Patents

Literature

39results about How to "Overcome wear resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion-resistant multi-coating neodymium iron boron and preparation process

ActiveCN106710767AAccelerated corrosionImprove wear resistanceMagnetic materialsSuperimposed coating processSingle processDysprosium

The invention provides corrosion-resistant multi-coating neodymium iron boron and a preparation process. The corrosion-resistant multi-coating neodymium iron boron is composed of a neodymium iron boron permanent magnet and multiple coatings arranged on the outer surface of the neodymium iron boron permanent magnet, the multiple coatings sequentially include a nickel-plated layer, a dysprosium-plated aluminum alloy thin film layer and a nickel-chromium composite coating, thickness of the nickel-plated layer is 10-15um, thickness of the dysprosium-plated aluminum alloy thin film layer is 10-20um, and thickness of the nickel-chromium composite coating is 6-10um; modification of the multiple coatings can be realized on the surface of the permanent magnet, binding strength between the coatings and a permanent magnet base is guaranteed, the defect that the coatings are thin and poor in corrosion resistance and wear resistance caused by single process is overcome, and the corrosion-resistant multi-coating neodymium iron boron prepared by the process has high corrosion resistance and wear resistance.

Owner:宁波元辰新材料有限公司

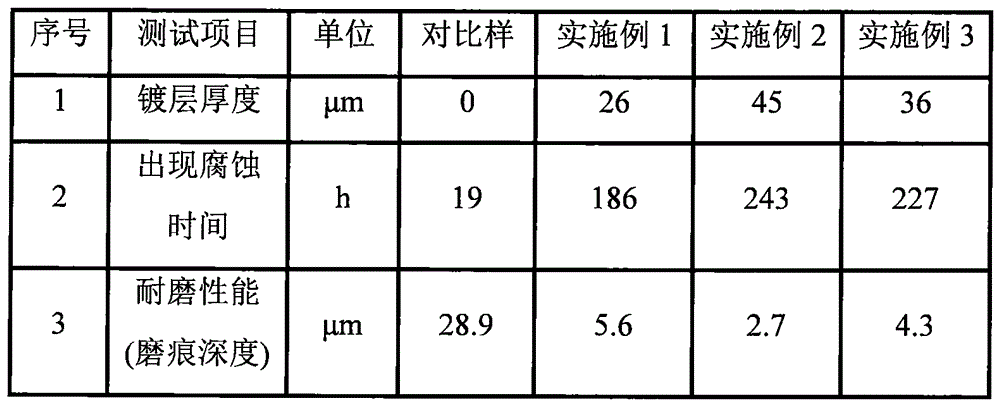

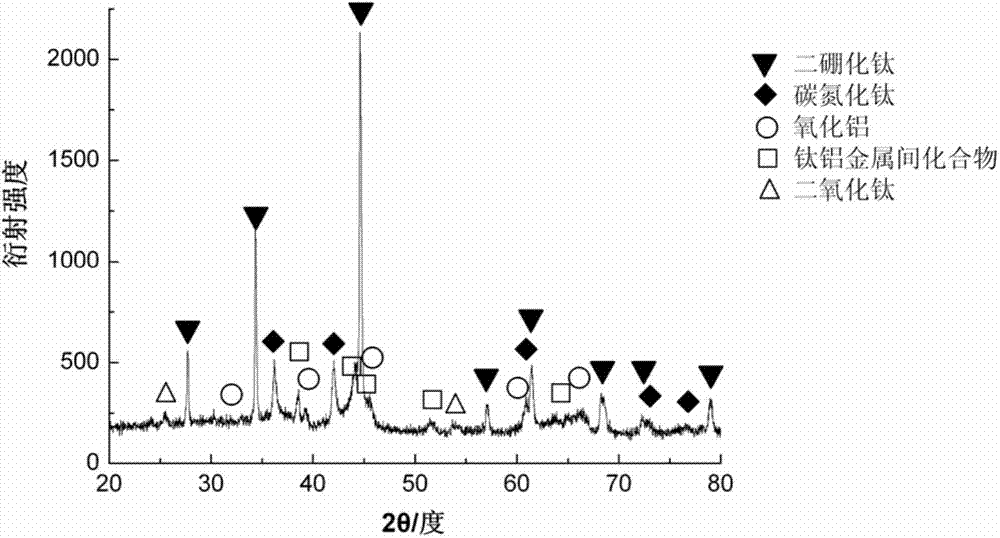

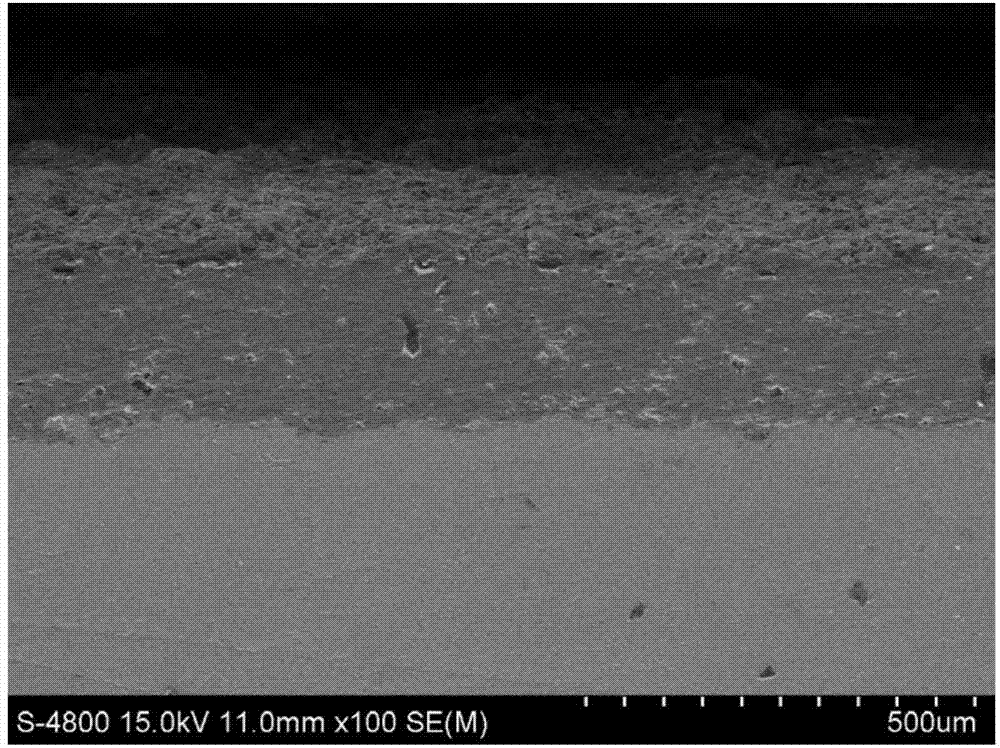

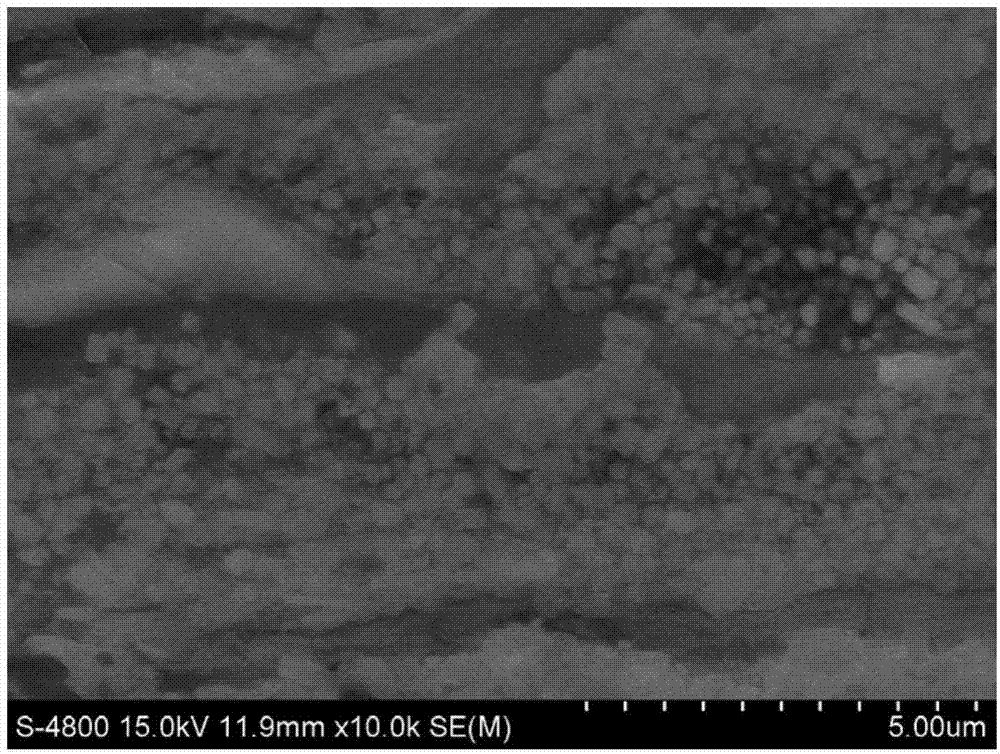

Preparation method of titanium boride based inorganic composite coating

Relating to plating of metal materials, the invention provides a preparation method of a titanium boride based inorganic composite coating. The mixed powder of micron-sized metal Al powder, micron-sized, submicron-sized or nano-sized TiO2 powder, and micron-sized, submicron-sized or nano-sized B4C powder is taken as a raw material, the mixed powder is sprayed on the alloy underlayer surface of a metal or alloy workpiece surface by thermal spraying. During thermal spraying, the Al, TiO2 and B4C in the mixed powder react with nitrogen in a powder feeding gas to synthesize the titanium boride based inorganic composite coating in situ. The method provided in the invention overcomes the defects of high raw material cost, complicated preparation process, high energy consumption, low efficiency, difficult control of coating processing precision, low coating density, poor coating uniformity, weak binding force between the coating and a substrate, low coating toughness, easy coating cracking, and unsuitability for application in large-scale industrial production existing in the prior art for preparation of titanium boride based composite coatings.

Owner:HEBEI UNIV OF TECH

High conductivity copper-magnesium alloy for automobile electrical equipment

The invention discloses a high-conductive Cu-Mg alloy of automobile, which is characterized by the following: adding 0.001-0.1% phosphor, 0.4-0.8% magnesium and copper; making the stretch-proofing strength Ra at 460MPa-520Mpa and extending rate A50mm not less than 6%; obtaining the product with Hv at 140-165 and conductive rate not less than 62%IACS.

Owner:中铜(上海)铜业有限公司

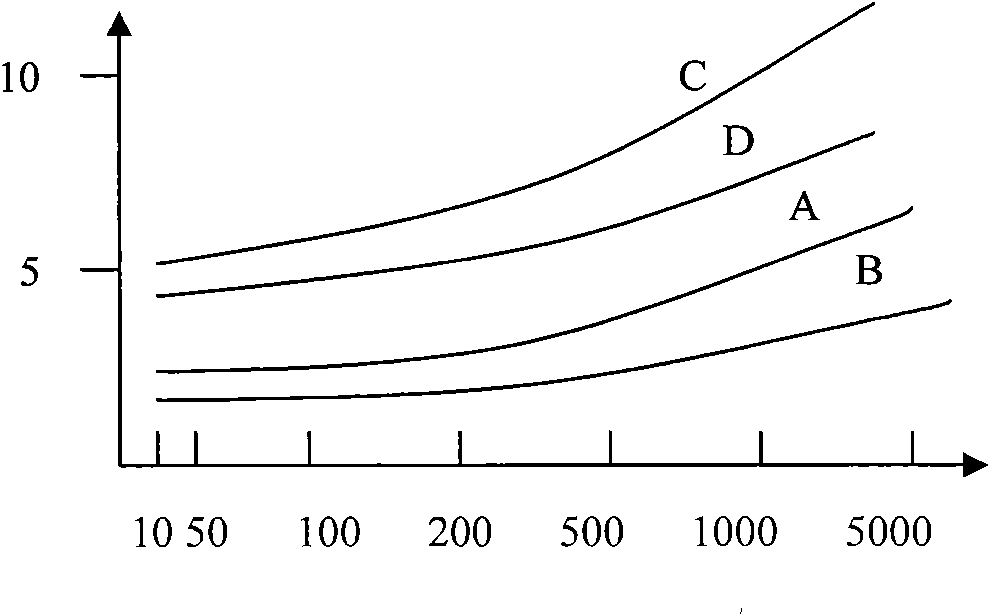

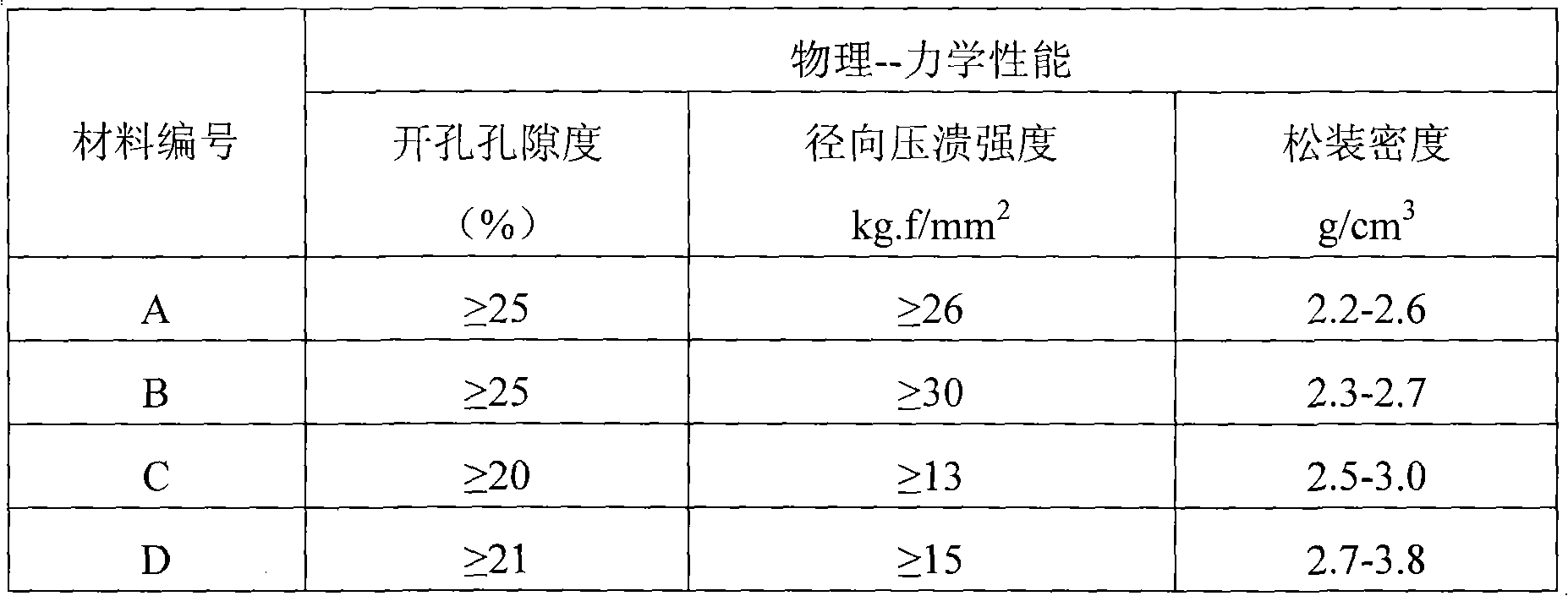

Steel pipe-straightening roller for casting high chromium iron or high chrome steel

