more than 600 Gu, and the crystal grains can be refined to nanometers; the stability is strong, It can still have an excellent bright effect after long-term electroplating operations or standing still; and the production cost is low, the efficiency is high, and it is environmentally friendly.

Owner:NANCHANG HANGKONG UNIVERSITY

High-adhesion pearized silver printing ink and preparation method thereof

The invention relates to high-adhesion pearized silver printing ink which comprises the following components in parts by weight: 50 parts of pearl powder, 35 parts of silver powder, 52 parts of hydroxy fluorosilicone resin, 20 parts of 1,4-butanediol diacrylate, 6 parts of diammonium citrate, 6 parts of butyl glycidyl ethe, 0.8 parts of octaphenyl polyoxyethyiene, 0.5 parts of antioxidant 1010 and 80 parts of mixed solvent. The environment-friendly printing ink adopts the mixed solvent of dimethyl carbonate and trimethylolpropane polyether with the molecular weight of 400-1000, is basically free of toxic chemicals such as benzene and methylbenzene, is very excellent in environment-friendly property, and has excellent dissolving and dispersing properties for resin and a pigment; good durability is endowed for the printing ink; very good printing quality is represented; the environment-friendly printing ink is suitable for silk-screen printing of the surfaces of glass and a PMMA (polymethyl methacrylate) substrate; and after the printing ink is dried, the printing ink is bright in color, stable in adhesivity, and good in oil resistance and alcohol resistance.

Owner:SUZHOU ANJIE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com