Semitransparent grey plasticizing ink for screen printing

A technology of screen printing and ink, applied in the field of printing ink, can solve problems such as ink usage limitation, and achieve the effect of reducing surface tension, reducing dispersion time, and strengthening grinding effect

Active Publication Date: 2014-07-16

SUZHOU ANJIE TECH

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the use of these inks is increasingly restricted due to environmental, health and safety concerns

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

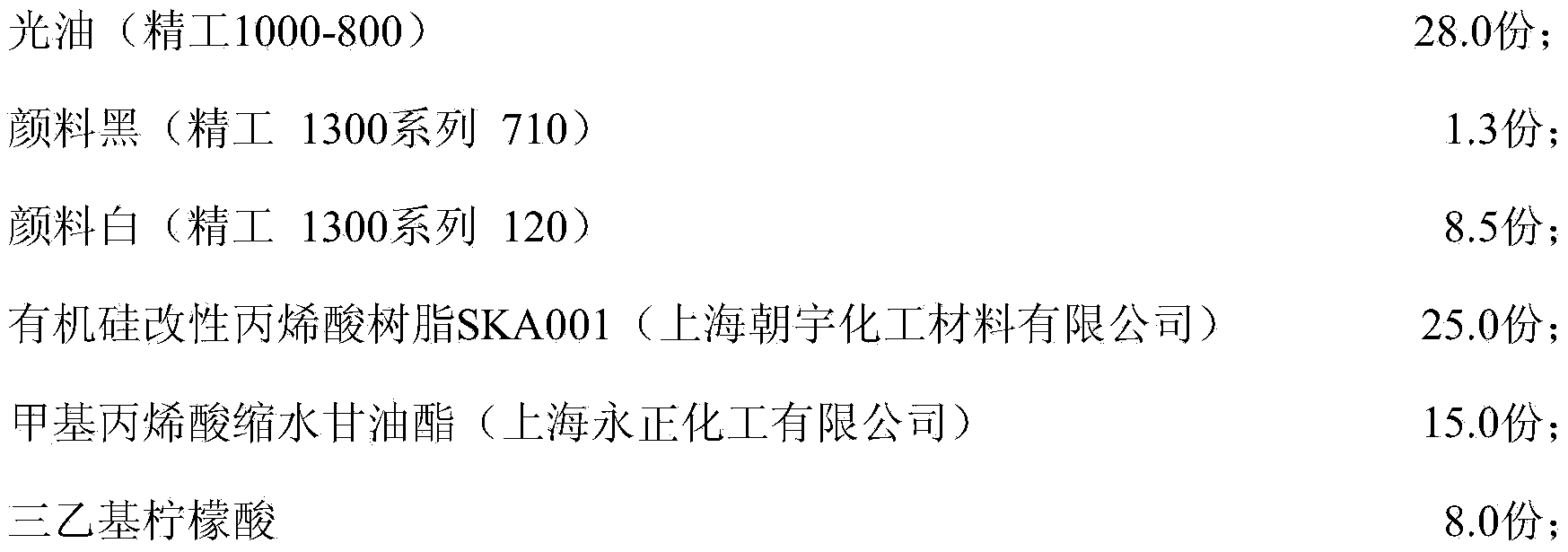

Embodiment 1

[0030] In the translucent gray plasticized ink of this embodiment, the viscosity of the ink is about 80,000 to 150,000 centipoise, and it contains the following components by weight:

[0031]

[0032]