A new type casting chromium iron or casting chromium iron tube rectifier roll is used for steel tube straightener, with main element of the direct roll with C: 1.8-2.8%,Si:<=1.0%,Mn:<=1.0%,P:<=0.04%,S:<=0.04%, Cr:12-22%,Ni:0.5-3.0%,Mo:0.8-3.0%,V:0-1.0%,Cu:0-1.0%, the rest with Fe. Rated in weight of the components should be C: 0.7-1.2%,Si:<=1.0%,Mn:<=1.0%,P:<=0.04%,S:<=0.04%; Cr:8.0-12%,Ni:0.5-2.0%,Mo:0.8-3.0%,V:0-1.0%, with the rest being Fe. Due to even inside and outside of the cast iron steel tube roll, it has higher performance in wearing resistance and toughness, with doubled durability. Due to reduced material, it greatly reduces production cost. Its performance surpasses the international level with life span of it over two times of the national made ones.

Owner:SHANDONG PROVINCE SIFANG TECHN DEV

Fresh cocoon silk reeling method

InactiveCN104593875AOvercoming poor cohesionOvercome wear resistanceSilk reelingEngineeringPermeation

The invention discloses a fresh cocoon silk reeling method. The method comprises the following steps: stacking and storing fresh cocoons, and then sequentially performing cocoon mixing, cocoon peeling and cocoon selecting according to process requirements to obtain cocoons for silk reeling; putting the cocoons for silk reeling into a closed water tank, and performing low-temperature water suction permeation; cooking the permeated water-sucked cocoons subjected to the low-temperature water suction permeation by using a cocoon cooking machine, performing silk reeling by using an automatic silk reeling machine, and controlling the reeling speed; putting a small net into the water tank, performing negative-pressure water intake and suction, and then performing immersion treatment; finally, performing rereeling finishing, and packaging reeled silks. The fresh cocoon silk reeling method has the advantages of simplicity, quickness and low cost, the defects of an existing fresh cocoon silk reeling method are overcome favorably, the technical problem of influence on the performance of fresh cocoon raw silks caused by lower cohesion and poor abrasion resistance of the raw silks is solved, and the grade of the fresh cocoon raw silks is improved.

Owner:ZHEJIANG UNIV

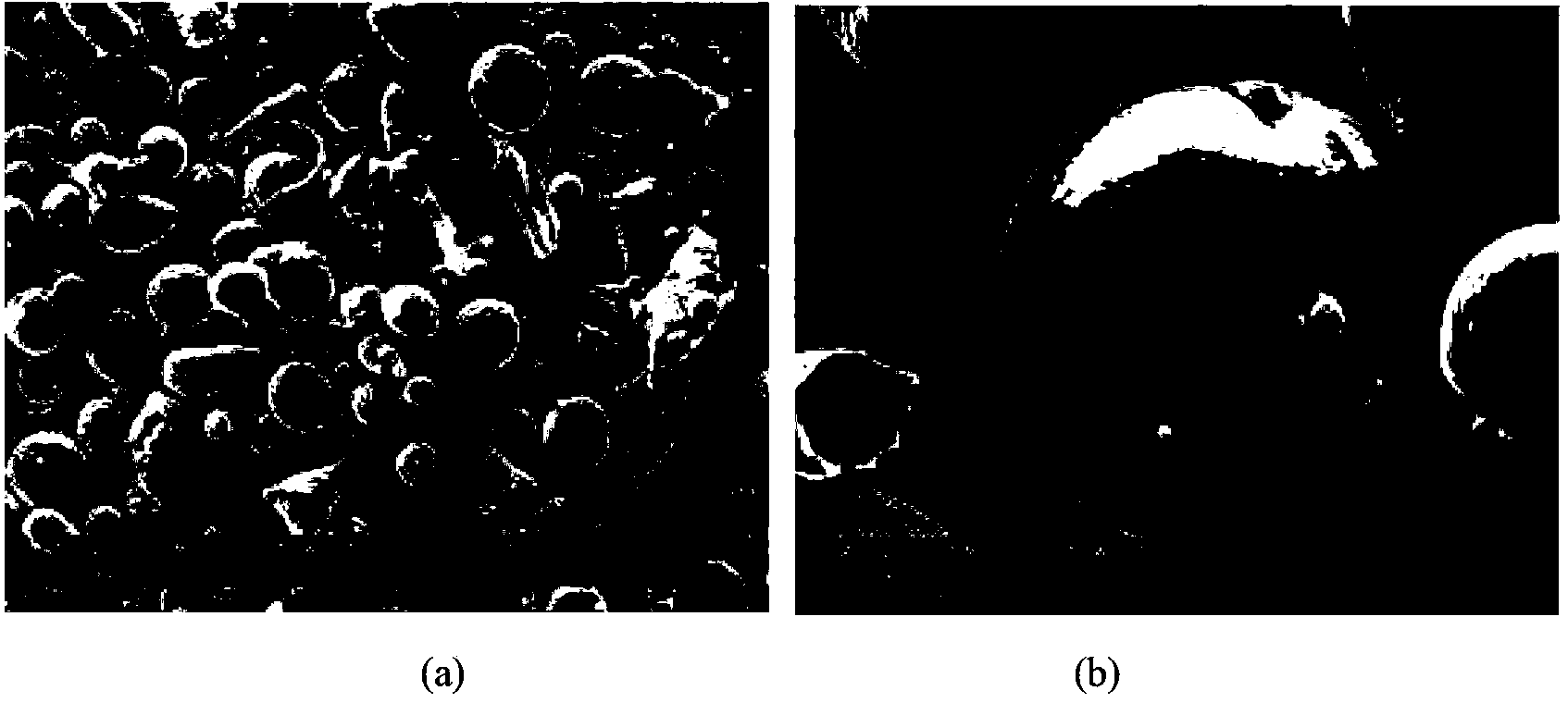

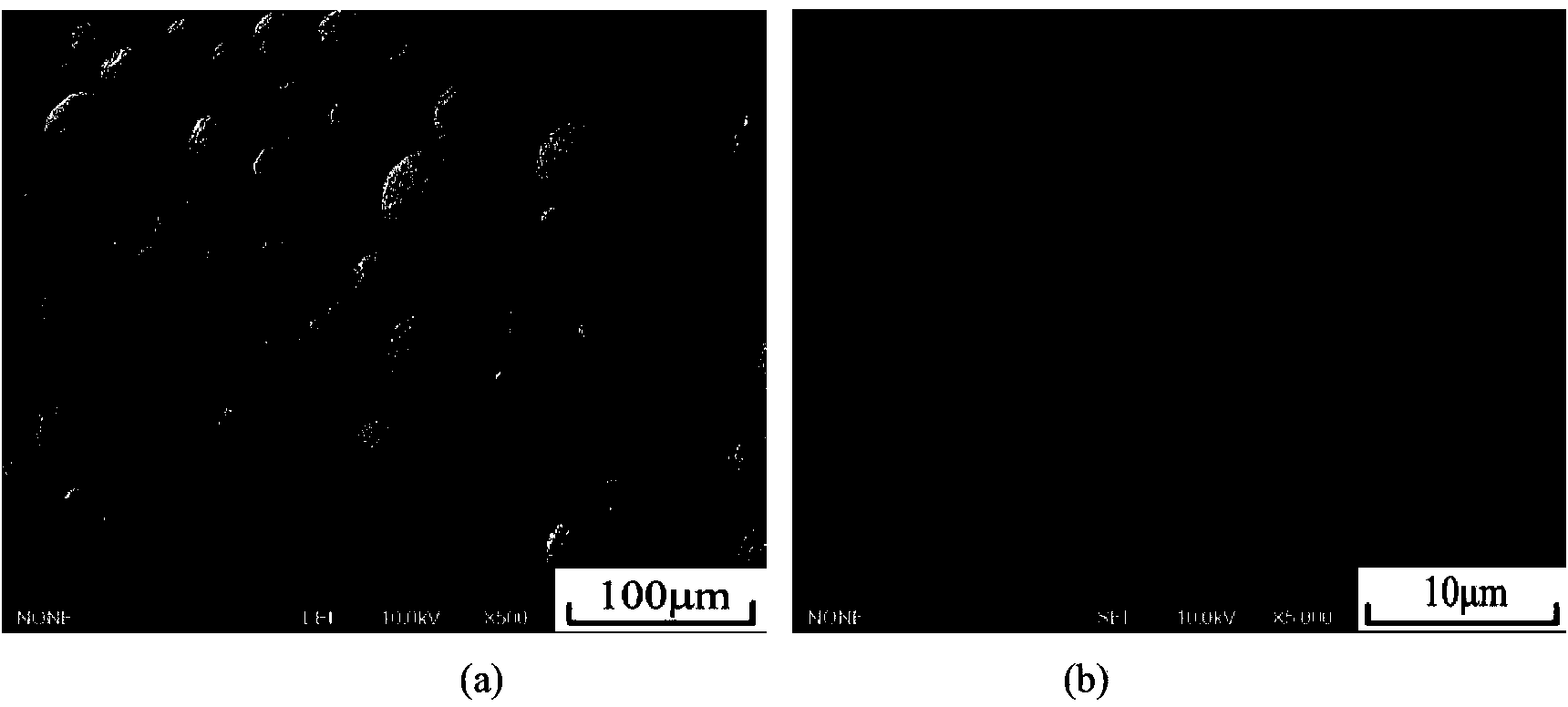

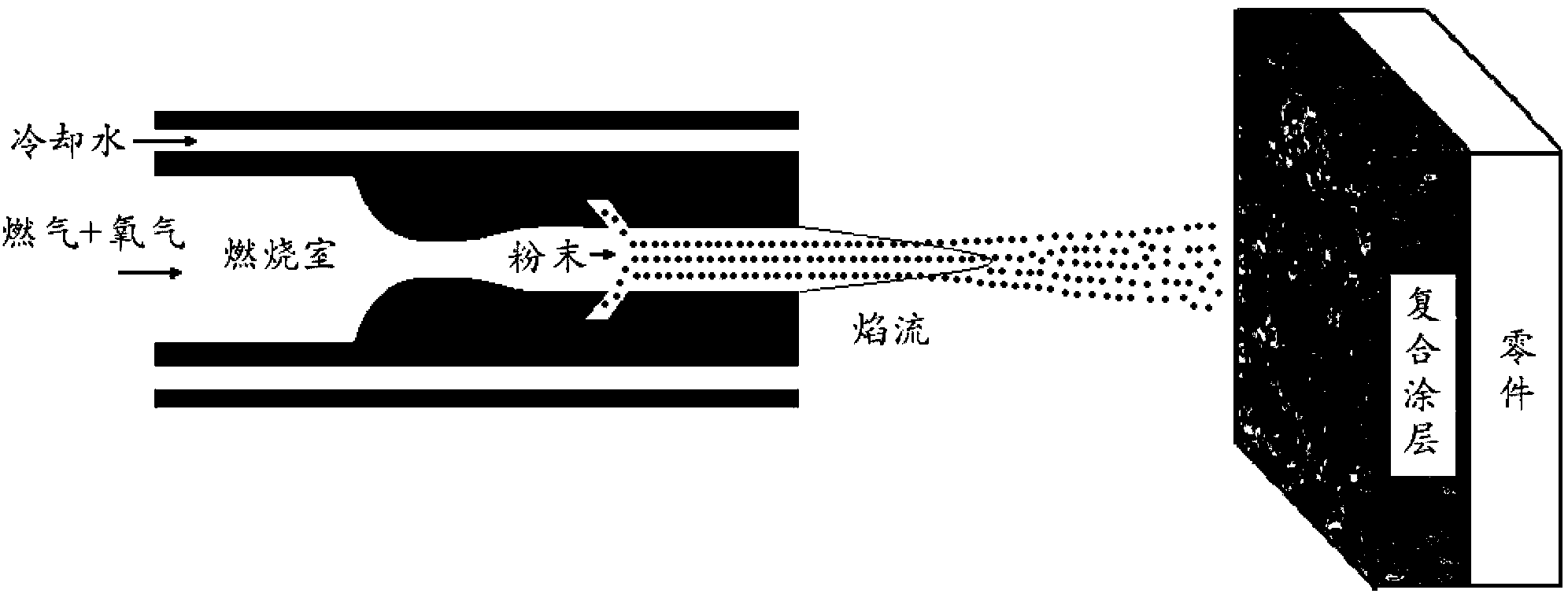

Fe-based metal glass composite coating enhanced by WC-Co as well as preparation method of the coating

InactiveCN103526135AHigh hardnessHigh strengthMolten spray coatingHeat inorganic powder coatingGlass compositesWaste product

The invention provides a Fe-based metal glass composite coating enhanced by WC-Co as well as a preparation method of the coating. By volume, 10%-30% of WC-Co powder and 70%-90% of Fe-based amorphous powder are mixed evenly to obtain a mixture serving as a spraying material, and by virtue of a hypersonic flame spraying technology, the metal glass coating enhanced by a hard alloy is prepared on the surface of a part. Compared with the existing Fe-based amorphous coating, the Fe-based metal glass composite coating is higher in hardness, strength and wear-resisting performance. Compared with a WC-Co coating prepared by the same method, the Fe-based metal glass composite coating is similar in performance but much lower in cost. The Fe-based metal glass composite coating with excellent performance and low cost can be used for not only enhancing product performance during production of new products, but also repairing or re-manufacturing waste products, and has extensive application prospect.

