Portable computer hinge shell manufacturing method

A manufacturing method and a technology for a laptop computer, which are applied in the fields of electrical digital data processing, anodizing, instruments, etc., can solve the problems of inability to meet diverse needs, difficult to achieve aesthetic requirements, and large core draft angle, and achieve aesthetic appearance. Better fit, flawless joints and greater depth of weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

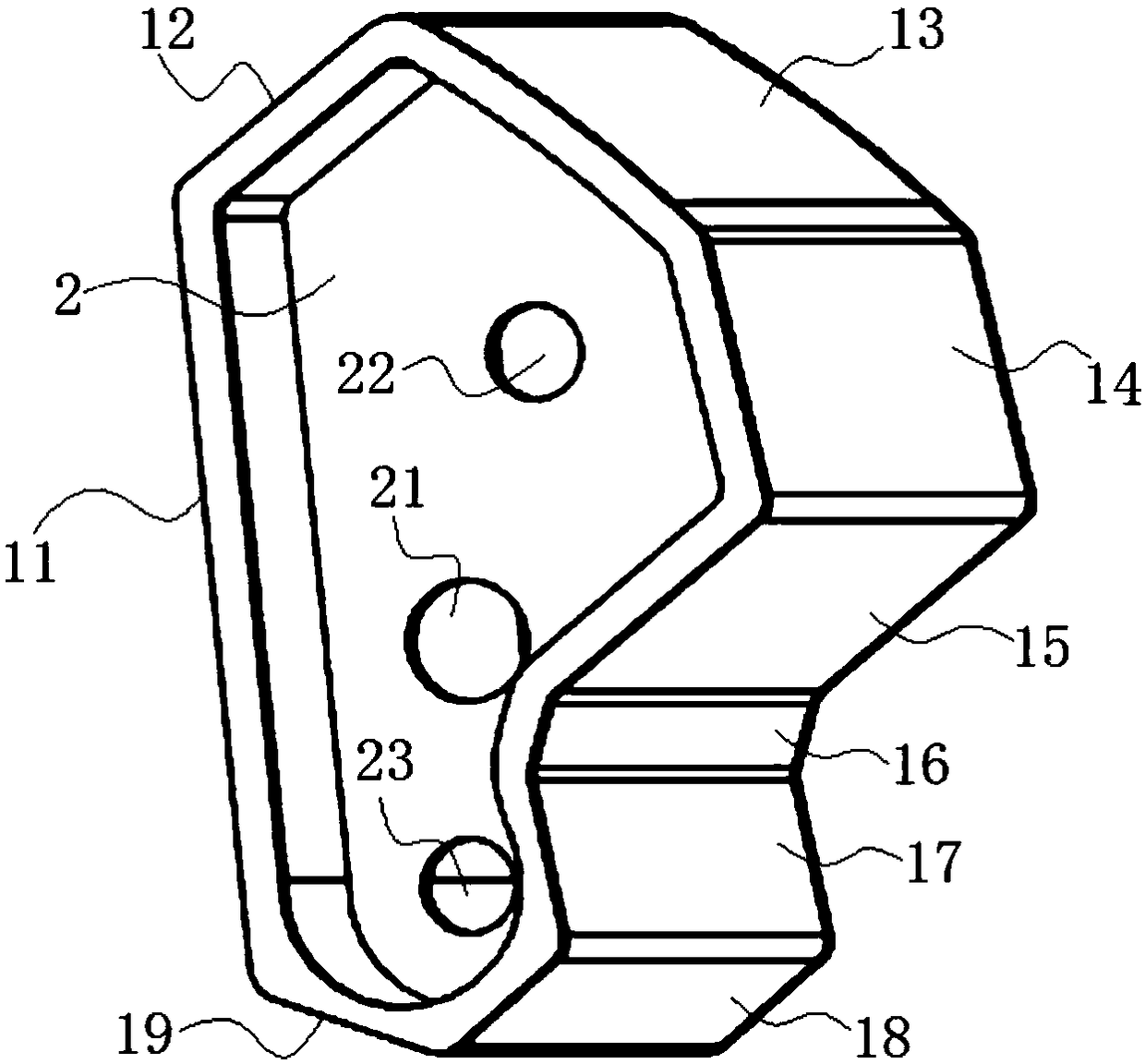

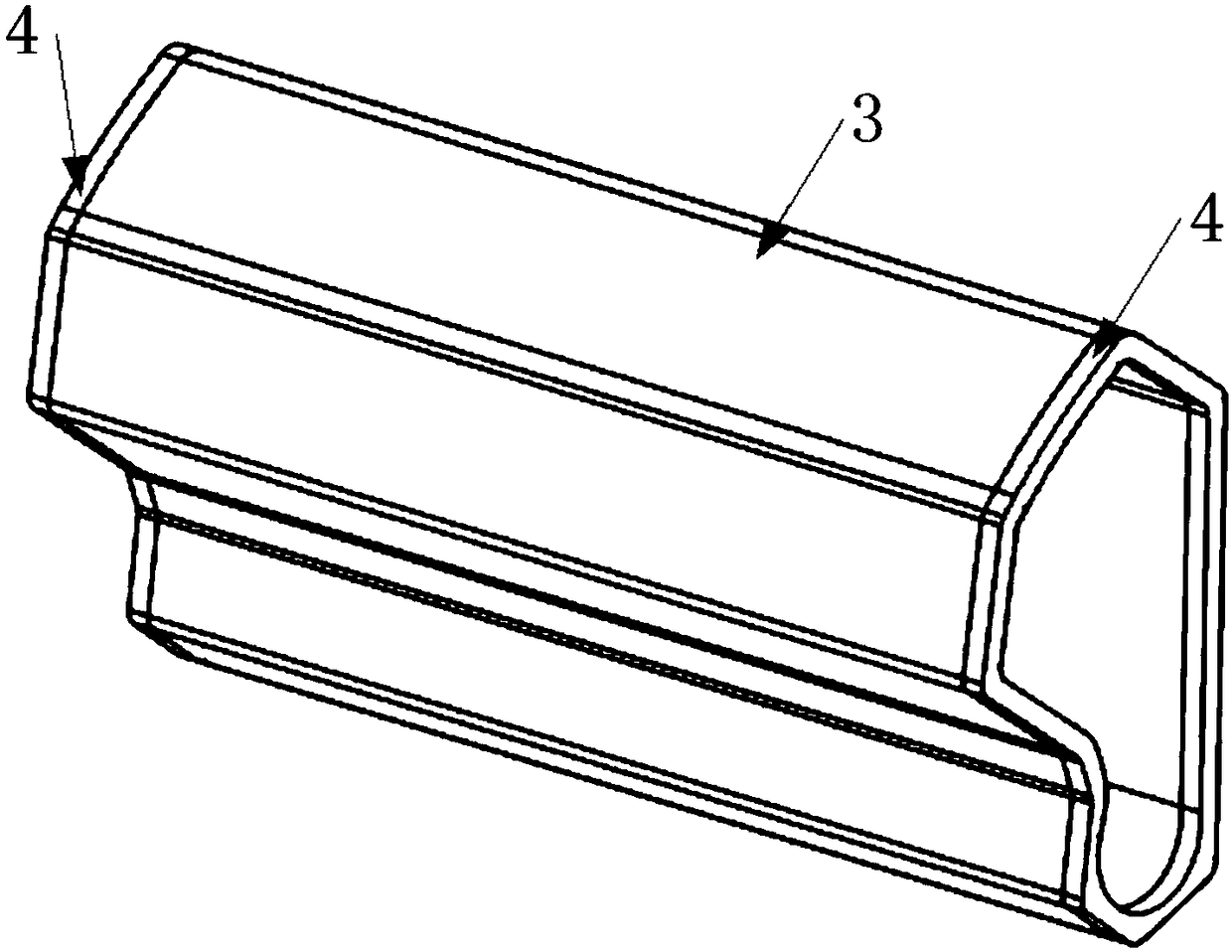

[0080] Embodiment 1: the product 1 that adopts described manufacturing method to produce below is: as Figure 1.1 to Figure 5 As shown, it includes a cylindrical shell 1 and a baffle 2 arranged in the cylindrical shell, an accommodating space is formed in the cylindrical shell, and the baffle is connected with the inner wall of the cylindrical shell by spot welding And the baffle is perpendicular to the inner wall of the cylindrical shell, and the edge of the baffle is closely attached to the inner wall of the cylindrical shell, and the outer surface and the middle part of the cylindrical shell are sub- The light area 3, the outer surface of the cylindrical shell and the two ends of the matt area are bright light areas 4, and both the matt light area and the bright light area are formed by anodic oxidation to form an anodized film;

[0081] The cylindrical housing includes nine successively connected surfaces, which are respectively the first plane 11, the second plane 12, the...

