High-shielding-property, wear-resistant and anti-corrosive paint for hydraulic support structural members and preparation method thereof

A technology of hydraulic support and anti-corrosion coating, applied in the field of coatings, can solve the problems of poor wear resistance and low shielding performance, and achieve the effects of excellent anti-corrosion performance, reduced maintenance costs, and excellent shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

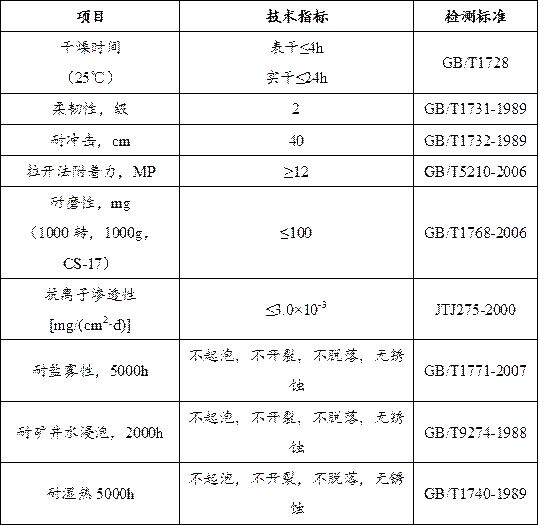

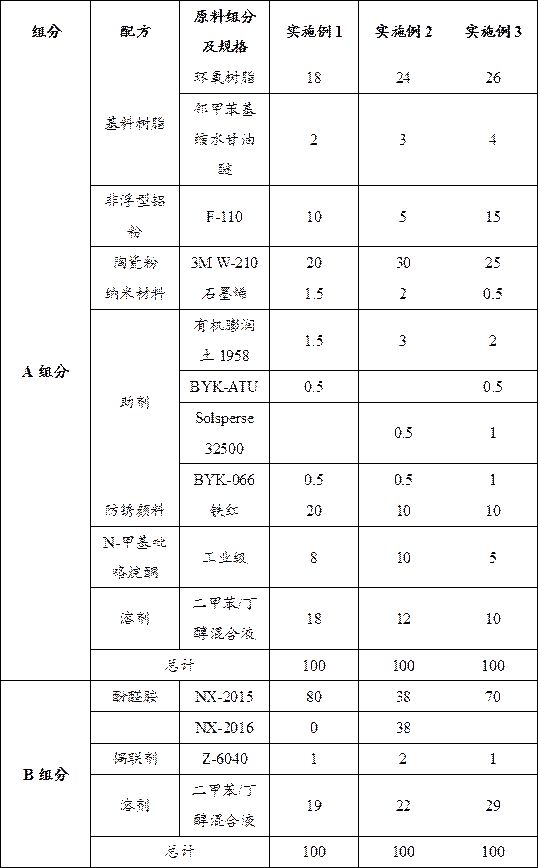

[0034] Examples 1-3 The formulas of component A and component B of high shielding wear-resistant anticorrosion coatings for hydraulic support structural parts are shown in Table 1.

Embodiment 1

[0038] The preparation method of component A of the high-shielding wear-resistant anti-corrosion coating for the hydraulic support structure of the present embodiment is as follows:

[0039] (1) Pre-soak 1.5 parts of nano-material graphene and 8 parts of N-methylpyrrolidone, and disperse with ultrasonic vibration for 1 hour to obtain graphene slurry;

[0040] (2) Add 18 parts of solvent, 1.5 parts of organic bentonite 1958, 0.5 parts of BYK-ATU, 0.5 parts of BYK-066 to 20 parts of epoxy resin and o-cresyl glycidyl ether at a ratio of 9:1 to the resin base material, mix well , continue to add 20 parts of ceramic powder W-210, 20 parts of anti-rust pigment iron red, graphene slurry, disperse and grind, control the fineness <80 μm, and then discharge to obtain a mixed solution;

[0041] (3) Add 10 parts of non-leafing aluminum powder F-110 to the mixture, and disperse at high speed for 30 minutes to obtain component A;

[0042] The preparation method of component B of the high-s...

Embodiment 2

[0046] The preparation method of component A of the high-shielding wear-resistant anti-corrosion coating for the hydraulic support structure of the present embodiment is as follows:

[0047] (1) Pre-soak 2 parts of nano-material graphene and 10 parts of N-methylpyrrolidone, and disperse with ultrasonic vibration for 1 hour to obtain graphene slurry;

[0048] (2) Add 12 parts of solvent, 3 parts of organobentonite 1958, 0.5 part of Solsperse 32500, 0.5 part of BYK-066 to 27 parts of epoxy resin and o-cresyl glycidyl ether in a resin base of 8:1, mix well, Continue to add 30 parts of ceramic powder W-210, 10 parts of anti-rust pigment iron red, graphene slurry, disperse and grind, control the fineness < 80 μm, and then discharge to obtain a mixed solution;

[0049] (3) Add 5 parts of non-leafing aluminum powder F-110 to the mixture, and disperse at high speed for 30 minutes to obtain component A;

[0050] The preparation method of component B of the high-shielding wear-resistant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com