Owner:TIANJIN UNIV

Brass composite powder and preparation method thereof

The invention provides brass composite powder, which is characterized in that the brass composite powder is prepared from 70 to 97 percent of copper and 3 to 30 percent of zinc in percentage by weight. The invention also provides a preparation method for the brass composite powder. The invention provides a substitute raw material with low cost and good product performance and quality for manufacture, application and development of the prior brass-based powder metallurgical products and parts.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

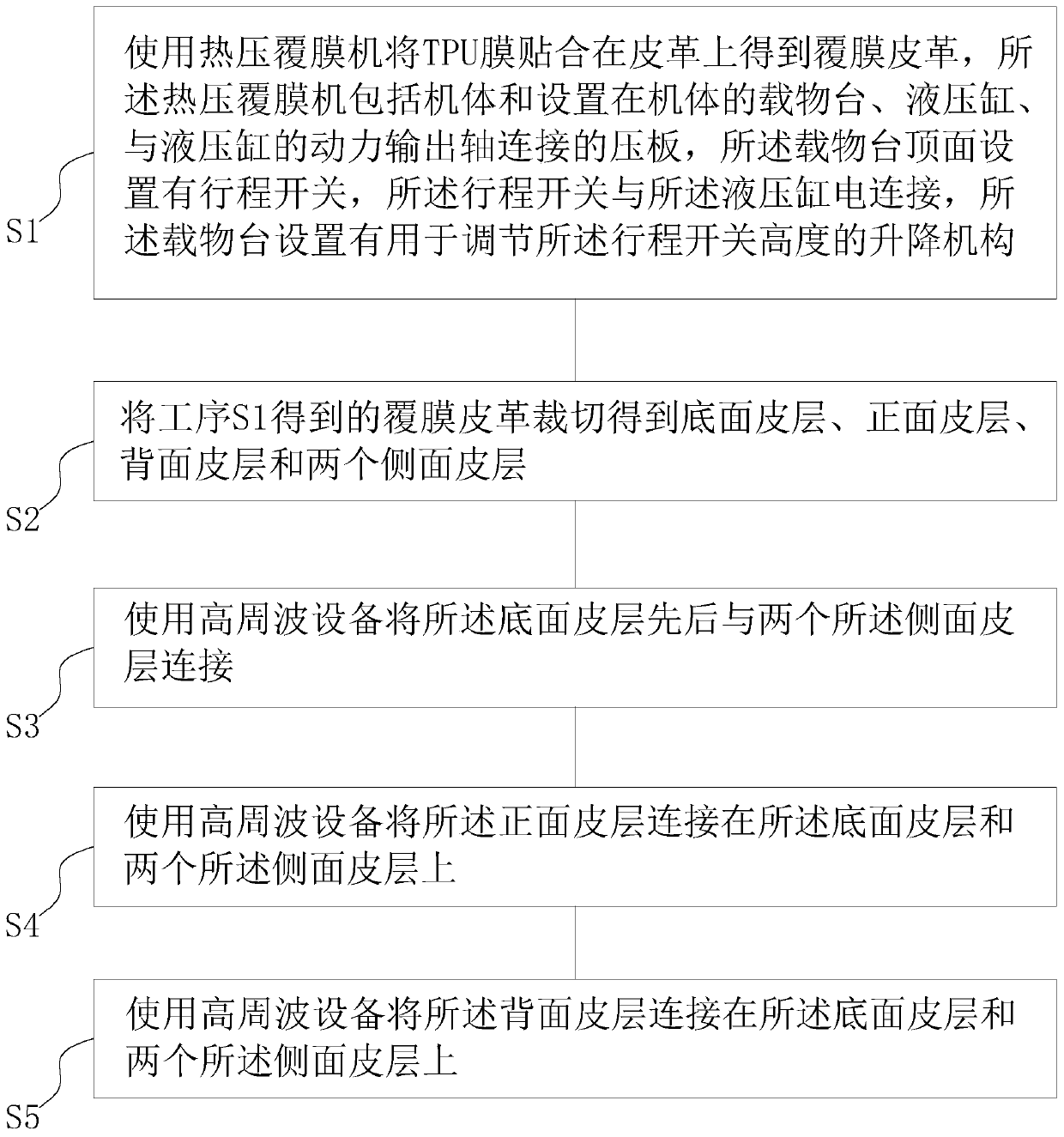

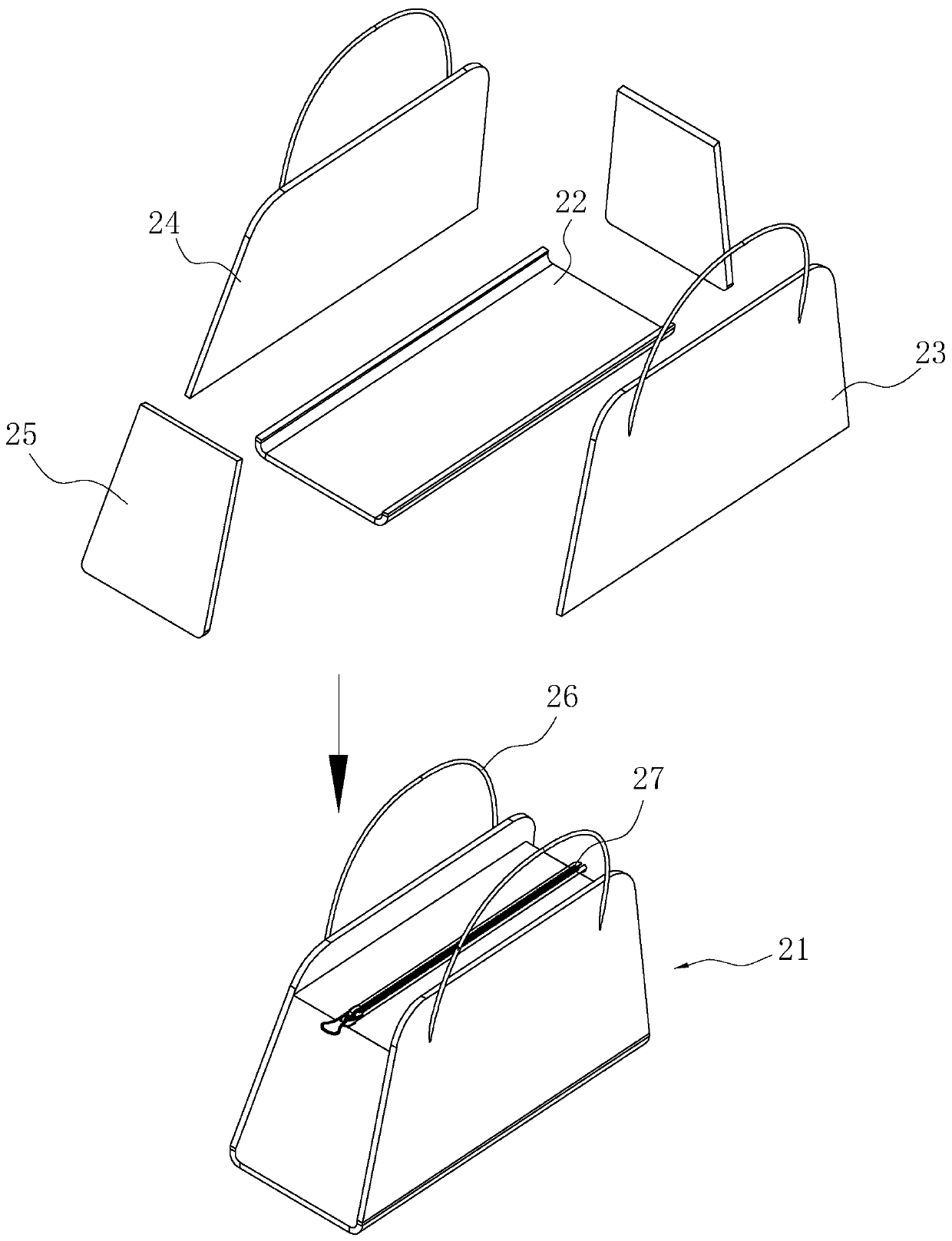

Leather bag processing technology and leather bag processed through technology

InactiveCN110123002AOvercome water resistanceOvercome wear resistanceSynthetic resin layered productsHandbagsHydraulic cylinderEngineering

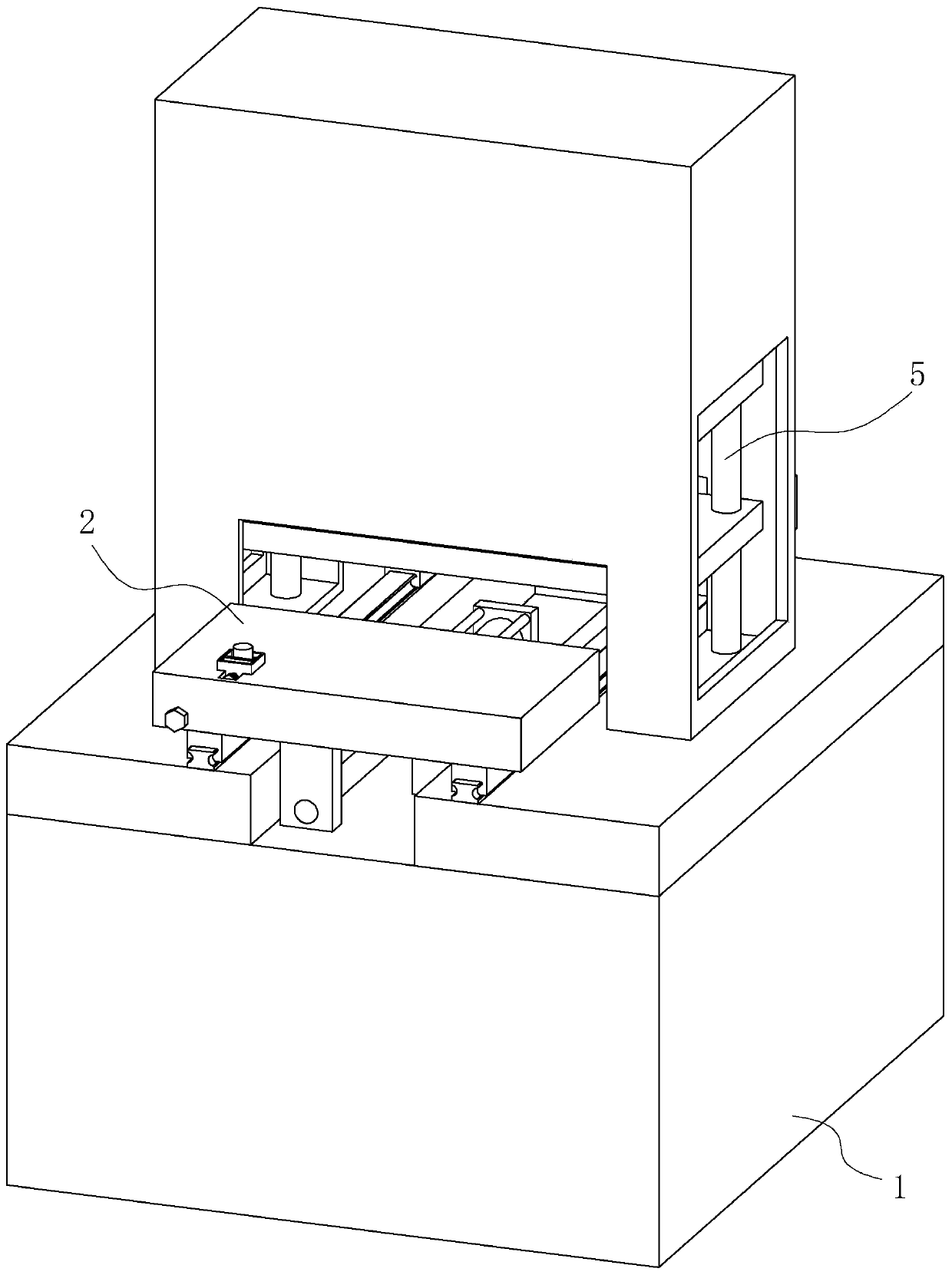

The invention relates to a leather bag processing technology. The technology comprises the following steps that S1, a TPU film is attached to leather by using a hot-pressing film laminating machine toobtain the coated leather, wherein the hot-pressure laminating machine comprises a machine body, a carrying table arranged on the machine body, a hydraulic cylinder and a pressing plate connected with a power output shaft of the hydraulic cylinder, a travel switch is arranged on the top surface of the carrying table, the travel switch is electrically connected with the hydraulic cylinder, and thecarrying table is provided with a lifting mechanism used for adjusting the height of the travel switch; S2, the coated leather obtained in S1 is cut to obtain a bottom leather layer, a front leatherlayer, a back leather layer and two side leather layers; S3, the bottom leather layer is sequentially connected with the two side leather layers by using high-frequency equipment; S4, the high-frequency equipment is used for making the front leather layer connected to the bottom leather layer and the two side leather layers; S5,the back leather layer is connected to the bottom leather layer and the two side leather layers by using high-frequency equipment. Meanwhile, the invention provides a leather bag processed through the technology. The leather bag has the advantage of improving the strength and attractiveness.