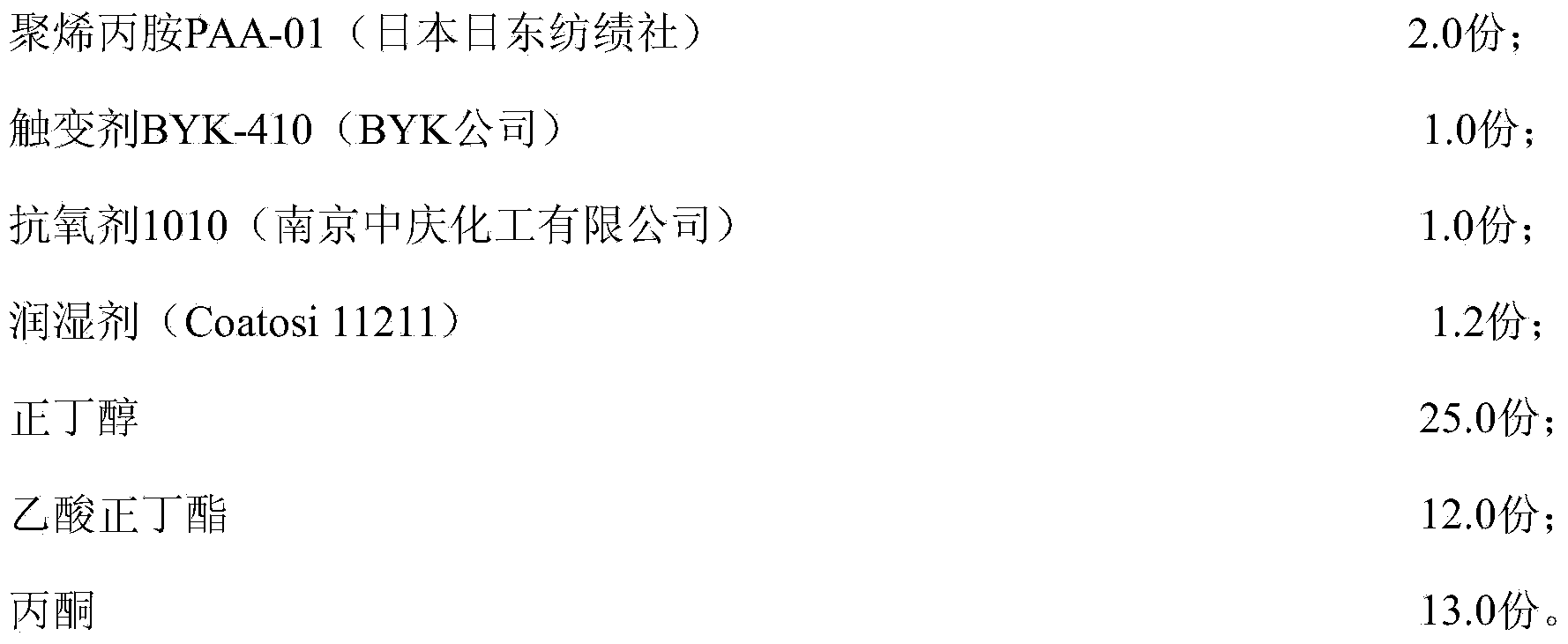

Embodiment 2

[0034] In the translucent gray plasticized ink of this embodiment, the viscosity of the ink is about 30,000 to 50,000 centipoise, and it contains the following components by weight:

[0035]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to semitransparent grey plasticizing ink for screen printing. The ink comprises 28.0-32.0 parts of refined 1000-800 gloss oil, 1.3-1.5 parts of black pigment, 8.5-8.7 parts of white pigment, 25.0-28.0 parts of organosilicone modified acrylic resin, 15.0-25.0 parts of glycidyl methacrylate, 8.0-10.0 parts of triethyl citrate, 2.0-2.5 parts of poly(allylamine) and 50-60 parts of mixed solvent by weight. The ink does not contain plasticizers including phthalate and polyvinyl chloride resin but has flow property equivalent to that of the prior art, and has good storage stability and excellent adhesion to glass or PMMA (polymethylmethacrylate) substrates.

Description

Technical field [0001] The invention belongs to the technical field of printing inks. More specifically, the invention relates to a translucent gray plasticizing ink for screen printing. Background technique [0002] Ink is an important material used for printing packaging materials. It displays patterns and words on the substrate through printing. The ink includes main and auxiliary components, which are uniformly mixed and repeatedly rolled to form a viscous colloidal fluid. Printing ink is a paste-like colloid formed by uniformly dispersing and mixing materials such as pigments, binders, additives and solvents. The binder of the solvent-based ink is composed of solid resin and a large amount of volatile organic solvent. After the solid resin is dissolved in the solvent, the colorant is evenly dispersed in the binder. After the ink is printed on the printing medium, the solvent evaporates quickly to dry the conjunctiva. [0003] For inks, it is generally desirable to use printi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D11/02C09D11/03C09D11/037

Inventor 王春生

Owner SUZHOU ANJIE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com