Embodiment 2

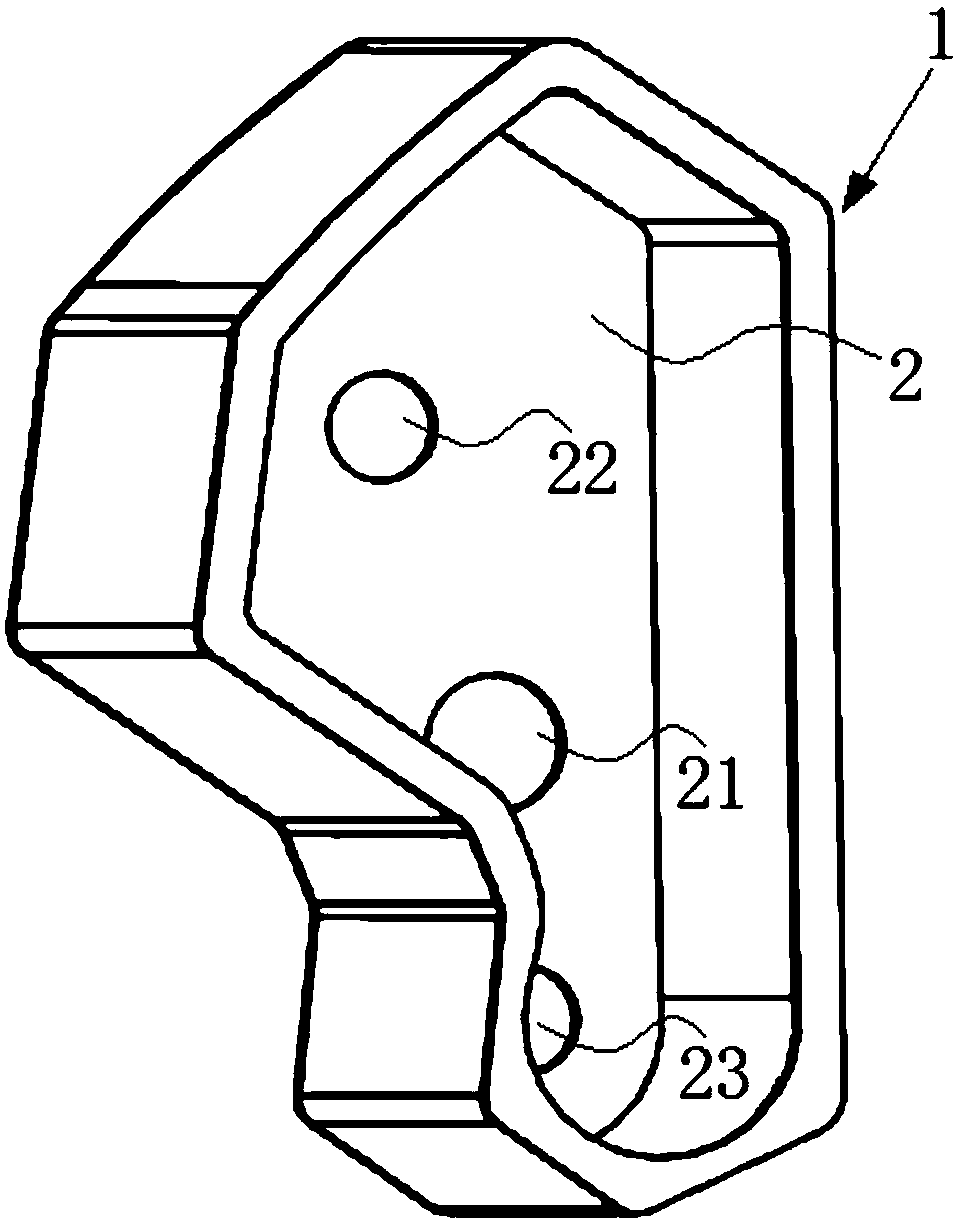

[0112] Embodiment 2: the following is the product 2 that adopts described manufacturing method to produce: as Figure 6.1 to Figure 9 As shown, it includes a cylindrical shell 1 and a baffle 2 arranged in the cylindrical shell, an accommodating space is formed in the cylindrical shell, and the baffle is connected with the inner wall of the cylindrical shell by spot welding And the baffle is perpendicular to the inner wall of the cylindrical shell, and the edge of the baffle is closely attached to the inner wall of the cylindrical shell, and the outer surface and the middle part of the cylindrical shell are sub- The light area 3, the outer surface of the cylindrical shell and the two ends of the matt area are bright light areas 4, and both the matt light area and the bright light area are formed by anodic oxidation to form an anodized film;

[0113] The cylindrical housing includes nine surfaces connected in sequence and are respectively the first plane, the second plane, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com