Owner:上海全邯电子科技有限公司

Method for improving cohesion of fresh cocoon reeling raw silk

InactiveCN104372415AOvercoming poor cohesionOvercome wear resistanceSilk reelingEngineeringPermeation

The invention discloses a method for improving cohesion of fresh cocoon reeling raw silk. Cocoon mixing, cocoon stripping and cocoon assorting are sequentially carried out on fresh cocoons according to process requirements after the fresh cocoons are stacked and stored, and reeling cocoons are obtained; the reeling cocoons are placed in a sealed water tank for low-temperature water suction permeation; water-permeable water-absorbing cocoons after low-temperature water suction permeation are reeled by means of an automatic reeling machine, and winding speed is controlled; a small net is placed in the water tank, negative-pressure water incoming and water absorbing are carried out firstly, and then dipping is carried out, finally re-reeling and sorting are carried out, and skein twisting and packaging are carried. The method has the advantages of being simple, quick and low in cost. Defects of existing fresh cocoon reeling are overcome, the technical problems that cohesion is poor, friction resistance of the raw silk is poor, and performance of the fresh cocoon raw silk is influenced are solved, and the grade of the fresh cocoon raw silk is improved.

Owner:ZHEJIANG UNIV

Method for improving ink adhesion in plastic printing product

ActiveCN106480416AFastGood response controllabilityVacuum evaporation coatingSputtering coatingEpoxyDimethylaniline N-oxide

The invention belongs to the field of printing machining and particularly relates to a method for improving ink adhesion in a plastic printing product. The method includes the following steps of (1) pretreatment of the plastic product and (2) printing. An ion sputtering method is adopted to conduct oxidation treatment on the surface of the plastic product, energy can be rapidly transferred to a special functional group on the plastic surface, and purposes of even heating and even oxidization are achieved; printing ink is prepared in the manner that based on ordinary ink, microcrystalline wax, N, N-dimethylaniline, lignin-based epoxy resin and a surface active agent are added, and consistency and permeability of the ink and the plastic product are increased. The plastic printing product prepared through the method has the advantages that adhesion between the plastic product and the ink is high, and friction resistance is achieved.

Owner:义乌市双杰日用品有限公司

TiC-particle-reinforced titanium-aluminum-molybdenum alloy material by in-situ synthesis and preparation method thereof

The invention discloses a TiC-particle-reinforced titanium-aluminum-molybdenum alloy material by in-situ synthesis. The alloy material comprises, by mass, 0.2%<=Al<=2.5%, 0.5%<=C<=1.5%, 2.5%<=Mo<=3% and the balance Ti and inevitable impurities. The alloy material is prepared according to a method including: 1) compounding by weighing powdered aluminum, graphite powder, molybdenum powder and titanium powder of a corresponding quantity according to the mass percent; 2) ball-milling and mixing; 3) pressing mixture subjected to ball milling and sieving by means of bidirectional mould pressing; 4) placing a green pressing on a cathode of a vacuum container; 5) regulating the vacuum degree in a furnace; and 6) performing particle bombardment sintering for the pressing and the cathode after argon gas reaches the working gas pressure. Carbon substitutes for part of aluminum to serve as an alloying element to be introduced to alloy, and a means that high-melting-point dispersed TiC particle phases are introduced to reinforce a matrix by solid solution strengthening of C and hollow cathode rapid sintering in-situ reaction, so that the TiC-particle-reinforced titanium-aluminum-molybdenum alloy material which is high in strength and wear resistance and low in cost is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

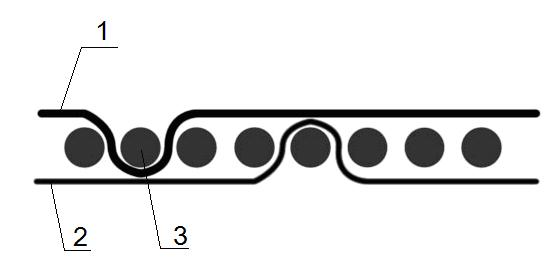

Aluminum silicate/nickel-chromium stainless steel wire fireproof rolling curtain cloth and manufacturing method thereof

InactiveCN102002789AImprove fire resistancePlay a supporting roleWoven fabricsAluminum silicateFire resistance

The invention discloses aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth and a manufacturing method thereof. Aluminum silicate yarns and nickel-chromium stainless steel wires are taken as raw materials to form a fabric through a weft backed weave structure. The warp yarns of the fabric are aluminum silicate / nickel-chromium stainless steel wire doubled wires, and weft yarns are two groups of aluminum silicate yarns and nickel-chromium stainless steel wire yarns, wherein the positive weft yarns are aluminum silicate yarns, and the reverse weft yarns are nickel-chromium stainless steel wires. The gram per square meter of the aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth is 800 to 1,200g / m<2>, the total tightness of the fabric is more than or equal to 115 percent, and the fire resistance temperature is 1,100 DEG C. The manufacturing method comprises the following steps of: (1) doubling the aluminum silicate yarns with the nickel-chromium stainless steel wires; (2) performing spooling, beaming, slashing and drawing processes on the doubled aluminum silicate / nickel-chromium stainless steel wires for weaving; (3) respectively quilling the aluminum silicate yarns and the nickel-chromium stainless steel wires for weaving; and (4) weaving the prepared warp yarns and weft yarns on a shuttle loom with a double-side multi-shuttle box mechanism according to the designed looming draft so as to prepare the aluminum silicate / nickel-chromium stainless steel wire fireproof rolling curtain cloth.

Owner:SICHUAN UNIV

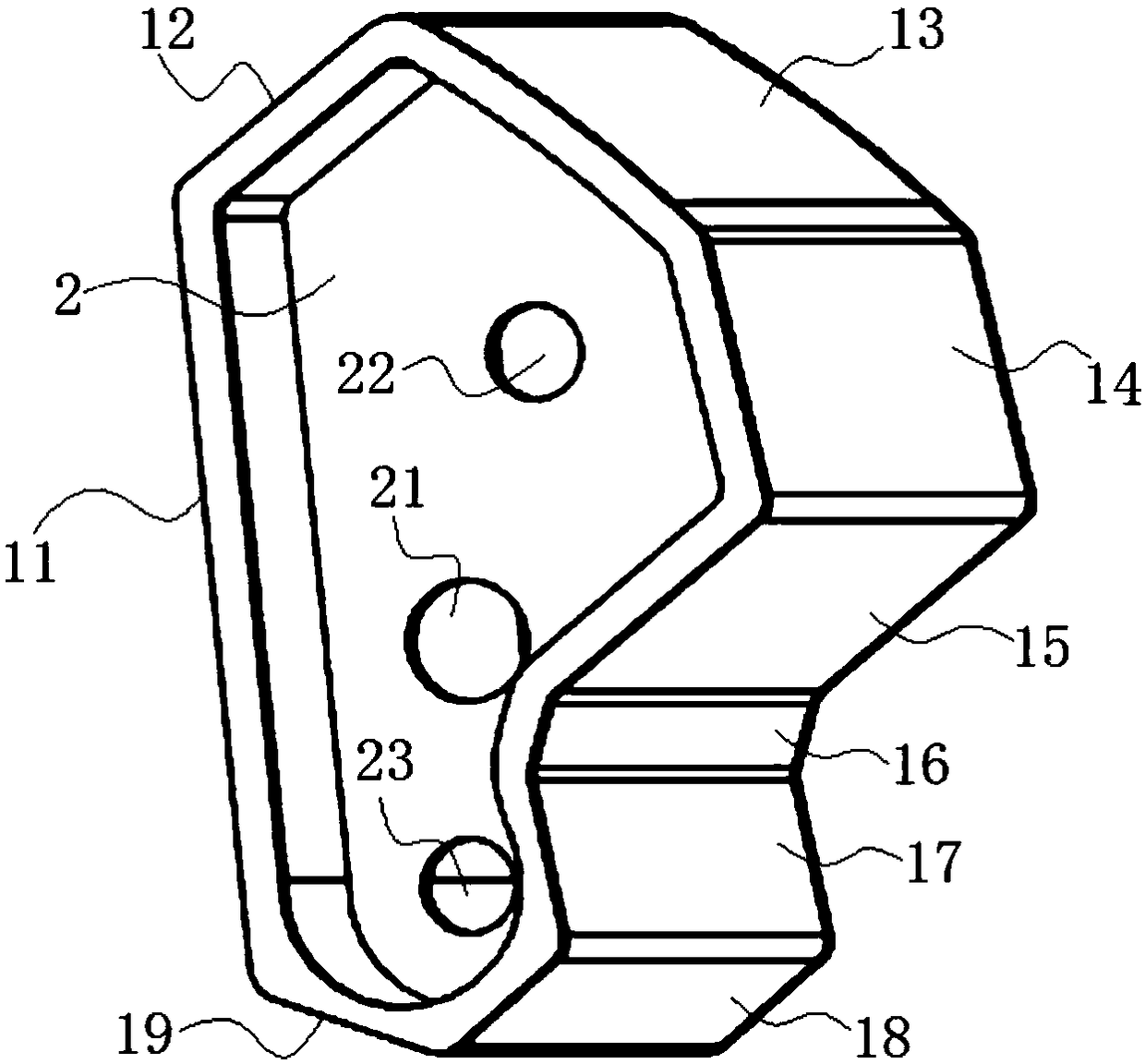

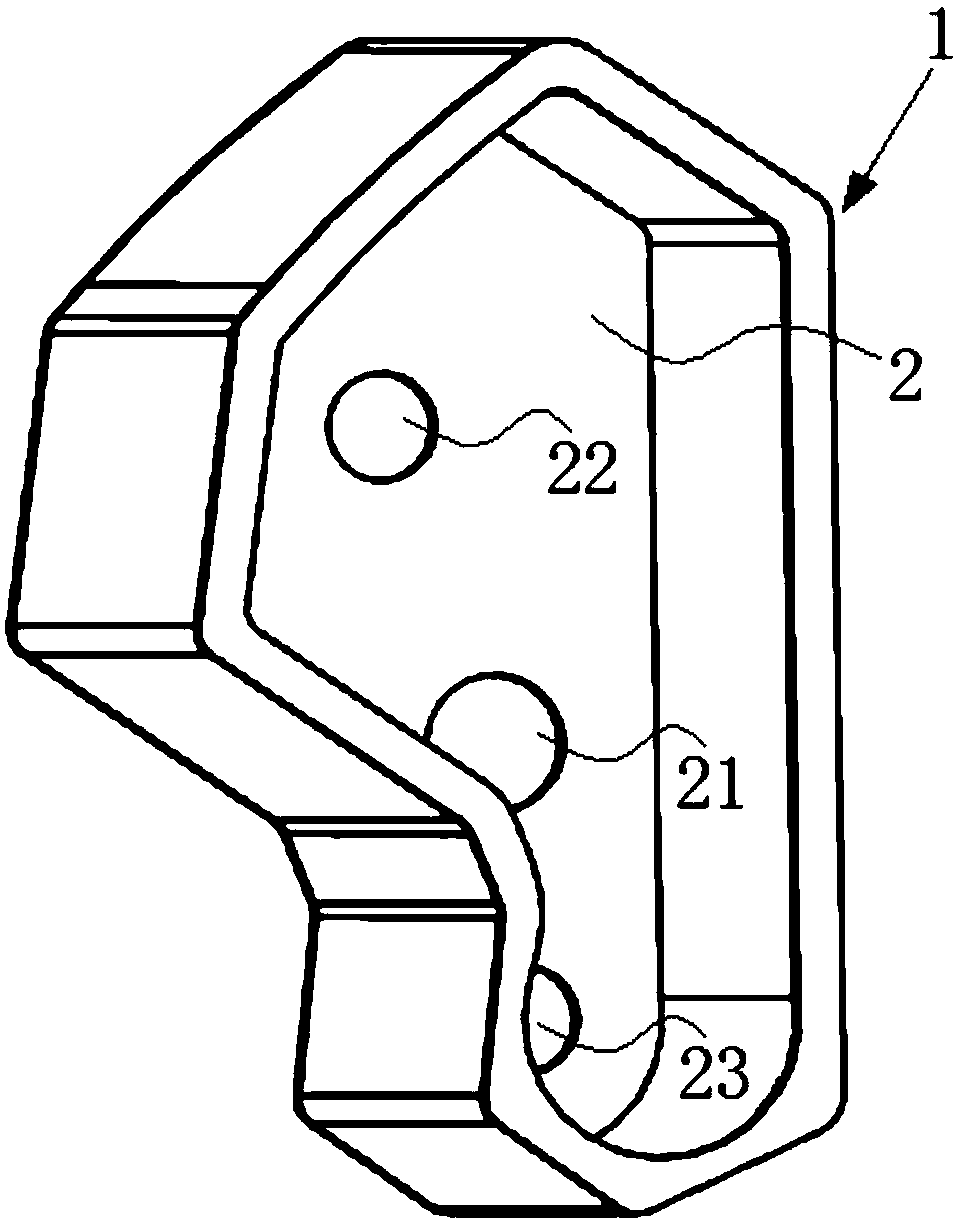

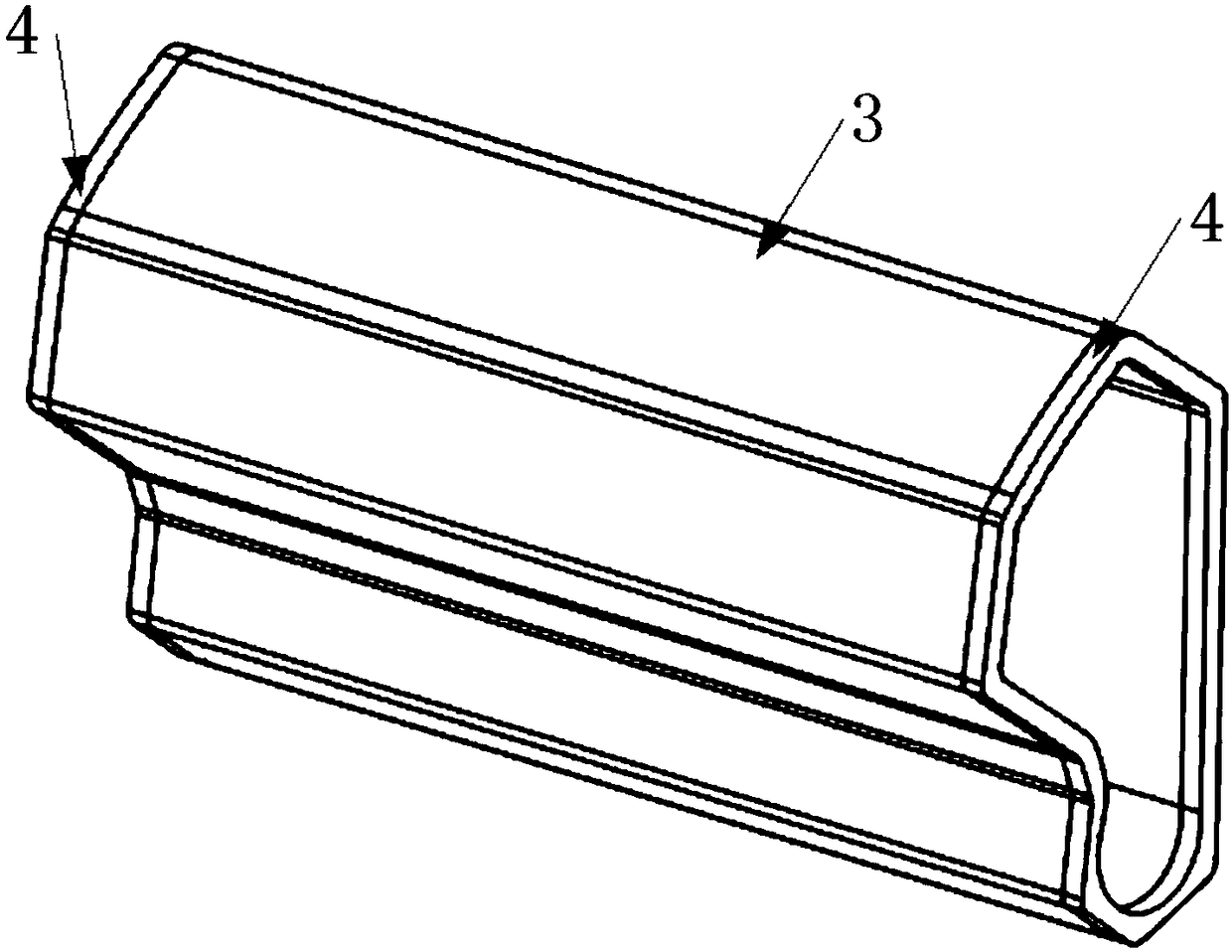

Portable computer hinge shell manufacturing method

InactiveCN108107977AImprove matchWon't looseAnodisationDigital data processing detailsAbrasive blastingPrinting ink

The invention discloses a portable computer hinge shell manufacturing method. A hinge shell comprises a cylindrical shell body and a baffle sheet arranged in the cylindrical shell body; an accommodation space is formed in the cylindrical shell body; and the baffle sheet is connected with the inner wall of the cylindrical shell body in a spot welding manner and is perpendicular to the inner wall ofthe cylindrical shell body. The manufacturing method comprises the following processes of stamping the baffle sheet; performing CNC machining on the cylindrical shell body; welding the edge of the baffle sheet to the inner wall of the cylindrical shell body in a laser spot welding manner; polishing the outer surface of the cylindrical shell body; forming a printing ink layer on the outer surfaceof the cylindrical shell body; performing laser carving to remove printing ink: performing the laser carving to remove the printing ink layer of a matte region; performing abrasive blasting on the outer surface of the cylindrical shell body; performing cleaning to remove the printing ink; and performing anodic oxidation. The hinge shell manufactured by adopting the method is simple in structure, attractive in appearance, convenient in machine shaping and high in degree of matching with a hinge of a portable computer; after installation, the hinge does not get loose and is high in matching degree and stable in rotation; the baffle sheet is connected with the cylindrical shell body through laser spot welding, so that no residues are generated; and the method is suitable for high-end portableproducts.

Owner:KUNSHAN WISPREN ELECTRONICS TECH CO LTD

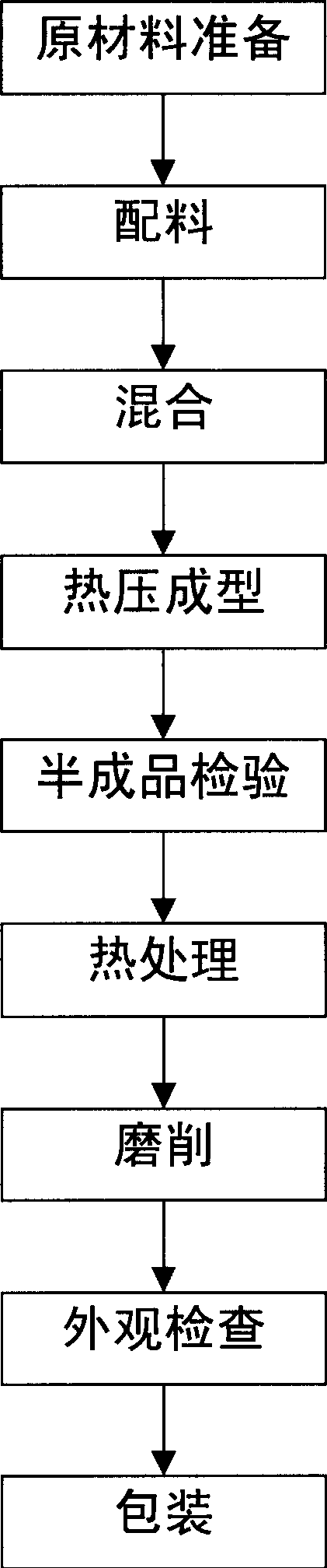

Pollutionless non-metal friction material and its preparing process

InactiveCN1377932AOvercoming Heat Recession HighOvercome wear resistanceOther chemical processesClutchBrake lining

Owner:西安信力石棉制品总厂

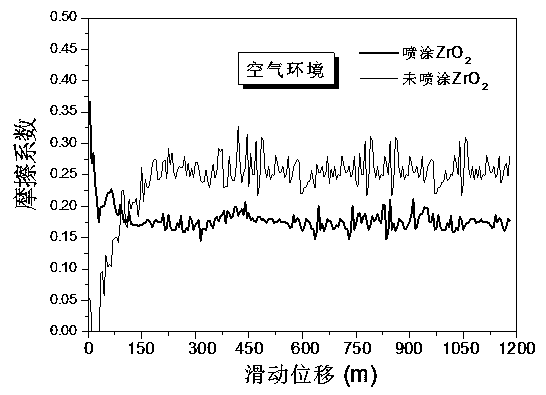

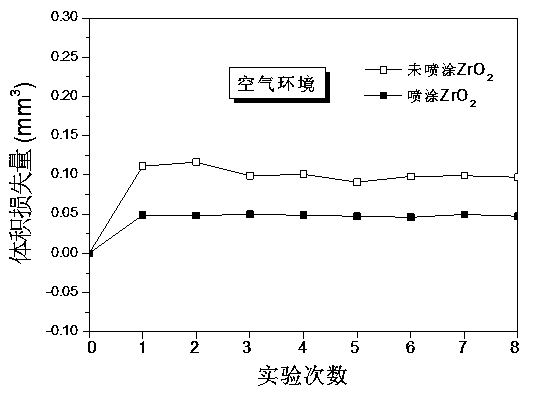

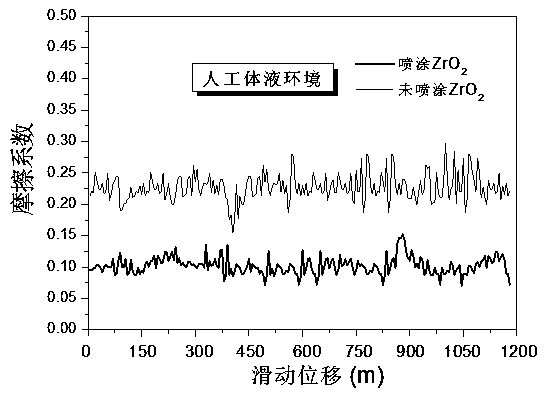

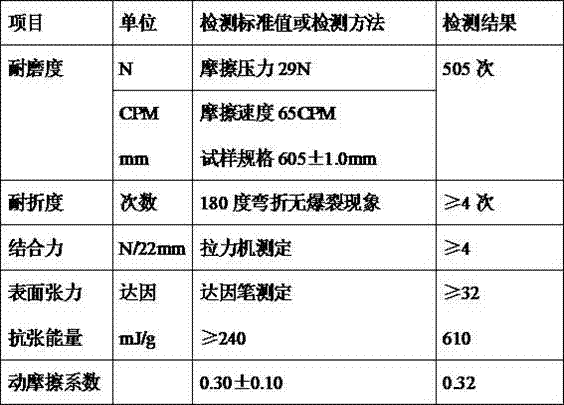

Technology method for improving surface abrasion resistance of laser additive manufacturing metal artificial knee joint

InactiveCN110923613AOvercome wear resistanceOvercome resilienceMolten spray coatingArticular surfacesSand blasting

The invention discloses a technology method for improving surface abrasion resistance of a laser additive manufacturing metal artificial knee joint, and belongs to the technical field of surface treatment. The technology method comprises the following steps that firstly, sand blasting treatment is conducted, sand blasting treatment is conducted on the surface of the artificial knee joint, and thesurface roughness reaches Ra3.2; secondly, preheating treatment is conducted, the artificial knee joint is heated to 40-50 DEG C, and nanometer zirconia powder is sprayed and heated to 40-50 DEG C; and thirdly, spraying is conducted, and zirconia ceramic powder is used for conducting plasma spraying on the sprayed surface. Nanometer zirconia particles are sprayed to the surface of the artificial knee joint, and inherent defects that a traditional knee joint is low in abrasion resistance, and full ceramic joint toughness is poor are overcome. A layer structure with anisotropism is formed on theceramic surface obtained after plasma spraying, the ceramic layer brittle fracture tendency can be greatly reduced through the structure, the structure and other structures are well matched after spraying, inherent forming and moving states of the knee joint cannot be influenced, the service life of the artificial knee joint is prolonged, and the pain of patients is reduced.

Owner:SHANDONG UNIV OF TECH

TiC particle-reinforced titanium-aluminum-molybdenum-silicon alloy material synthesized in situ and preparation method thereof

The invention discloses a TiC particle-reinforced titanium-aluminum-molybdenum-silicon alloy material synthesized in situ. The alloy material consists of the following components in percentage by mass: more than or equal to 0.2 percent and less than or equal to 2.5 percent of Al, more than or equal to 0.5 percent and less than or equal to 1.5 percent of C, more than or equal to 2.5 percent and less than or equal to 3 percent of Mo, more than or equal to 0.2 percent and less than or equal to 0.4 percent of Si and the balance of Ti and inevitable impurities. The alloy material is prepared with a method comprising the following steps of: (1) preparing materials: weighing corresponding amounts of aluminum powder, graphite powder, molybdenum powder, silicon powder and titanium powder according to the percentage by mass; (2) mixing through ball milling; (3) making a mixture sieved through ball milling in the step (2) pass through a bidirectional die pressing green compact; (4) placing a green compact onto the cathode of a vacuum container; (5) adjusting the vacuum degree in a furnace; and (6) after argon reaches the working air pressure, sintering a blank and the cathode through particle bombardment. Carbon serving as an alloying element is introduced into an alloy instead of a part of aluminum, and a measure for introducing a high-melting-point diffused TiC particle phase-strengthened substrate through solution strengthening of carbon and a rapid sintering in-situ reaction of a hollow cathode is used, so that a low-cost particle-reinforced alloy material with high strength and high wear resistance is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Production method of environment-friendly cigarette packet material

ActiveCN107119494AImproved rheological propertiesGood molding effectFlexible coversWrappersLaser patterningPolypropylene

The invention relates to a manufacturing method of a packaging material, in particular to a production method of an environment-friendly cigarette packet material. The production method mainly comprises the steps of: A, performing laser die pressing on a BOPP (biaxially-oriented polypropylene) film to form a laser pattern on the BOPP film, B, coating a first layer on the front surface of raw paper, performing flattening treatment on the front surface of the raw paper, coating a second layer on the front surface of the raw paper in a high-temperature pressed environment, performing rolling compounding on the raw paper and the BOPP film, and C, coating a first layer on the back surface of the raw paper and performing flattening treatment on the back surface of the raw paper. The method does not use non-renewable metal aluminum as a raw material any longer, saves non-renewable mineral resources and energy sources, makes full use of a high technology and a new technology to effectively avoid generation of environmental pollutants, raises an environment-friendly grade of a product, saves the resources to the greatest extent, protects an environment, achieves a zero utilization standard of the aluminum, and avoids the generation of three industrial wastes, the product with the higher environment-friendly grade has higher market competitiveness, and the method has wider market prospects.

Owner:SHANTOU XINDA COLOR PRINTING PACKAGING MATERIALS

Gray cast iron cylinder sleeve material and preparing method thereof

The invention provides a gray cast iron cylinder sleeve material. The components of the gray cast iron cylinder sleeve material include 3.25-3.5 wt% of carbon, 0.06-0.08 wt% of sulfur, 2.0-2.5 wt% ofsilicon, 0.06-0.1 wt% of phosphorus, 0.3-0.5 wt% of manganese, 0.3-0.5 wt% of chromium, 0.6-0.8 wt% of copper, 0.35-0.45 wt% of niobium, 0.02-0.04 wt% of antimony and the balance iron. By means of thealloy element and process design of the cylinder sleeve material, the metallographic structure of the prepared gray cast iron cylinder sleeve material comprises flake graphite, fine lamellar pearliteand about 1% of iron phosphide eutectic, and meanwhile niobium carbonitride is evenly distributed in the metallographic structure. The prepared cylinder sleeve material has high strength and excellent wear reduction partner adaptability and corrosion resistance and is stable in structure and low in cost.

Owner:ZYNP GRP

Fingerprint resistant coating, fingerprint resistant stainless steel plate and method for preparing fingerprint resistant stainless steel plate

The invention provides a fingerprint resistant coating, which is coated on the surface of a stainless steel plate so that the surface of the stainless steel plate is anti-fouling and fingerprint-resistant, is fine in hydrophobicity and lipophobicity and has a self-cleaning function. The fingerprint resistant coating comprises, in weight percent, 0.02%-0.04% of polysiloxane auxiliaries, 98.5%-99.5% of nano silica coatings or #337 luxurious ink and the balance BYK-430 solvents. The invention further provides a fingerprint resistant stainless steel plate, which is formed by coating the fingerprint resistant coating on the stainless steel plate. Besides, the invention further provides a method for preparing the fingerprint resistant stainless steel plate. The method includes the steps: cleaning and drying the surface of the stainless steel plate; coating the fingerprint resistant coating; and drying the fingerprint resistant coating to obtain the fingerprint resistant stainless steel plate.

Owner:SUZHOU HENGQIANG STAINLESS STEEL MATERIAL

In-situ synthesized TiC particle-reinforced titanium aluminium alloy material and preparation method thereof

The invention discloses an in-situ synthesized TiC particle-reinforced titanium aluminium alloy material which comprises the following components by mass: 0.2%<=Al<=2.5%, 0.5%<=C<=1.5%, and the balance of Ti and inevitable impurities; the alloy material is prepared by the following method: 1) material preparation, that is, weighing corresponding amounts of aluminium powder, graphite powder and titanium powder according to the above mass ratio; 2) ball milling mixing; 3) performing compaction of the mixture after ball milling and sieving in step 2) through bidirectional mold pressing; 4) putting the green compact on a vacuum container cathode; 5) adjusting the vacuum degree of the furnace; 6) performing particle bombardment sintering of the green compact and the cathode when the argon reaches a working air pressure. According to the invention, carbon substitutes part of aluminium and is introduced into the alloy as an alloying element; and the particle-reinforced titanium aluminium alloy material with high strength, wear resistance, and low cost is obtained by means of carbon solid solution reinforcement and matrix reinforcement by introducing high-melting point dispersed TiC particles through hollow cathode rapid sintering in-situ reaction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

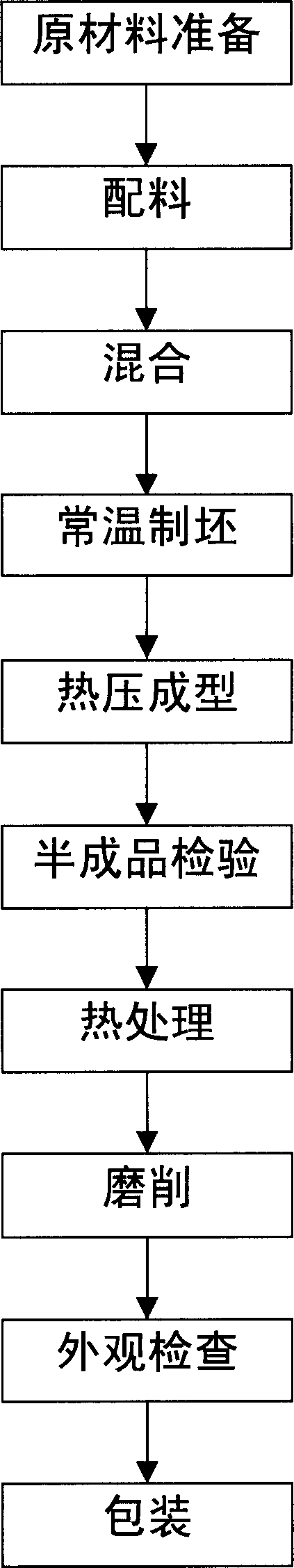

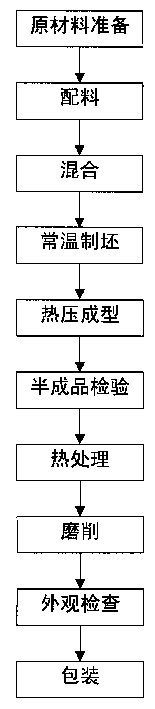

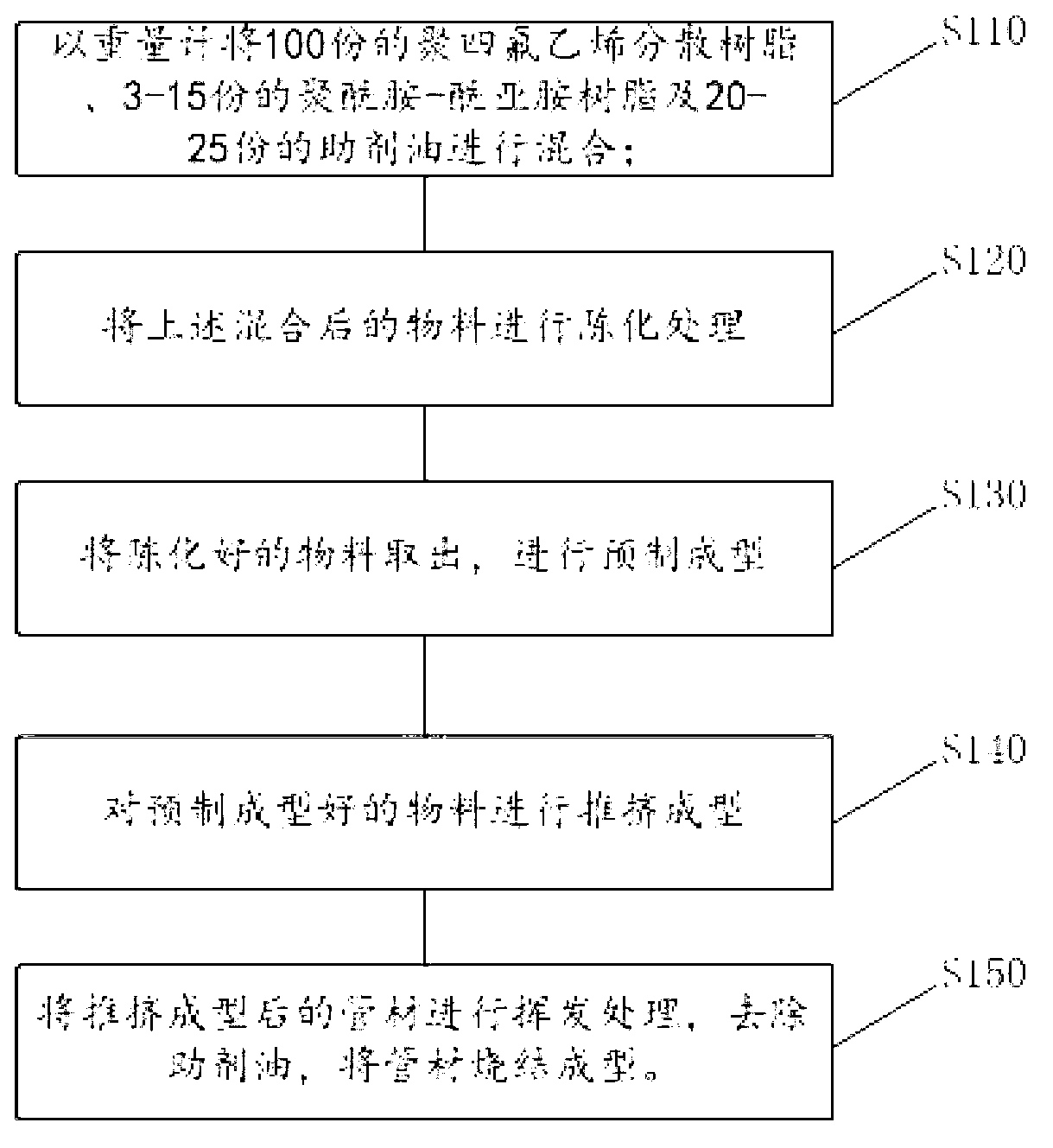

Manufacturing method of fluorine plastic sleeve

InactiveCN103102624AReduce coefficient of frictionReduced characteristicsTubular articlesPolyamide-imidePolyamide

The invention discloses a manufacturing method of a fluorine plastic sleeve. The method comprises the following steps: mixing 100 parts of polytetrafluoroethylene dispersion resins, 3 to 15 parts of polyamide-imide resins and 20 to 25 parts of assistant oil by weight; aging the mixed material; taking out the aged material, prefabricating and forming; forming the prefabricated and formed material in a pushing and squeezing manner; volatilizing the sleeve material, formed in a pushing and squeezing manner, to remove the assistant oil; and sintering the sleeve material to obtain the fluorine plastic sleeve. According to the fluorine plastic sleeve produced by utilizing the manufacturing method, the low friction coefficient and the self-lubricating characteristic of fluorine plastic are maintained to a maximum extent; and the defects of the fluorine plastic which is easy to creep and poor in abrasion resistance is overcome. Therefore, the fluorine plastic sleeve has the best balance characteristic of self lubrication and abrasion resistance.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

Manufacturing method of high-breathable fabric

InactiveCN108456973AOvercome wrinkling,Overcome wear resistanceMelt spinning methodsWoven fabricsPolyesterFiber

The invention discloses a manufacturing method of a high-breathable fabric. The method comprises the steps of preparing pearl fiber, preparing polyester fiber and preparing the fabric. The method hasthe advantages that the preparation method is easy to implement and suitable for large-scale industrial production, the obtained fabric solves the problem that an existing fabric is likely to be wrinkled, and poor in abrasion resistance, and meanwhile the fabric is good in breathability, high in wet guiding effect and high in water molecule evaporation rate.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

Technology for repairing dentures by using 3D printing titanium-based composite material

InactiveCN110946665AShort preparation cycleImprove comfortAdditive manufacturing apparatusArtificial teethDenturesFixed prosthodontic

The present invention provides a technology for repairing dentures by using a 3D printing titanium-based composite material. The technology combines 3D printing with an existing digital technology anda new titanium alloy formula is used to solve problems that existing fixed denture restorations are high in porcelain-falling rate and poor in binding with human body tooth tissues.

Owner:山西万佳康齿科技术有限公司

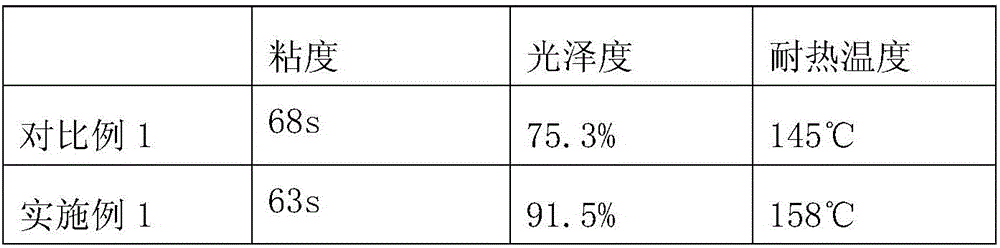

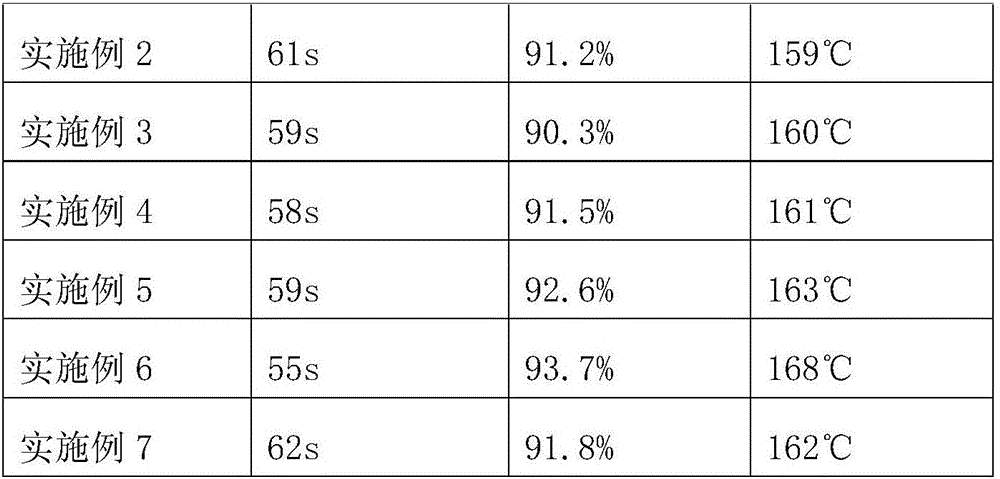

Method for preparing waterborne ultraviolet curing coating

InactiveCN106243989AOvercome the hardnessOvercome wear resistanceFireproof paintsAnti-corrosive paintsWater bathsUltraviolet

The invention discloses a method for preparing a waterborne ultraviolet curing coating, and belongs to the technical field of coating preparation. The method comprises the steps that konjac blocks are added into ionized water for ultrasonic oscillation and centrifugation, the mixture is stirred with a hydrogen dioxide solution, and after the mixture is added into an ammonium persulfate water bath, filtering is carried out; filtrate is stirred with glycerinum and methanesulfonic acid for an oil bath reaction, extraction is carried out with ethyl acetate, then concentrating and drying are carried out, and standby solids are obtained; smashed schima root-bark branches are soaked with absolute ethyl alcohol, N-methyl pyrrolidone and the like are added, after reacting, the product is mixed with the standby solids and mixed resin, then butyl hydroxy anisd and other assistants are added, and the waterborne ultraviolet curing coating is obtained. Living examples prove that after a material is coated with the obtained coating, the operating condition is good under high-temperature, high-acid and high-alkali conditions; in the use process of the coating, a coating film is smooth and flat in surface, self curing needs can be met, compared with a traditional coating, the curing time is shortened by 50%-80%, energy consumption is reduced by 50%-80%, and high use value is achieved.

Owner:宁波高智科技咨询服务有限公司

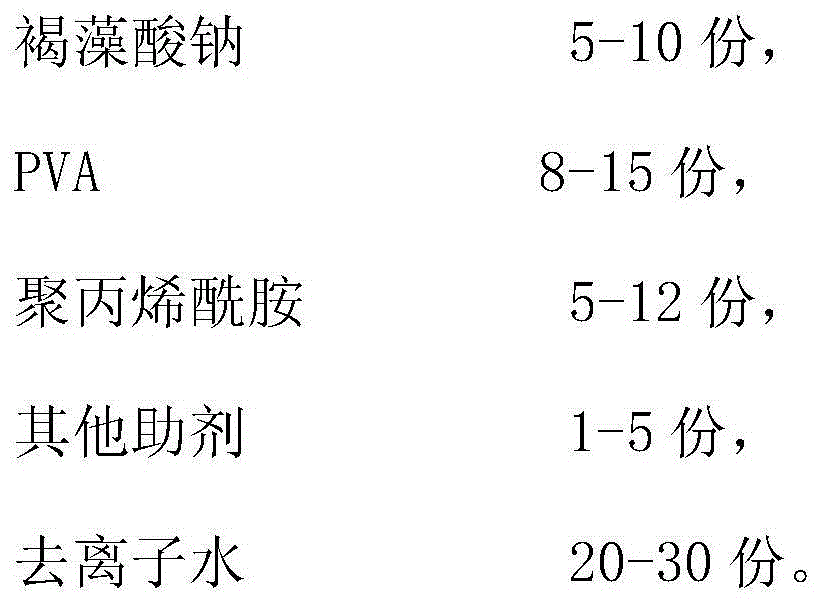

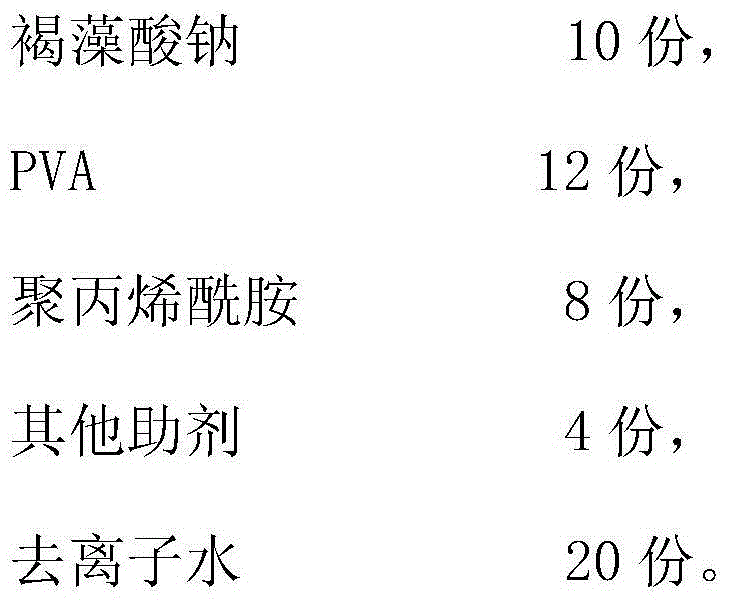

Novel environment-friendly composite slurry and preparation method thereof

The invention discloses novel environment-friendly composite slurry. The novel environment-friendly composite slurry is prepared from the following components in parts by weight: 5-10 parts of sodium alginate, 8-15 parts of PVA, 5-12 parts of polyacrylamide, 1-5 parts of other additives and 20-30 parts of deionized water. The invention further discloses a preparation method of the composite slurry. The composite slurry disclosed by the invention has a good sizing effect, has good stickiness and film-forming property on most fibers, and is good in flexibility, elasticity and wearing resistance, high in mechanical strength, pollution-free, biodegradable, easy to desize, simple in preparation process and low in cost.

Owner:张劲松

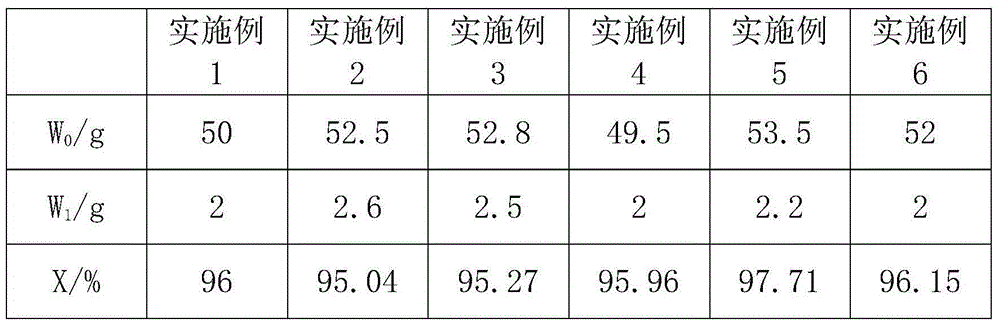

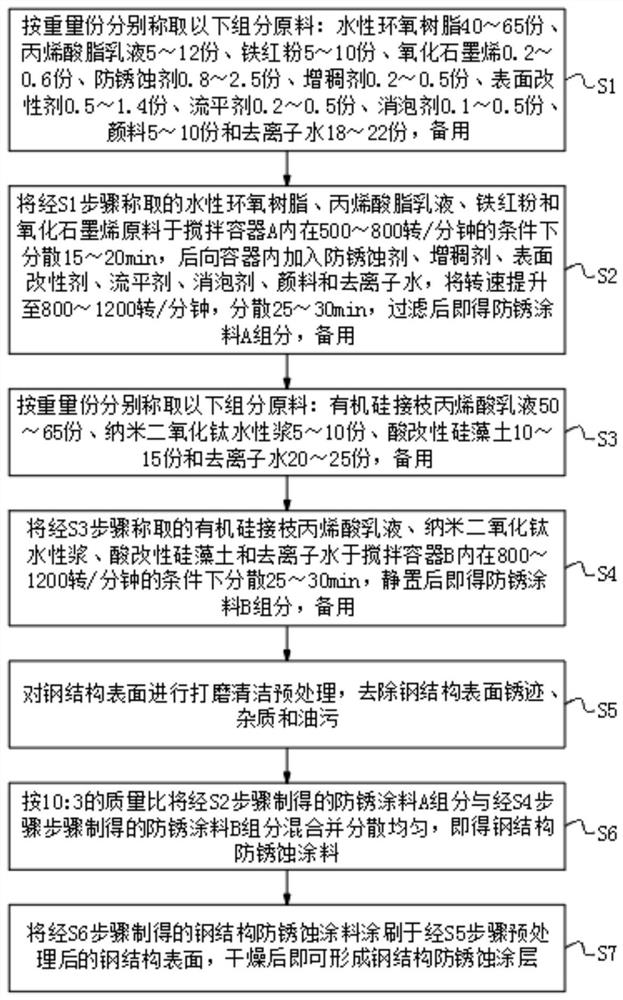

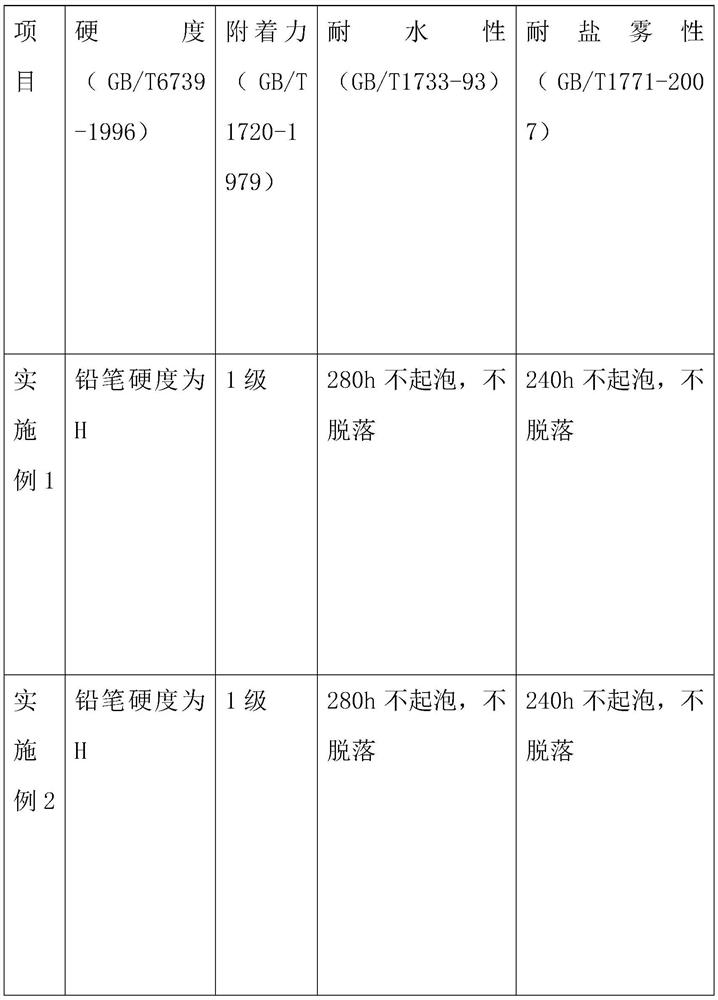

Steel structure house anti-corrosion treatment process

InactiveCN112940588AImprove mechanical propertiesImprove water resistanceFireproof paintsAnti-corrosive paintsPolishingPre treatment

The invention belongs to the technical field of anti-corrosion treatment processes, and particularly relates to a steel structure house anti-corrosion treatment process which comprises the following treatment steps: s1, weighing raw materials of a component A; s2, uniformly dispersing the raw materials of the component A to obtain the component A of an antirust coating; s3, weighing the raw materials of a component B; s4, uniformly dispersing the raw materials of the component B to obtain the component B of the antirust coating; s5, performing polishing and cleaning pretreatment on the surface of the steel structure; s6, uniformly mixing the antirust coating component A and the antirust coating component B according to the mass ratio of 10: 3 to obtain the steel structure antirust coating; and s7, coating the surface of the steel structure with the prepared steel structure antirust coating. The mechanical property, the water resistance, the heat resistance and the surface performance of the coating are greatly improved, the defects that a traditional coating is poor in mechanical strength, abrasion resistance, ultraviolet aging resistance, water resistance, scrubbing resistance, stain resistance and aging resistance are overcome, and the salt fog resistance is excellent.

Owner:CHINA CONSTR SEVENTH ENG DIV SHANGHAI CORP

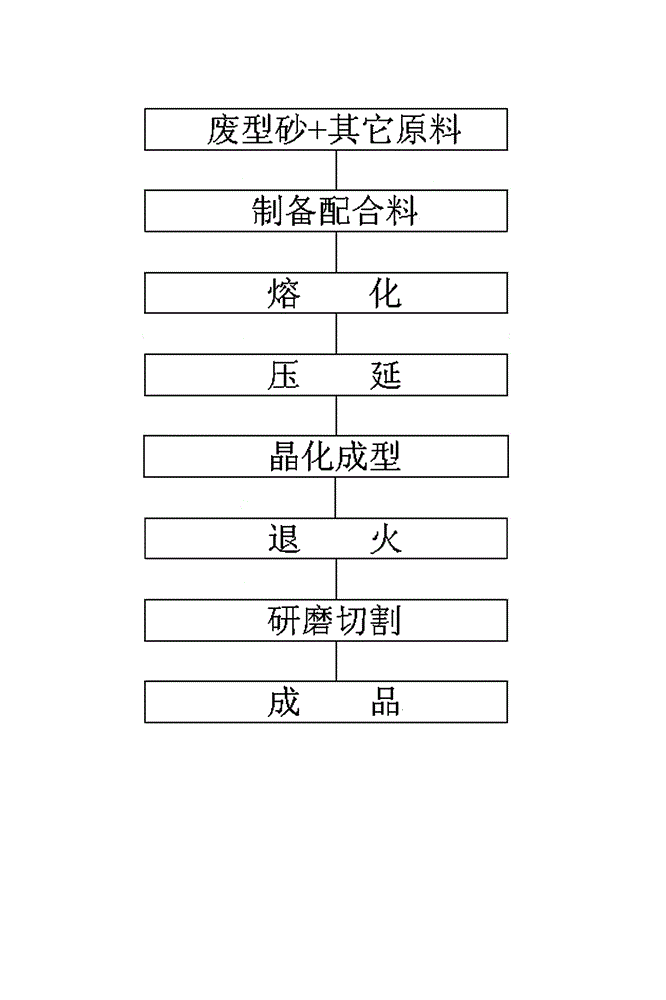

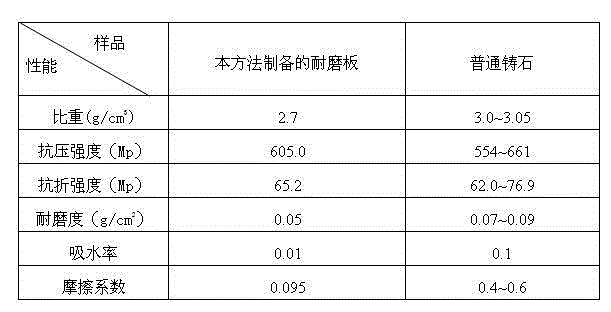

Novel wear-resisting plate produced by using waste moulding sand and preparation method of plate

The invention discloses a novel wear-resisting plate produced by using waste moulding sand and a preparation method of the plate. The novel wear-resisting plate produced by using waste moulding sand comprises the following raw materials in parts by weight: 40-60 parts of waste moulding sand, 0-15 parts of quartz sand, 22-40 parts of calcium carbonate, 1-7 parts of aluminum oxide, 0-2 parts of sodium nitrate, 2-10 parts of sodium carbonate, 8-20 parts of magnesium carbonate and 1-2 parts of chromium sesquioxide. According to the invention, waste is used as the production raw material, so that the cost for producing the wear-resisting plate is reduced; by taking diopside as the main crystalline phase, the wear-resisting plate is large in hardness, high in strength, corrosion resistant, weather resistant, non-absorbent and free of radioactive dangers; and at the same time, the volume of cargo in storage of the waste moulding sand is decreased, so that the recycling of the waste is realized and the environment pollution is prevented and treated. The wear-resisting plate is prepared by using a melting-calendaring-crystallization process and the product is capable of replacing certain metals or other materials at certain places, so that the cost is reduced and the service life of the equipment is prolonged; and the wear-resisting plate can be widely applied to the fields of electric power, coal, mine, metallurgy, building and the like.

Owner:CHINESE ACAD OF GEOLOGICAL SCI

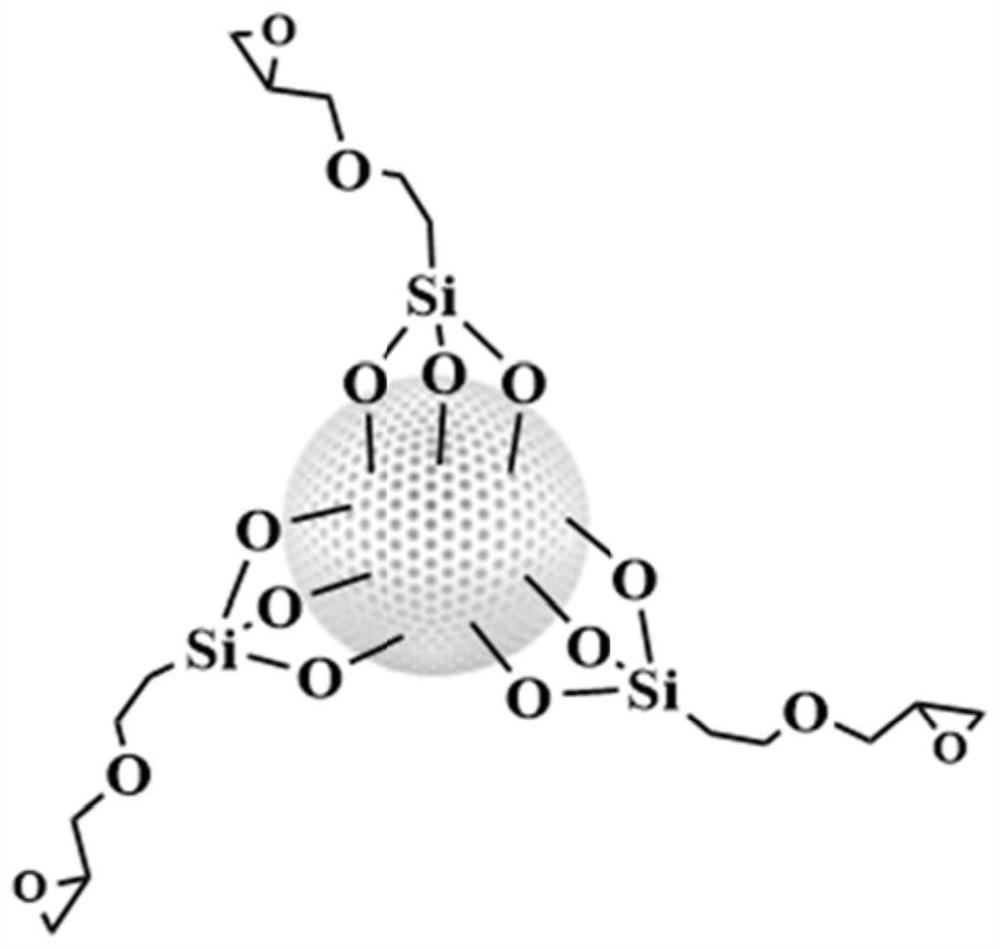

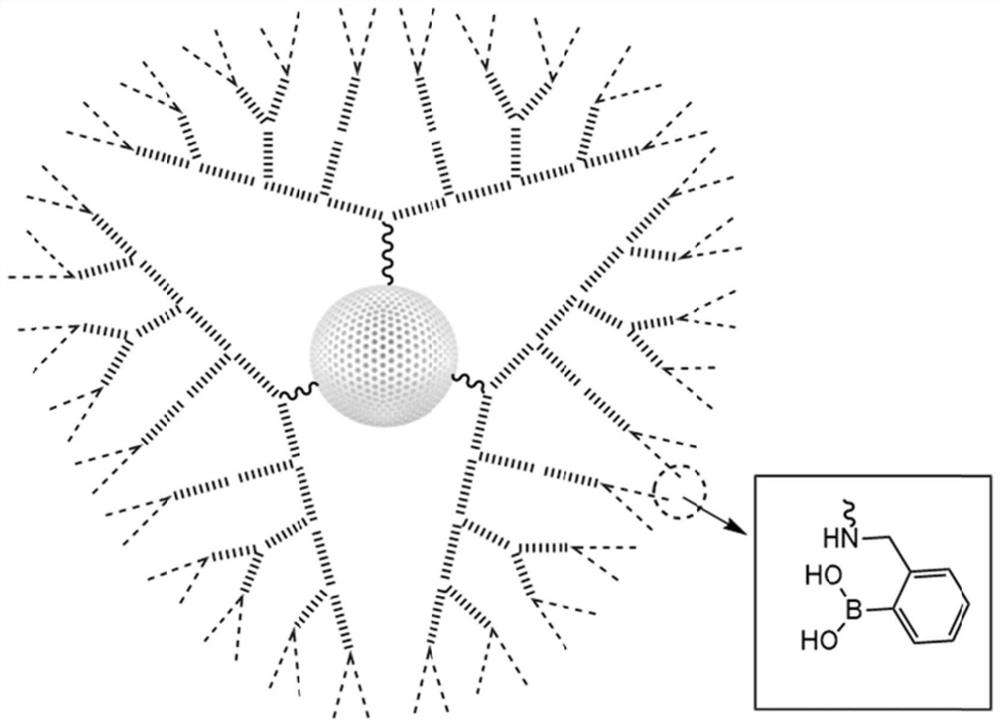

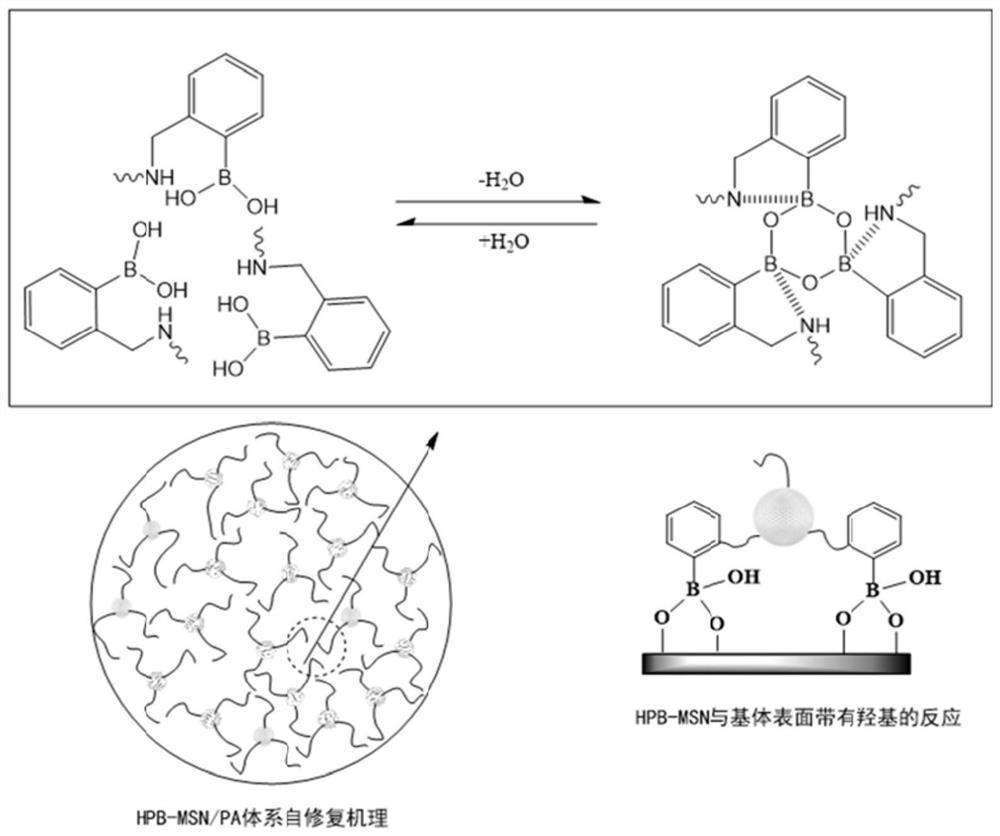

Self-repairing, breathable and wear-resisting composite coating and preparation method and application thereof

InactiveCN114045082AGood self-teaching functionImprove breathabilityPolyurea/polyurethane coatingsProtein coatingsPhenylboronic acidPolymer science

The invention discloses a self-repairing, breathable and wear-resisting composite coating and a preparation method and application thereof. The preparation method comprises the following steps of: preparing hyperbranched polyphenylboronic acid grafted mesoporous silica nanoparticles; preparing a composite emulsion by using the hyperbranched polyphenylboronic acid grafted mesoporous silica nanoparticles; and spraying the composite emulsion on the surface of a matrix, and drying to obtain the self-repairing, breathable and wear-resisting composite coating. The coating is endowed with good self-repairing function, air permeability and wear resistance by utilizing the enhancement benefit, abundant pore structure and dynamic reversible bond of the MSN. The composite coating not only overcomes the defects of poor wear resistance, poor air permeability and the like of a traditional water-based polymer coating, but also can be endowed with an excellent room-temperature self-repairing function. The preparation cost is low, the operation process is simple, and conditions are mild.

Owner:SHAANXI UNIV OF SCI & TECH

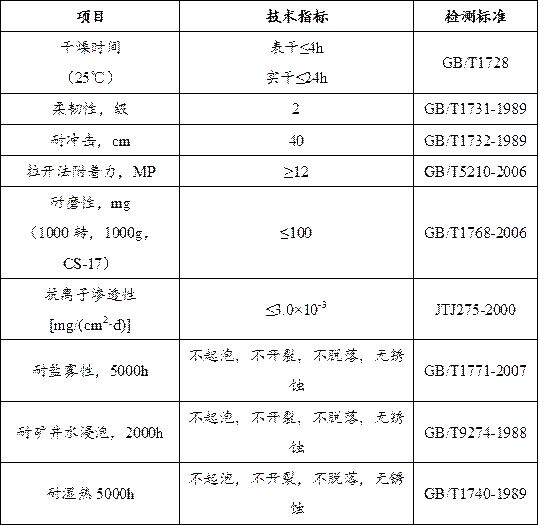

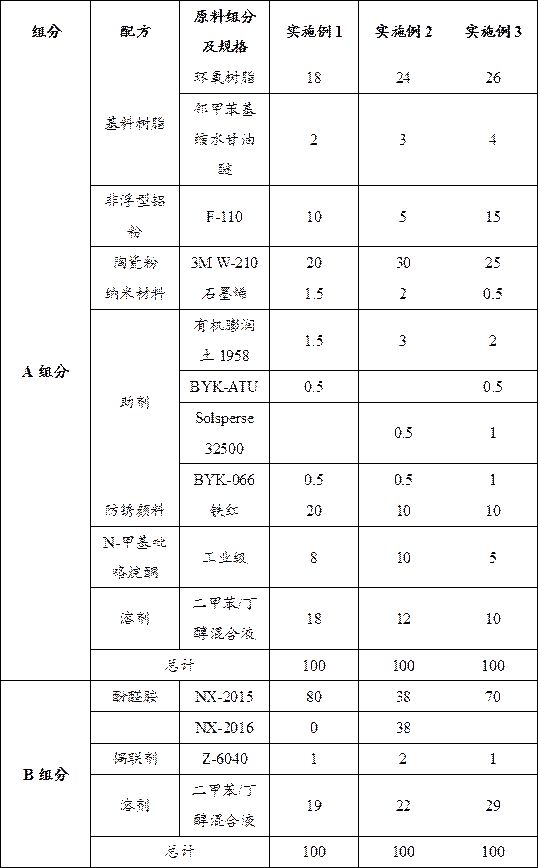

High-shielding-property, wear-resistant and anti-corrosive paint for hydraulic support structural members and preparation method thereof

ActiveCN113621294AMeet application environment requirementsImprove anti-corrosion performanceEpoxy resin coatingsAluminium powderPyrrolidinones

The invention discloses a high-shielding-property, wear-resistant and anti-corrosive paint for hydraulic support structural members and preparation method thereof. The high-shielding-property, wear-resistant and anti-corrosive paint for hydraulic support structural members comprises a component A and a component B. The component A comprises, by weight, 20-30 parts of a resin base material, 5-15 parts of non-floating aluminum powder, 20-30 parts of ceramic powder, 0.5-2 parts of a nano material, 2.5-4.5 parts of an auxiliary, 10-20 parts of anti-rust pigment, 5-10 parts of N-methyl pyrrolidone and 10-18 parts of a solvent. The component B comprises, by weight, 70-80 parts of phenolic aldehyde amine, 1-2 parts of a coupling agent and 18-29 parts of a solvent. The high-shielding-property, wear-resistant and anti-corrosive paint for hydraulic support structural members has long-acting corrosion resistance, excellent shielding property and high wear resistance, can be used in an underground mine environment, and has a wide application prospect.

Owner:兖矿能源集团股份有限公司 +3

Preparation method of fleece thermal cloth

InactiveCN108342810AOvercome wrinkling,Overcome wear resistanceMonocomponent copolyesters artificial filamentWoven fabricsFiberPolyester

The invention discloses a preparation method of fleece thermal cloth. The method includes the steps that pearl fibers are prepared, polyester fibers are prepared, and the cloth is prepared. The preparation method has the advantages that the preparation method is easy to operate and suitable for large-scale industrialized production; the prepared cloth overcomes the defects that existing cloth is not likely to wrinkle and poor in abrasion resistance; the cloth is good in thermal insulation, high in wet conduction and high in evaporation rate of water molecules.

Owner:HAIYAN SHUOCHUANG CLOTHING RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com